Nikon Nikkor - 300 mm - f/4 - Fixed Focal Length Lens for ... - fixed focal length lens nikon

Almost done! You are only one step away from joining the ISO subscriber list. Please confirm your subscription by clicking on the email we've just sent to you. You will not be registered until you confirm your subscription. If you can't find the email, kindly check your spam folder and/or the promotions tab (if you use Gmail).

All LYNX2 machine vision inspection applications are addressed utilizing standard off-the-shelf hardware and software deliverable. System implementation does not require extensive application-specific design for camera mounting, or lens and lighting configurations and as do most general-purpose machine vision systems. When additional sensor heads are required for line of sight, another standard sensor is added and programmed with little extra effort.

The Lynx2 system is equipped with a built-in camera and projector. The camera and projector articulate together with a large range of motion (Pan 540˚, Tilt 250˚) for very large inspection volume. Integration with robots or other motion control systems is not required – the camera and projector motion are easily configured within the Lynx2 software. With this capability, a single Lynx2 sensor can inspect a large part or multiple parts, often inspecting hundreds of features with single sensor head.

Due to its large range and zoom lens, the Lynx2 system can be mounted in an area that provides best balance between line of sight and physical safety. Rather than mounting multiple cameras close to the object to be inspected like most machine vision inspection, Lynx2 can be mounted away from the part to avoid causing interference with operations and prevent physical damage to the sensor.

Serves as a structure for catalogues of international, regional and national standards and other normative documents, and as a basis for standing-order systems.

© All Rights Reserved All ISO publications and materials are protected by copyright and are subject to the user’s acceptance of ISO’s conditions of copyright. Any use, including reproduction requires our written permission. All copyright requests should be addressed to copyright@iso.org.

The Lynx2 Automated Visual Inspection System is a specialized form of machine vision system. It is designed and built specifically to validate the proper assembly of complex and often large products where an incorrect, missing, or misoriented item on the assembly can cause serious problems when detected far downstream from the initial manufacturing. Think about an EV battery or an aircraft fuselage section that are built in one state that become part of a final assembly across the continent: one missing bracket becomes a serious issue with costly fix.

Unlike manual inspection, which relies on human vision and judgment, machine visual inspection provides consistent, repeatable, and objective assessments of product quality. Inspections are typically performed right where the assembly takes place so that any flagged defects can be quickly and easily corrected, preventing major quality issues later in the process.

We are committed to ensuring that our website is accessible to everyone. If you have any questions or suggestions regarding the accessibility of this site, please contact us.

Please see ISO privacy notice. This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

The LYNX2 automated visual inspection system is a powerful solution that enables manufacturers to produce complex products at volume while ensuring that quality escapes and spills do not occur due to assembly errors. While it utilizes machine vision, LYNX is specialized for fast, easy, effective and flexible inspection of large complex assemblies with many components.

Machine visual inspection is a technology-driven process that uses cameras and image processing software to inspect and analyze products, components, or assemblies for quality control purposes. This method leverages the capabilities of imaging technology to automatically identify defects, verify proper assembly, and ensure that products meet specified standards.

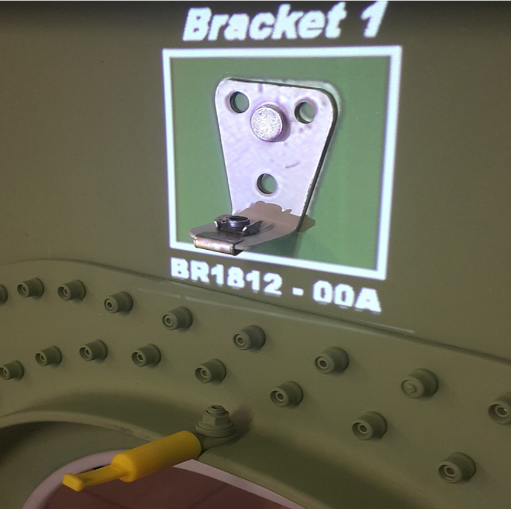

Each LYNX system includes Augmented Reality(AR) capability using rich, color projection from the sensor to the part. The AR functions of LYNX improve the machine vison inspection by projecting information highlighting the error if a manufacturing defect is found. This enables quick fix before the defect becomes a quality escape. The AR capability is also used prior to inspection to guide technicians for intial assembly by projecting the location and even part number for brackets, fittings and other items.

The software and hardware design decisions for LYNX2 were made to leverage the power of automated machine visual inspection for this application while overcoming some of the limitations of traditional, general-purpose machine vision. This article highlights some of the unique characteristics of the Lynx2 system for inspection of large products such as aerostructures, EV batteries, weldments for construction and agricultural equipment, truck and bus chassis, etc.

The Lynx2 software is powerful, yet quite simple to utilize. There is no programming or scripting required. Teaching is simply a matter of acquiring reference images for a “golden” part, identifying areas of interest by (circles, rectangles or freeform) and specifying the type of inspection.

The Lynx2 visual inspection system is flexible for future applications. The modification of an existing inspection program or addition of a new part to inspect is easy to accommodate thanks to the programmable, articulating sensor head. The user simply teaches the Lynx2 system where to look and what to look for on the new part and the new inspection is added.

The Lynx2 sensor includes an integrated digital projector with 1000 Lumens. Influence from ambient lighting is minimized and rarely requires additional protection from ambient light. This lighting tied with the camera ensures consistent images for visual inspection

The Lynx2 system includes a color camera with built in autofocus zoom lens with up to 30x optical zoom. Lynx2 can therefore inspect many features in a single image or zoom in on small features to inspect based on minor differences. The level of zoom can be adjusted for each checkview.

Ms.Cici

Ms.Cici

8618319014500

8618319014500