An achromatic X-ray lens - achromat lens

If a gel fails prematurely in a fixture, first check that the fixture has the voltage and wattage lamp for which it is designed.

Magnifyingglass uses in laboratory

A color filter blocks passage of some portion of the visible output from any light source or light reflector by absorbing and transmitting selectively. For example, a primary red filter will allow red-associated light frequencies to pass, and block all others. Of the radiant energy which is blocked, by far the largest part is absorbed by the filter as heat.

Rosco uses both polyester and polycarbonate plastics in their popular Roscolux range. Approximately 65% of the line is made from polycarbonate plastic. The remaining 35% are either light tint colors or colors that cannot yet be reproduced in the polycarbonate plastic and they are made from polyester. Polyester can be expected to resist deformation when raised to temperatures as high as 260° to 290° Fahrenheit (126° to 143°C).

To study the effects of filters, try sets of gels (or two gels side-by-side) in a Carousel projector. Swatches can be mounted conveniently in 2" by 2" slide mounts.

The bases were at one time dyed fabrics like silk, or gelatin derived from animal by-products. Polymer (or plastic) bases in current use include acetates, vinyls, polyesters and polycarbonates, in the approximate order of their heat stability; acetates and vinyls have the lowest melt temperatures, polycarbonates the highest.

MagnifyingGlass price

A magnifier is any positive lens with a focal length of less than 250 mm. The approximate magnification M provided by the lens is calculated by dividing its focal length into 250. For example, a 50-mm lens will provide a magnification of M = 250/50 = 5×. This formula applies to the case where the object is placed at the focal plane of the magnifier lens and the virtual image being viewed appears at infinity. This condition allows comfortable viewing with the relaxed eye. If the object is moved just a bit closer to the lens so that the image is formed at the closest possible viewing point, a distance of 250 mm from the eye, then the magnification factor will be increased by an additional 1×.

A real-world example will be helpful in demonstrating how a simple magnifier can actually improve our ability to visually resolve details. The back of a five-dollar bill contains a picture of the Lincoln Memorial. In the stone work above the twelve columns on the memorial, the names of several states have been engraved. Owing to the size (about 0.5 mm) and low contrast of the letters, the names of the states cannot be resolved with the naked eye. However, when this part of the image is examined using a 5× magnifier, the names of the states are easily readable.

The transmission of the particular dye used has a dramatic influence on the degree of heat a filter can withstand. Dark greens, for instance, absorb the rich output of reds in incandescent light and are thus subjected to heat damage much faster than dark reds, independent of the plastic base used.

The average young and healthy human eye is capable of focusing from infinity, down to a minimum distance of about 250 mm (10 in.). This same average eye is capable of resolving a repeating high-contrast target with equal width black and white lines when each line subtends an angle of 1 arcmin or more. Most often, when viewing an object it is our intent to distinguish as much detail on that object as is possible. To that end we first bring the object as close as possible to the eye. When that closest distance is 250 mm, the smallest resolved element on the object—a detail that subtends an angle of one minute (tanθ = 0.0003)—will have an actual size of 250 mm × 0.0003 mm = 0.075 mm. If this resolved element is a part of a repeating pattern of equal-thickness parallel black and white lines, then each cycle (one black plus one white line) will have a thickness of 0.150 mm. The frequency of this finest resolvable pattern will then be 1/0.150 mm = 6.67 cycles/mm.

All color manufacturing is subject to subtle variations in colorant chemistry from one product to the next. Whether it be printed wallpaper, house paint, artist’s oils or color filters—the finished product does change over considerable time spans. In filter production, new color dyes are added, basic dyes are changed or discontinued, and more heat-resistant dye formulations are adopted. The alert light designer, if he is active in his profession, exchanges his gel sample book with the manufacturer about once every three years. At Rosco, it is the policy to make an exchange at any time on request.

Two or more layers of lighter (higher value) filters may be used to produce a darker or more intensely colored light beam. However, the combination will be significantly less efficient than a single filter.

The filter contains light refracting elements, normally dyes, which are suspended in (or coated on) a relatively transparent base. The dyes are organic, primarily aniline colorants which undergo a complex change in the manufacturing process and actually become part of the base that carries them. Integral dyes must be sufficiently heat stable to survive the high processing temperatures.

Keep in mind that an audience never looks at the filter itself. Instead, it sees only the filter’s effect on the transmitted light. Side-by-side comparisons of filters themselves is convenient, but the best indicator of a filter’s effect is the appearance of surfaces lit by the filtered light. When you have no surface colors in particular to light, use your arm or hand to check the effect on skin tones.

Magnifyingglass definition physics

All plastic filters will ultimately be degraded by heat. As thermoplastics, they change dimensionally as the temperature rises at the color frame, approaching the melting point of the plastic. With extreme heats, the distortion sometimes brings the filter closer to the heat source, thus accelerating the melting and shortening its effective life. By holding the filter firmly at four or more points around the frame opening, the plastic will retain its shape through slightly higher temperatures. Ideally the filter should be held all around the frame perimeter for best retention and longest life.

