Lab Industrial Digital Microscope Camera BNC Color ... - bnc mount lens

Magnification is one important parameter. Magnification is usually denoted by an X next to a numeric value. Objectives are available in a range of magnifications from 2X to 200X.

The interactive tutorial above allows the visitor to adjust the correction collar on a microscope objective. There are some applications that do not require objectives to be corrected for cover glass thickness. These include objectives designed for reflected light metallurgical specimens, tissue culture, integrated circuit inspection, and many other applications that require observation with no compensation for a cover glass.

At Shanghai Optics, we design and manufacture custom objectives and imaging systems to support our customers’ needs in many industries, including medical, biomedical, machine version, scientific research, and metrology, etc. Taking the client’s budget and precision requirements into consideration, our experienced engineering team ensure that each design can be manufactured at a reasonable cost and the optical performance is being met based on fabrication, assembly, and alignment tolerance analysis.

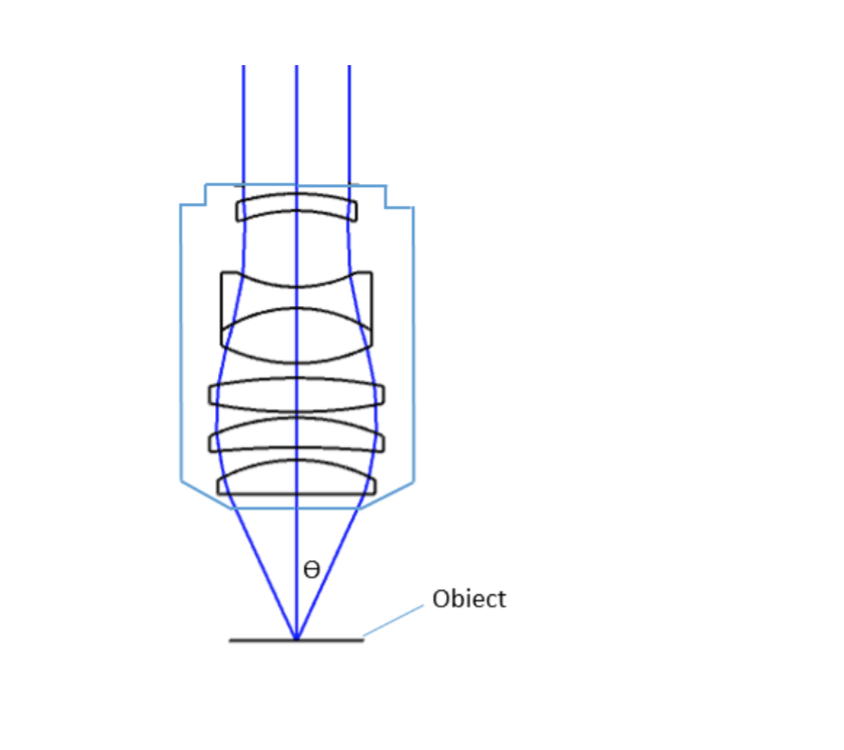

where θ is the maximum 1/2 acceptance ray angle of the objective, and n is the index of refraction of the immersion medium. Figure 2 shows the ray angle θ of an infinity-corrected objective.

Most objectives are designed to image specimens with air as the medium between the objective and the cover glass. However, for achieving higher working numerical apertures, some objectives are designed to image the specimen through another medium such as special oil with a refractive index of 1.51.

Parts of a microscope objective lenslabeled

The optical aberration correction determines the optical performance of an objective lens and plays a central role in the image quality and measurement accuracy of imaging or microscopy systems. According to the degrees of the aberration corrections, objective lenses are generally classified into five basic types: Achromat, Plan Achromat, Plan Fluorite (Plan Semi-Apochromat), Plan Apochromat, and Super Apochromat.

Parts of a microscope objective lenspdf

Since indirect backlight illumination is generally more effective than direct illumination, most microscopes do not include an internal light source. Instead, they rely on daylight or on background illumination such as a lightbulb. In brightfield illumination, also known as Koehler illumination, two convex lenses saturate the specimen with external light admitted from behind. These two lenses, the collector lens and condenser lens, work together to provide a bright, even, and constant light throughout the system: on the image plane as well as on the object plane. This system of illumination is used in many compound microscopes, including student microscopes and those found in many research labs.

Some objectives specifically designed for transmitted light fluorescence and darkfield imaging are equipped with an internal iris diaphragm that allows for adjustment of the effective numerical aperture. Abbreviations inscribed on the barrel for these objectives include I, Iris, and W/Iris. The 60x apochromat objective illustrated above has a numerical aperture of 1.4, one of the highest attainable in modern microscopes using immersion oil as an imaging medium.

