Meade Series 5000 2" Enhanced 90-degree Mirror Diagonal - 90 degree mirror

By clicking sign up, you agree to receive emails from Safeopedia and agree to our Terms of Use and Privacy Policy.

Military laser eye protection against Hand-held visible and Infra-Red Lasers. Developed in cooperation with the LAPD Air Support Division, NoIR GlareShield™ ...

The OD of a given piece of protective eyewear pertains solely to the specific wavelengths of light that it has been rated for. Lasers emit light at specific wavelengths; a given piece of eyewear will do a poor job blocking the energy from a laser that is emitted at a different wavelength than the one which the eyewear is rated for.

Conventional fluorescent lamps (white light) produce UV radiation but with a very short wavelength and, although it may work on some materials, we do not recommend it because it is inefficient. As we have already mentioned, we recommend using actinic fluorescent lights, or in other words: UV light.

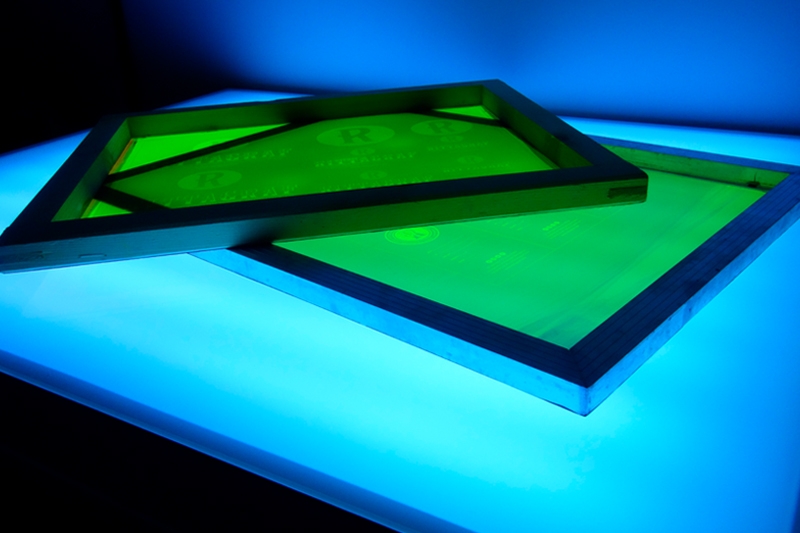

When assembling a light box of this type, it's very important to calculate a good distance between the UV fluorescent tubes. Depending on the height of the box, the fluorescent tubes should be more or less separated. We advise that the depth should not be less than 10 cm or greater than 25 cm. The box where we have built the exposure uv light box has a height of around 15 cm.

As we have already mentioned, among all the lighting options, UV fluorescent lights combine the best features of each one: they are versatile, compatible with most manufacturers of photomechanical products and processes, relatively affordable, and currently easy to access the components.

In professional workshops, we usually work with a photocell system that counts exposures through light steps rather than time measurements. This is very functional because this system accurately controls the amount of light exposed, readjusting the wear of the exposure unit and the possible variations in the electrical network.

As mentioned earlier, in screen printing and other photomechanical techniques, materials are used that require light exposure to reactivate the substances they contain. For most of these materials, the required type of light is UV (ultraviolet) light. This type of light falls within a wavelength range of 10 nm to 480 nm (nanometers). Below 400 nm, this wavelength range begins to become invisible to the human eye, and around this wavelength, the light tends towards violet tones.

Buy Thorlabs products. Newark Canada offers fast quotes, same day shipping, fast delivery, wide inventory, datasheets & technical support.

Within the range of ultraviolet light rays, various subtypes are distinguished, and sometimes they are divided into categories. The most well-known are UVA (315 to 400 nm), UVB (280 to 315 nm), and UVC (100 to 280 nm), but there are many more divisions. Roughly, rays close to 400 nm are called short-wave and those approaching 10 nm would be extreme wave. Thus, we need to choose UV light bulbs of type A.