While these aberration curves do give some indication of lens performance, a more useful tool would be one that yields an absolute value for lens resolution when used with the eye. This is best accomplished by computing MTF for each lens. The MTF curve plots the modulation (contrast) of the image formed by the lens as a function of image frequency. Figure 8.4 illustrates the concept of modulation and contrast, showing how they might be measured and calculated. Assuming a pattern of parallel black and white stripes with a range of frequencies, the modulation or contrast of the object (or image) is arrived at by comparing the maximum and minimum brightness values as follows:

10 uses ofmagnifyingglass

Your request is important to us. We will respond as soon as possible during regular business hours.Need help right away? Check out our frequently asked questions page here: FAQs

There are three ways to mate color with the filter base: (1) it can be coated on top of the base; (2) it can be diffused into the surface of the base material; or (3) it can be dispersed completely through the base. Coating one surface of the base is easier technically. A coated filter can be recognized by scratching the surface coating with a sharp object. The color scrapes off, leaving a faulty filter.

The Heat Shield product is a clear film. The resin of this plastic can take a continuous operating temperature nearly twice that of either the polyester or polycarbonate plastic. It protects the color filter by blocking the convected heat, however, it does not block the infrared energy.

Magnifying lensconcave or convex

Doubtless, even better filter manufacturing processes and materials are possible. The effort to improve Rosco products is a continuing program. Currently an average of ten new dyes are tested each week and runs of experimental resins are produced and tested long before the materials are offered on the market. Such constant concern for product improvement has contributed to Rosco’s domination of color filter manufacturing technology.

Magnifyingglass uses

Of the resins available today, polycarbonate plastic offers the best combination of properties for a color filter base. It is extremely heat-stable and does not deform until temperatures in the 300° to 325°F (149° to 163°C) range are reached. It is very tough when formed into an extruded film. However, it is a most difficult material to process so that consistent thickness and dye dispersion are achieved. It requires a special combination of dye technology and plastics experience to produce this type of color medium from this difficult resin. These filters are the most heat resistant type manufactured today. Rosco's Polycarbonate filters are inherently self-extinguishing.

Magnifyingglass drawing

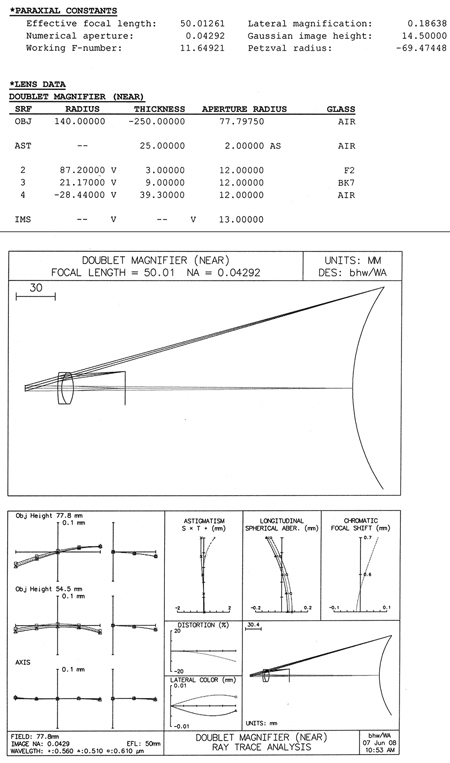

These magnification formulas relate to a thin lens with that lens placed very close to the eye, both of which are hypothetical assumptions. Due to the ready availability of optical design software, it has become a relatively simple matter to analyze a real lens and to generate its actual magnification numbers. Let's assume a simple cemented doublet with a focal length of 50 mm and a diameter of 24 mm. We will further assume that we are using this lens to examine a coin that is 26 mm in diameter, as is shown in Fig. 8.1. When set for an infinite image distance, ray-trace analysis indicates that the tangent of the half angle to the edge of the image will be 0.265. Without the lens, if we look at the coin held at a distance of 250 mm, it will subtend a half angle whose tangent is 13/250 = 0.052. Comparing the two half angles will give us the effective magnification of 0.265/0.052 = 5.1×. Next, if we reduce the distance from the lens to the object by about 9.4 mm, we will find that the image is formed at a point 250 mm from the eye. At that distance, the half angle to the edge of the image will now become 0.281. For this near point example the magnification will become 0.281/0.052 = 5.4×. These results represent real and accurate magnification numbers for this specific lens, including any residual distortion that may be present.

