Nikon Lenses - lens of nikon

Reflective coating paint

All specifications are based on manufacturer's calculations. All performance figures are based on standard day, standard atmosphere, sea level, gross weight conditions unless otherwise noted.

Anti-reflective (AR) and high-reflective (HR) coatings are two types of coatings used in optical systems across most wavelength bands.

Coatings are manufactured by depositing thin layers of alternating materials in a well-controlled vacuum environment. Vacuum deposition can be achieved by vaporizing a solid or liquid coating material in vacuum. In the process of vaporization, atoms or molecules are deposited on the surface of the optical component that needs to be coated.

Embark on a journey of continuous learning: from prepping for checkrides, perfecting instrument approaches, to proficiency flights. Enhance your aviation skills here!

An optical coating consists of thin layers of various materials on the surface of an optical component like a window or lens. Optical coatings work in a limited wavelength range by reflecting a fraction (R) of incident light while transmitting the rest (1-R). The purpose of coatings is to protect the surfaces of optical components or to improve their properties.

The 235-horsepower MT-7-235 (the T stands for tricycle gear) and its close cousin, the M-7-235 that is mounted on floats, skis, or conventional gear, are used for a variety of adventurous assignments nationwide. A recent check shows these aircraft tracking wild animals in the Northwest, towing gliders for the Civil Air Patrol, and providing commercial seaplane transportation in Florida and the Bahamas. Maule is famous for the budget prices of its new airplanes,. Compare what you get for what you pay and you'll see Maule stands up well to the competition.

For more information, contact Maule Aircraft Inc at or via https://www.mauleairinc.com/mx-7-series

In the case of HR coatings, they are increasing reflectivity where it is needed. For that reason, highly reflective coatings have extensive application potential in products that are sensitive to heat damage. Among many applications of reflective coatings are beam splitters, which create mirror surfaces that reflect infrared radiation back to their sources.

Join us in protecting your freedom to fly: Engage with state agencies, monitor airports, participate in lobbying efforts, and support general aviation!

High reflective coating

Immerse yourself in a world of aviation insights: Explore in-depth articles, watch engaging videos, listen to enlightening podcasts, and join informative webinars.

Join the vibrant aviation community: Attend showcases, connect with fellow enthusiasts, participate in fly-ins, and immerse yourself in aviation events!

Embark on your next aviation adventure: Explore exciting destinations, read inspiring travel stories, plan your trip with our flight planner, and access exclusive discounts!

The quality, performance, and effectiveness of optical coatings are influenced by the uniformity and thickness of the material. In IR coating materials, spectral transmission and chemical composition differ. A material that is used for IR radiation is less mechanically durable than one that is used for shorter wavelengths, or visible light. In terms of chemical composition, the materials vary widely. In order to achieve the necessary durability and functionality of thin film coatings, the arrangement, type, and ratio of atoms in molecules of chemical substances must be measured and evaluated in depth.

Ar coating

Embark on a journey of continuous learning: from prepping for checkrides, perfecting instrument approaches, to proficiency flights. Enhance your aviation skills here!

Optical coating process

NLIR’s spectrometer 2.0-5.0 μm combines speed, high sensitivity, and high resolution providing innovative revolutionary solutions in IR coating quality control and production monitoring.

Join us in protecting your freedom to fly: Engage with state agencies, monitor airports, participate in lobbying efforts, and support general aviation!

Join the vibrant aviation community: Attend showcases, connect with fellow enthusiasts, participate in fly-ins, and immerse yourself in aviation events!

Embark on your next aviation adventure: Explore exciting destinations, read inspiring travel stories, plan your trip with our flight planner, and access exclusive discounts!

Join our community for exclusive benefits: Access pilot information, participate in sweepstakes, enjoy legal & medical services, discounts, and enhance your aviation journey!

Join our community for exclusive benefits: Access pilot information, participate in sweepstakes, enjoy legal & medical services, discounts, and enhance your aviation journey!

For example, testing laser line filter transmittance, increasing solar cells’ lifespan, measuring and monitoring lighting reflectors, motion detectors, or telecommunications systems are just some of the applications of optical coatings that have been developed for several industries.

Anti reflection coating

Fast and accurate optical measurements are needed to achieve depth coating analysis during the production process. The most common measurement tool used for spectral optical testing is a spectrophotometer. Spectrophotometers with high accuracy, speed, and resolution are ideal for measuring the transmission, reflection, scattering, and absorption of light on optical coatings.

The new MX-7-180C Millennium tailwheel 180-hp model comes with long-range tanks (73 gallons of usable fuel) as standard. Obviously, owners won't fill the tanks every time; but when they're full, the aircraft has an eight-hour endurance and, with reserves, a range of 940 nautical miles. The useful load averages about 1,000 pounds. The four-place aircraft features the new spring-aluminum gear and a constant-speed propeller, and it can be put on floats. The 180-hp MXT-7-180A Comet has a nosewheel for those not willing to spend the 10 hours or so it takes to learn tailwheel flying. While the Comet comes with standard fuel tanks (43 gallons usable), long-range tanks can be added as an option. The Comet, with a useful load of 950 lb, features the spring-aluminum gear and a fixed-pitch propeller. On the day it was flown, it was lightly loaded and climbed at nearly 900 feet per minute; cruise speeds averaged 113 KTAS. https://www.aopa.org/go-fly/aircraft-and-ownership/aircraft-fact-sheets/maule-7