Many of you have asked for it, and here it is. We have retrieved and improved upon the classic tutorial written by our technician, Carlos Alguacil, back in 2016 when he led the technical content of Vostok Printing Shop. At that time, it was titled Un Tutorial esperado: Construir una caja de luz UV (An Expected Tutorial: Building a UV Light Box), and it helped many workshops and individuals take the first step in professionalizing their work. You won't find it on the internet anymore, but we have recovered and expanded upon it here. A significant part of this tutorial can also be found dissected in the book Triunfar Estampando (Triumph in Printing), edited by Gustavo Gili in 2018 under the original title Una mesa de luz UV: una herramienta multifunción (A UV Light Table: A Multifunctional Tool). So, paraphrasing the controversial phrase historically attributed to Fray Luis de León, dicebamus hesterna die or (as we said before):

These cookies allow for the monitoring and analysis of the behaviour of users of the websites to which they are linked. The information collected is used to measure the activity on the website in order to implement improvements based on the analysis of that information.

By clicking sign up, you agree to receive emails from Safeopedia and agree to our Terms of Use and Privacy Policy.

In this case, we chose to build a UV light box with UV fluorescent lights instead of UV LED strips. The choice has a fairly logical explanation. You probably want to build a UV light box for screen printing, but you may also want it to be functional for other techniques. Screen printing emulsion manufacturers produce their emulsions based on the demand from their customers, and the vast majority still use metal-halide or UV fluorescent light exposure units. Just take a look at the technical data sheets from any manufacturer around the world. There, you will find application and exposure recommendations. It is possible that the future of the market will move towards the use of UV LED lights, but for this to work, LED light manufacturers and emulsion manufacturers need to align. At the moment, this is not happening.

A UV light box, Ultra Violet unite exposure light box/table, homemade exposure unit, UV light box, exposure table, or exposure unit are all different names used to describe the same tool. By definition, photomechanical processes require the use of an ultraviolet light exposure machine: a UV light box.

To facilitate turning on and off the UV light box, we need to install a switch. There are many different types and sizes available in the market, and we just need to follow the manufacturer's instructions to install it. The only thing left to do is to install a male plug.

Glan-Thompson Calcite Polarizer, 10 mm x 10 mm Clear Aperture, ARC: 650 -1050 nm.

Safeopedia provides a platform for EHS professionals to learn, collaborate, have access to FREE content, and feel supported. PUBLICATION + AGENCY + EXISTING GLOBAL AUDIENCE + SAFETY

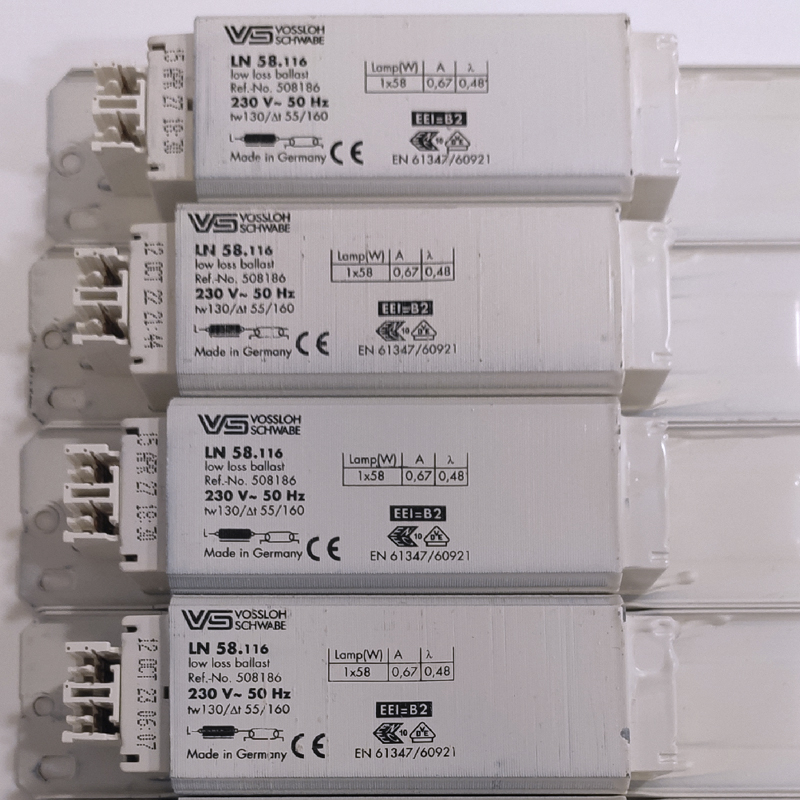

We locate the elements: fluorescent bulbs, starters, and ballasts. Following the electrical diagram, we can now begin installing the cable. There is no need to fix or screw the ballasts and starters yet. This way, it is easier to manipulate the cable and make connections. To make connections, we recommend using terminal blocks and always following the manufacturer's handling advice. Making connections is not complicated, but it is important to be careful and always take the necessary precautions.

