How To Check If Your Sunglasses Are Polarized - polarized image test online

As part of daily maintenance, thoroughly wipe away dust and chips from the outer circumference of the spindle and the measurement surface. Also, thoroughly wipe away dirt and fingerprints from each part with a dry cloth.

You do not have subscription access to this journal. Cited by links are available to subscribers only. You may subscribe either as an Optica member, or as an authorized user of your institution. Contact your librarian or system administrator or Login to access Optica Member Subscription

When measuring, slowly bring both measuring surfaces into light contact with the workpiece to be measured in the same posture and under the same conditions as when the base point was checked, and turn the ratchet stop slowly 3 to 5 times to avoid excessive measuring force by the spindle. To avoid deformation of the workpiece, turn the ratchet stop slowly during contact.

DoubleGaussian function

A micrometer is a simple-looking tool, but the standard model can read down to 1 μm(micrometer). 1 μm is 1/1000 of 1 mm, which is about 90 μm for copy paper, 70 to 80 μmfor a hair, and 10 μm for food film. This unit is very fine, showcasing how precise a tool such as the micrometer is.

A study of the use of aspherics in the design of double Gauss lenses optimized at f/2 with a total field of view of 42° has been performed. Several specific designs incorporating one or two aspheric surfaces at different positions in the lens are presented. The aspheric designs yield substantially increased resolution as compared with an optimized spherical system.

Doublegaussian lens

When the ratchet stop is turned, it spins with a crackling sound to apply the appropriate measuring force to the surface to be measured.

Gauss' signature

Abbe's principle states that "the object to be measured and the standard scale must be aligned in the direction of measurement". Micrometers are tools based on this principle and are capable of higher precision measurements than calipers and other measuring instruments.

The thimble scale is read where the reference line on the sleeve and the thimble scale line are aligned. If there is a deviation, read the scale below the reference line. The sleeve scale reads the maximum visible value.

Things named afterGauss

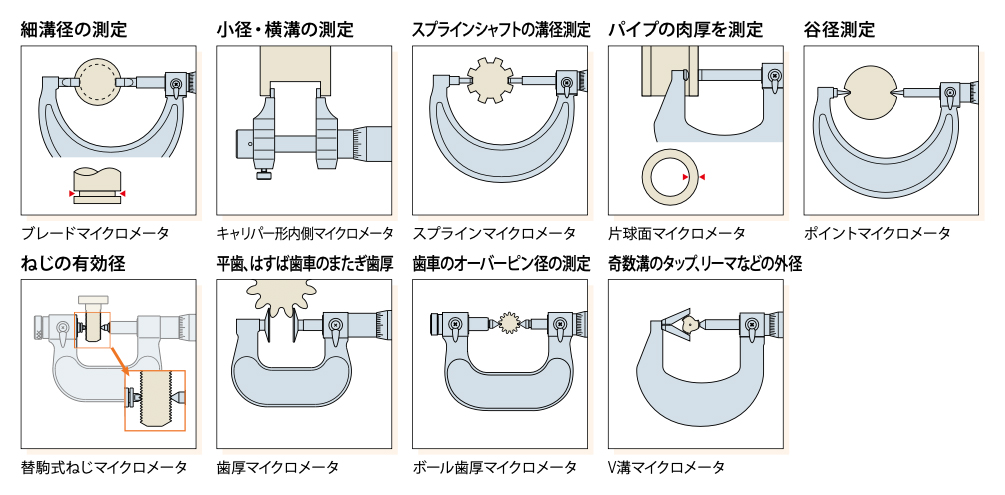

As shown in the figure below, there are various other types available for different purposes of use, such as measuring the diameter of narrow grooves, pipe wall thickness, and gear overpindiameter. *We can also accommodate custom-made products according to the purpose of use.

Examples of typical types include the "caliper type inside micrometer" for measuring small diameter and horizontal grooves, the "replacement piece type screw micrometer" for measuring the effectiveness of screws, and the "tooth thickness micrometer" for measuring the straddle tooth thickness of spur and helical gears.

This website uses cookies to deliver some of our products and services as well as for analytics and to provide you a more personalized experience. Click here to learn more. By continuing to use this site, you agree to our use of cookies. We've also updated our Privacy Notice. Click here to see what's new.

Gaussstory

Gausslens

Micrometers are indispensable precision measuring tools in the manufacturing field. This section provides basic explanations of the measurement methods and features of micrometers, as well as correct usage and precautions.

You do not have subscription access to this journal. Figure files are available to subscribers only. You may subscribe either as an Optica member, or as an authorized user of your institution. Contact your librarian or system administrator or Login to access Optica Member Subscription

A micrometer is a tool to precisely measure the outer diameter and length (thickness) of an object to be measured by clamping it. The measurement method uses a precision screw with a pitch of 0.5 mm, and the rotation of the screw is calculated as the axial displacement of the screw. Currently, there are models that use a 2.0 mm pitch precision screw, enabling faster measurement by using a screw with a larger pitch.

Generally speaking, micrometers are cylindrical in shape, with the measuring surfaces facing each other, but there are various types of micrometers for different purposes.

When reading the scale, be sure to read the scale from the front. As shown in the figure, changing the eye position from (A) to (B) to (C) will change the scale alignment position. To avoid errors due to eye position, read the scale from the position (B) perpendicular to the point where the sleeve reference line and thimble scale line meet.

For example, more than 3,000 micrometers are actually used at production sites of aircraft-related companies, playing an important role in air safety. *The above is a description of the outer micrometers.

Sonnar vsdouble Gauss

1Both authors were at the Institute of Optics, University of Rochester, Rochester, New York 14627, when this work was done USA

Ratchet stop type is generally used as a device to keep the measuring force constant, but friction thimble type and ratchet thimble type are also available for the same purpose.

Gaussheight

A study of the use of aspherics in the design of double Gauss lenses optimized at f/2 with a total field of view of 42° has been performed. Several specific designs incorporating one or two aspheric surfaces at different positions in the lens are presented. The aspheric designs yield substantially increased resolution as compared with an optimized spherical system.

This website uses cookies to deliver some of our products and services as well as for analytics and to provide you a more personalized experience. Click here to learn more. By continuing to use this site, you agree to our use of cookies. We've also updated our Privacy Notice. Click here to see what's new.

Since ancient times, measurement has been necessary in various aspects of human society, including pyramids. In manufacturing, "what cannot be measured correctly cannot be processed correctly," and "measurement" is essential to evaluate the quality of products. A micrometer is one of the indispensable tools for precision measurement.

When mounting the micrometer on a micrometer stand, clamp it across the center of the micrometer frame and do not excessively tighten. Then, adjust the angle of the stand so that the upper and lower scales are evenly visible centered on the zero scale line of the thimble, and fix it in place.

Here we explain the main usage and precautions, using a standard outside micrometer as an example. Micrometers can measure from 0 mm to 2000 mm. Confirm the measuring range and select a type suitable for the shape of the object to be measured and the purpose of use.

You do not have subscription access to this journal. Article tables are available to subscribers only. You may subscribe either as an Optica member, or as an authorized user of your institution. Contact your librarian or system administrator or Login to access Optica Member Subscription

Ms.Cici

Ms.Cici

8618319014500

8618319014500