How to read an USAF1951 target? - OptoWiki Knowledge Base - usaf test target

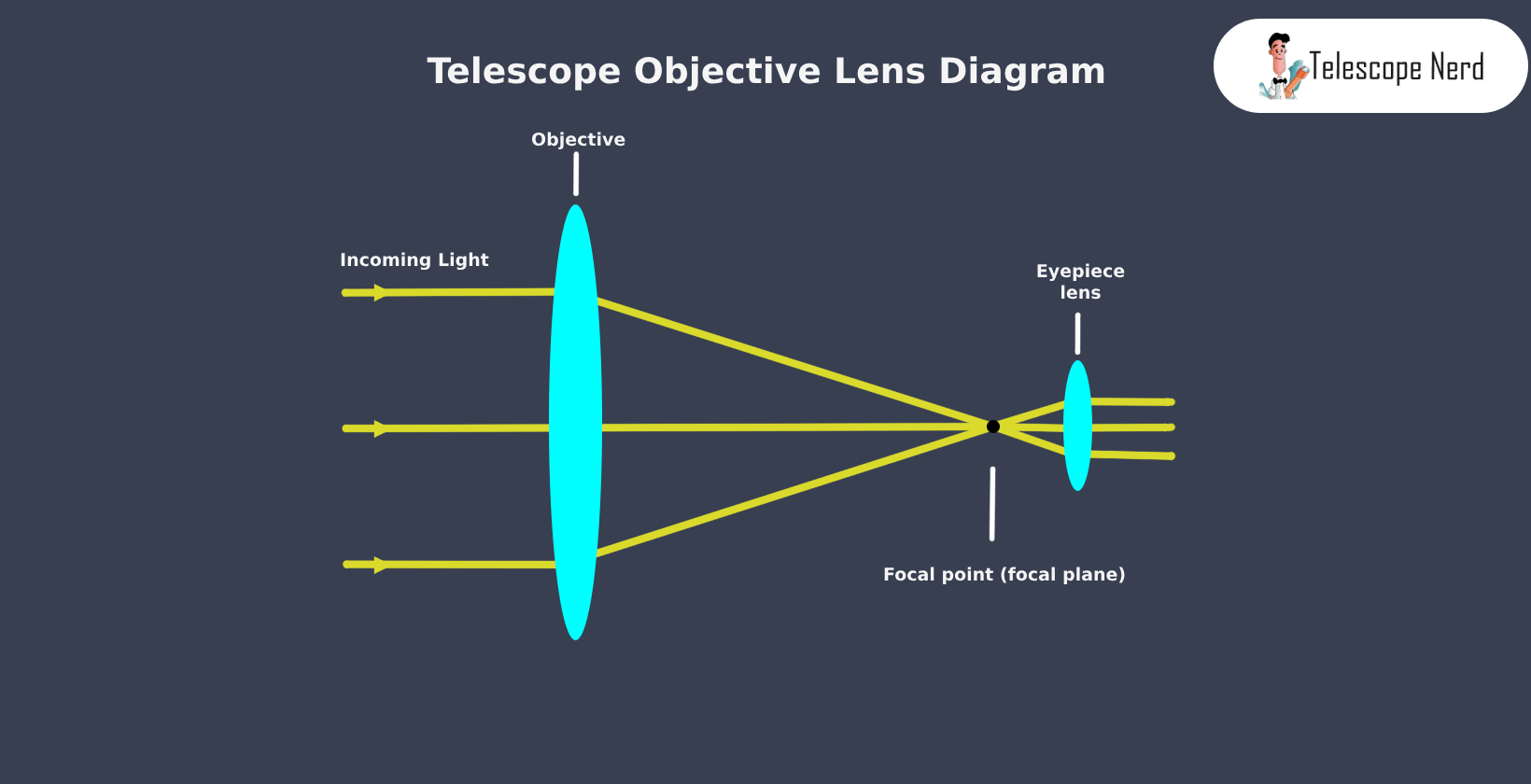

The objective lens refracts light into the focal point because the lens is thinner at the edges than in the middle. When light passes through the thinner parts, it is refracted at a higher angle than in the middle. This causes light to converge into focus at the same point where it is magnified and observed.

