Fluorescence Filter Set for mCherry Fluorescence Protein - mcherry excitation emission

There are 25.4 millimeters in one inch. Therefore to get amount of inches in millimeters, value in millimeters has to be divided by amount of millimeters in one inch:

Lasercutting fiber

The gain medium is the material in which photons are generated and amplified, while the pumping creates electrical energy that is turned into photons within the medium. Finally, the mirrors reflect light over and over again until it creates a beam of concentrated light known as a laser beam.

In contrast, a fiber laser cutter utilizes a series of optical cables made from thin strands of fibers that transmit light waves directly into the material being worked on. This property allows for greater precision and more focused heat concentration, resulting in cleaner cuts and higher-strength bonds between materials.

This property means that in order to effectively machine parts from silver, machine shops often need to use specialized equipment and techniques. One common solution for dealing with this issue is the use of a heat sink bracket.

FiberCleaver

When product designers need to manufacture a metal part, they’ll find they have a wide variety of fabrication methods to choose from. Among these, two of the most popular options are casting and machining. But how do they compare? This article provides an overview of...

How to jointfiberoptic cable without machine

One popular option is fiber laser cutting machines, which are a type of CNC laser cutter. This article will discuss the basics of fiber laser cutting machines and how they work.

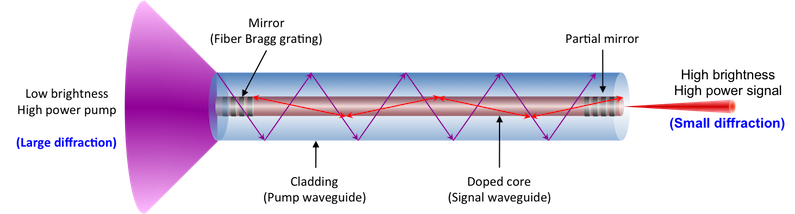

Schematic diagram of high power fiber laser using a double-clad fiberImage Source: Danielsoh8, CC0, via Wikimedia Commons

When you need to cut intricate shapes out of sheet metal or acrylic, there is often no better tool than a laser cutter. This cutting technology uses high-powered lasers to quickly and precisely cut through materials with incredible accuracy. Not only can laser cutters be used to make clean, crisp cuts in all kinds of materials, but they also have the ability to engrave designs into surfaces as well.

Accidentally cutfiberoptic cable cost

Other important components of this machine include the software that controls it and the parts that guide and support the material being cut.

Additionally, fiber lasers can be used with many different shapes and sizes of cutting heads, which allows them to be customized according to specific needs and applications. Overall, fiber lasers represent a state-of-the-art tool for cutting and manipulating all types of materials with unparalleled speed and accuracy.

FiberOptic Cutter Tool

However, not all laser cutters are created equal. Some have more powerful lasers, which allows them to work with thicker materials or create deeper cuts. Others may have more advanced features like auto-feeders or dual-laser capabilities, which can increase the speed and efficiency at which you can process your projects.

How long does it take to fix afibercut

The key component of the fiber laser cutting machine is the fiber laser itself, which produces a highly focused beam of light capable of cutting through even some of the toughest materials with ease.

Cutting fiberoptic cable

This process relies on the careful regulation of electromagnetic wavelengths, which allows laser beams to transmit information with incredible precision and efficiency.

While the basic principles behind these cutting machines are largely the same as those used in other conventional laser cutters, the main difference lies in how energy is transmitted and focused onto a workpiece.

When working with materials such as silver, it is crucial to pay careful attention to their unique properties. Silver, for example, has a relatively high melting point and is prone to heat warping during laser-cutting operations.

CNC milling is a CNC process that involves the use of rotating cutters to remove portions of a block of material (or workpiece) till the desired custom shape (or feature) is made. It allows manufacturers to create intricate parts accurately while meeting tight...

Cutting fibermachine

The heat sink acts as a buffer between the laser and the workpiece, evenly distributing any excess heat and preventing it from causing excessive warping or damage to the workpiece. Ultimately, using a bracket as a heat sink in fiber laser cutting operations gives manufacturers greater flexibility when choosing materials while also ensuring that they can achieve optimal results every time.

At its core, a fiber laser cutter is a highly specialized device that uses laser technology to manipulate a variety of materials. This type of machine produces precise, high-quality cuts in a wide range of different materials.

If you are looking for a production partner that can help to reduce your costs while maintaining high-quality standards, look no further than Gensun. Our state-of-the-art laser cutting services are second to none, enabling us to deliver the highest quality results quickly and efficiently.

Gensun Precision Machining offers rapid prototyping and precision machining services for innovative companies around the world. Whether you need a custom prototype, low-volume production, or high-volume production, our service is second to none. With a strong emphasis on quality control, we get the job done right, every time!

The metal machining and casting processes are often portrayed as a “pick one or the other” comparison for fabricators. But as we hinted in our recent article about casting vs. machining, there are many cases where the most efficient means of production will leverage...

Ms.Cici

Ms.Cici

8618319014500

8618319014500