Understanding & Using Polarizing Filters - how does polarizer work

In various industries, ranging from automotive sensors and LED lighting systems to cutting-edge cameras and medical diagnostic devices, the significance of aspheric lenses is steadily growing. These lenses are part of the subset defined by rotationally symmetric optics with a radially varying radius of curvature. Aspheric lenses play an increasingly crucial role in various aspects of the optics, imaging, and photonics industries. This is attributed to the unique advantages they provide compared to traditional spherical optics and spherical elements.

The choice of materials for aspherical lenses is influenced by factors such as wavelength requirements and manufacturing cost. The following summarizes materials compatible with each manufacturing process.

"The Backyard Blacksmith" mostly deals with mild steel which can be forged a lot hotter than the steels used for knives.

Asphericlens glasses

To achieve the necessary performance of an imaging lens, optical elements designers frequently resort to stopping down, or increasing the f/# of their design. Although the desired resolution goal is obtained, the approach results in a reduction in light throughput. Using aspheric lenses in the design, however, improves aberration correction and enables the creation of high-throughput systems with low f/#s, while also maintaining excellent image quality. The following table compares two designs: an 81.5mm focal length, f/2 triplet lens (depicted in Figure 2) with all spherical surfaces and the same triplet with an aspheric first surface. Both designs utilize identical effective focal length, f/#, field of view, glass types, and total system length. The table provides a comparison of the modulation transfer function (MTF) at 20% contrast for on-axis and off-axis collimated, polychromatic light rays at 486.1nm, 587.6nm, and 656.3nm. The triplet lens with the aspheric surface demonstrates significantly improved imaging performance at all field angles with high tangential and sagittal resolution values, surpassing those of the triplet with only spherical surfaces by factors as high as four.

For optical engineers, a crucial aspect is comprehending manufacturing techniques and selecting the most appropriate method based on lens application, performance requirements, development cost, sample cost, production part cost, and project timeline.

Fabricating aspherical lenses poses greater challenges due to their complex surface profiles compared to conventional spherical lenses. Various methods are available for producing aspheric lenses, each with its distinct advantages and limitations.

Unlike spherical lenses, which can be specified solely by the radius of curvature that fluctuates radially from the center of the lens, aspheric lenses exhibit a surface with varying local radii of curvature. The definition of rotationally symmetric aspheres often involves a surface sagitta (the measure of the surface shape in relation to a plane), or sag, expressed through an even aspheric polynomial.

Unlike conventional spherical optics, aspheric lenses use less elements to enhance aberration correction. An example would be zoom lenses. Zoom lenses typically use ten or more elements while two aspheric lenses can be replaced for a handful of spherical lenses in order to achieve similar or better optical results. The system size and overall cost of production are also potentially reduced.

VIETNAM:Alpha Industrial Park, Tu ThonVillage, Yen My District, HungYen Province 17721+84 221-730-8668sales-vn@avantierinc.com

And before you get to tempering: please ignore temper colors. They are not accurate enough. Get a method of using thermal mass and an accurate thermometer.

I'm a little confused - I've been reading "The Backyard Blacksmith" as well as "The Complete Bladesmith" (referred by this forum) and both authors refer to the most effective "temperature colour indication" for mild steel. However, Lorelei Sims says "forging is most effective when the metal has turned yellow"(2100°F)... while our friend Jim Hrisoulas says that "most of the carbon steels" beginners will use should be worked at "the cherry red range" (1500°-1800°F). I'm fairly certain they're considering the same steels so what is up? If I'm just starting with 10 series steel what guideline should I use?

Lastly, I don't have a lot of equipment and tools, but one thing I do have access to is a Temperature Gun as shown here: http://www.reedinstruments.com/product/reed-r2007-dual-laser-infrared-thermometer I'm kind of shocked I've not seen it used before in any of the online videos or instructionals, but I thought, as a beginner, it might help me pinpoint these 'colours' more effectively...at least starting out.

I get about as irritated when people use these things as Jarrod does when people talk about tempering colors. I have seen them be 200% off with surfaces that had emissivities that were odd.

Aspheric meaningeye

Unless you have a glowing version right next to your forge, no, it isn't really that helpful. That was my original point.

The advantages custom aspheric lenses bring to high-performance optics are substantial. Particularly, these lenses are an optimal choice when designing systems with a limited footprint, as their inherent characteristics lend themselves well to compact assemblies.