The maximum allowed power for a particular sensor head is mostly limited by damage issues. Note, however, that one can easily damage a sensor head with optical powers well below the maximum allowed power, when delivering the input beam with an inappropriately small beam diameter. The local intensity then becomes too high, which is particularly an issue for photodiode-based devices. (Even well before damage occurs, there may be local saturation effects, leading to wrong readings.) Instrument specifications therefore often include a maximum allowed input intensity. For operation with laser pulses (particularly from Q-switched lasers), there may be an additional specification for the maximum allowed pulse fluence (in J/cm2).

The mechanical dimensions of an optical power sensor can be quite relevant for applications, e.g. when a sensor needs to be temporarily inserted into some beam path, where there is little available space. There are some very flat hand-held sensors, mostly based on photodiodes, which require quite little space.

CNI offers various thermopile laser power meters and photoelectric laser power meters. They are able to detect output powers from 1 nW to 200 W. The wavelength range is from 0.19 μm to 25 μm.

Please do not enter personal data here. (See also our privacy declaration.) If you wish to receive personal feedback or consultancy from the author, please contact him, e.g. via e-mail.

For example, such powermeters can be used to check in the case of a failure or excessive bit error rate whether the optical power level in some fiber is appropriate.

Thermal power sensors are intrinsically relatively slow – particularly those for high powers, where the thermal capacity of the sensor is tentatively higher. Typical response times are of the order of 0.2 s to 2 s. Even photodiode-based power meters are normally not made very fast, since one could anyway not read a display which is updated e.g. 10 times per second. For power measurements with a higher measurement bandwidth, other types of instruments (certain photodetectors) must be used.

Thermal power meters are fairly robust (although too tight focusing onto the absorber should be avoided), moderately precise, usable in a wide wavelength range (with fairly wavelength-independent sensitivity), and relatively slow.

The downsides of using an objective lens are primarily chromatic aberration, weight and size constraints, and potential lens imperfections.

Weight and size constraints arise because crafting large, high-quality lenses is both challenging and heavy, limiting the practical size of refracting telescopes. The process involves shaping and polishing thick glass or other transparent materials to exact specifications, ensuring that the entire lens is free from imperfections. As the diameter of the lens increases, the challenges in manufacturing become exponentially more complex.

A smaller curvature will cause light to focus further from the objective, increasing the focal length. The increase in focal length will provide more detailed images of distant objects, but it also narrows the field of view. Decreasing the curvature, thus increasing the focal length, will also result in higher magnification.

The objective lens directly affects telescope’s performance, including the magnification, light-gathering power and resolution. The curvature of this lens plays a pivotal role in determining the telescope’s focal length. A stronger curvature bends light at a higher angle, causing it to focus at a shorter distance. This results in a shorter focal length because focal length describes the distance from the objective lens to the focal point.

Power meters require some electrical power, which may either be provided with an external power supply or with batteries (which are normally rechargeable). Battery-powered operation is of course convenient by eliminating another cable enter the requirement of a nearby power socket, but on the other hand the need for regular recharging can also be inconvenient. Devices connected to a computer e.g. via USB cable can get the power from there.

There are also “meterless” sensor heads, which can be directly connected to a computer, typically with a USB interface. They contain only little electronics, in particular an analog-to-digital converter in addition to the digital interface, and those electronics may be integrated either into the sensor head itself or into a compact device at the USB connector or somewhere along the cable. One uses a software coming with the device for displaying values, changing measurement ranges, possibly also for data logging and similar purposes, going beyond the functionality of a typical stand-alone power meter. Such devices save the cost for an extra display and may also be quite convenient, for example for an engineer traveling with a notebook and only a minimum of extra instruments to carry. Also, such power sensors may be connected to more complex systems, for example to laser marking machines.

Chromatic aberration occurs because objective lenses refract different wavelengths of light at varying angles. This results in a failure to focus all colors to the same convergence point, leading to color fringing around observed objects.

Some telescopes incorporate multiple lenses in their design, with each lens serving to correct aberrations or enhance the image quality. The choice and combination of lenses influences various factors, including the telescope’s focal length, magnification, and overall performance.

Telescope objective lensfocal length

When a thermal power meter is set for high sensitivity (responsivity), for example for a maximum power below 100 mW, its mount should not be touched with the hand during measurements. This is because any warming of the mount can induce temperature differences which modify the reading.