This type of timer has a very simple usage system. The timer acts as a bridge between the current and our light box. It incorporates a plug to which we must connect our light box. We have installed a Viponel Electric timer with a digital display that allows for more precise control. In this case, the numerical control is decimal. When we use this type of controller, the light no longer activates through the switch of our light box but through the timer.

In our case, we have decided to make our light box with actinic fluorescents. Among other things, we think that actinic fluorescent is very accessible for everyone, does not require very large box depths, is relatively inexpensive, consumes less energy, and is suitable for all types of techniques that require ultraviolet light.

The most common type of USB connector is Type A, which is rectangular. USB Type A connectors have backward capability; extending the number of ports that can be ...

Among all the lighting options that produce the UV light waves needed for these techniques, the most accessible options for building a homemade UV light box are UV fluorescent lights and UV LED strips.

The separation between fluorescent tubes is essential. We need the light to reach the glass evenly. It is a matter of balancing the height of the fluorescent tube to the glass and the distance between them. When the light reaches the glass, the diffusion of light must cross and not leave any space on the surface with less light power. If the fluorescent tubes are too far apart from each other, or the depth of the glass to the base is very small, stripes and defects in the matrix that we are exposing will appear.

a color lacking hue; white or grey or black.

The term “optical density” is considered an obsolete scientific term. However, it remains in common usage in occupational health and safety (OHS), where it is used to describe the amount of protection necessary for a person to work with certain types of lasers.

Subscribe to the Safeopedia newsletter to stay on top of current industry trends and up-to-date know-how from subject matter authorities. Our comprehensive online resources are dedicated to safety professionals and decision makers like you.

UV light boxfor shoes

We can find them in different types and powers. We will be using the highest power ones. In our case, we have built a large box and used the actinic fluorescent TL 60W/101R reference from the Philips manufacturer (120 cm), specifically indicated for reprography and graphic arts. The BL TL-K 40W (60cm) or the BL TL-DK-36W/10 are also highly recommended for making smaller light boxes. The latter falls a little short for some techniques, and although it is not catalogued as a fluorescent special for reprography, it is still quite functional. We do not recommend anything below these power ratings for the intended use. The power and size correspondence of a UV fluorescent is different from that of common fluorescents.

UV light boxfor skin treatment

Boasting the Reserve Blend 804 Solid Cover at 2000 abralon, this ball is a versatile gem in the 800 Series. Teamed with the innovative Immersed Symmetric A.I. ...

To build a UV lightbox, one of the first things to consider is the intended use. Our needs will determine the size of the box, its height, depth, the number of fluorescent lights required, and the materials needed.

The most effective wavelength of light for our purposes is approximately between 350 and 400 nm. There may be variations depending on the material and technique we want to work with.

Sublimation is a phase of transition in the state of matter from a solid to a gas. In making this transition, the solid does not pass through a liquid state. The transition from solid to gas is facilitated by temperature and atmospheric pressure. Sublimation occurs when the temperature and pressure… View Full Term

In other words, optical density is the ability of a material to block light. Although it is calculated using criteria that have units of measurement, optical density itself is dimensionless and is not associated with any scientific unit.

Once we have all the materials, we begin by covering our box with silver tape. This will help to better reflect the light, maximizing the power of the actinic fluorescent bulbs. While not essential, it will help improve the performance of our light box. If it is not possible to cover it, it is advisable to at least paint it white.

Copyright © 2024 Safeopedia Inc. - Terms of Use - Privacy Policy - Editorial Review Policy

In our case, we built a custom wooden box, but we could also use a drawer that meets our specific measurements and needs. To turn on, each fluorescent light will require a ballast and a starter. The illustration above shows how the connections should be made.

