Diffraction Gratings - Optometrics - optical grating

RMS (Too Mean Square) is a commonly mistaken for Ra (Roughness Average). Roughness average is a specification which controls the average extremes of the surface irregularities that result from the manufacturing tool used to cut the metal. These are the mico-scores on the surface of the metal.

Please realize these items are not actually the RMS I suggest, this is simply a general touch and feel test. They would test much differently. But... this gives you a reasonable and useful set of examples.As you noticed there is a tendency to use 4, 8, 16, 32, 64, 125, 250, and 500 as common numbers to call out on a product.-randy-

Apr 20, 2023 — Similar questions · Dual 12MP camera system: Main and Ultra Wide cameras · Main: ƒ/1.6 aperture · Ultra Wide: ƒ/2.4 aperture and 120° field of ...

2024621 — A microscope objective lens produces a real, magnified image of an object placed within the field of view.

Deformable mirrorsfor sale

Shop high-quality magnifiers, loupes, and magnifying glasses at Magnifier.com. Affordable prices, expert-rated lenses, and USA-made options.

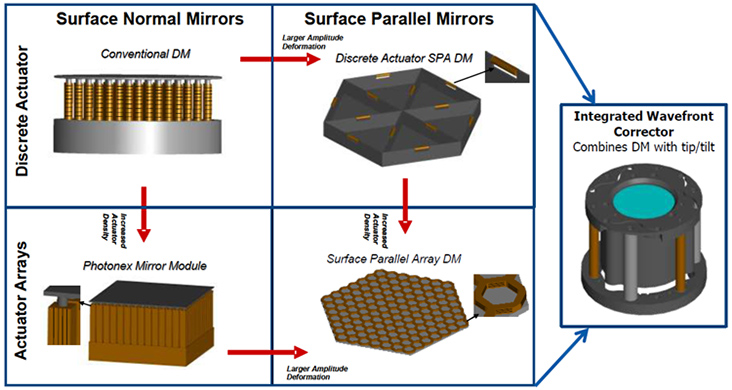

AOA Xinetics standard deformable mirror designs utilize a modular assembly approach. Its distinguishing feature is the single optical assembly consisting of base, actuators, and facesheet potted inside a metal bezel. The RTV potting prevents thermal distortions of the optical components by absorbing any differential expansion between the metal bezel and optical assembly. A single board accepts the actuator wires and relays the signals to individual connectors. These connectors provide the interface to the driver electronics.

The face of a plastic spoon is around 16 to 8.I haven't spotted a good example of a 500 RMS, But... generally a fairly well done torch cut is about a 500 RMS. Please realize these items are not actually the RMS I suggest, this is simply a general touch and feel test. They would test much differently. But... this gives you a reasonable and useful set of examples.As you noticed there is a tendency to use 4, 8, 16, 32, 64, 125, 250, and 500 as common numbers to call out on a product.-randy-

We are having a 1/2'' thick aluminum plate sent out for a vertical brush finish applied to it. They want to know what RMS are we looking for. Nobody here knows what RMS is, let alone what to tell them. Can ANYBODY help me?

MEMSdeformablemirror

Cylindrical Cavities. Cylindrical cavities feature a tried-and-true geometry for spectroscopy, offering locked laser linewidths at the 10 Hz level. They are the ...

Surface Parallel Array (SPA) holds great promise for the next generation of Deformable Mirrors (DMs) as well as active control of large scale optics. Actuators integrated within the mirror base in a surface parallel orientation provide low amplitude mirror shape control compatible with thermal induced distortions. SPA technology allows much greater stroke range and is much simpler and lighter than traditional SNA DMs. A nominal total stroke of 50 microns is achievable without sacrificing active flattening precision (8 nm rms has been demonstrated). A new level of optical figure control becomes possible by integrating an SPA into a large, lightweight optic. Because no reaction structure is required, SPA technology does not result in a significant weight increase but it does result in an increase in the effective stiffness of the optic via active control.

SNA DMs feature a continuous facesheet of ULE or single crystal silicon for directed energy applications. To minimize thermal distortions, the acutuators are athermally bonded to the rigid reaction structure, which is fabricated from the same material as facesheet. Apertures up to 30 cm are available. Fast actuator rise time of 100μs (99% settled) enables > 5 kHz small signal bandwidth.