Microscope partsand functions

A simple magnifier (magnifying glass), works when the object to be examined is situated within focal length of the magnifier lens, enabling larger virtual image is produced. This type of magnifier is very limited in both resolution and magnification. A compound microscope, on the other hand, uses a relay lens system instead of the single lens, and since each lens component can contribute magnifying power, the result is greatly increased capability.

Room 609, 6/F, Global Gateway Tower, No.63 Wing Hong Street, Cheung Sha Wan, Kowloon, Hong Kong +852-54993705 info@shanghai-optics.com

Other features found on specialized objectives are variable working distance (LWD) and numerical aperture settings that are adjustable by turning the correction collar on the body of the objective as illustrated in Figure 2. The plan fluor objective on the left has a variable immersion medium/numerical aperture setting that allows the objective to be used with multiple different immersion media, including oil, water, and glycerin. The plan apo objective on the right has an adjustable working distance control (termed a "correction collar") that allows the objective to image specimens through glass coverslips of variable thickness. This is especially important in dry objectives with high numerical aperture that are particularly susceptible to spherical and other aberrations that can impair resolution and contrast when used with a cover glass whose thickness differs from the specified design value.

Microscope manufacturers offer a wide range of objective designs to meet the performance needs of specialized imaging methods, to compensate for cover glass thickness variations, and to increase the effective working distance of the objective. Often, the function of a particular objective is not obvious simply by looking at the construction of the objective. Finite microscope objectives are designed to project a diffraction-limited image at a fixed plane (the intermediate image plane), which is dictated by the microscope tube length and located at a pre-specified distance from the rear focal plane of the objective. Microscope objectives are usually designed to be used with a specific group of oculars and/or tube lenses strategically placed to assist in the removal of residual optical errors. As an example, older Nikon and Olympus compensating eyepieces were used with high numerical aperture fluorite and apochromatic objectives to eliminate lateral chromatic aberration and improve flatness of field. Newer microscopes (from Nikon and Olympus) have objectives that are fully corrected and do not require additional corrections from the eyepieces or tube lenses.

There is a wealth of information inscribed on the barrel of each objective, which can be broken down into several categories. These include the linear magnification, numerical aperture value, optical corrections, microscope body tube length, the type of medium the objective is designed for, and other critical factors in deciding if the objective will perform as needed. A more detailed discussion of these properties is provided below and in links to other pages dealing with specific issues.

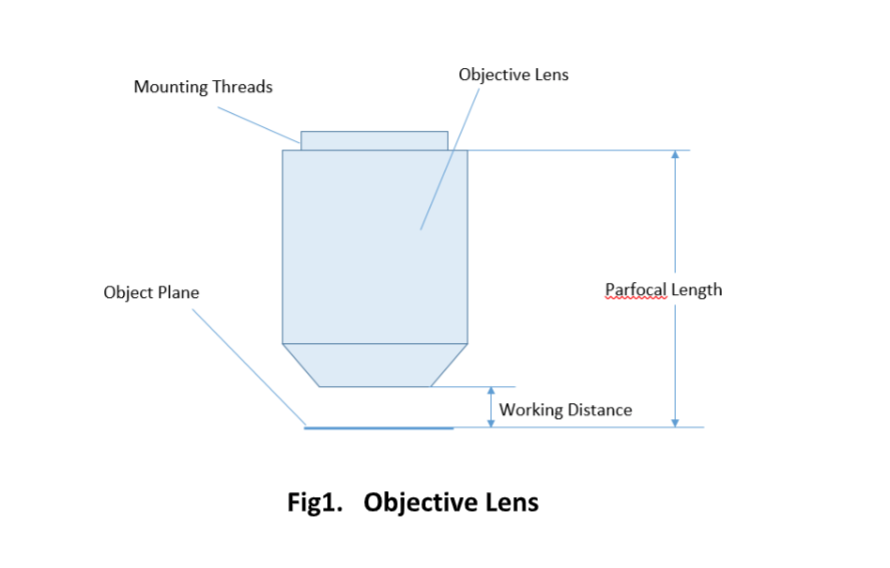

For keeping the objective at the proper position, there are mounting threads on almost all objectives. Commonly used mounting threads include RMS, M25 x 0.75, M26X 0.706, M32 x 0.75.