It’s also important to monitor other components such as the lens mount, where the objective lens is attached to the telescope. The lens mount should be periodically inspected for debris to ensure the telescope focuses optimally. Additionally, the storage environment of the telescope plays a pivotal role in its longevity. A dry environment is paramount to prevent the onset of fungus or moisture damage to the objective lens.

Some instruments have an analog output (e.g. through a BNC socket), where the output voltage is usually proportional to the output power relative to the maximum power in a certain measurement range.

Telescope lensconcave or convex

The minimum measurement range is limited by measurement noise – typically by noise coming from the sensor head. That noise may be somewhat reduced by low-pass filtering, when a slower response is acceptable for the application. The lowest range will usually be chosen such that the measurement uncertainty still stays at least 10 to 20 dB below the maximum power.

Most power meters are suitable only for light beams with a quite limited beam radius, not e.g. for diffuse light, but there are e.g. special sensor heads with an integrating sphere, which can accept and precisely measure even highly divergent input beams, for example from light emitting diodes.

Photodiode-based power sensors are far more sensitive than thermal ones. Here, the lowest measurement ranges are often in the microwatt region or possibly even lower. For the sensitive measurement ranges, one will of course have to carefully avoid influences of ambient light, e.g. by using proper shields (e.g. black anodized tubes around the beam path) and/or by working in a dark laboratory.

By submitting the information, you give your consent to the potential publication of your inputs on our website according to our rules. (If you later retract your consent, we will delete those inputs.) As your inputs are first reviewed by the author, they may be published with some delay.

Here you can submit questions and comments. As far as they get accepted by the author, they will appear above this paragraph together with the author’s answer. The author will decide on acceptance based on certain criteria. Essentially, the issue must be of sufficiently broad interest.

Digital interfaces are very versatile, allowing for substantially expanded functionality on a computer. For example, although data logging may be provided even by stand-alone devices, it can be more convenient to process and store such data on a computer.

Most power meters are based on the principle of a thermal detector: optical power is converted to heating power in some absorber structure with a black coating, and the resulting temperature rise (or actually the temperature difference between the absorber and the mount) is measured, e.g. with a thermopile. Such a thermal power meter (see Figure 1) is useful for average powers between ≈ 0.01 W and several kilowatts (but note that a single sensor head cannot span that whole range). Typically, some cooling with a fan or even with water is required for powers above roughly 10 W.

The objective lens of a telescope, integral to the viewing experience, is constructed using a combination of materials. The lens is typically crafted from crown or flint glass, each known for its unique refractive properties. The objective lens is secured within the telescope’s optical tube assembly (OTA). To enhance performance, the surface of the objective lens should be treated with anti-reflective coatings, commonly derived from materials such as magnesium fluoride, to maximize light transmission and minimize unwanted reflections. Each material, combined with its quality and any applied coatings, plays a pivotal role in determining the clarity, brightness, and color accuracy of the images produced by the telescope.

Laser power and energy meters are available from Edmund Optics in a wide selection of wavelength ranges for customization over a large number of laser measurement needs.

An optical power meter (or laser powermeter) is an instrument for the measurement of the optical power (the delivered energy per unit time) in a light beam, for example a laser beam. Typically, it allows for power measurements only with a relatively low bandwidth, and will e.g. display only the average power when receiving a pulse train with a high pulse repetition rate, e.g. from a Q-switched or mode-locked laser. For measuring pulse energies, there are other instruments, called optical energy meters.

Substantially better accuracies would require regular re-calibration and are anyway limited by detector uniformity (see below), thermal drifts and other influences.

Optical power meters are mostly used for temporary purposes, e.g. when testing laboratory setups or doing maintenance operations. For permanent monitoring of powers, mostly in the context of optical fiber communications, one often uses optical power monitors, which can be integrated into systems. Such power monitors are also available in fiber-coupled form, where the light from the source under test is supplied via a fiber cable and a fiber-optic connector. There are also devices which can be set to register only light with certain wavelengths, e.g. for measuring powers of specific WDM transmission channels.

Will Kalif is an amateur astronomer at TelescopeNerd.com. Will is an author of the book "See It With A Small Telescope". Will Kalif has been passionate about telescopes and the wonders of the night sky ever since he received his first telescope as a teenager. And for several decades now he has been making and using his own telescopes and helping other people to also enjoy the various things that can be seen on a dark and starry night.