Bayonet? K-mount? What is what? Forum: Pentax SLR Lens Discussion. Nimrad 07-09-2010 04:55 AM. I'm surfing eBay for _cheap_ lenses and I just don't ...

May 10, 2024 — On a more macro level, hyperspectral imaging can be used to help prevent or reduce the impacts of climate change, by detecting the flooding ...

My cell phone has an RMS of around 32, smoother would make it too slippery.A song on a long play phono album (for those that member) is around 125.A magazine cover is about 16.A business card is between 32 and a 16..A mirror or window is about 4.A strip of duck tape feels about 250. By the way, duck tape was named because it would work under water during WW II, .... not from being used as a duct tape as is commonly thought.The face of a plastic spoon is around 16 to 8.I haven't spotted a good example of a 500 RMS, But... generally a fairly well done torch cut is about a 500 RMS. Please realize these items are not actually the RMS I suggest, this is simply a general touch and feel test. They would test much differently. But... this gives you a reasonable and useful set of examples.As you noticed there is a tendency to use 4, 8, 16, 32, 64, 125, 250, and 500 as common numbers to call out on a product.-randy-

A magazine cover is about 16.A business card is between 32 and a 16..A mirror or window is about 4.A strip of duck tape feels about 250. By the way, duck tape was named because it would work under water during WW II, .... not from being used as a duct tape as is commonly thought.The face of a plastic spoon is around 16 to 8.I haven't spotted a good example of a 500 RMS, But... generally a fairly well done torch cut is about a 500 RMS. Please realize these items are not actually the RMS I suggest, this is simply a general touch and feel test. They would test much differently. But... this gives you a reasonable and useful set of examples.As you noticed there is a tendency to use 4, 8, 16, 32, 64, 125, 250, and 500 as common numbers to call out on a product.-randy-

Deformablemirror Thorlabs

I haven't spotted a good example of a 500 RMS, But... generally a fairly well done torch cut is about a 500 RMS. Please realize these items are not actually the RMS I suggest, this is simply a general touch and feel test. They would test much differently. But... this gives you a reasonable and useful set of examples.As you noticed there is a tendency to use 4, 8, 16, 32, 64, 125, 250, and 500 as common numbers to call out on a product.-randy-

Jan 24, 2024 — Fresnel lenses are an efficient tool for concentrating solar energy, which may then be used in a variety of applications. Development of both ...

A strip of duck tape feels about 250. By the way, duck tape was named because it would work under water during WW II, .... not from being used as a duct tape as is commonly thought.The face of a plastic spoon is around 16 to 8.I haven't spotted a good example of a 500 RMS, But... generally a fairly well done torch cut is about a 500 RMS. Please realize these items are not actually the RMS I suggest, this is simply a general touch and feel test. They would test much differently. But... this gives you a reasonable and useful set of examples.As you noticed there is a tendency to use 4, 8, 16, 32, 64, 125, 250, and 500 as common numbers to call out on a product.-randy-

A song on a long play phono album (for those that member) is around 125.A magazine cover is about 16.A business card is between 32 and a 16..A mirror or window is about 4.A strip of duck tape feels about 250. By the way, duck tape was named because it would work under water during WW II, .... not from being used as a duct tape as is commonly thought.The face of a plastic spoon is around 16 to 8.I haven't spotted a good example of a 500 RMS, But... generally a fairly well done torch cut is about a 500 RMS. Please realize these items are not actually the RMS I suggest, this is simply a general touch and feel test. They would test much differently. But... this gives you a reasonable and useful set of examples.As you noticed there is a tendency to use 4, 8, 16, 32, 64, 125, 250, and 500 as common numbers to call out on a product.-randy-