A typical 5× loupe, or magnifier, will most often take the form of a cemented doublet, or a symmetrical Hastings cemented triplet lens. We will evaluate typical designs in both of these forms to identify any significant performance differences between the two. The 50-mm doublet that was shown in Fig. 8.1 is more completely described, and its performance characteristics are shown in Fig. 8.2. Similar information has been generated for a second 5× loupe in the form of a Hastings triplet (see Fig. 8.3).

If your fixture operates with excessive temperatures at the filter frame (most easily recognized a when filters sag in the frame), try fastening the filter down all around with double-faced polyester tape. Or drill addition holes in the filter frame and use brass paper fasteners at four or more points.

In the lens pictures in both figures the final image surface is the convex curved surface on the far right. The field curvature shown there (about 0.5 D) has been introduced for evaluation purposes. The aberration curves shown indicate that, while both lenses are very well corrected on axis, in this particular case the doublet actually appears to offer a slight advantage in off-axis performance over the Hastings triplet.

The subject of trade-offs tends to come up frequently when discussing various optical situations. It will be noted that, when viewing with the naked eye, we can easily determine that it is a US five-dollar bill, containing numerous details including the picture of the Lincoln Memorial. When viewed using the 5× magnifier, we can now determine that the state name on the far left is Delaware, but the fact that this is indeed an entire piece of paper currency becomes a matter of speculation. In optical terms, the observed field of view has been reduced from around 140 deg with the naked eye to about 40 deg with the magnifier. We have traded a large field of view for finer detail within a smaller field.

In any color filter, the dye eventually migrates from the hottest area. The rate at which the filter fades is a function of the dye employed and the depth of penetration by the dye into the base material. When simply coated on the surface, a dye will sublimate from the base into the air as a gas more easily than a dye which is uniformly locked by chemistry into the surface of the material. The greatest stability is achieved when the dye is dispersed uniformly through an extruded plastic base.

A magnifying glass (or loupe, from Old French, meaning an imperfect gem), is the simplest of optical instruments intended for the enhancement of visual capability. It is a device frequently associated with jewelers, usually taking the form of a simple positive lens. In use, the magnifier is held close to the eye, while the object to be viewed is brought to the focal point of the lens.

The illustration (Fig. 2) shows a typical stress pattern seen on a polyester filter. Polycarbonate material will show the pattern less, but similar stresses will be present in all types of plastic filters when heated.

Define magnifying lensin physics

The inside surfaces between the two layers will form an insulating barrier, and become hotter than the outside surfaces. The net result may not be desirable when the filter is used in a hotter fixture. Instead of sandwiching the two filters try Rosco’s Dual Filter Frame holder (Fig. 3).

For MTF analysis, the object brightness from line to line is assumed to vary as a sine function. The modulation of a high contrast object is assumed to be 1.0 at all frequencies. At the image of that object, when the frequency is very low, the modulation will be close to 1.0. As the frequency at the image increases, the modulation of the image will decrease, i.e., the image will appear to be smeared as a result of diffraction effects and residual aberrations of the lens under test. Figure 8.5 shows the MTF curves for the two magnifier designs under consideration. That figure also contains a companion curve that is labeled "visual response curve." This curve indicates, for a typical visual system (eye) plus a 5.3× magnifier, the amount of image modulation that is required in order to visually resolve the corresponding frequency. While this typical visual response curve cannot be taken as absolute, it is valid for the relative comparison of two similar systems or designs. The point where this visual response curve crosses the MTF curve of the optics represents the maximum resolution possible when viewing a high contrast target with the 5.3× magnifier. Figure 8.5 shows that while both lenses are the same for on-axis imagery, for the off-axis case, the doublet will allow the viewer to resolve about 33 cycles/mm, while the triplet's off-axis resolution will fall to about 25 cycles/mm. axial travel per diopter = 282 / 1000 = 0.784 mm/D. Moving the eyepiece closer to the image being viewed will result in a diverging output beam, which corresponds to a negative diopter setting. To achieve the +3 to —4 diopter focus range, the 28-mm eyepiece will have to be moved from —3.2 to +2.4 mm relative to the infinity, or zero-diopter setting. The eyepiece focus design should provide a smooth, firm mechanism and an easily read scale indicating the approximate eyepiece diopter setting.

Check the general alignment and assembly of the fixture. Often a filter may be placed at a beam cross-over and a small focusing adjustment or movement of the filter will solve the problem.

If you have any specific questions regarding filter applications, we invite your inquiry at the Rosco office nearest you.

Special formulations of clear glass and plastics exist which may be employed specifically to absorb or reflect infrared emissions (heat) before they reach the color filter. Rosco’s Heat Shield is such filter. The Heat Shield must be placed so that there is an air space on both sides of the filter to allow an escape for the convected heat. Do not sandwich two filters together in one holder, this will cause premature failure of the filter. We recommend the use of the Rosco Dual Frame holder when using two filters in a fixture. See Fig. 3.

Ms.Cici

Ms.Cici

8618319014500

8618319014500