Typical measurement accuracies are of the order of ±3% or ±5% for powers near the maximum reading in a certain measurement range. Powers well below the maximum in some range may be less accurately measured.

The objective lens is a part of a refracting telescope that collects and focuses light from distant objects. Knowing the design and material of an objective lens is crucial as it influences the telescope’s field of view, magnification, and overall performance.

The maintenance of an objective lens in a refractor is easier than a primary mirror in a reflector, due to the delicate nature of mirrors. However, both types of telescopes provide both upsides and downsides.

First of all, this has nothing to do with a nonlinear response. The problem is a wavelength-dependent responsivity. It cannot be solved by applying a correction factor, but because generally you do not know the spectral shape of the light, and the correction factor would have to be different for the different spectral components.

Using our advertising package, you can display your logo, further below your product description, and these will been seen by many photonics professionals.

When measuring the power of a broadband source, most companies mention that using photodiode-based sensors are not advised due to the strong nonlinear response over the large bandwidths. I wonder why this would be a big issue? How would this nonlinear response show itself in the measured power? can't we just measure the power of the source using the photodiode and then apply a correction for the response of the detector?

Due to the high sensitivity of photodiodes, they are also quite suitable for sensor heads with an integrating sphere. In that case, one may also use an InGaAs photodiode because a large input area can then be achieved despite a small area photodiode.

Objective lens telescopefunction

In refracting telescopes, the entire volume of objective lenses must be free from imperfections, as any flaws will lead to image distortion. This is because light must pass through the entire lens uninterrupted, while in reflecting telescopes, only the surface quality is critical for accurate image representation.

Refracting telescopes use an objective lens as their primary optical component. A refracting telescope, or refractor, operates on the principle of refraction, using an objective lens to gather and bend incoming light. At the front of a reflector, this lens refracts and concentrates the light rays to a focal point inside the telescope.

A possible problem with both thermal and photodiode-based optical power meters is the uniformity of response. For thermal power meters, a lack of uniformity can result from a dependence of the resulting absorbance or temperature distribution for different beam positions. For photodiodes, a nonuniform response can easily result from damage with too high optical intensities.

Far more sensitive and also faster power meters can be made with photodiodes, most often based on silicon (Si), but for the near infrared also on germanium (Ge). Indium gallium arsenide (InGaAs) is less common for power meters, since large area InGaAs detectors are expensive. Powers in the microwatt region or possibly even lower can be measured. These instruments can also be used for measuring high powers when a suitable attenuator is used. They are, however, less robust than thermal power meters: they are more easily damaged when exposed to too high optical intensities.

The shape of the objective lens is convex, meaning it bulges outward. This design allows it to act as a converging lens, focusing parallel rays of light to converge at a focal point. The distance from the focal point to the objective lens is called the focal length.

Quantifi Photonics offers a range of optical power meters in compact benchtop, PXI and rackmountable form factors for versatile, high-channel density fibre optic power monitoring from -60 to +10 dBm across 750 – 1700 nm wavelengths. Ideal for fiber optic manufacturing test, silicon photonics development and manufacturing, automated test systems, and as general R&D and production environment tools.

Telescope objective lensfor sale

Kentek is an authorized distributor in the United States and Canada for Gentec EO power measurement meters and displays. We work with a handful of companies to provide the most comprehensive line of laser and IPL measurement devices. Whether your application requires a thermopile, photodiode, or pyroelectric sensor, we can cross-reference your specifications and find a solution for your application.

Although these aberrations negatively impact the telescope’s performance, proper maintenance of the objective lens can mitigate their effects. Dust, smudges, or scratches will degrade the image quality. Regular maintenance along with careful handling will prolong the lens’s life and maintain its performance.

Also, the sensitivity of a photodiode is rather wavelength-dependent, so that a photodiode-based power meter usually requires the user to make a setting for the wavelength. The device then uses an internal calibration table to compensate for the wavelength-dependent responsivity. One should of course not forget to adjust that setting when using the power meter for a laser operating at a different wavelength because otherwise the power calibration will be wrong. Obviously, this method does not work for beams with a very broadband or variable optical spectrum, whereas it may be perfectly suitable in situations where the laser wavelength is rarely changed.

Besttelescope objective lens

To prolong the life of an objective lens, it’s crucial to maintain it properly by protecting it from scratches and pollutants, like dust. Dust accumulation not only compromises image clarity but also leads to optical aberrations if not addressed.