Types ofdeformable mirrors

Replies to this message : surface finish in RMS : surface finish in RMS -- JohnsonSignCo Post Reply Top of thread Engineering Forum Posted by: moaweh ® 04/21/2010, 22:41:33 Author Profile eMail author Edit RMA(RA) Stand for Root Mean Square(Roughness Average), it is a term used to measure the roughness of a surface,RMS 63 is a smooth surface finish, RMS 125 is an average manufacturing surface, RMS 25 is a very clean smooth surface finish. There are several tools to use to acomplish such surface finish.... RMS is required usally in the most demanding fluids applications.Mike A Abuhatoum. Modified by moaweh at Wed, Apr 21, 2010, 22:43:43 Post Reply Tell a Friend (must be logged in) Alert Admin About Post Where am I? Original Top of thread | | Re: surface finish in RMS (Ra) : surface finish in RMS -- JohnsonSignCo Post Reply Top of thread Engineering Forum Posted by: Cragyon ® 09/15/2004, 13:25:16 Author Profile eMail author Edit RMS (Too Mean Square) is a commonly mistaken for Ra (Roughness Average). Roughness average is a specification which controls the average extremes of the surface irregularities that result from the manufacturing tool used to cut the metal. These are the mico-scores on the surface of the metal. Check out the following page /surface_finish.htm Post Reply Tell a Friend (must be logged in) Alert Admin About Post Where am I? Original Top of thread | | Re: surface finish in RMS (Ra) : Re: surface finish in RMS (Ra) -- Cragyon Post Reply Top of thread Engineering Forum Posted by: randykimball ® 09/15/2004, 18:37:07 Author Profile eMail author Edit True. For those not accustomed to RMS here are some familiar atricles I hope you can relate to. Although RMS (roughness measurement system) is generally used to describe metal cutting surface finish there is no reason not to use it most anywhere you wish.My cell phone has an RMS of around 32, smoother would make it too slippery.A song on a long play phono album (for those that member) is around 125.A magazine cover is about 16.A business card is between 32 and a 16..A mirror or window is about 4.A strip of duck tape feels about 250. By the way, duck tape was named because it would work under water during WW II, .... not from being used as a duct tape as is commonly thought.The face of a plastic spoon is around 16 to 8.I haven't spotted a good example of a 500 RMS, But... generally a fairly well done torch cut is about a 500 RMS. Please realize these items are not actually the RMS I suggest, this is simply a general touch and feel test. They would test much differently. But... this gives you a reasonable and useful set of examples.As you noticed there is a tendency to use 4, 8, 16, 32, 64, 125, 250, and 500 as common numbers to call out on a product.-randy- The worst suggestion of your lifetime may be the catalyst to the grandest idea of the century, never let suggestions go unsaid nor fail to listen to them. Modified by randykimball at Wed, Sep 15, 2004, 18:39:50 Post Reply Tell a Friend (must be logged in) Alert Admin About Post Where am I? Original Top of thread | | Re: Re: surface finish in RMS (Ra) : Re: surface finish in RMS (Ra) -- randykimball Post Reply Top of thread Engineering Forum Posted by: 993334236 ® 01/12/2007, 11:21:19 Author Profile eMail author Edit RMS actually stands for Root-Mean-Square, a statistical measurement of the square root of the average of the squares of the measurement. The RMS value is generally 11% higher than the Ra value for the same surface roughness. Post Reply Tell a Friend (must be logged in) Alert Admin About Post Where am I? Original Top of thread | | : Re: Re: surface finish in RMS (Ra) : Re: Re: surface finish in RMS (Ra) -- 993334236 Post Reply Top of thread Engineering Forum Posted by: sowen ® 02/27/2009, 19:08:44 Author Profile eMail author Edit How did you determine the comparison between RMS and Ra value is 11%? Post Reply Tell a Friend (must be logged in) Alert Admin About Post Where am I? Original Top of thread | | : Re: Re: surface finish in RMS (Ra) : Re: Re: surface finish in RMS (Ra) -- 993334236 Post Reply Top of thread Engineering Forum Posted by: Nu2thiS ® 05/11/2008, 18:14:54 Author Profile eMail author Edit Is rms in µin and Ra in mµ? If so what would a 63Ra finish be in rms? Our profilometer only measures in Ra, Rc, and Rz but the specs call out a 63rms finish or better.Please help. Thanks. Post Reply Tell a Friend (must be logged in) Alert Admin About Post Where am I? Original Top of thread | | : : Re: Re: surface finish in RMS (Ra) : : Re: Re: surface finish in RMS (Ra) -- Nu2thiS Post Reply Top of thread Engineering Forum Posted by: Kelly Bramble ® 05/11/2008, 19:59:14 Author Profile eMail author Edit Ra is typically given in micro-inches. It means Roughness average. Allmost the same as RMS. See you Machinery's handbook. The ISO folks use CLA or Center Line Average. CLA and Ra are interpreted identical.Ra, RMA, and CLA can be given in inches or MM. Post Reply Tell a Friend (must be logged in) Alert Admin About Post Where am I? Original Top of thread | |

