A Small-Divergence-Angle Orbital Angular Momentum ... - divergence angle

Meanwhile, an objective lens for which the degree of chromatic aberration correction to the secondary spectrum (g ray) is set to medium between Achromat and Apochromat is known as Semiapochromat (or Flulorite).

Microscope objective lensnames

An objective lens is the most important optical unit that determines the basic performance/function of an optical microscope To provide an optical performance/function optimal for various needs and applications (i.e. the most important performance/function for an optical microscope), a wide variety of objective lenses are available according to the purpose.

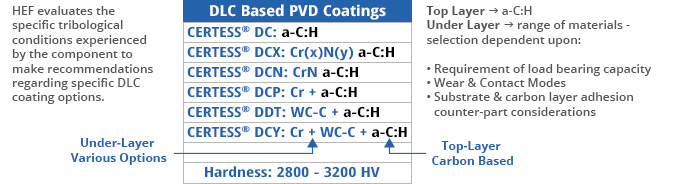

As shown below, DLC coatings can be deposited using a diverse range of technologies and alloyed with elements such as hydrogen and metals such as chromium. These constituent elements and deposition technique can have a significant impact on the properties and structure of the DLC coating.

Microscope objective lensfunction

Liquid nitriding is a subcritical surface enhancement process with one of the longest track records of success of any case hardening technology.

Microscope objective lensprice

Photography or image pickup with a video camera has been common in microscopy and thus a clear, sharp image over the entire field of view is increasingly required. Consequently, Plan objective lenses corrected satisfactorily for field curvature aberration are being used as the mainstream. To correct for field curvature aberration, optical design is performed so that Petzval sum becomes 0. However, this aberration correction is more difficult especially for higher-magnification objectives. (This correction is difficult to be compatible with other aberration corrections) An objective lens in which such correction is made features in general powerful concave optical components in the front-end lens group and powerful concave ones in the back-end group.

An optical microscope is used with multiple objectives attached to a part called revolving nosepiece. Commonly, multiple combined objectives with a different magnification are attached to this revolving nosepiece so as to smoothly change magnification from low to high only by revolving the nosepiece. Consequently, a common combination lineup is comprised from among objectives of low magnification (5x, 10x), intermediate magnification (20x, 50x), and high magnification (100x). To obtain a high resolving power particularly at high magnification among these objectives, an immersion objective for observation with a dedicated liquid with a high refractive index such as immersion oil or water charged between the lens end and a specimen is available. Ultra low magnification (1.25x, 2.5x) and ultra high magnification (150x) objectives are also available for the special use.

Axial chromatic aberration correction is divided into three levels of achromat, semiapochromat (fluorite), and apochromat according to the degree of correction. The objective lineup is divided into the popular class to high class with a gradual difference in price. An objective lens for which axial chromatic aberration correction for two colors of C ray (red: 656,3nm) and F ray (blue: 486.1nm) has been made is known as Achromat or achromatic objective. In the case of Achromat, a ray except for the above two colors (generally violet g-ray: 435.8nm) comes into focus on a plane away from the focal plane. This g ray is called a secondary spectrum. An objective lens for which chromatic aberration up to this secondary spectrum has satisfactorily been corrected is known as Apochromat or apochromatic objective. In other words, Apochromat is an objective for which the axial chromatic aberration of three colors (C, F, and g rays) has been corrected. The following figure shows the difference in chromatic aberration correction between Achromat and Apochromat by using the wavefront aberration. This figure proves that Apochromat is corrected for chromatic aberration in wider wavelength range than Achromat is.

Microscope objective lenssize

Microscope objective lenslabeled

In the optical design of microscope objectives, commonly the larger is an N.A. and the higher is a magnification, the more difficult to correct the axial chromatic aberration of a secondary spectrum. In addition to axis chromatic aberration, various aberrations and sine condition must be sufficiently corrected and therefore the correction of the secondary spectrum is far more difficult to be implemented. As the result, a higher-magnification apochromatic objective requires more pieces of lenses for aberration correction. Some objectives consist of more than 15 pieces of lenses. To correct the secondary spectrum satisfactorily, it is effective to use "anomalous dispersion glass" with less chromatic dispersion up to the secondary spectrum for the powerful convex lens among constituting lenses. The typical material of this anomalous dispersion glass is fluorite (CaF2) and has been adopted for apochromatic objectives since a long time ago, irrespective of imperfection in workability. Recently, optical glass with a property very close to the anomalous dispersion of fluorite has been developed and is being used as the mainstream in place of fluorite.

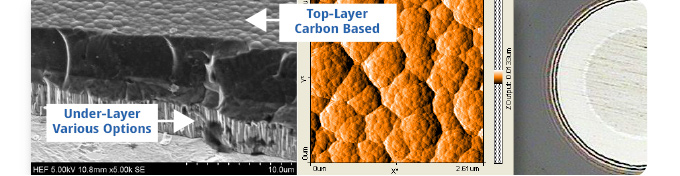

PVD coatings involve the deposition of thin (2-10 microns; 0.0001" – 0.0004") films on the surface of tools and components.

