Govee TV Backlight 3 Lite with Fish-Eye Correction ... - backlight

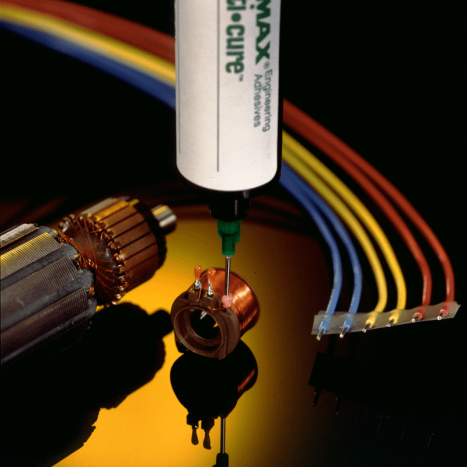

Dymax UV adhesives cure in seconds when exposed to high intensity UV light, and find many applications as adhesives for electronics assembly. The “on demand” cure feature of these resins means no rework as a result of adhesive migrating onto solder pads or through holes. Dymax adhesives for electronic assembly are ideal for bonding heat sinks and heat sensitive components, wire and component tacking, strain relief of large parts and securing hand inserted components prior to wave soldering. Single part UV light curing adhesives can give productivity gains over two part systems like epoxies, and slower curing chemistries like silicones.

Light illuminationtest

These adhesives provide optimal circuit protection. Their “on-demand” cure feature makes them ideal for manual applications such as wire tacking and coil termination, where optimal placement and immediate strength is critical.

Light illuminationlevel

There are generally two types of lighting that can be used for microscopes: transmitted and reflected illumination.With transmitted lighting, light shines from behind an object (usually a transparent target) to illuminate the features within that target, while reflected light is used to illuminate the surface of an object. Reflected light can be coaxial (brightfield) or from an angle (darkfield). Coaxial lighting travels along the same direction as the optical path of the lens and is used to view flat surfaces. Ring illumination reflects off of the angled surfaces of an object and is usually used for imaging objects with textured or irregular surfaces.

Light illuminationNagoya

Dymax component ruggedizing and staking materials are engineered to hold critical components, such as Ball Grid Arrays (BGA) and Video Graphics Arrays (VGA), for secondary processes or for long-term reliability. Each material helps enhance shock and vibration resistance of electronic assemblies.

Dymax light cure UV potting materials cure tack-free in seconds upon exposure to UV/Visible light. Each potting compound is engineered to bond different substrates, offering tenacious adhesion to plastics and metals. UV potting resins reduce waste from off-ratio mixing and are free from isocyanates and heavy metals. Processing in seconds eliminates fixtures, jigs, racks, and ovens to increase space and lower total inventory costs.

Dymax Multi-Cure® thermal interface materials may be cured with light, heat, or activator. Most applications utilise a combination of these methods for optimal cure speed. Light cure allows for exposed areas to cure immediately, fixturing parts in place so the activator or heat can continue curing in shadowed areas without interruption to process flow.

Light illuminationcalculation

Illuminationlighting meaning

The Dymax BlueWave® MX-Series LED UV spot and flood curing system provides manufacturers with the curing flexibility of other Dymax systems but in a small, efficient design with expansion capabilities.

Light illuminationunit

01865 842842 orders@intertronics.co.uk Name* Company* Phone* Email* Post code* If you’re in the UK, knowing your postcode would help us get in touch even more quickly. If you’re outside the UK, please indicate your country. Tell us about your application Any information that you submit using this form will be processed according to our privacy policy.

Our dispensing component kits provide a variety of components to help you evaluate and establish your dispensing process. They complement many dispensing methodologies, from manual dispensing with a thumb plunger, to use of a dispensing controller, to highly accurate and repeatable dispensing valves and pumps.

Statements, technical information and recommendations contained herein are based on tests we believe to be reliable but they are not to be construed in any manner as warrantees expressed or implied. The user shall determine the suitability of the product for his intended use and the user assumes all risk and liability whatsoever in connection therewith.

Dymax 9000 Series Electronics Encapsulants are tough, flexible UV curing electronics-grade encapsulants which are single part and cure in seconds; they cut costs and processing times associated with electronic assembly. These encapsulating materials have high ionic purity, excellent adhesion and resistance to humidity and thermal stock to effectively protect components. Dual cure (light/moisture) available.

Dymax UV Curing Flood Lamps offer moderate- to high-intensity curing over a 12.7cm x 12.7cm (5" x 5") or 20.3 cm x 20.3 cm (8" x 8") area. Curing in 5-30 seconds is typical using Dymax light-curable materials. Dymax UV Curing Flood Lamps can be used as bench-top curing systems or integrated into automated assembly systems.

Ms.Cici

Ms.Cici

8618319014500

8618319014500