Aspheric lens - aspheric contacts

Linearlypolarized electromagnetic wave

The glazing profile refers to the edge detail where the interior glass meets the wood, or in the case of the exterior, either the wood or the extruded aluminum. This edge detail, sometimes referred to as sticking or bead, adds a more traditional or contemporary aesthetic to a window or door. Ogee and Putty profiles are more traditional, while a Square profile provides a clean, crisp, contemporary look.

Zero-Order Waveplates - Fortunately, a technique is available for realizing true half-waveplate performance, while retaining the high optical quality and rugged construction of crystalline quartz waveplates. By combining two waveplates whose retardations differ by exactly half a wave, a true half-waveplate is created. The fast axis of one plate is aligned with the slow axis of the other, so that the net retardation is the difference between the two retardations. The change in retardation with frequency (or wavelength) is minimized as shown in Figure 7. Temperature sensitivity is also reduced to a typical value is 0.0001λ per °C. The change in retardation with rotation is highly dependent on manufacturing conditions and may be equal to or greater than that of a multiple order waveplate.

It is also possible to induce small amounts of birefringence into a normally isotropic material through stress. For example, most polymers exhibit birefringence from stress applied in the manufacture. Polymer waveplate material is available in half or quarter-wave retardation. This material can be sandwiched between two high quality windows to make precision zero-order waveplates.

An instant boost to curb appeal, optional exterior casing adds architectural detail and character to the profile of your home. Factory-applied casing saves time on the job site, with beauty and durability that lasts. Exterior casings, optional at the time of order, are available in extruded aluminum and are factory-finished with the same AMMA 2605 finish and paint as the clad exterior for a perfect match.

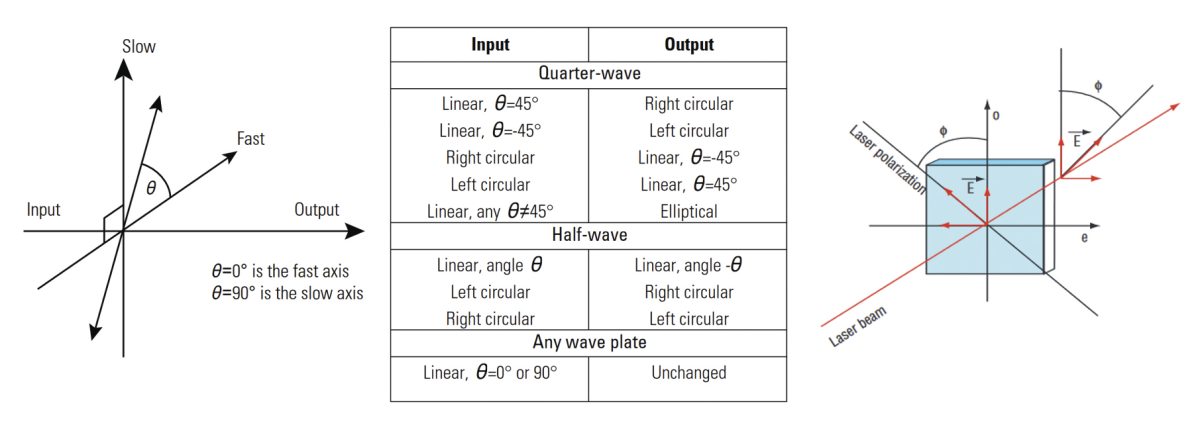

Optical Isolation - A quarter-waveplate can be used in an optical isolator, that is, a device that eliminates undesired reflections. Such a device uses a quarter-waveplate and a linear polarizer or polarizing beamsplitter cube.

You can count on consistency with our process, as every piece of wood receives a coat of prime and is sanded before being painted. The paint is baked twice in an oven before your window or door is built to create a consistent, durable and high-quality painted finish that performs to the industry standard.

Get detailed information on the Ultimate product line including types of windows and doors, color and finish options, sizing, hardware, and other key details.

Circular polarization

Simulated Divided Lite (SDL) - An energy-efficient way to create the look of authentic divided lites, SDL bars are permanently adhered to both sides of the glass and are available with or without a spacer bar installed between the glass to create even more depth that resembles an ADL.

Circularly polarized light

Yes, opt-in. By checking this box, you agree to receive our newsletters, announcements, surveys and marketing offers in accordance with our privacy policy

Ultimate Interiors: Square glazing profile is available on all products. Ogee is offered on all products except direct glaze and the commercial door.