Most power meters allow the user to switch between different power measurement ranges – for example, with maximum powers of 0.1 W, 0.3 W, 1 W and 3 W. With an analog display, accurate readings are possible only when choosing an appropriate measurement range. Even for digital displays, one should choose an appropriate range, since the accuracy may suffer when measuring in a too high range.

The objective lens also affects the brightness and clarity of the image. A lens with a larger diameter collects more light, resulting in brighter and more detailed images. The quality of the lens material and its coatings also influences the clarity and color accuracy by reducing aberrations.

Note: this box searches only for keywords in the titles of articles, and for acronyms. For full-text searches on the whole website, use our search page.

In refractors, the objective lens is designed to focus different wavelengths of light onto the same plane. While this design leads to chromatic aberrations, where colors don’t converge at the same point, the lens’s precise curvature effectively reduces coma.

Telescope objective lensprice

Telescope objective lensreplacement

Photodiode-based instruments may also work in a wide wavelength range, e.g. with a Si-based diode from the near ultraviolet to somewhat beyond 1 μm, but with the responsivity varying substantially in such a range. Therefore, as explained above, the user will have to set the wavelength, and the instrument will usually have to “believe” that this setting is correctly done. In principle, such a power meter may be equipped with a wavelength sensor, but this is not common.

Note: the article keyword search field and some other of the site's functionality would require Javascript, which however is turned off in your browser.

Gentec Electro-Optics offers a variety of laser power meters, ranging from ultracompact photodiode-based devices for microwatt power levels to thermal detectors for powers up to 100 kW. We have a wide range of power measurement heads which can be combined with a great choice of displays and PC interfaces.

Typical active areas of power meters are circular or square-shaped with dimensions between 5 mm and a few centimeters. Larger active areas are typically offered by higher-power devices.

Telescope objective lensamazon

Display instruments can often be combined with different sensor heads – even with sensor heads of different type, e.g. pyroelectric and photodiode-based types. Some instruments can also work as optical energy meters.

To maintain the condition of the lens, use a lens cap consistently when the telescope is not in active use. To clean an objective lens, begin with a soft brush or compressed air to delicately remove any loose dust particles. If the lens has more stubborn marks or smudges, use a lens cleaning solution with a microfiber cloth. It’s crucial to remember to apply the solution to the cloth and not directly onto the lens, using gentle, circular motions to avoid potential damage. Excessive or incorrect cleaning methods will inadvertently scratch the lens or harm its protective coating.

Artifex OPM Series optical power meters use photodiodes as well as integrating spheres to measure and monitor optical power from UV to near IR. Our optical power meters are designed for fast response with a high signal to noise ratio. We offer a wide range of wavelengths (400-1600nm) and powers (nW-kW) and a variety of options in photodiode material and optical input. Visit our product page for more information about our OPM series. We look forward to your inquiry.

While most optical power meters have a free-space input for light, there are also fiber-coupled optical power meters, mostly for applications in the area of optical fiber communications. Here, the input is usually supplied through a fiber connector with a fiber patch cable.

The manufacturer normally specifies a certain range of optical wavelengths for which the quoted measurement accuracy is achieved. For thermal power meters, that range can be rather broad, e.g. extending far into the infrared spectral region because it is not too difficult to make a broadband absorber, e.g. with a black coating. Note that the quoted spectral range may be smaller than the spectral response; there may be wavelength regions where the detector reacts, but not with a calibrated response.

Normally, an optical power meter comes with a sensor head (see Figure 1) containing the power sensor, which is typically mounted with a post for receiving a horizontal input light beam in a certain height above the optical table. A sensor head may be equipped with additional optical attenuators for extending the measurement range; these are particularly offered for photodiode-based devices.

The sensor head may be connected to a stand-alone display instrument, containing an analog or digital display for the laser power. Frequently, it allows the user to choose between different power ranges, and possibly to do other settings, for example concerning the speed of response (slow or fast mode) or the laser wavelength. Devices for telecom applications may also display powers in dBm, meaning decibels relative to 1 mW. Some instruments have an analog electrical output, delivering a voltage signal which is proportional to the received light power, and/or a digital interface (e.g. USB, GPIB, RS-232, WLAN or Bluetooth) for connection to a computer.

Ms.Cici

Ms.Cici

8618319014500

8618319014500