Parts of a microscope objective lensand functions

Parfocal Distance - This is another specification that can often vary by manufacturer. Most companies produce objectives that have a 45 millimeter parfocal distance, which is designed to minimize refocusing when magnifications are changed.

Michael W. Davidson - National High Magnetic Field Laboratory, 1800 East Paul Dirac Dr., The Florida State University, Tallahassee, Florida, 32310.

A microscope is a special optical device designed to magnify the image of an object. Depending on the type of microscope, it may project the image either onto a human eye or onto a recording or video device. As an example, consider the photographs of cells that can be found in a science textbook. These photographs have all been taken by a specialized microscope, and may be called micrographs.

Field of View is the area of the object that can be imaged by a microscopy system. The size of the field of view is determined by the objective magnification or focal length of the tube lens for an infinite-corrected objective. In a camera system, the field of view of the objective is related to the sensor size.

The objective depicted on the left in Figure 3 has a parfocal distance of 45mm and is labeled with an immersion medium color code in addition to the magnification color code. Parfocal distance is measured from the nosepiece objective mounting hole to the point of focus on the specimen as illustrated in the figure. The objective on the right in Figure 3 has a longer parfocal distance of 60 millimeters, which is the result of its being produced to the Nikon CFI60 200/60/25 Specification, again deviating from the practice of other manufacturers such as Olympus and Zeiss, who still produce objectives with a 45mm parfocal distance. Most manufacturers also make their objective nosepieces parcentric, meaning that when a specimen is centered in the field of view for one objective, it remains centered when the nosepiece is rotated to bring another objective into use.

Parts of a microscope objective lensand its function

From the discussion above it is apparent that objectives are the single most important element of a microscope. It is for this reason that so much effort is invested in making sure that they are well-labeled and suited for the task at hand.

Multilayer Coatings - Quality microscope objectives are protected and enhanced by unique high-transmission anti-reflective multilayer coatings that are applied to the lens air-interface surfaces to reduce flare and ghosts and ensure high-contrast images. These specialized coatings are also used on the phase plates in phase contrast objectives to maximize contrast.

To attain higher working numerical apertures, many objectives are designed to image the specimen through another medium that reduces refractive index differences between glass and the imaging medium. High-resolution plan apochromat objectives can achieve numerical apertures up to 1.40 when the immersion medium is special oil with a refractive index of 1.51. Other common immersion media are water and glycerin. Objectives designed for special immersion media usually have a color-coded ring inscribed around the circumference of the objective barrel as listed in Table 3 and described below. Common abbreviations are: Oil, Oel (oil immersion), HI (homogeneous immersion), W, Water, Wasser (water immersion), and Gly (glycerol immersion).

A microscope objective is an important component of a microscopy or imaging system for a range of science research, biological, industrial, and general lab applications.. An objective lens determines the basic performance of an optical microscope or imaging systems and is designed for various performance needs and applications. It is located closest to the object and is an important component in imaging an object onto the human eye or an image sensor.

Objective lens microscopefunction

Identification of the properties of individual objectives is usually very easy because important parameters are often inscribed on the outer housing (or barrel) of the objective itself as illustrated in Figure 1. This figure depicts a typical 60x plan apochromat objective, including common engravings that contain all of the specifications necessary to determine what the objective is designed for and the conditions necessary for proper use.

The ocular lens, or eyepiece, is also an optical assembly rather than a single lens, but it is typically more simple than the objective. Often it is composed of two lenses: a field lens and an eye lens. The design of the ocular lens determines the field of view of the microscope, as well as contributing to the total magnification of the system.

Investigate how internal lens elements in a high numerical aperture dry objective may be adjusted to correct for fluctuations in coverslip thickness.

Microscope partsdiagram

Objective lenses can be classified based on the objective construction, field of use, microscopy method, performance (optical aberration corrections), and magnification. Many microscope objective manufacturers offer a wide range of objective designs, which provide various degrees of optical aberration corrections for supporting different needs. Mirrors or reflective elements are used in objective lenses for the applications that requires chromatic aberration over board spectral ranges. Most traditional microscopy systems use refractive objectives such as achromatic objectives (the cheaper objectives) for laboratory microscope applications and plan apochromats (expensive objectives) for biological and science research microscope applications.

Since the objective is closest to the specimen being examined, it will relay a real image to the ocular lens. While doing so, it contributes a base magnification of anywhere from 4x (for a scanning objective lens, typically used to provide an overview of a sample) to 100x (for oil immersion objectives).