Choose from six extruded aluminum subsill options to best match your sill thickness and depth with your casing and window style. Custom clad subsills ideal for historical matching are also available.

Specialty Glass OptionsOur specialty glass options include glass for unique project needs like sound management (STC/OITC), high altitudes, Sea Turtle Conservation Codes and California fire zones. We also offer laminated glass in products designed specifically for hurricane zones.

Find technical documents for this product, including installation instructions, sizes and elevations, 3D drawings, architectural detail manuals and more.

A variety of decorative glass options are available to meet the unique needs of each project, and laminated glazing is also available in clear, bronze, gray, or green with tinted interlayers.

A high-quality window deserves a dependable finish. Our low maintenance clad-wood products feature an extruded aluminum exterior finished in commercial-grade paint for superior resistance to fading and chalking. Our palette of 19 color options spans from muted, earthy tones to bold, rich colors and three pearlescent finishes. Custom color matching is also available to meet any design vision.

Every piece of wood receives even coats of conditioning and stain, two coats of clear finish, and is sanded and baked twice in an oven before your window or door is built to create a consistent, durable, and high-quality finish that brings out the natural beauty, texture, and grain of the wood. Our stained wood products meet industry standards and arrive ready to install.

These waveplates are recommended for use in systems using tunable radiation sources, such as a diode laser or white light sources.

Grilles-between-the-Glass (GBGs) - Grilles are permanently installed between the glass panes for a low-maintenance, smooth exterior and easy cleaning. Choose from six exterior colors and three interior colors.

Simulated Divided Lite with Spacer Bar (SDLS) - Paired with SDL bars on the interior and exterior of the glass, a spacer bar is installed between the glass, creating an even closer resemblance to the ADL look.

Since waves repeat themselves every 2π radians, we could subtract an integral number of 2π's or waves, and for example, call the crystal showing 2π(m+1/4) radian a quarter waveplate. It would not matter, provided it was only used at exactly the optical frequency designed for the waveplate. However, if the frequency was changed, the retardation would change at a rate faster than it would for a plate that had only 1/4 wave retardation. This difference can be noted by calling it a “multiple order quarter waveplate".

Painting on the job site or scheduling off-site finishing is an extra step that takes time and coordination. Choose our primed white or white painted interior finish option on any Marvin pine windows and doors with a wood exterior, or an additional designer black paint option for products with an aluminum-clad exterior. Your windows and doors will arrive factory-painted and ready to install.

The two most common applications of waveplates have been mentioned: rotating the plane of polarization with a half-waveplate and creating circular polarization with a quarter-waveplate. A quarter-waveplate can also be used to create plane-polarization from circular polarization — just reverse the direction of light propagation in Figure 4. The operation of a waveplate and a summary of how quarter and half waveplates convert one polarization state to another are shown in Figure 6.

Incidentally, if a new polarizer doesn’t provide as good an extinction as the ones you used before, it likely means this waveplate isn’t exactly a half-waveplate at the operating wavelength of your interest. Small errors in retardation can be corrected by rotating the waveplate a small amount to move the incident beam's plane of polarization towards the fast or slow axes. Moving towards the fast axis decreases the retardation while moving towards the slow axis increases the retardation. Try both ways and use a linear polarizer to check for improvement in the extinction ratio.

A linearly polarized wave with its plane rotated 90° will propagate with the maximum index of refraction and minimum phase velocity, as shown in Figure 2. This wave is polarized along the slow axis.

Setting up a waveplate to produce circularly polarized light proceeds exactly the same as described for rotating 90° with a half-waveplate: first, cross a polarizer in the beam to find the plane of polarization. Next, insert the quarter-waveplate between the source and the polarizer and rotate the waveplate around the beam axis to find the orientation that retains the extinction. Then rotate the waveplate 45° from this position. Half of the incident light should now be passing through the polarizer (the other half being absorbed or deflected, depending on which kind of polarizer being used). The quality of the circularly polarized light can be checked by rotating the polarizer - the intensity of light passing through the polarizer should remain unchanged. If it varies somewhat, it means that the light is actually elliptically polarized, and the waveplate isn’t exactly a quarter-waveplate at operating wavelength of your interest. This may be corrected (as with the half-waveplate) by tilting the waveplate about its fast or slow axes slightly, while rotating the polarizer to check for constancy.

