C-BLUE Series - blueseries

Diffraction gratings are manufactured either classically with the use of a ruling engine, or holographically with the use of interference fringes generated at the intersection of two laser beams.

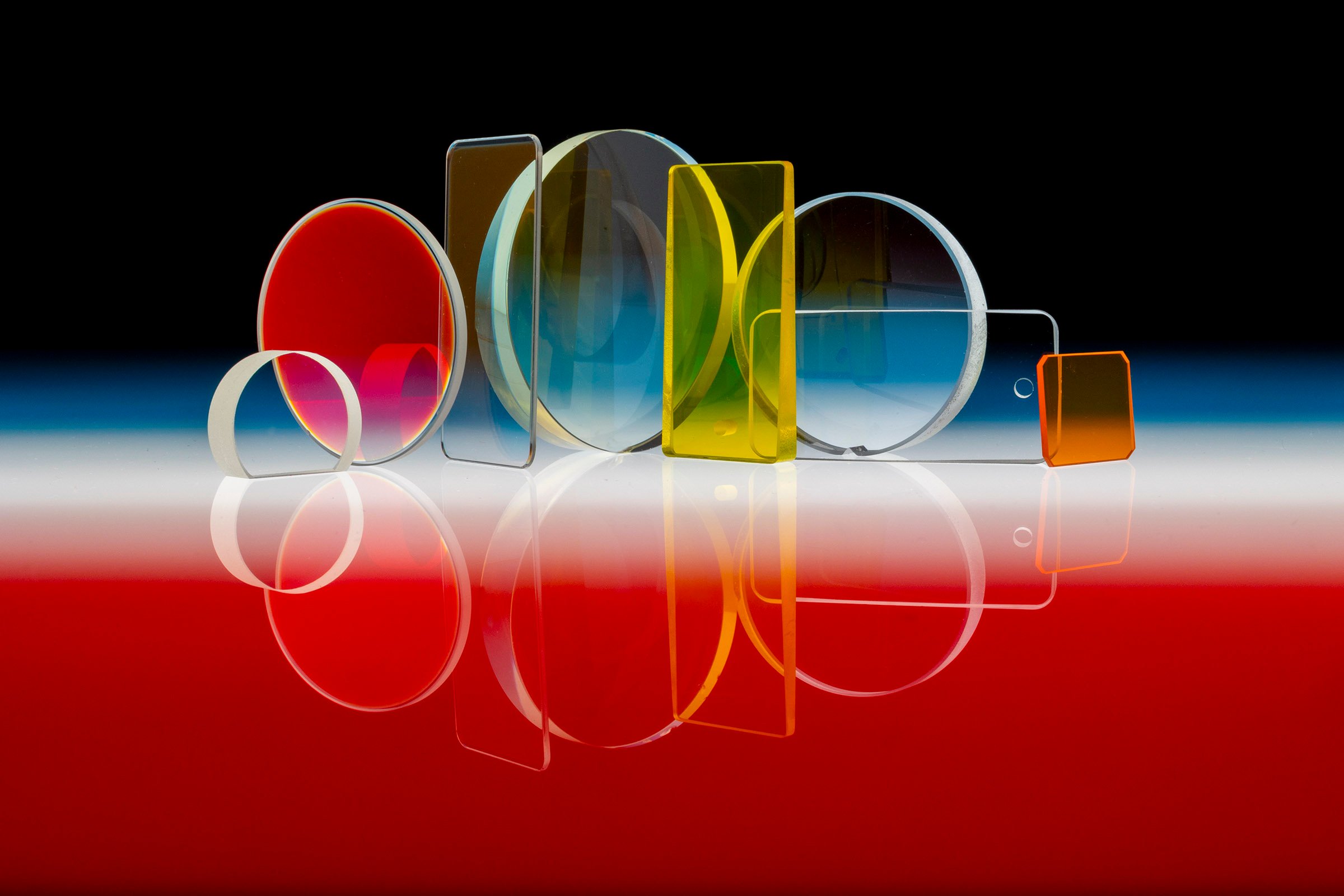

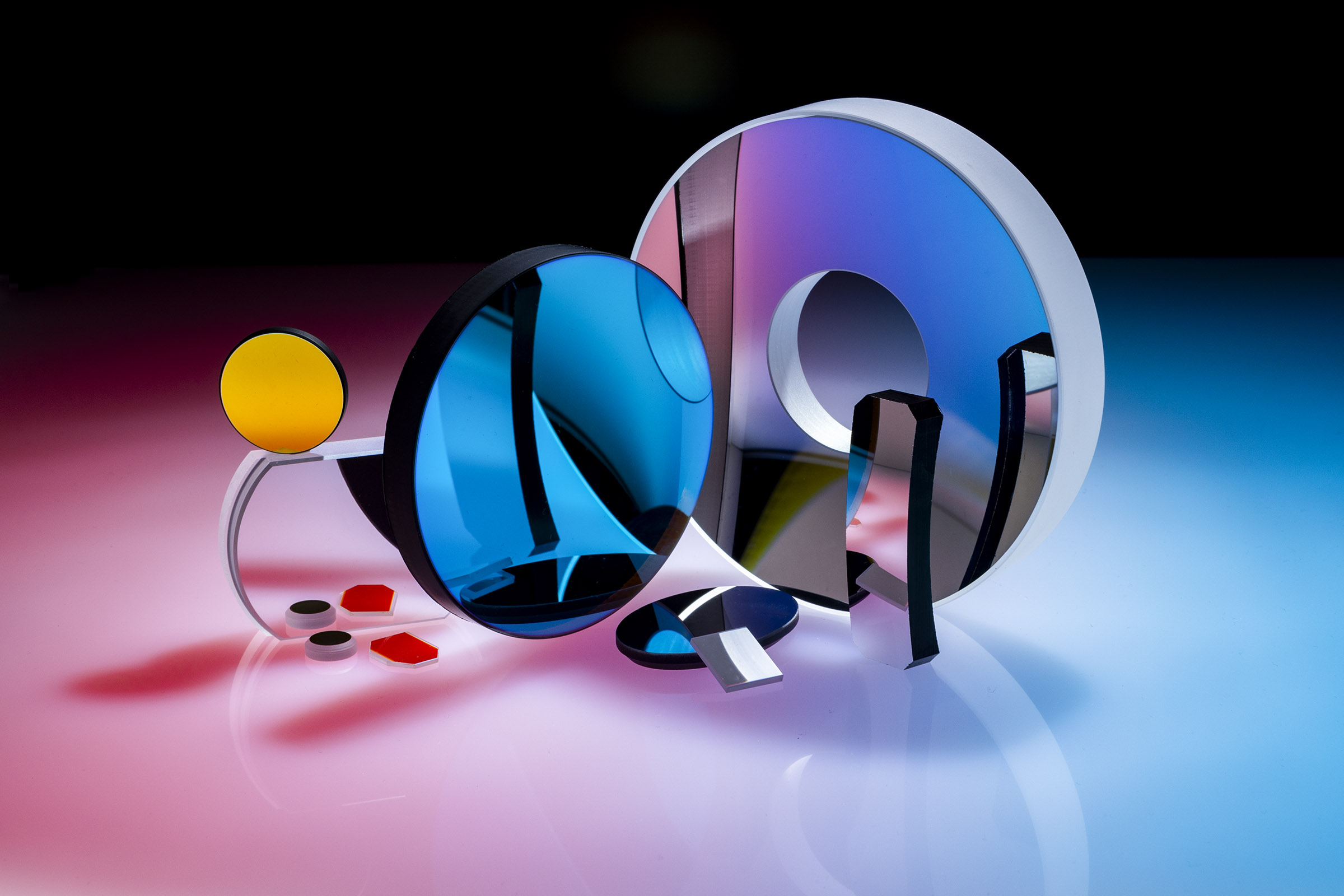

Combining our long-tenured, experienced staff and state-of-the-art equipment, we craft custom precision optics and optical assemblies in a large or small quantity without compromising quality.

Before introducing the basic equations, a brief explanation on monochromatic light and continuous spectra must first be presented.

Dec 1, 2011 — In a recent blog post Kirk Tuck writes, "You can design a lens for high resolution or high contrast but not necessarily both.

Blazed grating groove profiles are calculated for the Littrow condition where the incident and diffracted rays are in auto collimation (i.e., α = β). The input and output rays, therefore, propagate along the same axis. In this case, at the “blaze” wavelength λB.

Note: Just because a grating is “non-blazed” does not necessarily mean that it is less efficient! See Fig. 7 showing the efficiency curve for an 1800 g/mm sinusoidal grooved holographic grating.

Diffraction gratingformula

Holographic gratings show no ghosts because there are no periodic ruling errors and, therefore, often represent the best solution to ghost problems.

Relative efficiency measurements require the mirror to be coated with the same material and used in the same angular configuration as the grating.

A grating blazed in first order is equally blazed in the higher orders. Therefore, a grating blazed at 600 nm in first order is also blazed at 300 nm in second order, and so on.

