Embroidery and Eyesight – Magnifier Lights are Magnificent! - i need a magnifying glass

CNCmachinesafetyglassreplacement

The area acts as a "magnifier" for global warming, Zheng Guoguang, head of China Meteorological Administration, said at a meeting in Lhasa last spring.

Choosing the right glass for milling is a multifaceted decision that requires a thorough understanding of both the material's properties and the project's requirements. By giving due consideration to the factors mentioned above, one can ensure not only the success of the milling process but also the durability and beauty of the finished product.

The area acts as a "magnifier" for global warming, Zheng Guoguang, head of China Meteorological Administration, said at a meeting in Lhasa last spring.

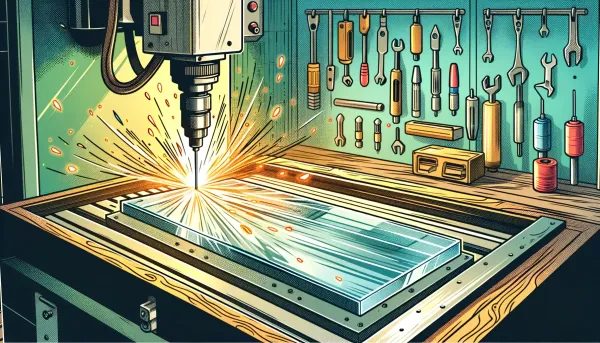

The tools used in glass milling are a blend of modern technology and time-tested techniques. Each tool plays a crucial role in ensuring that the milling process is efficient, precise, and safe. Investing in high-quality tools and understanding their proper usage is paramount for anyone venturing into the intricate world of glass milling.

Setting up your machine for glass milling is a meticulous process that requires attention to detail. Each step, from calibration to safety measures, plays a crucial role in ensuring a successful milling operation. By investing time in proper setup, you not only ensure the longevity of your machine and tools but also guarantee the best possible results in your glass milling projects.

Regular inspection of milling tools ensures they are free from damage and adequately sharp, as dull or damaged tools can cause chipping or overheating. The consistent flow of coolant is vital to prevent the glass from overheating and cracking, but pooling should be avoided to prevent slippage. Proper lifting techniques and the use of edge protectors during storage can prevent accidental breakages. Lastly, ensuring that all operators are well-trained in both machine operation and safety protocols, coupled with prominently displayed safety signage, reinforces the importance of safety precautions and practices in the milling environment.

Safety during glass milling is of utmost importance due to the delicate nature of glass and the potential hazards of the milling process. Personal Protective Equipment (PPE) is essential: safety glasses shield the eyes from flying glass particles, cut-resistant gloves protect hands from sharp edges, and dust masks prevent inhalation of harmful glass dust. Ensuring the CNC machine's emergency stop is functional and within reach allows for immediate shutdown during anomalies, while safety shields or doors, if present, should always be closed to guard against flying debris. Properly securing the glass to prevent movement during milling is crucial, but care should be taken to avoid over-tightening, which can introduce stress and lead to cracks.

The decision to mill glass goes beyond its sheer beauty. It's about pushing the boundaries of what's possible, innovating for the future, and creating pieces that hold both functional and symbolic value. Whether for artistic expression, technological advancement, or economic benefit, milling glass stands as a testament to human ingenuity and the endless possibilities that arise when we challenge the status quo.

The tools used in the milling of glass are pivotal in determining the quality, precision, and safety of the final product.

The area acts as a "magnifier" for global warming, Zheng Guoguang, head of China Meteorological Administration, said at a meeting in Lhasa last spring.

Setting up your machine correctly is a critical step in the glass milling process. Proper setup ensures precision, safety, and optimal results.

The area acts as a "magnifier" for global warming, Zheng Guoguang, head of China Meteorological Administration, said at a meeting in Lhasa last spring.

In embracing the challenges and intricacies of glass milling, we are reminded of the importance of patience, precision, and passion. As we continue to push the boundaries of what can be achieved, it's essential to approach each project with an open mind and a willingness to learn. The journey of glass milling, with its highs and lows, ultimately leads to creations that are as breathtaking as they are unique, showcasing the true potential of human ingenuity and technological advancement.

Once the milling process is complete, there are several post-milling practices and tips that can enhance the final product's quality, safety, and longevity.

The art of milling glass is a testament to the incredible advancements in manufacturing and the boundless creativity of artisans. By merging the precision of CNC machinery with the delicate nature of glass, we open up a world of possibilities, allowing for intricate designs and impeccable craftsmanship. This union of technology and artistry not only challenges our conventional understanding of what's possible but also paves the way for innovations that were once deemed unattainable.

The area acts as a "magnifier" for global warming, Zheng Guoguang, head of China Meteorological Administration, said at a meeting in Lhasa last spring.

Windows: The Windows built-in magnifier tool was designed more for aiding those with vision problems than aiding those giving presentations.

As we venture into the intricate dance of CNC machines and glass sheets, we uncover a realm where precision meets artistry. Here, patience is the key to unlocking breathtaking designs. Join us as we delve into the mesmerizing world of glass milling, exploring its nuances, challenges, and the sheer magic it can produce.

MilkGlass

Milling, a well-established technique in the world of manufacturing, has traditionally been associated with metals, woods, and plastics. But what happens when this age-old technique meets the delicate and ethereal world of glass? Glass, a material synonymous with fragility and elegance, presents a unique set of challenges and rewards for those daring enough to shape it using milling.

Post-milling practices are as crucial as the milling process itself. They ensure that the final product is not only aesthetically pleasing but also safe and durable. By dedicating time and attention to these post-milling steps, you can elevate the quality of your work and achieve a higher level of craftsmanship in glass milling.

The area acts as a "magnifier" for global warming, Zheng Guoguang, head of China Meteorological Administration, said at a meeting in Lhasa last spring.

Glass has been used in art, architecture, and everyday items for centuries. Its unique properties make it a sought-after material for various projects. Milling glass allows for precision cuts, intricate designs, and a polished finish that's hard to achieve with other methods.

The area acts as a "magnifier" for global warming, Zheng Guoguang, head of China Meteorological Administration, said at a meeting in Lhasa last spring.

The glass milling process is a journey from conceptual design to a tangible piece of art or utility. Each step requires careful consideration and expertise. While the process can be time-consuming and demands attention to detail, the end result—a beautifully milled piece of glass—is often well worth the effort.

Not all glass is created equal. For milling, it's crucial to select a type that can withstand the process without shattering. Tempered or laminated glass is often recommended due to its strength and durability.

Ms.Cici

Ms.Cici

8618319014500

8618319014500