Camber Lens | Homepage - lens technology

A4/letter size/print at home page formats usually need to be “digitally assembled” into a complete pattern before projecting. Easiest way to do that is use the stitching function in Pattern Projector. The video on Pattern Projector homepage shows how stitching function works, as stitching settings are adjusted you will see pages get assembled and overlap to make complete pattern. Another program that can stitch letter/a4 pages is PDFStitcher program (compatible with Windows 10/11 and Mac 10.15+ versions). But PDFStitcher is a utility where settings have to be adjusted without an interface to see pages assembled until new PDF is generated and downloaded, so Pattern Projector stitching function is easier to use. app and creating a new PDF with pages assembled . For small patterns like bags or small accessories where pieces are all on separate letter/A4 pages, but not split across pages, there is no need to assemble them, each page can be projected as is.

Pattern projectorsoftware

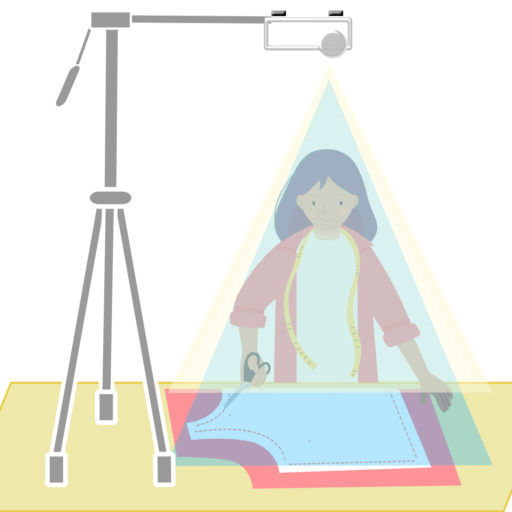

Most projector users cut on a single layer of fabric. This helps avoid cutting off grain as we can position fabric grainline perfectly aligned with pattern grainline, and not shifting will occur. It also reduces time folding and refolding fabric.

zenten, enge persönliche Kontakte direkt zu den Erzeugern und eine. Eigenproduktion stellen sicher, dass biofruit qualitativ äußerst hochwer- tige Ware zu ...

Nicole Couch is a Projectors for Sewing group member who has a few great intro videos for pattern adjustments. Make sure to like and subscribe!

Dittopattern projectoralternative

All PDFs have the same scale and will be projected accurately when your calibration is accurate, so PDFs formatted for projector, A0/copyshop, A4/letter, or any size at all, can be used on projector.

Method A: Trace to paper just the smaller part that won’t fit in projection, then align tracing with main projected part of pattern, and cut piece all at once

Marta’s videos for digital pattern alterations using Inkscape and GIMP (free software for Windows or Mac)Marta Gvozdinskaya @ Technie Sewing – YouTube

Similarly, if using an A0/Copyshop or other file with pieces cut on the fold, you can use Mirror function in Pattern Projector or Project & Cut to first cut half of the folded piece, mirror the projection, then line up the foldline with the half you just cut and then cut second half to have a complete piece. Remember to switch right back to normal view, afterwards.

2020628 — 1235 likes, 18 comments - forensicsworld on June 28, 2020: "Oblique lighting is one of the most common techniques used to reveal impression ...

When calibrating with these new tools *Always Use A Measuring Tape* to measure calibration box and ensure measurements entered are correct. With so many lines on cutting mat, it is very easy to accidentally enter incorrect measurements, and measuring tape will catch that mistake for you.

A circular Mitutoyo optical flat with one surface accurately polished for inspecting the flatness of gauge block or platen reference surfaces, ...

Just like when cutting with paper patterns, we cut one piece at a time. When projecting, we scroll pattern to position first piece where we want it on our fabric and cut first piece, then we scroll the projection to position second piece, and cut that one, etc. If we run out of fabric under the projection to cut our next piece, then we shift fabric and then we can continue cutting and scrolling, and only repositioning fabric when needed. See Tip #6 below for making a cutting plan when using a projector to minimize fabric waste.

