Telescope Collimation - 4 Simple Steps for the Complete ... - collimating mirror

Diffraction grating material is made up of thousands of small grooves (or rulings) that run parallel over the transparent material, acting as slits. This causes diffraction to occur on all those grooves. Due to interference, the different colors combine. The final result is seen as a series of spectra of white light after transmission through the grating material.

Laser galvanometerfor sale

The versatility of laser galvo technology makes it a valuable tool in various industries. In laser marking applications, laser galvo systems are used to engrave logos, serial numbers, or barcodes on products. The precise control of the laser beam ensures consistent and high-quality markings on different materials, including metals, plastics, and ceramics.

In opal, the spaces between silica spheres cause diffraction by reflection and is partly responsible for the famous opalescence of precious opal.

Laser galvanometeramazon

Laser galvo technology is also employed in material processing applications such as cutting, welding, and drilling. The dynamic control of the laser beam allows for precise adjustments in real-time, enabling efficient and accurate processing of materials. Additionally, the speed and precision of laser galvo systems contribute to increased productivity and cost-effectiveness in industrial settings.

CO2 GalvoLaser

In gemology, diffraction is the bending of light waves around an obstacle or sharp edge, either by transmission of light or reflection.

When dispersion happens with a prism, the violet part of the spectrum is bent the most, but in diffraction, it is the red light that gets thrown the furthest. This happens because the longer the wavelength, the more the waves will diffract. As the diffraction occurs in radiant waves, you will see a repetition of spectra along the center of the zero order spectrum(where little to no dispersion occurs). The first order spectra(on both sides of the zero order) are the ones most clear, so it is a first-order spectrum that is used in diffraction grating spectroscopes.

Laser galvanometerprice

Furthermore, laser galvo systems are compact and lightweight, making them ideal for integration into automated production lines or handheld devices. The small footprint and fast response time of laser galvo technology enable seamless integration into various applications, from laser cutting machines to medical instruments.

Galvolaservs fiber

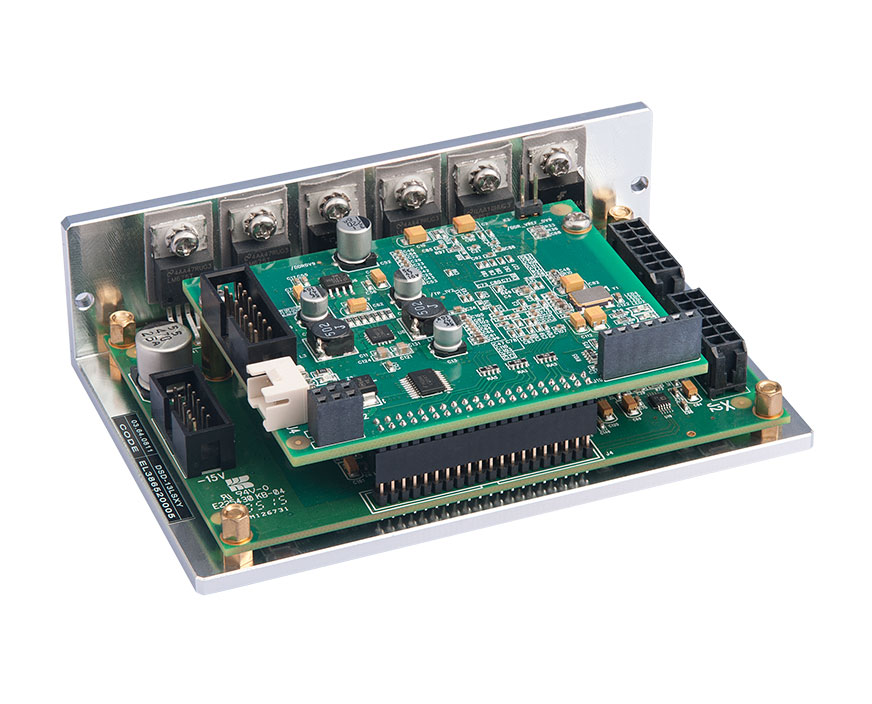

Laser Galvo, short for galvanometer, is an optical device that moves a mirror or lens in response to electrical signals, usually in the laser galvo scanner. The movement of the mirror or lens allows for precise control of the laser beam's direction and focus. This rapid movement is facilitated by a closed-loop control system that detects the position of the mirror and adjusts it accordingly.

In conclusion, laser galvo scanning technology solutions has revolutionized the field of laser processing with its precision, speed, and versatility. By understanding the principles of operation, applications, and advantages of laser galvo systems, industries can harness the full potential of this innovative technology for a wide range of applications. Whether in laser marking, material processing, or medical devices, laser galvo technology continues to push the boundaries of what is possible in the world of laser technology.

Galvo FiberLaser

Galvo scanner

The adoption of laser galvo technology offers several advantages over traditional laser systems. One of the key benefits is the ability to achieve high-speed scanning and positioning, leading to improved efficiency and productivity. The precise control of the laser beam allows for intricate patterns and designs to be created with unparalleled accuracy.

Colin Winter compares diffraction to water coming from a hose. It will travel in one direction. If you hold your thumb partly over the opening, the water will be dispersed in different directions. Diffraction is the dispersion of white light into its spectral colors (red, orange, yellow, green, blue, indigo and violet).

The LibreTexts libraries are Powered by NICE CXone Expert and are supported by the Department of Education Open Textbook Pilot Project, the UC Davis Office of the Provost, the UC Davis Library, the California State University Affordable Learning Solutions Program, and Merlot. We also acknowledge previous National Science Foundation support under grant numbers 1246120, 1525057, and 1413739. Legal. Accessibility Statement For more information contact us at info@libretexts.org.

The heart of the laser galvo system is the galvanometer motor, which converts electrical signals into mechanical motion. By applying a voltage to the motor, the mirror or lens can be positioned with high accuracy and speed. This controlled movement enables the laser beam to scan across a surface, creating intricate patterns or markings with precision.

This page titled 7.17: Diffraction is shared under a CC BY-NC-SA 2.5 license and was authored, remixed, and/or curated by gemology via source content that was edited to the style and standards of the LibreTexts platform.

Laser Galvo, a crucial component in laser technology, plays a significant role in various applications such as laser marking, material processing, and medical devices. Understanding how laser galvo works is essential for optimizing its performance and achieving desired results. In this blog, we will delve into the principles of operation, applications, and advantages of laser galvo technology, with a focus on its functionality in the modern industrial world.

Ms.Cici

Ms.Cici

8618319014500

8618319014500