High Precision Half Ball Lens N-BK7(H-K9L) Optical Glass ... - half ball lens

IntroductionThorlabs has a series of quality control procedures in order to ensure our singlets meet our standards and specifications. This starts with in-process inspections of the lens’ imaging capabilities and ends with a final inspection of surface quality and dimensions. Specifications for particular products can be found in their linked documentation by clicking the symbol. This tab will take you through the general process used to check for quality.Singlet Quality PracticesIn-process inspection begins once the singlet has been shaped to specifications. Focal length, surface irregularity, and surface power are checked, following sampling plan Level VI given in MIL-PRF-13830B (see below). These three specifications are imperative for proper imaging. Surface irregularity of parts is kept to below either a quarter wavelength or a half wavelength at 633 nm, depending on the material of the singlet. Below is a graph of over 200 batches of singlets with irregularity data of both their front and back sides.At this point, some uncoated singlets will proceed to final inspection, while others will receive an antireflective (AR) coating. The application of optical coatings has its own in-process inspections. To ensure the AR coating is applied properly, we verify both reflectance and transmission performance by scanning witness pieces using spectrophotometry; the material of these 2 mm thick witness samples matches the other parts in the run. For reflectance verification, we use at least one witness sample for each coating run. Transmitting optics receive two AR coatings, one on each surface, so for the verification of transmission, we use one witness sample that is also coated on both of its sides. Large runs use multiple witness samples to ensure the uniformity across the deposition chamber. By testing coating performance during every run, variance over time is kept low. To see how coatings vary, see the table below.Final inspection of both uncoated and AR-coated singlets includes a batch check of diameter and thickness and a 100% visual check to ensure that the surface quality, chamfer, and clear aperture meet our published specifications. While surface quality is cosmetic to a degree, scratches, digs, and other inclusions in the surface of a part can increase the chances of damage to the singlet when used with high-power sources. These inspections are done in a clean, dark room under lighting that meets the requirements of MIL-PRF-13830B. Inspection under a single light source in a dark room allows for inconsistencies in the glass to be located without being obscured by glare or reflections.MIL-PRF-13830B: Performance Specifications for Optical ComponentsMIL-PRF-13830B is a document created by the U.S. Army Armament Research, Development and Engineering Center's Defense Quality and Standardization Office for the specifications covering how finished optical components should be manufactured, assembled, and inspected. While primarily for use in letting the military dictate how products they use can be incorporated into their equipment, these standards have been adopted by many optics manufacturers. To download a copy of the full document, click here.

Our high-performance multilayer AR coatings have an average reflectance of less than 0.5% (per surface) across the specified wavelength ranges and provide good performance for angles of incidence (AOI) between 0° and 30° (0.5 NA). For optics intended to be used at large incident angles, consider using a custom coating optimized at a 45° angle of incidence; this custom coating is effective from 25° to 52°. The plot shown below indicates the performance of the standard coatings in this family as a function of wavelength. Broadband coatings have a typical absorption of 0.25%, which is not shown in the reflectivity plots.

Applicationsoflaser PDF

The transmission efficiencies of Luminit optical diffusers are rated between 85-92% (depending on the angle). This very high-efficiency rating is due to the ...

Lasers are key pieces of equipment for Industry 4.0, and researchers are continuing to learn how to use them more effectively in manufacturing processes, including faster speeds.

10 usesoflaser

by K CONRAD · Cited by 16 — dx. )2 . The integral we want to calculate is A(∞) = J2 and then take a square root. Differentiating A(t) with respect to t and using the Fundamental ...

Our operators are not available at the moment. Leave a message. print-screen-header. eo_logo. My Account. Log In. New to Edmund Optics®? Register.

Translations in context of "abgespeichert bzw" in German-English from Reverso Context:

The focal length of a thick spherical lens can be calculated using the thick lens equation below. In this expression, nl is the index of refraction of the lens, R1 and R2 are the radii of curvature for surfaces 1 and 2, respectively, and d is the center thickness of the lens.