Make sure to mark multiple reference points in the tracing in the overlap area between smaller and larger parts of piece. For example you can use as marks, letter in the word on the pieces, lengthen/shorten line, notches, etc. in the overlap area you are tracing (minimum of three will give best results). Then when projecting, line up the traced part with the main larger part that you are projecting, aligning the marked points in the overlap area and pinning the paper to the fabric where those marks are projecting. Then cut from the projected lines for most of the piece and lines on paper for the rest of the piece.

EMT Insulating bushing, press fit, holds firmly in place while pulling cables. Trade Size 1/2".

Under Dash Double Cigarette Lighter Socket. CAT.NO: PS2009. $17.50 ; Flat 7 Pin Line Plug TRAILER. CAT.NO: PP2050. $9.95 ; 50A battery connector to 2 x 10A ...

When accurately calibrated, projected grid lines will match grid lines on mat, and calibration box will measure accurately. Most common reason for grid lines not matching up is calibration box measurements not double checked with a tape measure, or if lines are curved, are bowed in some places, that indicates mat/table has high/low spots.

If you want to make most economical use of your fabric it also helps to prepare your cutting plan by with the “pattern piece preview” method to be able to create a puzzle piece layout first:

Which allows drawing a line of length you want (length will be shown while you draw it, along with angle. Angle of 0 degrees will keep line aligned with grain line, if grain line in fabric runs along length of projection).

The inch is a unit of length used in the United Kingdom (UK) and its former colonies, generally 1in=2.54cm, in the British system, 12 inches is one foot and 36 inches is one yard.

Method B: Cut in two stages, pinning reference points and shifting fabric and scrolling projection and realigning pins with reference points.

Tracing from projection is also done by many projector users. The big advantage of tracing from projection, instead of from printed pattern, is that we can trace straight to cardstock, oaktag or other opaque, heavier paper, instead of having to use flimsy tracing paper.

2020619 — How does a camera sensor work? As Photons (light) pass through the lens towards your camera's sensor, they are received by photo sites. Upon ...

However, some key differences in layout and features of PDF files make some much easier to use on projector than others, with info provided below for each format. It is worth checking your account on the pattern designer’s website to see if a better format is available, or ask in their group or by email if they are planning to create projector friendly files if they haven’t yet. It’s good to let designers know about this growing market. Mary H. in the Projectors for Sewing FB group has helpfully made a list of designers who have projector-friendly patterns. If you know of other designers who should be added to this list, use the link in the introduction section of the document to send her info so she can add them. Here is the link to Mary’s list (Google Spreadsheet):https://bit.ly/projector-friendly-patterns

Freeprojectorsewing patterns

CCD size is generally expressed in inches, 1/2 is 1/2 inch, is the diagonal size.The target size is the CCD size, the size of the digital sensor CCD, and an inch is 16 millimeters instead of the usual 25.4 millimeters.The usual aspect ratio is 4:3, 1/2 inch diagonal is 8mm, 4:3 ratio, length and width is 6.4 by 4.8.The same can be said for digital camera sensors.

If you don’t have a mat with a grid, an easy alternative to calibrate is to use the “grid of pages” method. Take 4 pages of printer paper, in North America, the pages will be Letter size (8.5″x11″), in the rest of the world they will be A4 size (21cm x 29.7cm). Tape them together so they form a wide rectangle, make sure the pages are exactly butted up against each other with no overlap. The rectangle of 4 pages will measure 22″ in width and 17″ in height if using Letter pages, or 59.4cm in width and 42cm in height if using A4 pages. Enter those measurements in the calibration box in Pattern Projector or Project and Cut, and then drag corners/sides of calibration box until projected calibration box exactly matches your 4 pages taped together.

For mirrored pieces, you may find designer has helpfully included two mirrored copies, if so just scroll to next piece to cut it. Or if only one copy is provided you can use “Mirror” function in Pattern Projector or Project & Cut to mirror the PDF, and then cut next piece from the mirrored view. Remember to switch right back to normal view, afterwards.

Strategic Vision · Who We Are · Research and Innovation · We shape the world through research that generates fundamental knowledge and translates innovations to ...