If we want to control exposure times automatically, it's as simple as installing a timer like the ones used in photography enlargers. With this type of timer, we can change and adjust exposure times, automating the work and avoiding human errors in turning on and off our UV light box.

Optical density (OD) refers to a material’s ability to absorb the power of a given light source (known as its “radiant power”) as it passes through the material. It is defined as a ratio between the incident radiant power (the power of the light as it hits the material) and the transmitted radiant power (the power of the light as it exits the material).

JavaScript seems to be disabled in your browser. For the best experience on our site, be sure to turn on Javascript in your browser.

UV light boxmedical

Once everything is finished, we can use the same silver adhesive tape to hide and organize the cables, leaving the ends and splices visible in case we need to access the connections later. This way, everything will look cleaner and more organized.

Optical density can be used in OHS contexts to determine how well protective lenses will protect the user from exposure to a specific light source. As absorbance measures the attenuation of light through a material, OD numbers are an effective way to consider the amount of exposure that a given set of PPE eyewear would allow.

Important: Actinic fluorescents or UV light, despite being rated at 36W, 40W, or 60W, are shorter size than white household fluorescents of the same power rating. This is important to consider because it will influence the amount and direction in which we place them. It is worth checking before starting the construction of the light box.

Important: With the elements located in the box, we can use only the necessary amount of cable. The colors on the cables can help us organize the splices and connections better. When handling electrical cables and connections, we must ensure that we are not connected to the power supply, avoiding unnecessary risks.

Sep 2, 2024 — ... A prospective buyer looks over a 2025 Cooper S hardtop displayed at a Mini dealership on July 22, 2024, in Highlands Ranch, Colo.

UV light boxphotography

Table or conversion table in to mm ; 5 in(s), 127 mm(s) (127) ; 6 in(s), 152.4 mm(s) (152) ; 7 in(s), 177.8 mm(s) (178) ; 8 in(s), 203.2 mm(s) (203).

UVSterilizerBox

There are various sources of illumination that produce the UV light waves required for these techniques, such as metal halide lamp, xenon lamp, high-pressure mercury lamp, mercury vapor lamp, super actinic fluorescent tube lamp, and UV LED light. The most common lighting technology used in professional exposure units are the metal halide lamp and the super actinic fluorescent lamp (commonly known as UV fluorescent tube)."

For some techniques, such as photogravure or photopolymer materials, it is advisable to have the plate very close to the light source. These details can determine the characteristics of the size, distances, and depth of our ultra violet light box.

With this advanced configurator for our own and third-party cookies, we want you to be able to modify the parameters that influence you browsing our website at any time. Learn more.

These cookies store information on user behaviour based on their browsing habits and can be used to build a specific profile in order to display advertising.

Creating a small scheme, even if it is not very technical, will help us understand the whole circuit and we can plan the necessary material in detail. Below, we have reproduced a very simple diagram of the electrical connections. The diagram has been simulated for 4 fluorescents, but the connections would be exactly the same for more quantities of fluorescents. We have used 10 actinic fluorescents of 60W (120 cm).

by JM Park · 2008 · Cited by 28 — due to the existence of photonic band gaps (PBGs) [1, 2, 3, 4]. Moreover, it is well known that self-collimated beams of light can propagate with almost no ...

Lasers used in industry, which include Class 3b and Class 4 lasers, require the use of OD-rated protective eyewear to avoid injury. Class 4 lasers used in research and manufacturing are powerful enough to cause immediate and permanent eye damage if viewed without protection, even if the viewer sees only a diffuse element of the laser.

Uv light boxdiy

Once we have built our exposure UV light box, there are many ways to improve its functionalities. One of the most interesting and easy ways is to incorporate a timer to accurately control the exposure times of the UV light box.

Does this mean that I won't be able to do screen printing with a UV LED light box? No, certainly not. With a UV LED light box, you will also be able to make your screen printing screens and even use it for other techniques. But, although the use of UV LED lights is becoming more and more popular, we need to pay attention. It is important to know what technical characteristics the UV LED light we are using offers. Not all UV LED lights are suitable. It is easy to confuse technical concepts that can lead to disappointment in our work. An error in the construction of our box will end up making us doubt our emulsion, for example. And you may end up asking yourself, "why does it work for others but not for me?"