Suppose a linearly polarized wave is normally incident on a waveplate, and its plane of polarization is at an angle θ with respect to the fast axis. To see what happens, resolve the incident field into components polarized along the fast and slow axes, as shown. After passing through the plate, pick a point in the wave where the fast component passes through a maximum. Since the slow component is retarded by one half-wave, it will also be a maximum, but 180° out of phase, or pointing along the negative slow axis. If we follow the wave further, we see that the slow component remains exactly 180° out of phase with the original slow component, relative to the fast component. This describes a linearly polarized wave, but making an angle θ on the opposite side of the fast axis. The original polarization axis has been rotated through an angle 2θ. The same result will be found if the incident wave makes an angle θ with respect to the slow axis.

Berek’s Variable Waveplates - A Berek compensator quantitatively determines the wavelength retardation of a crystal, fiber, mineral, plastic film or any other birefringent material. Berek tunable or variable waveplates have a variable birefringence or thickness that can be tuned to a certain wavelength or shift the retardation value for a single wavelength. If the material’s thickness can be measured, this optical device can be used to learn its birefringence value. The Berek compensator works by measuring the rotation angle of a calcite or magnesium fluoride optical plate that is cut perpendicular to the optical microscope’s axis.

The Ultimate Picture Narrow Frame window offers a classic style in a non-operable window, bringing expansive views and natural light into a room. Its narrow frame allows for replacement without disturbing existing interior or exterior trim.

The look of multiple, individual panes of glass in a door panel is popular in a wide range of architectural styles–from historic replications to modern farmhouses. For those who seek historical accuracy, authentic divided lites utilize individual glass panes. Simulated divided lites, available in a number of different styles, mimic the look of individual panes of glass in a window sash without sacrificing the energy efficiency of a single pane of glass.

The difference in the number of wavelengths shown in Figures 1 and 2 (2 2/3 and 4, respectively) would imply a ratio of the two indices of refraction nfast : nslow = 2 : 3, a much larger difference than in typical natural crystals; the ratio has been exaggerated for clarity.

Similarly, the sensitivity of the retardation to rotation about the fast and slow axes is found to be about (2m + 1) times larger for a multiple order plate than a true zero-order half-waveplate. This means much smaller rotations are required to correct for retardation errors. But it also means that light rays not parallel to the optical axis will see a (2m + 1) larger change in retardation. Multiple order waveplates are not recommended in strongly converging or diverging beam portions of an optical system. Similarly, the sensitivity of retardation to changes in length caused by changes in temperature is multiplied by (2m + 1), so that tighter temperature control will be required. A typical temperature sensitivity is 0.0015λ per °C for a visible 1 mm thick half-waveplate.

The interaction of light with the atoms or molecules of a material is wavelength dependent. A result of this dependence is the resonant interactions related to material dispersion. Birefringence is another consequence of such resonant interaction, which is the change in refractive index with the polarization of light. The orderly arrangement of atoms in some crystals results in different resonant frequencies for different orientations of the electric vector relative to the crystalline axes. In turn, this results in different refractive indices for different polarizations. Unlike dispersion, birefringence can be avoided by using amorphous materials such as glass, or crystals that have simple symmetries, such as NaCl or GaAs. We can also “use” birefringence to modify the polarization state of light, which is a useful thing to do in many situations. The optical components that do this “trick” are called birefringent waveplates or retardation plates (or just waveplates or retarders, for short).

Linearly polarisedmeaning

Quarter-waveplates are used to turn linearly polarized light into circularly polarized light and vice versa. To do this, the waveplate must be oriented so that equal amounts of fast and slow waves are excited. This is achieved by orienting an incident linearly polarized wave at 45° to the fast (or slow) axis, as shown in Figure 4.

Wood is a product of nature and will vary in color, texture and grain. Wood options shown are to demonstrate the approximate look of each species only, and stain samples are shown on Pine. Photos are not intended to reflect a product's interior or exterior profile.

Choose products to compare anywhere you see 'Add to Compare' or 'Compare' options displayed. Compare All Close

Meet your design vision with natural, stained or painted wood. With Marvin factory-applied interior finishes, you can order beautifully finished windows and doors that are ready to install the day they arrive to save valuable time on the job site. Choose from a selection of high-quality standard wood options, including Pine, Cherry, Douglas Fir, Mahogany, White Oak, and Vertical Grain Douglas Fir.