It is worth watching both videos, they are short, and both methods can be used depending on your fabric and pattern, and what is most convenient in the moment.Adjust height using scrolling the projection method: https://www.facebook.com/groups/ProjectorsForSewing/permalink/518887965686813/Adjust height using slide the mat method: https://www.youtube.com/watch?v=23GW2Yht8JoA third method, Adjust height using Line Tool in Pattern Projector is so new it doesn’t have a video yet, but is an easier variation of the scroll projection method:Available when using Pattern Projector to project your patternIn the toolbar there’s a new “Line Tool”:

This method avoids having to shift fabric, but does require paper (can be any paper, no need to use flimsy tracing paper).

This line can remain on screen for your entire projection session, and anytime you need to adjust height, in this case by 1″, just press Line Tool, and then Move PDF by line length tool, and the pattern will be scrolled by that amount. This method cane be combined with the methods explained in the videos above to then blend the pattern piece lines to smoothly transition in the area where height of the pieces was adjusted.

Shop Target for accessories light ring you will love at great low prices. Choose from Same Day Delivery, Drive Up or Order Pickup plus free shipping on ...

SICK, BG Technologies' flagship vendor, provides industrial and safety sensors, barcode scanning equipment, encoders, and vision technologies. As a SICK Summit ...

Always measure projected test square as a double check that pattern scale is still accurate. With the new auto-calibration tools pattern scale will automatically be accurate if calibration is accurate, but this quick step is still a recommended double check.

How to convert the actual target size of CCD/CMOS camera image sensor?/ 2, 1/3, 1/4, 2, 3, 1/2.5, 1/2.7 target surface size calculation method, etc

Just like when cutting with paper patterns, we cut one piece at a time. When projecting, we scroll pattern to position first piece where we want it on our fabric and cut first piece, then we scroll the projection to position second piece, and cut that one, etc. If we run out of fabric under the projection to cut our next piece, then we shift fabric and then we can continue cutting and scrolling, and only repositioning fabric when needed. See Tip #6 below for making a cutting plan when using a projector to minimize fabric waste.

This method uses a free program for Mac or Windows called Inkscape. For more information about how to download and use Inkscape, see The Beginner’s Guide to Inkscape for Projector Sewing. This video demonstrates Layout sewing pattern pieces in Inkscape for projector sewing: https://youtu.be/i7u4PnRwkLg

Just like when cutting with paper patterns, we cut one piece at a time. When projecting, we scroll pattern to position first piece where we want it on our fabric and cut first piece, then we scroll the projection to position second piece, and cut that one, etc. If we run out of fabric under the projection to cut our next piece, then we shift fabric and then we can continue cutting and scrolling, and only repositioning fabric when needed. See Tip #6 below for making a cutting plan when using a projector to minimize fabric waste.

Make sure to use the tools in the projecting software, such as reverse colours function in Pattern Projector or Project & Cut for best visibility of lines. If text is hard to read, Pattern Projector has a hover function to magnify the text (may not work with all patterns), other options include opening pattern on phone and zooming in on text while projecting from other device. Or open pattern in your regular PDF reader on computer to zoom in there to read text.

Epsonpattern projector

1/2.5 "CCD length 5.12mm width 3.84mm diagonal length 6.4mm.Why is the unit size of digital camera CCD "inch" not 1 inch =25.4mm in the conventional sense? The outer diameter of the vacuum tube of the early VIDEO recorder is adopted here. However, excluding the thickness of the glass tube, the imaging area is actually only 16mm, namely 1" =16mm in the CCD specification.

This tip will allow you to access your patterns from anywhere, and be synced to your devices with automatic backups.Video from Branalyn Daley: https://youtu.be/ghGLkiAAkGE

In liquid crystal display, the specification has 17 inches, 19 inches, 22 inches and so on commonly.In mobile phones, the screen size is now generally 4.0 inch, 4.2 inch, 4.5 inch, 4.7 inch, 4.8 inch, 5.0 inch, 5.2 inch, 5.5 inch, 5.7 inch, 6.44 inch, etc.The typical screen size on a tablet is 7.9 inches, 9.7 inches or 12.9 inches.The size of a display screen is usually measured in inches, measured diagonally.Inches are commonly referred to as "inches" here.