Additionally, AR coatings help in reducing eye fatigue at work. They are especially suited for people who spend long hours working on computers, which can cause ...

Vertically integrated with deep expertise in optics manufacturing, assembly, and coating, for engineers looking to optimize imaging systems in the most demanding industries.

Rely on our experienced technical sales and manufacturing engineers. Design for Manufacturability principles helps bring your concept to a more affordable reality.

Diffraction grating

Dec 31, 2022 — Inexpensively made Fresnel lenses make poorer quality images than traditional glass lenses because of a problem called spherical aberration: ...

Regardless of the shape of the surface or whether classically ruled or holographic, the text that follows is applicable to each; explanations are provided where there are differences.

Monochromatic light has infinitely narrow spectral width. Good sources which approximate such light include single mode lasers and very low pressure, cooled spectral calibration lamps. These are also variously known as “line” or “discrete line” sources.

Fig. 4 shows a first order spectrum from 200 to 1000 nm spread over a focal field in spectrograph configuration. From Equation (1) with a grating of given groove density and for a given value of α and β:

λ = the central wavelength of the spectral line to be resolved Wg= the illuminated width of the grating N = the total number of grooves on the grating

Blaze is defined as the concentration of a limited region of the spectrum into any order other than the zero order. Blazed gratings are manufactured to produce maximum efficiency at designated wavelengths. A grating may, therefore, be described as “blazed at 250 nm” or “blazed at 1 micron,” etc. by appropriate selection of groove geometry.

In most monochromators, the location of the entrance and exit slits are fixed, and the grating rotates around a plane through the center of its face. The angle, DV, is, therefore, a constant determined by:

Linear dispersion defines the extent to which a spectral interval is spread out across the focal field of a spectrometer and is expressed in nm/mm, Å/mm, cm-1/mm, etc. For example, consider two spectrometers: one instrument disperses a 0.1 nm spectral segment over 1 mm while the other takes a 10 nm spectral segment and spreads it over 1 mm.

where, dλ is the difference in wavelength between two spectral lines of equal intensity. Resolution is then the ability of the instrument to separate adjacent spectral lines. Two peaks are considered resolved if the distance between them is such that the maximum of one falls on the first minimum of the other. This is called the Rayleigh criterion.

If, for example, a light source emits a continuum of wavelengths from 20 nm to 1000 nm, then at the physical location of 800 nm in first order (Fig. 4) wavelengths of 400, 266.6, and 200 nm will also be present and available to the same detector. In order to monitor only light at 800 nm, filters must be used to eliminate the higher orders.

Because bandpass is also determined by the slit width of the spectrometer and residual system aberrations, an achieved bandpass at this level is only possible in diffraction limited instruments, assuming an unlikely 100% of theoretical.

Blazedgrating

Theoretically, a 1200 g/mm grating with a width of 110 mm that is used in first order has a numerical resolving power R = 1200 × 110 = 132,000. Therefore, at 500 nm, the bandpass is equal to:

Remember, ghosts and subsequent stray light intensity are proportional to the square of order and groove density (n2 and k2 from Equation (17). Beware of using ruled gratings in high order or with high groove density.

See Fig. 6 and Fig. 7 for typical efficiency curves of a blazed, ruled grating, and a non-blazed, holographic grating, respectively.

diffractiongrating中文

Classically ruled gratings may be planar or concave and possess grooves, each parallel with the next. Holographic grating grooves may be either parallel or of unequal distribution in order to optimize system performance. Holographic gratings are generated on planar, spherical, toroidal, and many other surfaces.

Echellegrating

First order wavelengths between 200 and 380 nm may be monitored without filters because wavelengths below 190 nm are absorbed by air. If, however, the instrument is evacuated or N2 purged, higher order filters would again be required.

Table 1 shows how α and β vary depending on the deviation angle for a 1200 g/mm grating set to diffract 500 nm in a monochromator geometry, based on Fig. 2.

From a single prototype to full production runs reaching into the hundreds of thousands, we are unique in our ability to be flexible and dependable, while continually exceeding quality standards, no matter the quantity.

360Cities is the leading source of 360° panorama / VR media for education, publishing, advertising, film, and mobile apps & games.

Efficiency in higher orders usually follows the first order efficiency curve. For a grating blazed in first order, the maximum efficiency for each of the subsequent higher orders decreases as the order k increases.

This experiment: calibrate grating spectrometer measure ... the turntable – supports the diffraction grating ... (a) Place the diffraction grating on the turntable ...