Yep! Lorelei is using mild steel, which over here is usually A36, a grade of remelted scrap that does not have a carbon content specification. It just has have a minimum tensile strength of 36 Kpsi. The carbon can vary wildly, but there's never enough for a good blade. We can also get 1018 and 1020 if we're willing to pay extra for clean, easier to weld mild steels.

Aspheric meaningmedical

And those in between are in between. Generally, colors aren't a great guide, because my definition of "cherry red" is going to be different from yours (and likewise from everyone's), and ambient lighting skews things. Personal experience, especially with a knowledgeable guide present, is going to be your best guide.

Asphericcontact lenses

No, they are not. Blacksmiths use mild steel, low carbon in in the 0.18-0.25-ish %. Bladesmithing steels are in the 0.60-1.20% carbon range, which makes a huge difference in behavior.

In Figure 1, the difference in focusing performance of spherical lenses and aspheric lenses is further explained by the table below. It compares the performance of a spheric lens and an aspheric lens both with a diameter of 25mm and focal lengths of 25mm (f/1 lenses). The table presents a comparison of spot sizes, or blur sizes, for collimated 587.6nm light rays under different conditions: on-axis (0° object angle) and off-axis (at 0.5° and 1.0° object angles). The spot sizes of the asphere are significantly smaller, differing by several orders of magnitude compared to those of a spherical lens.

You don't see us using IR thermometers because they are both expensive and do not work on glowing steel. They are calibrated for black body emissivity, and if you throw incandescent heat at them they freak out. That one does spec that it reads up to 2012 degrees F, which is much higher than I have seen on any other unit, but I have my doubts it does so with any accuracy. When we need to know the temperature we use a pyrometer setup consisting of a type K thermocouple and something to read it with.

Aspheric meaningin Bengali

Then there are the other alloying elements we use that blacksmiths do not. Our steels have more manganese, chromium, vanadium, silicon, tungsten, nickel, and other fun things that can cause problems if forged too hot or too cold. Problems like turning into the steel equivalent of cottage cheese when too hot, or filling with microfractures when too cold. With mild steel all you have to worry about is burning or breaking at higher and lower temperatures than we usually use.

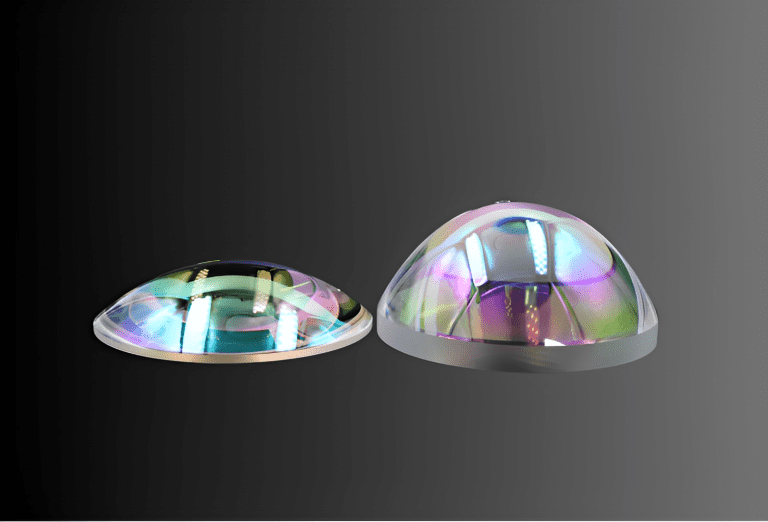

A spherical lens with a significant amount of aberration and an aspherical lens with almost no aberration can be seen(Figure 1). Aspherical Lenses address the issue by deviating from a perfectly spherical shape. An aspheric lens can be designed by modifying the curvature length and adjusting the conic constant and aspheric coefficients of the curved surface of the lens. By carefully shaping the lens, aspheric lenses ensure that all incoming light rays converge to a single focal point. minimizing spherical aberration and improving image quality.

Observation and experience are far more valuable than color charts since there are too many variables involved that affect color both to an individual's perception and in individual environments.