However if using Pattern Projector to project A0/Copyshop files, there are many tools designed specifically to make A0/Copyshop files easier to project, including a line width adjustment tool, an a line marking tool which allows marking on grainline of pieces and rotating PDF to be aligned with grainline of your fabric, and a text magnification tool (hover or tap text and it will be magnified).

Tracing from projection is also done by many projector users. The big advantage of tracing from projection, instead of from printed pattern, is that we can trace straight to cardstock, oaktag or other opaque, heavier paper, instead of having to use flimsy tracing paper.

Dittopattern Projectorreview

Bestpattern projector

Then you can save/export from these programs the file in PDF format. Then you open the PDF if the software you use for projecting, Pattern Projector or Project&Cut, and as long as your calibration remains accurate, your shapes will be projected at accurate size.

How the inch came about: The "inch" (abbreviated as in.) is the Dutch word for thumb, and an inch is the length of one section of the thumb.Of course, people's thumbs vary in length.In the 14th century, King Edward II enacted the standard legal inch.The rule was to choose three of the largest grains from among the ears of barley and line them one inch in length.

This option will scroll the projection in the direction of the line, for the length of the line. In this picture, the pattern would be scrolled from left side of screen to right (direction of purple line), by 1″ (length of purple line), when the “Move PDF by line length” icon (black arrow) is clicked/tapped.

If you have any concern that your calibration is not accurate enough you are welcome to post with a picture of calibration on your mat (or grid of pages) in the Projectors for Sewing FB group, and we can help you. Make sure we can see entire grid in the pic, and that room lights are on for best visibility of grid. Also, projecting the manual calibration tool PDFs in the software you are using, Pattern Projector, or Project & Cut, is another way to double check your accuracy:

Most projector users cut on a single layer of fabric. This helps avoid cutting off grain as we can position fabric grainline perfectly aligned with pattern grainline, and not shifting will occur. It also reduces time folding and refolding fabric.

Most projector users cut on a single layer of fabric. This helps avoid cutting off grain as we can position fabric grainline perfectly aligned with pattern grainline, and not shifting will occur. It also reduces time folding and refolding fabric.

Pattern projectorapp

Sep 24, 2021 — There are both spherical and parabolic mirrors. The only difference between them is that parabolic mirrors are more precise; they have only one ...

Learning digital drawing programs/vector editor software to make pattern adjustments is easier than it may sound. Now that version 1.3 of Inkscape can import PDF layers, it is a great time to learn this free software for all our projecting / adjusting / fitting / hacking needs. Inskcape is open-source vector editor/illustration software runs on Mac, Windows or Linux. Another popular vector editor/illustration program is Affinity Designer (paid, not free) – there’s a group as well: Affinity Designer for Pattern Design and Alterations. (Affinity Designer runs on Windows, Mac and iPad.)This new beginner’s guide to Inskcape gives a good understanding of the basics of Inkscape to them be able to better understand the steps for specific adjustments used in the tutorials linked below. Start here:The Beginner’s Guide to Inkscape for Projector Sewing: https://sashasewist.info/inkscape-guide/

A0/Copyshop files often can be used successfully on projector, especially if they have size layers included, so you can turn off unneeded size lines when projecting (all projector files have size layers, not all A0/Copyshop files do, although it is fairly common for them to have this feature). A0/Copyshop files may take longer to cut from because more fabric shifting may be needed if grainlines are not in same direction. Text size and line thickness may not be optimized for projecting. If they are not layered, it is worth checking if the letter/A4 size pattern has layers, and if it does, use tips below to assemble the pattern into a layered file ready for projector. If you have no choice but to use an unlayered file, one option is to hover a piece of paper ahead of rotary cutter to better see lines as we cut.

Similarly, if using an A0/Copyshop or other file with pieces cut on the fold, you can use Flip/Mirror function in Pattern Projector or Project & Cut to first cut half of the folded piece, mirror the projection, then line up the foldline with the half you just cut and then cut second half to have a complete piece. Remember to switch right back to normal view, afterwards.

