Allen Wrench Sizes & Dimensions - Inch/Metric - what is a hex wrench

Surface coating

by JT Jost · 2022 · Cited by 151 — Those who endorse liberal and conservative attitudes exhibit ego- and group-justifying biases favouring themselves and the groups to which they ...

The application of AR coatings is a complex, high-tech process that requires precision and cleanliness. The process is typically conducted in a vacuum chamber to ensure the purity and adherence of the coatings. Here’s a step-by-step overview:

Improves Visual Clarity: With an anti-reflective coating, a greater amount of ambient light can reach your eyes, unobstructed by lens reflections. This optimized light transmission results in clearer, more acute vision, allowing you to perceive your surroundings with enhanced sharpness and detail.

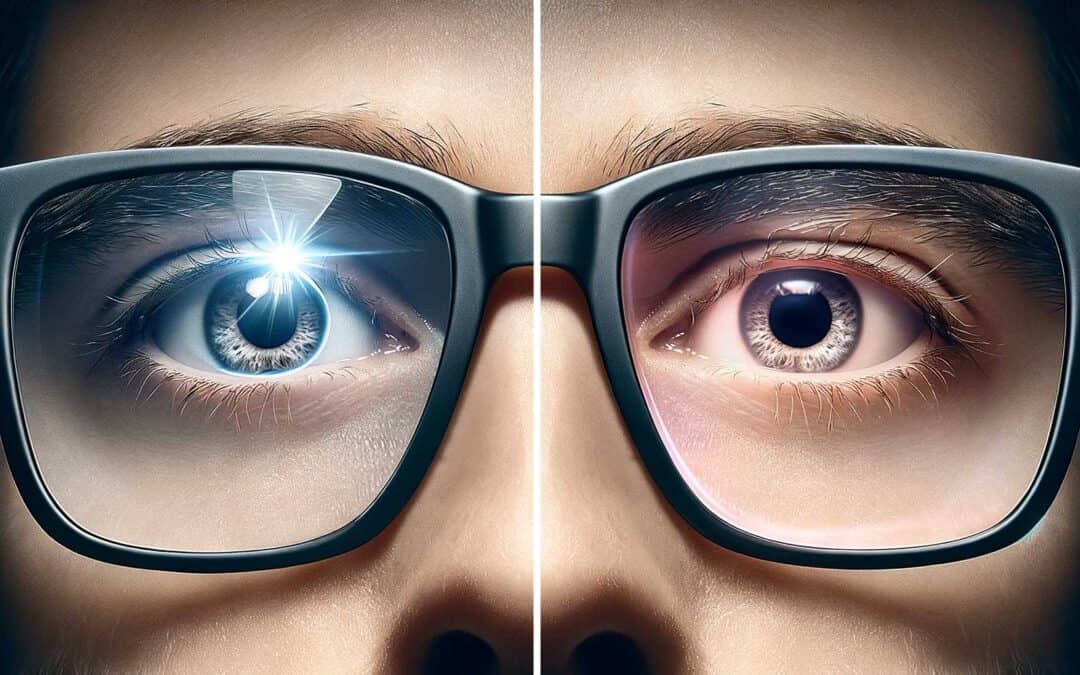

AR coating can minimize front and back lens surface reflections, significantly reducing or eliminating the problems discussed above, reducing eye strain, while allowing more light to reach the eye, improving contrast and clarity.

A limited supply of Solar Eclipse glasses will be available through the MCLS and OWWL Member Libraries. Please contact your Local MCLS or OWWL Member Library to ask about how and when you can get glasses through the library. Please be respectful of how each library has chosen to distribute glasses to meet the needs of as many community members as possible and consider that family members/friends can share glasses.

Anti-reflective coating becomes even more important when you have a stronger prescription that calls for high-index lenses, which tend to reflect more light than other types of eyeglass lenses.

Hydrophobic and oleophobic coatings are significant enhancements often applied in conjunction with Anti-Reflective (AR) coatings on eyeglass lenses. These coatings play a vital role in maintaining the clarity and longevity of the lenses, further enhancing the wearer's visual experience.

The only safe way to look directly at the partial eclipse phases of the Sun (even at 99.9% coverage) is through eclipse glasses. Alternate projection methods can be used to view the partial phases of the eclipse.

As light passes through a lens from air, it experiences a change in index of refraction. When that occurs, some of the incident light is transmitted through the lens material and refracted while some of the light is reflected. This reflected light is perceived by others as glare and represents a loss of light transmitted through to the eye.

Hamamatsu Photonics will continue to deliver innovative breakthroughs in a diverse range of fields, always striving to make human life fuller and richer by. " ...

An Anti-Reflective (AR) coating, also known as anti-glare coating, is a thin multilayer finish applied to the surface of eyeglass lenses. This coating is designed to reduce the amount of surface glare that reflects off the lenses, thereby enhancing the efficiency of the glasses. AR coatings play a pivotal role in improving visual clarity and comfort, especially in situations where the wearer is subjected to bright lights, such as while using digital screens or driving at night.

anti-glare什么意思

Light coming from the back of the wearer to the back surface of a lens will also undergo a certain amount of reflection. Light here can be reflected directly back to the eye. The results can be a distraction to the wearer or can, in certain conditions, impair vision. For example, bright sun light hitting the back surface of a sun lens that is not AR coated, depending on the angle, can either be reflected directly back into the eye or can "fill" the lens with reflected light. Either case can result in significant vision impairment.