LA = Entrance arm length LB = Exit arm length at λn βH = Angle between the perpendicular to the spectral plane and the grating normal LH = Perpendicular distance from the spectral plane to grating.

Table 1 shows how the angle of incidence and angle of diffraction vary depending on the deviation angle for a 1200 g/mm grating set to diffract 500 nm in a monochromator geometry.

Protected Silver Mirror, 50 x 75mm, 4-6λ. Quick info. SKU: PSLV-50x75 Categories: General Coatings, Mirrors. Detailed Specifications. Thickness (mm), coating.

A continuous spectrum has finite spectral width, e.g. “white light.” In principle, all wavelengths are present, but in practice a “continuum” is almost always a segment of a spectrum. Sometimes a continuous spectral segment may be only a few parts of a nanometer wide and resemble a line spectrum.

If the diffraction grating has periodic ruling errors, a ghost, which is not scattered light, will be focused in the dispersion plane. Ghost intensity is given by:

Our reputation, built over three generations, has made the LaCroix name synonymous with delivering quality precision optics. Our personal approach to every customer has driven our success for more than 70 years.

It is easy to imagine that fine spectral detail would be more easily identified in the first instrument than the second. The second instrument demonstrates “low” dispersion compared to the “higher” dispersion of the first. Linear dispersion is associated with an instrument’s ability to resolve fine spectral detail.

Fraunhoferdiffraction

The most difficult component of an optical microscope to design and assemble, the objective is the first element that light encounters as it passes from the ...

In most monochromators, the location of the entrance and exit slits are fixed, and the grating rotates around a plane through the center of its face. The angle, DV, is, therefore, a constant.

Unless otherwise indicated, the efficiency of a diffraction grating is measured in the Littrow configuration at a given wavelength.

In a monochromator, LB is the arm length from the focusing mirror to the exit slit, or if the grating is concave, from the grating to the exit slit. Linear dispersion, therefore, varies directly with cos β, and inversely with the exit path length, LB, diffraction order (k), and groove density, n.

Blazed grating groove profiles are calculated for the Littrow condition where the incident and diffracted rays are in auto collimation.

Diffraction gratings are manufactured either classically with the use of a ruling engine by burnishing grooves with a diamond stylus, or holographically with the use of interference fringes generated at the intersection of two laser beams1.

In industries where there's no room for error, we take pride in making quality optical lenses right here in America that serve vital roles around the world, from protecting our troops to diagnosing disease.

Gratingequation

The efficiency also decreases the farther away from Littrow conditions in which the grating is used (e.g. α ≠ β). Holographic gratings may be designed with groove profiles that discriminate against high orders. This may be particularly effective in the UV and VIS using laminar groove profiles created by ion etching.

As a general approximation, for blazed gratings the strength of a signal is reduced by 50% at two-thirds the blaze wavelength, and 1.8 times the blaze wavelength.

High Power Objective Lens (40x). This is referred to as the high powered objective lens since it is ideal for observing the small details within a specimen ...

In a spectrograph, the linear dispersion for any wavelength other than the wavelength which is normal to the spectral plane will be modified by the cosine of the angle of inclination or tilt angle (γ) at wavelength λn. Fig. 3 shows a “flat field” spectrograph as used with a linear diode array.

A blazed grating is one in which the grooves of the diffraction grating are controlled to form right triangles with a “blaze angle, ω,” as shown in Fig. 5. However, apex angles up to 110° may be present especially in blazed holographic gratings. The selection of the peak angle of the triangular groove offers opportunity to optimize the overall efficiency profile of the grating.

Diffraction gratingexperiment

Holographic gratings show no ghosts because there are no periodic ruling errors and, therefore, often represent the best solution to ghost problems.

Light other than the wavelength of interest reaching a detector (often including one or more elements of “scattered light”) is referred to as stray light.

No one works harder or faster to help you achieve your optics production goals. Our workflow, from initial print to production management, speeds up the process when you need it most.

Metric Allen Hexagon, Hex Key, Hexagon Keys Series Tools.

Ghosts are focused and imaged in the dispersion plane of the monochromator.Stray light of a holographic grating is usually up to a factor of ten times less than that of a classically ruled grating, is typically non-focused, and when present, radiates through 2π steradians.

Diffraction gratings are manufactured either classically with the use of a ruling engine, or holographically with the use of interference fringes generated at the intersection of two laser beams.

Our facilities are certified to ISO 9001:2015 standards and is ITAR Registered and Compliant. We offer unmatched production capability, while also keeping your prints and proprietary information securely stateside.

Ms.Cici

Ms.Cici

8618319014500

8618319014500