You don't see us using IR thermometers because they are both expensive and do not work on glowing steel. They are calibrated for black body emissivity, and if you throw incandescent heat at them they freak out. That one does spec that it reads up to 2012 degrees F, which is much higher than I have seen on any other unit, but I have my doubts it does so with any accuracy. When we need to know the temperature we use a pyrometer setup consisting of a type K thermocouple and something to read it with.

I had the chance to play with an IR gun that was supposed to work on liquid steel. You had to determine the emissivity constant for that grade, but once you did that and plugged it into the unit it worked fairly well. Until smoke or slag got in the way. Which it did. Constantly. And that gun was $30,000.

To put it in simple terms forging should happen in that zone between ""tfh" and when it cools to the point it stops moving readily under the hammer. Your reading should have told you the effects of forging too hot or too cold.

Asphericpronunciation

Custom aspheric lenses play a crucial role in advancing high-performance imaging across various fields. From aerospace applications like night vision imaging optics to defense imaging systems, and from microscope imaging objectives to semiconductor wafer inspection tools, these lenses serve as indispensable components in precision imaging devices. A notable example is the Smite Cassegrain telescope, which utilizes custom aspheric lenses along with reflective elements to mitigate aberrations and achieve superior resolution.

Going back to the original post, one thing nobody has addressed (although Mr. Giagni came close) was the question of whether the steels in the blacksmithing book were the same as those in the bladesmithing book.

Going back to the original post, one thing nobody has addressed (although Mr. Giagni came close) was the question of whether the steels in the blacksmithing book were the same as those in the bladesmithing book.

That is the tempering color chart I was referring to (note that it only goes up to 600F). The OP was asking about forging temps. Do yourself a favor and forget that the chart you found even exists.

AsphericIOL

The "IR guns" do have their place, and I actually own two of them. I keep one in the kitchen to check the temp of my cast iron frying pans before the food goes in, and I use another to check the shell temps of my pet tortoises.

Asphericlenses advantages disadvantages

Many years ago I was a test engineer in an elevator manufacturing plant. I got into an argument with a design engineer over a new product were were making. There was a shiny (reflective) copper plate in the product that I was concerned was getting too hot. This guy came out with his IR temp gun and told me there was no issue, that it was only 120F. You could see the heat (and smoke) coming off of it, so I told him to touch it if he felt his measurement was accurate. (He declined) The guns are tuned for something that has an emissivity near 0.95. (A perfect black body is 1.0) A shiny surface will be much lower. If I remember right, I back calculated that the copper must have been closer to 0.3, but that was 20 years ago.

As Alan said, the inaccuracy gets worse once the surface is incandescent. There are optical pyrometers out there that are supposedly good for glowing materials, but I haven't had the opportunity to use one yet. The ones I have seen for sale are quite expensive.

When the aspheric coefficients are equal to zero, the resulting aspheric surface is considered to be a conic. The following table shows how the actual conic surface generated depends on the magnitude and sign of the conic constant, k.

One of the most important features of aspheric lenses is their ability to correct for spherical aberration. Spherical aberration is found in all spherical lenses, such as plano-convex or double-convex lens shapes. However, aspheric lenses excel in focusing light to a precise point, resulting in minimal blur and enhanced image quality. Spherical Aberration is the consequence of the uniform curvature of the lens surface and not the result of a manufacturing error. The outer rays converge at a different focal point than the inner rays resulting in blurred or distorted images.

Ahhh... thanks! That would explain the difference..they both used the same terminology and didn't seem to contradict each other at any other point. Odd though, I went back and looked and while Jim mentioned 'carbon steels', Lorilei never mentions what particular steel she is working with in that section.

No, they are not. Blacksmiths use mild steel, low carbon in in the 0.18-0.25-ish %. Bladesmithing steels are in the 0.60-1.20% carbon range, which makes a huge difference in behavior.

Spend some time initially with your steel getting used to what it tells you. For instance. Heating it up initially use a magnet as the steel heats. When the steel stops attracting the magnet, with 10xx series you are in the 1415-1425 F range. Get to know what that color looks like to your eyes in those conditions. Next you want to watch for the decalescence effect. This will be of great importance in the hardening process. Get to know what color, again to you, that occurs at. The next milestone is when sparks come off the blade. In technical terms, for the purpose of forging on an homogeneous bar, it is called "too frigging hot !" You are burning the steel. Don't do that again.

Ms.Cici

Ms.Cici

8618319014500

8618319014500