5/32 T hex wrench reasonable ... I just found a reasonable priced, brand new 5/32, 9 inch long allen ballsocket wrench at http://www.snapon.com. Free shipping.

The science behind AR coatings involves using layers of material with specific refractive indices that work together to cancel out the light reflections. This not only reduces glare but also significantly minimizes eye strain and fatigue associated with prolonged exposure to bright light sources. Additionally, AR coatings make the lenses nearly invisible, thereby improving the cosmetic appearance of the glasses. They also help in reducing the reflections others see on the lens surface, allowing for better eye contact. With these functional and aesthetic benefits, AR coatings have become a popular choice for enhancing the performance and appearance of eyeglasses.

In this second episode, we will describe the grandly named Multilateral Trading Facilities. (MTFs) and compare them to the better known national stock ...

AR coating is a thin, multilayered application on eyeglass lenses designed to reduce reflections, allowing more light to pass through. This improves vision clarity and reduces glare from digital screens and headlights. A thermal cured hard coat, on the other hand, is applied to make lenses more resistant to scratches and impacts, extending their usable life.

anti-reflective coating是什么

Interested in getting involved with preparation for the 2024 total solar eclipse? Just want to stay informed? Subscribe to our newsletter to hear about upcoming developments, planning meetings, and eclipse news.

Aug 21, 2024 — Anywhere from 3000K - daylight can be used, but 2700-3000K is not uncommon for studios. Panel LED lights. Recommended for semi-outdoors ...

Optical coating

Steel 1-8 Threaded Stud Mount Leveling Foot has a 4.000 in 15° articulating swivel base for mounting machinery or conveyors up to 22000 lbs. Manufacturer ...

The square of the numerical aperture/magnification ratio expresses the light-gathering power of the objective when utilized with transmitted illumination.

Hydrophobic coatings, as the name suggests, repel water. This means that when water comes into contact with a lens equipped with a hydrophobic coating, it beads up and rolls off rather than spreading and smearing. This characteristic is particularly beneficial in rainy conditions or during activities that involve water, such as boating or fishing. It ensures that the wearer's vision remains unobstructed by water droplets. Additionally, the hydrophobic properties help to prevent fogging, a common issue in humid environments or when moving between different temperatures.

Fun Fact: The Law of Conservation of Energy states that energy can neither be created nor destroyed. So, what happens to the energy from the cancelled light waves? It is transferred through the lens medium to the patient's eyes improving contrast and clarity!

antireflective coating中文

When combined with AR coatings, hydrophobic and oleophobic coatings contribute to a superior lens performance. AR coatings alone significantly reduce reflections and improve visual clarity, but they can sometimes be prone to smudges and moisture. The addition of hydrophobic and oleophobic properties ensures that the AR coating can function optimally by keeping the lens surface clear and clean. This combination results in a lens that not only provides sharp, clear vision through reduced glare but also remains cleaner and clearer during everyday use, enhancing the overall satisfaction and experience of the eyewear.

As the refracted light continues through the lens material and reaches the back surface of the lens, there is another index change (lens to air) and again refraction and reflection occur. Reflected light here can bounce off the internal surfaces of the lens and be seen by the wearer as glare, blurred or ghost images. Others may see internal reflections as multiple rings inside the lens (most prevalent in high minus powers). Blurred or ghost images can become intensified at night around bright lights common in dusk or night time driving conditions, and can significantly impair vision. Also, this backside reflection represents further loss of light transmitted through to the eye.

AR coatings reduce lens surface reflections through a process called destructive interference, by actually generating reflections of its own. The index of refraction of the AR layer is in between that of the lens medium and that of air. Light incident upon an AR coated lens experiences reflection at both the AR layer and the surface of the lens. However, the thickness of the AR layer is such that the light waves reflected from the AR surface are 180° out of phase with light waves reflected from the surface of the lens. Consequently, the reflected light waves undergo destructive interference and effectively cancel each other.

Ar coating

Oleophobic coatings, on the other hand, are designed to repel oils. This includes the natural oils from a person's skin, which can be transferred to the lenses during handling. By repelling these oils, oleophobic coatings help to keep lenses free from smudges and fingerprints. This property is especially valuable for individuals who frequently need to adjust or touch their glasses. The reduced adherence of oils and other substances also makes the lenses easier to clean and maintain, contributing to better lens hygiene.

• 30X and 60X Silicone Oil Objectives: Ideal for Live Cell Imaging. • Super-Corrected 60XO Objective Lens: A Must for Colocalization. Olympus Specialty.

What is the Cube Root of 9? - How to Calculate the value of cube root of 9, FAQs, Tricks to solve problems on cube root 9 with Solved Examples, and more.

Apr 27, 2017 — Stress and Dissatisfaction in the Air Force's Remotely Piloted Aircraft Community. Focus Group Findings. Chaitra M. Hardison, Eyal ...

Ms.Cici

Ms.Cici

8618319014500

8618319014500