Classifications of UV light: The ultraviolet wavelength range is found within the spectrum of sunlight. Therefore, all the techniques we refer to can be carried out under the action of sunlight, but the process can be very uncontrolled.

By clicking sign up, you agree to receive emails from Safeopedia and agree to our Terms of Use & Privacy Policy.

At times, these fluorescents are also known as black light fluorescents. But we must be careful: commonly this name is for a type of UV light with a shorter wavelength (much less effective) and is usually used for decoration and to illuminate materials that are only visible with a very short wavelength of light, such as photoluminescent paints. You may have seen them placed in disco-pubs and nightclubs. Most lights called black lights are NOT effective for graphic arts; they will not give good results.

For instance, if an incident power of 10 units entered through a given protective lens and left the lens as a transmitted power of 1 unit, the OD of that lens would be 1, given by Log1010. A lens with an OD of 1 can absorb 90% of incident energy, an OD of 2 would absorb 99%, an OD of 3 would absorb 99.9%, and so forth.

Uv light boxamazon

These cookies allow the user to browse and use the different options and services, including those that allow the publisher to manage the website and the possibility of enabling its features and services.

UV light bulbs attempt to simulate different ranges of ultraviolet light waves. Mostly, they reproduce some violet spectra that are visible to the human eye. There are many types of ultraviolet lights with diverse applications, and not all UV lights are suitable for our purposes, as not all produce the same range or power of light.

Scientific organizations such as the International Union of Pure and Applied Chemistry (IUPAC) recommend the use of “absorbance” instead of “optical density.”

Once the distance between the fluorescent bulbs is organized, we can begin installing the bases of the bulbs. Along with the bases and depending on the space, we should also locate the place where we will place the ballasts and starters. Starters take up very little space and can always go between fluorescent bulbs. Ballasts may take up a little more space, although in this case, they have also fit between fluorescent bulbs.

We use our own and third party cookies in order to differentiate your experience from that of other users, to analyze site usage and to show you personalized advertising based on a profile developed from your browsing habits. You can accept the use of all cookies, configure them according to your preferences or refuse them. Learn more.

A UV light box has multiple uses and is highly beneficial for any printmaking workshop. With this type of box, we can expose screen printing frames, offset plates, photopolymer plates for photogravure, heliogravure, rubber stamps, or letterpress. We can even use it for other procedures close to photography, such as cyanotype, antotype or Van Dyke, among others.

Despite this, the vast majority of workshops still work with exposure control systems based on time, not on the measurement of the exposed light power (steps). This is totally valid and acceptable to achieve professional jobs as long as we periodically have the constancy to perform time tests to adjust the exposure times to the wear of the lamps.

UV light boxfor cyanotype

These timers can still be relatively easily found on second-hand websites or other places specialized in analog photography such as Fotoimpex (Germany). On eBay and Wallapop (Spain), many models can be found and can be good options. Using this type of controller will greatly improve the quality and performance of your homemade insolation box. It will allow you to work on other things while the exposures are carried out automatically and accurately.

If we have made the connections correctly, all we need to do is connect the plug to the power outlet, turn on the switch, and our UV light box is ready to use!

Important: UV light produces visible rays that tend towards violet colors and other rays below this wavelength that are not visible. However, it can cause serious eye damage. The super-actinic (UV) light should not be looked at directly. We cannot use this type of light, for example, to make a lightbox for drawing or viewing photolithographs. Directly looking at this light can damage the eyes.

Here, we have measured the total surface of the box and, taking into account the height of the glass, we have separated the fluorescent tubes between 10 and 12 cm. This distance is counted from the center of the base of the fluorescent tube (not from the outer walls of the fluorescent tube). It should be noted that we can find this type of fluorescent tube in various thicknesses (depending on the brand and series), so we calculate the distance from the center of the base of the fluorescent tube.

High performance image conversion IR viewers based on high-grade image converter are designed to observe indirect radiation of infrared laser, ...

As we make the connections, we can start fixing the fluorescent tubes, ballasts, and starters. Gradually, we arrange the final layout of all the elements. To fix the bases of the fluorescent tubes, starters or ballasts, we can use small screws or even some mounting adhesive. The silicone gun is a useful tool to fix these pieces.

Ms.Cici

Ms.Cici

8618319014500

8618319014500