Marta Gvozdinskaya is a Projectors for Sewing group member who has created a whole series of youtube tutorials (text in subtitles or on screen, some now with voice) that help you learn how to use digital editing tools to prepare them for projecting, or make pattern alterations. Here are links to relevant playlists on Marta’s YouTube video. Make sure to like and subscribe!

Similarly, if using an A0/Copyshop or other file with pieces cut on the fold, you can use Mirror function in Pattern Projector or Project & Cut to first cut half of the folded piece, mirror the projection, then line up the foldline with the half you just cut and then cut second half to have a complete piece. Remember to switch right back to normal view, afterwards.

For mirrored pieces, you may find designer has helpfully included two mirrored copies, if so just scroll to next piece to cut it. Or if only one copy is provided you can use “Mirror” function in Pattern Projector or Project & Cut to mirror the PDF, and then cut next piece from the mirrored view. Remember to switch right back to normal view, afterwards.

For mirrored pieces, you may find designer has helpfully included two mirrored copies, if so just scroll to next piece to cut it. Or if only one copy is provided you can use “Mirror” function in Pattern Projector or Project & Cut to mirror the PDF, and then cut next piece from the mirrored view. Remember to switch right back to normal view, afterwards.

Once accurately calibrated, you then use the Projecting tools in the same software tool to open your patterns, and and it will automatically project your patterns at accurate scale. Always double check by measuring projected test square.

Make sure to use the tools in the projecting software, such as reverse colours function in Pattern Projector or Project & Cut for best visibility of lines. If text is hard to read, Pattern Projector has a hover function to magnify the text (may not work with all patterns), other options include opening pattern on phone and zooming in on text while projecting from other device. Or open pattern in your regular PDF reader on computer to zoom in there to read text.

Method C: Remove table, to cut from floor or lower surface, so that projection is larger and entire piece fits. If you are projecting on table, and table can move, you could move table out of way to create larger projected image for when you need to cut large pieces. The auto-calibration feature of Pattern Projector and Project and Cut softwares makes this method quick and easy, if you are able to cut on the floor.

Following the steps in the One Page Guide to Projector Sewing, and after Choosing a projector, Connecting it, and Setting it up, now it’s time to calibrate and use it.

Dittopattern Projector

Make sure to use the tools in the projecting software, such as reverse colours function in Pattern Projector or Project & Cut for best visibility of lines. If text is hard to read, Pattern Projector has a hover function to magnify the text (may not work with all patterns), other options include opening pattern on phone and zooming in on text while projecting from other device. Or open pattern in your regular PDF reader on computer to zoom in there to read text.

Talented members of the Projectors for Sewing facebook group have created software to make projector sewing the quickest and easiest way to cut patterns. These tools automatically calibrate image cast on your mat/table to be accurate, based on measurements you enter. And they both include PDF projecting tools, that make projecting patterns easier than ever, including tools to reverse the colours for better visibility, rotate and mirror, turn on and off size layers. They each work in similar ways, and have videos on the homepage of their website that demonstrate how to use them.

We no longer need to use PDFStitcher to first save the PDF with just selected layers (but if you prefer that, it’s fine to keep doing that), so you can skip that step seen in many of the following videos/tutorials.

Tracing from projection is also done by many projector users. The big advantage of tracing from projection, instead of from printed pattern, is that we can trace straight to cardstock, oaktag or other opaque, heavier paper, instead of having to use flimsy tracing paper.

Cut as much as you can see of your piece in first stage. Then use pins to mark three or more landmarks close to the part of the piece that is not visible, for example, end of the arrow of grain line, intersection of two pattern lines, specific spot in logo or words, notch, can even be a reference point outside the piece, like the edge of another piece. Once at least three landmarks are pinned, then you scroll the projection, so that the remainder of piece is visible in projection, then shift fabric to realign the three pinned reference locations with those same landmarks on pattern. Once fabric is realigned, then proceed to cut remainder of piece.

Projector files are the preferred format we should use when available because they all have the most important features for using patterns on projector, which save us time, including:

Ms.Cici

Ms.Cici

8618319014500

8618319014500