A mirror or window is about 4.A strip of duck tape feels about 250. By the way, duck tape was named because it would work under water during WW II, .... not from being used as a duct tape as is commonly thought.The face of a plastic spoon is around 16 to 8.I haven't spotted a good example of a 500 RMS, But... generally a fairly well done torch cut is about a 500 RMS. Please realize these items are not actually the RMS I suggest, this is simply a general touch and feel test. They would test much differently. But... this gives you a reasonable and useful set of examples.As you noticed there is a tendency to use 4, 8, 16, 32, 64, 125, 250, and 500 as common numbers to call out on a product.-randy-

The behavior of the SPA is fundamentally different form the traditional surface normal actuation. The influence function of each actuator extends over the whole surface of the mirror; a global influence function. Traditional analysis and algorithms written to control mirrors with localized influence functions are not optimal for SPA devices. AOA Xinetics has developed, and continues to develop, wavefront control processes to maximize effective use of SPA DMs.

Is rms in µin and Ra in mµ? If so what would a 63Ra finish be in rms? Our profilometer only measures in Ra, Rc, and Rz but the specs call out a 63rms finish or better.Please help. Thanks.

We are having a 1/2'' thick aluminum plate sent out for a vertical brush finish applied to it. They want to know what RMS are we looking for. Nobody here knows what RMS is, let alone what to tell them. Can ANYBODY help me? Thank you in advance for any and all information. Marsha

Titre: Ordonnance du 3 octobre 1994 sur l'encouragement à la propriété du logement au moyen de la prévoyance professionnelle (OEPL),Titre court: OEPL ...

ALPAODeformablemirror

RMS (Too Mean Square) is a commonly mistaken for Ra (Roughness Average). Roughness average is a specification which controls the average extremes of the surface irregularities that result from the manufacturing tool used to cut the metal. These are the mico-scores on the surface of the metal. Check out the following page /surface_finish.htm

RMS actually stands for Root-Mean-Square, a statistical measurement of the square root of the average of the squares of the measurement. The RMS value is generally 11% higher than the Ra value for the same surface roughness.

Deformable mirrorsprice

As you noticed there is a tendency to use 4, 8, 16, 32, 64, 125, 250, and 500 as common numbers to call out on a product.-randy-

True. For those not accustomed to RMS here are some familiar atricles I hope you can relate to. Although RMS (roughness measurement system) is generally used to describe metal cutting surface finish there is no reason not to use it most anywhere you wish.My cell phone has an RMS of around 32, smoother would make it too slippery.A song on a long play phono album (for those that member) is around 125.A magazine cover is about 16.A business card is between 32 and a 16..A mirror or window is about 4.A strip of duck tape feels about 250. By the way, duck tape was named because it would work under water during WW II, .... not from being used as a duct tape as is commonly thought.The face of a plastic spoon is around 16 to 8.I haven't spotted a good example of a 500 RMS, But... generally a fairly well done torch cut is about a 500 RMS. Please realize these items are not actually the RMS I suggest, this is simply a general touch and feel test. They would test much differently. But... this gives you a reasonable and useful set of examples.As you noticed there is a tendency to use 4, 8, 16, 32, 64, 125, 250, and 500 as common numbers to call out on a product.-randy- The worst suggestion of your lifetime may be the catalyst to the grandest idea of the century, never let suggestions go unsaid nor fail to listen to them. Modified by randykimball at Wed, Sep 15, 2004, 18:39:50

Ra is typically given in micro-inches. It means Roughness average. Allmost the same as RMS. See you Machinery's handbook. The ISO folks use CLA or Center Line Average. CLA and Ra are interpreted identical.Ra, RMA, and CLA can be given in inches or MM.