Terms Of Use | Privacy Notice | Cookies | Cookie Settings | About Us | Careers | Careers | Sitemap

HEF bushings are recognized worldwide for their excellent frictional and anti-seizure properties, and ability to withstand high loads.

Microscope objective lensmagnification

The properties of DLC coatings in terms of hardness; coefficient of friction; roughness; adhesion level; load carrying capacity; resistance to humidity influenced degradation; fatigue tolerance, etc. can be tailored over a wide range depending upon deposition parameters, deposition technology and the combination of materials constituting the coating. Some of the more common commercial variants of WCC and DLC coatings from HEF are shown below.

In order to meet the diverse operating conditions encountered by engineered components used for automotive and other generic industrial applications, HEF has developed a family of diamond-like-carbon DLC coatings. These coatings usually include several layers of different materials such as Cr, CrN, W, WC-C, Si with a top layer of amorphous carbon, with hydrogen. The selection of the under-layer is based upon several factors such as: adhesion requirements, wear mode and contact mode, friction regimes encountered during operation, load carrying capacity, and other metallurgical considerations. These coatings have a unique combination of high hardness and low friction coefficient, compared to conventional PVD coating (TiN, CrN, ALTiN etc) and soft coatings (such as solid lubricants like Molybdenum di-sulfide).

The purposes of optical microscopes are broadly classified into two; "biological-use" and "industrial-use". Using this classification method, objective lenses are classified into "biological-use" objectives and "industrial-use" objectives. A common specimen in a biological use is fixed in place on the slide glass, sealing it with the cover glass from top. Since a biological-use objective lens is used for observation through this cover glass, optical design is performed in consideration of the cover glass thickness (commonly 0.17mm). Meanwhile, in an industrial use a specimen such as a metallography specimen, semiconductor wafer, and an electronic component is usually observed with nothing covered on it. An industrial-use objective lens is optically designed so as to be optimal for observation without any cover glass between the lens end and a specimen.

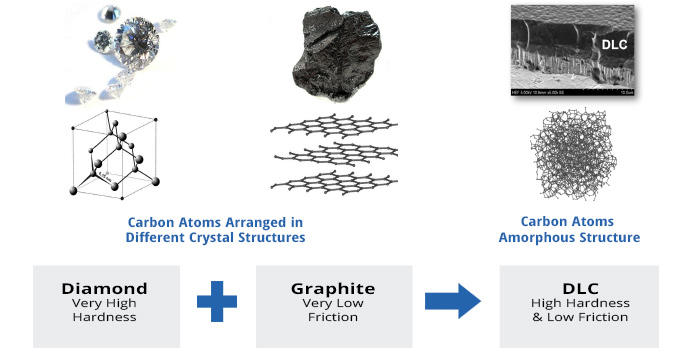

In recent years, a new generation of PVD + PACVD (plasma-assisted CVD) coatings has gained widespread commercial success. As is well known, carbon can exist in three allotropic forms. Carbon, in a diamond crystal structure, is one of the hardest know materials. Carbon, in a graphite crystal structure, is very soft and lubricous. Carbon-based coatings, referred to as Diamond-like-Carbon (DLC) coatings, combine these two different properties of diamond and graphite - hence possess high hardness levels - in the range of conventional tribological PVD coatings (1500 - 3200 HV), coupled with a coefficient of friction which is 200-500% lower than that of conventional PVD coatings.

Microscope objective lenstypes

Microscope objective lensreplacement

Other DLC coatings can be customized based upon the unique combination of wear mode, contact mode and the friction regime under which the component in operating.

Objective lenses are roughly classified basically according to the intended purpose, microscopy method, magnification, and performance (aberration correction). Classification according to the concept of aberration correction among those items is a characteristic way of classification of microscope objectives.

Besides this unique combination of properties, this new generation of coatings has high load-bearing capabilities, making them an ideal choice for improving the performance of engineered components. Moreover, these coatings are usually bio-compatible and hence suitable for food-contact and medical applications. The lubricious surface also has good release properties, making these coatings a good choice for plastic processing applications.

A variety of microscopy methods have been developed for optical microscopes according to intended purposes. The dedicated objective lenses to each microscopy method have been developed and are classified according to such a method. For example, "reflected darkfield objective (a circular-zone light path is applied to the periphery of an inner lens)", "Differential Interference Contrast (DIC) objective (the combination of optical properties with a DIC( Nomarski)prism is optimized by reducing lens distortions)", "fluorescence objective (the transmittance in the near-ultraviolet region is improved)", "polarization objective (lens distortions are drastically reduced)", and "phase difference objective (a phase plate is built in) are available.

Terms Of Use | Privacy Notice | Cookies | Cookie Settings | About Us | Imprint | Careers | Careers | Sitemap

Ms.Cici

Ms.Cici

8618319014500

8618319014500