Important specifications are marked on the barrel of the objective, so students or researchers can easily identify the properties of an objective and determine the optical performance and working conditions for proper use. Figure 1 shows a diagram of an objective lens. A detailed discussion of the objection specifications is provided below.

The parfocal length is the distance between the objective mounting plane and the specimen / object. This is another specification that can often vary by manufacturer.

World-class Nikon objectives, including renowned CFI60 infinity optics, deliver brilliant images of breathtaking sharpness and clarity, from ultra-low to the highest magnifications.

Although not common today, other types of adjustable objectives have been manufactured in the past. Perhaps the most interesting example is the compound "zoom" objective that has a variable magnification, usually from about 4x to 15x. These objectives have a short barrel with poorly designed optics that have significant aberration problems and are not very practical for photomicrography or serious quantitative microscopy.

Alpha Industrial Park, Tu Thon Village, Ly Thuong Kiet Commune, Yen My District, Hung Yen Province Vietnam 17721 +84 221-730-8668 rfqvn@shanghai-optics.com

The ocular lens, located at the top of a standard microscope and close to the sensor (receiving eye) receives the real image from the ocular lens, magnifies the image received and relays a virtual image to the sensor. While most eyepieces magnify 10x, there are some which provide no magnification and others which magnify as much as 30x. The magnification power of the microscope can be calculated by multiplying the magnification power of the eyepiece, or ocular lens, by the magnification power of the objective lens. For example, an objective lens with a magnification of 10x used in combination with a standard eyepiece (magnification 10x) would project an image of the specimen magnified 100x.

Parts of a microscope objective lensand their functions

Special Features - Objectives often have additional special features that are specific to a particular manufacturer and type of objective. The plan apochromat objective illustrated in Figure 1 has a spring-loaded front lens to prevent damage when the objective is accidentally driven onto the surface of a microscope slide.

Many objectives are designed to be used with a cover glass. Using an incorrect coverslip thickness can greatly reduce the optical performance of a microscopy system.

Objectives are complex multi-element lenses. For any given application, careful consideration of the optical parameters and specifications is necessary. In many cases, custom-designed objective assemblies provide the best-fit solution for meeting all the requirements of a specialized application. Custom parameters may include antireflection coatings, chromatic focus shift, working distance, image quality (MTF and spot size), lens mount, glass window thickness, and field of view, among others.

Each microscope objective is itself a complex assembly of lenses, and besides contributing to the magnification, it is the objective lens which determines the resolution power of the microscope. An objective lens can also provide optical aberration corrections. A reflective objective, for instance, includes two mirrors within the assembly. These mirrors can focus laser light as well as provide chromatic corrections.

While the simplest of microscopes is simply a magnifying glass with a single lens, compound microscopes used today are highly complex devices with a carefully designed series of lenses, filters, polarizers, beamsplitters, sensors, and perhaps even illumination sources. The exact combination of optical components used will depend on the application of the microscope; the wavelength of light with which it is intended to be used, and the resolution and magnification required in the final image.

Microscope Objectives or Objective lenses are in many ways the heart of the microscope, and are typically mounted on a rotating nosepiece or turret to enable easy selection. Many microscopes will be equipped with a scanning objective (4x), a low power objective (10x), a high power objective (40x), and perhaps even an oil immersion objective lens.

Most manufacturers have now transitioned to infinity-corrected objectives that project emerging rays in parallel bundles from every azimuth to infinity. These objectives require a tube lens in the light path to bring the image into focus at the intermediate image plane. Infinity-corrected and finite-tube length microscope objectives are not interchangeable and must be matched not only to a specific type of microscope, but often to a particular microscope from a single manufacturer. For example, Nikon infinity-corrected objectives arenot interchangeable with Olympus infinity-corrected objectives, not only because of tube length differences, but also because the mounting threads are not the same pitch or diameter. Objectives usually contain an inscription denoting the tube focal length correction as will be discussed.

Glass Design - The quality of glass formulations has been paramount in the evolution of modern microscope optics. Numerous designs have been implemented by a variety of manufacturers, but we will limit this discussion to a specialized low dispersion glass formulation. Extra Low Dispersion (ED) glass was introduced as a major advancement in lens design with optical qualities similar to the mineral fluorite but without its mechanical and optical demerits. This glass has allowed manufacturers to create higher quality objectives with lens elements that have superior corrections and performance.

Two major lens components—the objective lens and the ocular lens, or eyepiece—work together to project the image of the specimen onto a sensor. This may be the human eye or a digital sensor, depending on the microscope setup.

Ms.Cici

Ms.Cici

8618319014500

8618319014500