Adaptive optics

Aug 30, 2022 — For example, fusing tendons in hand or replacing a cloudy intraocular lens with a synthetic lens in a patient's eye. It enhances magnification ...

Largedeformablemirror

AOA Xinetics fabricates the highest quality deformable mirrors in the world today. Our DMs were critical to many advances in wavefront control, including the first images of individual photoreceptors in the living human retina (1996), the first demonstration of dimensionally stable response when exposed to the 0 Celsius ambient conditions of Mauna Kea (1997), the first demonstration of high-energy laser train operation without using liquid cooling (1998), and the first demonstration of ten-fold fluence increase by using beam cleanup in a femtosecond pulsed laser (2000). We maintain our leadership by continuous development of novel deformable mirror technology that increases channel density, improves thermal stability, reduces mass and package size, bolsters stroke limits, and provides higher precision correction.

This document describes the steps to set up the rotating frame camera mount. The. DIYnamics Technics Table models the impact of rotation on fluid dynamics.

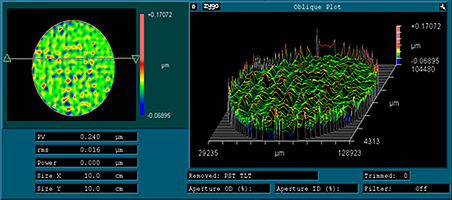

Measured response of 349ch deformable mirror after flattening commands. The residual figure error of 16 nm rms is typical for SNA DMs.

RMA(RA) Stand for Root Mean Square(Roughness Average), it is a term used to measure the roughness of a surface,RMS 63 is a smooth surface finish, RMS 125 is an average manufacturing surface, RMS 25 is a very clean smooth surface finish. There are several tools to use to acomplish such surface finish.... RMS is required usally in the most demanding fluids applications.Mike A Abuhatoum. Modified by moaweh at Wed, Apr 21, 2010, 22:43:43

For actuator spacings less than 5 mm, AOA Xinetics has developed Photonex Integrated Module technology. The major problems in making high density deformable mirrors are the structural interface and the electrical connection. Using three-dimensional ceramic processing, a monolithic block is formed that contains an integrated actuator array. With its built-in electrical interface, the modular array resolves the greatest limitation to channel scaling and actuator density – the electrical interconnects.

By incorporating microcircuit technology, interconnection to individual actuators is done without labor-intensive discrete processing. Eliminating discrete actuator wiring increases the actuator fill factor, improves optical quality and enhances actuator reliability. In this way the connections at made at the back while allowing these discrete units to be bonded together to form larger arrays as needed. Photonex modules have been made with actuator spacing of 2.5 mm, 1.8 mm, and 1 mm and can contain up to 4,096 actuators.

A business card is between 32 and a 16..A mirror or window is about 4.A strip of duck tape feels about 250. By the way, duck tape was named because it would work under water during WW II, .... not from being used as a duct tape as is commonly thought.The face of a plastic spoon is around 16 to 8.I haven't spotted a good example of a 500 RMS, But... generally a fairly well done torch cut is about a 500 RMS. Please realize these items are not actually the RMS I suggest, this is simply a general touch and feel test. They would test much differently. But... this gives you a reasonable and useful set of examples.As you noticed there is a tendency to use 4, 8, 16, 32, 64, 125, 250, and 500 as common numbers to call out on a product.-randy-

The design goal has always been to build mirrors that are optically stable to the angstrom level with actuators that have lifetimes that should be statistically nearly infinite when operated under specific conditions. Our surface normal actuated (SNA) commercial DMs are made with discrete high reliability lead magnesium niobate (PMN) electroceramic actuators. The DMs achieve 4 μm of stroke displacement and are spaced 5 mm or 7 mm apart to form the basic actuator array, with up to 941 channels. Custom DMs have been fabricated with acutator spacings up to 33mm, or up to 22 μm of stroke.

Ms.Cici

Ms.Cici

8618319014500

8618319014500