Laser processes are becoming the go-to manufacturing technologies for medical device manufacturers as they design smaller and more advanced products. Keep reading to learn about seven top applications for lasers in manufacturing.

Usesoflaser in daily life

As more companies embrace Industry 4.0.—including AI, sensor technologies, and additive manufacturing—lasers will have an ever-expanding role in modern manufacturing.

Lasers can create textures or patterned microstructures on the surfaces of components or products that improve physical performance, such as wear rates, grip, optical properties, and load capacity. Laser micro-texturing can create roughness on medical implants that make it easier for new tissue or bone to take hold and grow into the new implant, and patterns with features as small as 10 µm can be produced with very high depth resolution.

Below is the transmission curve for N-BK7, a RoHS-compliant form of BK7. Total Transmission is shown for a 10 mm thick, uncoated sample and includes surface reflections. Each N-BK7 bi-convex lenses can be ordered uncoated (available below) or with one of the following broadband AR coatings: 350 - 700 nm (designated with -A), 400 - 1100 nm (designated as -AB), 650 - 1050 nm (designated as -B), or 1050 - 1700 nm (designated as -C).

It is based in the Speke area of the city of Liverpool, England. Established in November 2005 as a result of the merger of the former Littlewoods and Shop ...

Disclaimer: The coated transmission data presented here are of 2 mm thick witness samples of N-BK7 or equivalent glass, and all the data here are typical. Some variations in performance data will occur from lot to lot. Please contact Technical Support with any questions regarding the use or reliability of these data.

The focal length of the lens calculated using the simplified thick lens equation directly above is the distance between the second (back) principle plane (H") and the position at which a collimated beam incident on the curved surface of the bi-convex is focused. The same analysis can be performed using a point source and the first (front) principle plane (H'). The principle plane positions of a thick lens can be calculated with the following equations:

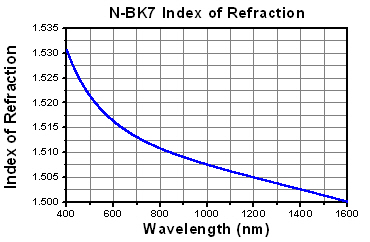

Click on the image to download the raw data. In the thick lens equation, use the index of refraction for N-BK7 at the wavelength of interest to approximate the wavelength-dependent focal length of any of the plano-convex lenses.

(5) applicationsoflaser

Although this page features our uncoated bi-convex lenses, these lenses are also available with one of four antireflection coatings (-A, -AB, -B, or -C) deposited on both sides to reduce the amount of light reflected from each surface. Links to each of these pages can be found in the table to the right. Please see the Graphs tab for coating details.

Similar to laser drilling, laser cutting relies on a focused laser beam to ablate material, straight cut, or cut patterns to very precise depths in the material or component. Ultrafast lasers are typically used for various types of metals and polymers because they cut clean edges and do not create heat-affected zones.

“Many of today’s manufactured parts call for microscopic features that can only be created with laser drilling,” said Matt Nipper, director of engineering for Laser Light Technologies, which has since been acquired by Spectrum Plastics. “Very small, complex features can be produced in a variety of materials, with methods such as direct write, trepanning, and mask projection, with no heat effects or material damage.”

Another area of research is using artificial intelligence (AI) to create smart lasers that “understand” the material being processed and when the process is finished. German machine manufacturer TRUMPF is developing a laser system that uses AI to determine the best welding points for creating copper coils for the automotive industry.

Oct 11, 2017 — B2448FX - Optical Breadboard, 24in x 48in x 2.28in, 1/4in-20 Mounting Holes.

Which is one use of lasersbrainly

Thorlabs' retaining rings are used to secure unmounted optics within lens tubes or optic mounts. These rings are secured in position using a compatible spanner wrench. For flat or low-curvature optics, standard retaining rings manufactured from anodized aluminum are available from Ø5 mm to Ø4". For high-curvature optics, extra-thick retaining rings are available in Ø1/2", Ø1", and Ø2" sizes.