Due to the variety of possible combinations of casings and subsills, special dimensional considerations for installation methods are required. Contact your local Marvin retailer when specifying casing and subsill combinations.

Elliptical polarization

Polarization Cleanup - Often an optical system will require several reflections from metal or dielectric mirrors. There is no change in the polarization state of the reflection if the beam is incident normally on the mirrors, or if the plane of polarization lies in or normal to the plane of incidence. However, if the polarization direction makes some angle with the plane of incidence, then the reflection often makes a small phase shift between the parallel and perpendicular components. This is particularly true for metal mirrors, which always have some loss. The resulting reflected wave is no longer linearly polarized, but will be slightly elliptically polarized. This can easily be determined by its degraded extinction when a polarizer is inserted and rotated. This small ellipticity can often be removed by inserting a full waveplate (which ordinarily does nothing) and tilting it slightly about either fast or slow axes to change the retardation slightly to just cancel the ellipticity.

S-polarization vs p-polarization

The result is elliptically polarized light - where the amount of ellipticity is a function of the retardation of the incident plane wave; and the tilt of the axis is a function of the tilt of the incident plane wave. The exception is a half-wave retardation, in which case the ellipse degenerates into a plane wave making an angle of 2θ with the fast axis. Note that the quarter-waveplate does not produce circularly polarized light here, because equal amounts of fast and slow wave components were not used; the incident tilt angle must be exactly 45° with respect to the fast (or slow) axis to make these components equal.

where f0 and λ0 are the design frequency and wavelength, and m is the order of the waveplate. Thus, the rate of change of retardation with frequency σΓ/σf will be 2m + 1 times as large for an mth order plate as a true half-waveplate, (m = 0, or “zero-order” plate). This would be 31 times larger for our 1 mm “15.5-waveplate”. Calculate the frequency or wavelength range required by a given system, and see if the error in retardation will be tolerable over that range with a multiple-order waveplate.

The propagation phase constant k can be written as 2πfn/c radians per meter, so that a wave of frequency f will experience a phase shift of φ = 2πfnL/c radians in traveling a distance L through the crystal. Thus, the phase shift for the wave in Figure 1 will be φfast = 2πfnfastL/c, and for the wave in Figure 2, φslow = 2πfnslowL/c. The difference between these two-phase shifts is termed the retardation, Γ= 2πf(nslow - nfast)L/c. The value of Γ in this formula is in radians, but is more common to express in ”wavelengths” or “waves”, with a “full-wave” meaning Γ = 2π, a “half-wave” meaning Γ = π, a “quarter-wave” meaning Γ = π/2, and so forth.

Ultimate Exteriors: Putty glazing profile is available on all products. Square is offered on all except more traditional products such as the French doors and Double Hung windows.

Authentic Divided Lite (ADL) - Separate pieces of glass are glazed between muntin bars – the way windows have been made since the beginning but with Marvin's updated design to increase energy efficiency.

On the other side of the plate, examine the wave at a point where the fast-polarized component is at maximum. At this point, the slow-polarized component will be passing through zero, since it has been retarded by a quarter-wave or 90° in phase. Moving an eighth wavelength farther, we will note that the two are the same magnitude, but the fast component is decreasing and the slow component is increasing. Moving another eighth wave, we find the slow component is at maximum and the fast component is zero. If the tip of the total electric vector is traced, we find it traces out a helix, with a period of just one wavelength. This describes circularly polarized light. Right-hand circularly polarized light is shown in the Figure; the helix wraps in the opposite sense for left-hand. Left-hand polarized light is produced by rotating either the waveplate or the plane of polarization of the incident light 90° in Figure 4.

Achromatic Waveplates - Achromatic waveplates consist of two different materials that are carefully choosen to eliminate chromatic dispersion. The most common type is crystalline quartz and magnesium fluoride birefringent crystals in an air-spaced design. Achromatic polymer waveplates are also avaiable which consitint of film stack laminated between two high-precision AR coated N-BK7 windows. Compared to zero-order waveplates, achromatic waveplates offer better retardation accuracy over broadband wavelength ranges, as example of achromatic quartz-MgF2 1/2 waveplate shown in Figure 8.

Linearlypolarized wave

By taking just the right slice of a crystal with respect to the crystalline axes, it can be arranged so that the minimum index of refraction is exhibited for one polarization of the electric vector of a linearly polarized wave, as shown in Figure 1. The wave is polarized along the fast axis, since its phase velocity will be a maximum.