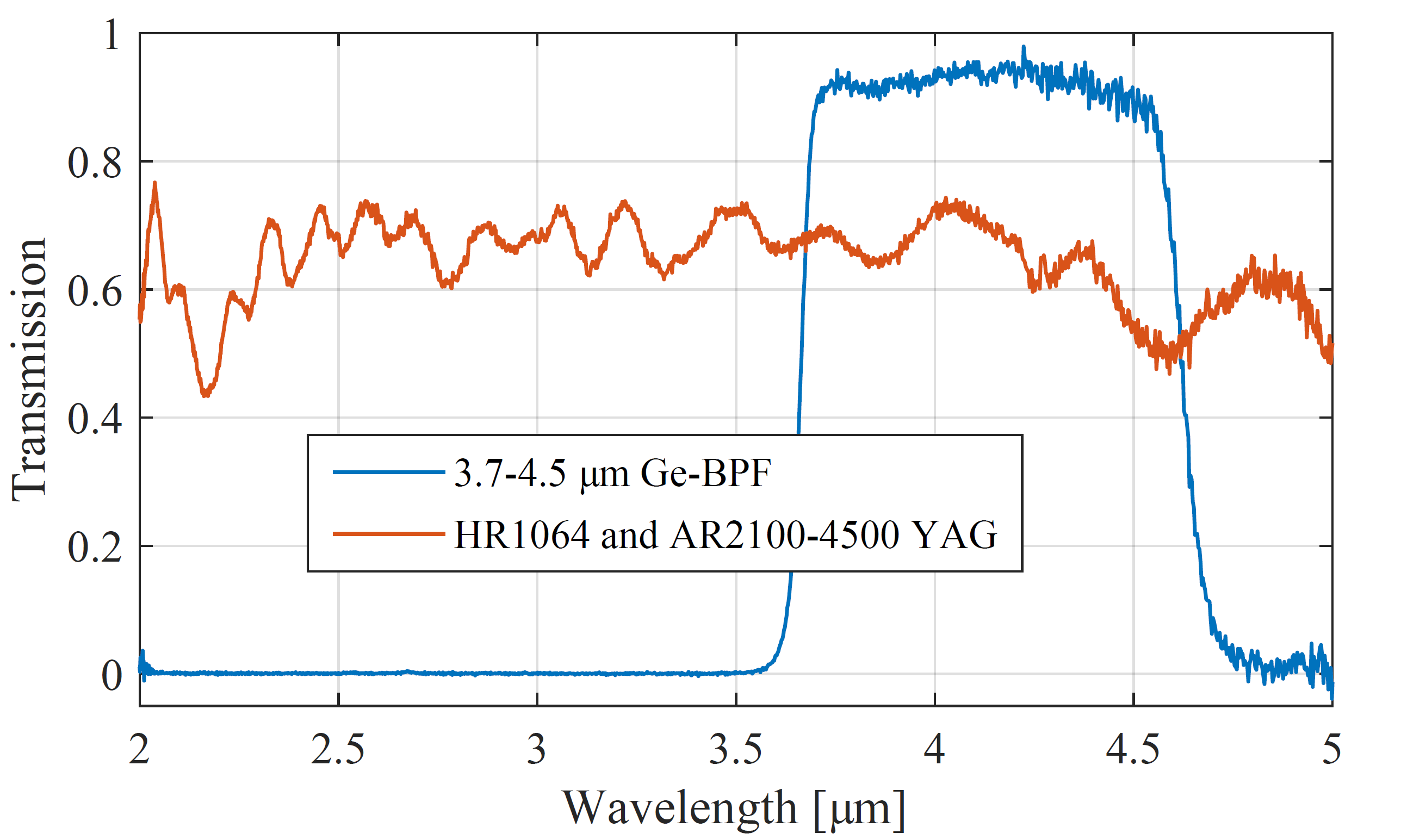

A 30 W globar was used as the light source for these transmission measurements of coated optical windows: a Ge bandpass filter (BPF) for 3.7 – 4.5 µm and a YAG mirror coated with high reflection at 1064 nm and high transmission at 2.1 -4.5 µm. The S2050-400 spectrometer was set to 20 ms exposure time and captured just single shots. No averaging or smoothing has been applied to the data subsequently.

The term infrared (IR) optical coating refers to the coating procedure for light in the infrared spectrum, from 740 and beyond 25000 nm wavelength. Applications include high-power lasers, thermal cameras, and airborne imagers.

Immerse yourself in a world of aviation insights: Explore in-depth articles, watch engaging videos, listen to enlightening podcasts, and join informative webinars.

In the IR spectral range, many different molecules have very strong absorption properties. High-speed, high-resolution, and ultrasensitive IR spectrometers are the best option for measuring optical film thickness and measuring the uniformity of film thickness across coated surfaces.

The application of AR coating reduces surface reflections by increasing light transmission. Various applications, including display panels, solar cells, and optical lenses, incorporate antireflection coatings due to reduced reflection.

Ms.Cici

Ms.Cici

8618319014500

8618319014500