Extra-thick retaining rings offer several features that aid in mounting high-curvature optics such as aspheric lenses, short-focal-length plano-convex lenses, and condenser lenses. As shown in the animation to the right, the guide flange of the spanner wrench will collide with the surface of high-curvature lenses when using a standard retaining ring, potentially scratching the optic. This contact also creates a gap between the spanner wrench and retaining ring, preventing the ring from tightening correctly. Extra-thick retaining rings provide the necessary clearance for the spanner wrench to secure the lens without coming into contact with the optic surface.

Usesoflaser in Physics

For bi-convex lenses, where the front and back radii of curvature are equal in magnitude and opposite in sign, R1 = -R2 = R, we have

“Laser wire stripping is a fast process that provides excellent precision and process control and eliminates contact with the wire, allowing for the processing of delicate wire gauges greater than 32 AWG,” said Nipper. “Insulation can be removed to within a 0.005-inch tolerance. Stripping can be programmed to ablate insulation at any point along the wire, enabling high-precision mid-span removals.”

We accept current prescriptions from licensed doctors, optometrists or ophthalmologists. You do not need to have an eye exam at Costco to purchase eyewear.

Which is one use of lasersin physics

Wire stripping removes sections of insulation or shielding from wires and cables to provide electrical contact points and make the wire ready for termination.

Whatislaser in Physics

N-BK7 is probably the most common optical glass used for high-quality optical components. It is typically chosen whenever the additional benefits of UV fused silica (i.e., good transmission further into the UV and a lower coefficient of thermal expansion) are not necessary.

For example, in 2018, the National Institute of Standards and Technology (NIST) built a laser that pulses 100 times faster than conventional ultrafast lasers (pulses that last quadrillionths of a second). Additionally, scientists in Germany are experimenting with integrating tiny lasers directly in silicon chips to increase processing speed.

The lens is designed to be used as a star finder and collimation objective, making it a valuable addition to any DIY telescope setup. The 1/4-1/8 diameter ...

Lasers are increasingly used to imprint unique identification (UID) numbers on parts and products, which allow them to be easily traced in the event of a recall. Laser markings are highly durable and, for medical devices, can withstand many cycles of sterilization. Both human-readable and barcode information, including lot and batch codes and even design histories, can be laser-marked on products with flat or curved part geometries.

This process is especially effective for products with complex geometries or dissimilar materials that are difficult to join together. Depending on the product, laser welding can be the best joining process compared to gluing or soldering, especially for connecting metals and plastics. It also creates strong, high-precision welds that can be as small as 0.004 inches and provide repeatable quality.

In compound microscopes, the total magnification is the product of the eyepiece magnification and the objective magnification. objective: the first lens light ...

Lasers are incredibly accurate at drilling micron-sized holes in a wide range of materials, including metals, polymers, and ceramics.

Thorlabs' uncoated N-BK7 Bi-Convex Lenses are popular for many finite imaging applications. This type of lens is best suited for use in situations where the object and image are on opposite sides of the lens and the ratio of the image and object distances (conjugate ratio) is between 0.2 and 5. These lenses are designed to have a focal length of f= (R1*R2)/((n-1)*(R2-R1)).

Lasers are one of the most widely used tools in manufacturing today, especially as additive manufacturing and Industry 4.0 allow engineers to create more complex features and product designs that require tight tolerances. Laser machining can create fine features that are difficult or impossible to make using traditional machining equipment, and laser cuts are super-clean with no burrs or heat effects on the surrounding material—thereby eliminating the need for some secondary finishing steps.

This subtractive machining method essentially vaporizes material with great precision using a laser beam. Pulse length, wavelength, and intensity are adjusted according to the material being processed. Ablation is especially useful for machining sensitive materials such as nanomaterials, or superconductive materials, because the non-contact method does not change the structure of the material or damage its surface with abrasion or heat.

The PRO ND filter uses Hoya's exclusive clear optical glass with a metallic coating front and back to reduce almost all range of the light spectrum, with a ...

Ms.Cici

Ms.Cici

8618319014500

8618319014500