When compared to painting or staining on the job site, factory-stained finishes offer consistent quality and performance resulting from our expertise with wood as a material and years of perfecting our staining process.

Materials — Many naturally occurring crystals exhibit birefringence, and could, in principle, be used for waveplates. Calcite and crystalline quartz are typical materials used. While they are durable and of high optical quality, the refractive index difference, nslow - nfast is so large that a true half-waveplate would be too thin to polish, therefore impractical to create.

Finish samples are approximate and colors on screen can vary. Visit your local dealer to see actual color samples.Black only available on clad.

Marvin’s custom capabilities allow us to create almost any divided lite pattern you can dream up, with combinations of widths, unique profiles, rectangular or radius cuts, and more. Choose from an existing lite cut, specify custom divided lites according to a new design, or ask our design professionals to assist in creating a pattern for your needs.

What effect do retardations other than a half-wave or a quarter-wave have on linearly polarized light? Figure 5 shows the effect of λ/4 retardation on linearly polarized light with the plane of polarization making an arbitrary angle with respect to the fast axis.

In 1913, Max Berek developed this style of polarization compensator, as a variable waveplate that imposes a quarter- or half-wave retardation at wavelengths between 200 and 2800 nm. This greatly reduced the number of compensation plates needed to conduct quantitative polarized light microscopy.

Not all decorative glass is compatible with all products. Check with your dealer for a recommendation on which glass is right for your project. Images may not be an accurate representation.

A half-waveplate is very helpful in rotating the plane of polarization from a polarized laser to any other desired plane (especially if the laser is too large to rotate). Most large ion lasers are vertically polarized, for example, so to obtain horizontal polarization, simply place a half-waveplate in the beam with its fast (or slow) axis 45° to the vertical. If it happens that the half-waveplate being used does not have marked axes (or if the markings are obscured by the mount), place a linear polarizer in the beam first and orient it for extinction (horizontally polarized), then interpose the half-waveplate normal to the beam and rotate it around the beam axis, so that the beam remains extinct - one of the axes has now been found. Then, rotate the half-waveplate exactly 45° around the beam axis (in either direction) from this position, and the polarization of the beam will have been rotated by 90°. Check this by rotating the polarizer 90° to see that extinction occurs again. If you need some other angle, instead of 90° polarization rotation, simply rotate the waveplate by half the angle you desire. A convenient waveplate mount calibrated in angle is the RSP-1T or GM-1RA.

Multiple-order waveplates can be used when a waveplate is required to be used at two discrete wavelengths, for example, the 488 and 514.5 nm wavelengths of an argon-ion laser or the 532 and 1064 nm wavelengths from an Nd:YAG laser. By choosing the thickness to give a (2m1 + 1) plate at one wavelength and a (2m2 + 1) plate at the other, both wavelengths will see a “half-waveplate” (but not the wavelengths in between). The integers must be selected by a computer program, since the dispersion in index also has to be accounted for, but it is usually possible to find a plate of reasonable thickness provided the two wavelengths are not too close together.

Linearly polarisedlight

Energy EfficiencyGlass is an important aspect for managing the energy efficiency of your home. Our standard glazing is dual pane: two panes of glass with Low-E coatings and argon insulating gas. We offer variations to help meet climate and code requirements across the country, described in more detail on our glass page.

Any color. Any window or door. You name it. No matter what your inspiration for a custom window or door color, Marvin will match it. You get any color your heart desires, with your own personal custom color name and a 20-year warranty. See your Marvin dealer for details and ask about special pricing.

Multiple-Order Waveplates - One alternative to polishing or cleaving very thin plates is to use a practical thickness of a durable material such as crystalline quartz and obtain a high-order waveplate, for example, a 15.5 waveplate for a 1 mm thickness. Such a plate will behave exactly the same as a half-waveplate at the design wavelength. However, as the optical wavelength is changed, the retardation will change much more rapidly than it would for a true half-waveplate. The formula for this change is easily derived from the definition of Γ:

MKS Newport offers an outstanding variety of Waveplates, Half-Waveplates and Quarter-Waveplates to provide a wide range of solutions to customer needs. Please contact us if you have any questions or special requests.

The most commonly used waveplates are the half-waveplate (Γ = π) and the quarter-waveplate (Γ = π/2). Half-waveplates can be used to rotate the plane of linearly polarized light as shown in Figure 3.

Ms.Cici

Ms.Cici

8618319014500

8618319014500