Bar/Linear Lights - bar of lights

You want to work with a machine shop that has state-of-the-art CNC machining equipment and highly qualified engineers who can manufacture parts accurately and accurately. Additionally, you should look for manufacturers that meet regulatory standards in the industry you want to serve.

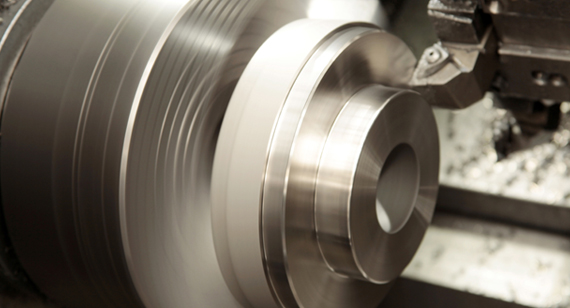

Our state-of-the-art multi-axis CNC machining milling equipment allows us to deliver mechanical optics to meet your exacting requirements and to make your designs within tolerances of ±0.0005" or better.

Aspheric optics and microstructured optics require very tight tolerances, which are provided by precision machining with diamond tools on ultra-precision machinery. In this way, both a high surface finish and tighter tolerances can be achieved. These ultra-precision manufacturing methods are used to obtain dimensional accuracy of optical components and their molds.

Choose products to compare anywhere you see 'Add to Compare' or 'Compare' options displayed. Compare All Close

Our state-of-the-art multi-axis CNC machining milling equipment allows us to deliver mechanical optics to meet your exacting requirements and to make your designs within tolerances of ±0.0005" or better.

CNC machines are used to manufacture housings, starter rings, and mirrors commonly found in lasers. Since CNC machine tools can process parts with a dimensional tolerance of 4 μm and a surface roughness Ra of 0.9 μm, it is the preferred processing technology for laser parts that require high dimensional accuracy and good surface finish.

Toss some slick, ticking style into your timepiece collection with G-Shock's Baby-G polarized clear and white watch! Hearkening back to the see-through ...

Our state-of-the-art multi-axis CNC machining milling equipment allows us to deliver mechanical optics to meet your exacting requirements and to make your designs within tolerances of ±0.0005" or better.

Our state-of-the-art multi-axis CNC machining milling equipment allows us to deliver mechanical optics to meet your exacting requirements and to make your designs within tolerances of ±0.0005" or better.

Since Methane is colorless and odorless, it is essential to use CH4 gas sensors to detect the gas concentrations in...

Application/Usage: Camera, Environmental Monitoring System, Video Management; Brand Name: 1866~Industrial Video & Control; Category: Video Surveillance.

The two most important factors in determining the quality of optical component manufacturing are the edge sharpness and roundness of the tool. Therefore, special tool geometries are incorporated, which include diamond micro end mills, ball end mills, and other tools for forming and turning.

Open your Camera app and point it steadily for 2-3 seconds towards the QR Code you want to scan. Whenever scanning is enabled, a notification will appear. If ...

... m walkthrough star archway, 7.5m dual light Merry Christmas, 7.5m walkthrough giant bauble, 6.7m MCR with Bee and Santa hat, 6.5m walkthrough stargate, 3.5m ...

Upload Your Files or Contact [email protected] to Get Instant Quote (Please attach 2D CAD drawings and 3D CAD models in any format including STEP, IGES, DWG, PDF, STL, ZIP, etc.).

4MINUTES. BL Recaps TV Series · Sweet Pleasures and Bitter Revelations in "4Minutes ...

Our state-of-the-art multi-axis CNC machining milling equipment allows us to deliver mechanical optics to meet your exacting requirements and to make your designs within tolerances of ±0.0005" or better.

Our state-of-the-art multi-axis CNC machining milling equipment allows us to deliver mechanical optics to meet your exacting requirements and to make your designs within tolerances of ±0.0005" or better.

With advanced CNC glass machining capabilities, Portland Precision can provide special optical machining processes to enhance the performance of your components. Lightweighting can greatly reduce the weight of your mecha-optics without compromising their structural integrity. Special features, such as slots, bevels, reverse drilling, and more, can be machined to provide you with parts that meet your design and performance specifications. Complex geometries can be reproduced with perfect precision and repeatability.

Combined with an ultra-precise vibration-free CNC machine, compact toolholders and suitable fixtures, a single-point natural diamond tool will scrape material from the workpiece appropriately and efficiently. Its extremely high level of sharpness ensures that extremely high but concentrated cutting forces are applied to the workpiece. This allows for minimal distortion elsewhere and perfect surface finish and forming accuracy.

Yes, opt-in. By checking this box, you agree to receive our newsletters, announcements, surveys and marketing offers in accordance with our privacy policy

Our state-of-the-art multi-axis CNC machining milling equipment allows us to deliver mechanical optics to meet your exacting requirements and to make your designs within tolerances of ±0.0005" or better.

Redtronic™ Mega-Flash™ Bullitt (BX) grille lamps are available both in single or multi colour models in 4 specific shapes and sizes.

Leitmotiv SOST nt. Leitmotiv. leitmotiv m. Esempi monolingue (non verificati dalla Redazione di PONS). tedesco. Er schrieb die Filmmusik in zwölf Wochen und ...

Lasers are essential equipment in a wide range of industries, especially in the medical sector for surgical procedures. Lasers are made up of several components, all of which must be manufactured with high precision and tight tolerances to achieve desired performance.

There is no doubt that CNC machine tools are ideal equipment for manufacturing various precision optical components. However, the success of your optics manufacturing project depends largely on the machine shop where you work.

Buy Dino-Lite Backlight Stage, For Digital Handheld Microscopes BL-CDW or other Microscope Accessories online from RS for next day delivery on your order ...

Our state-of-the-art multi-axis CNC machining milling equipment allows us to deliver mechanical optics to meet your exacting requirements and to make your designs within tolerances of ±0.0005" or better.

With the increasing complexity and complexity of optical components, the precision machining of optical components has entered a whole new era. For non-complex optics, the methods outlined in Spherical Optics play a key role. These methods include conventional grinding and polishing processes. However, due to low dimensional accuracy, complex optical components can only be partially fabricated by these conventional processes. These parts require the use of multi-axis machining and metrology.

Our state-of-the-art multi-axis CNC machining milling equipment allows us to deliver mechanical optics to meet your exacting requirements and to make your designs within tolerances of ±0.0005" or better.

The application of this processing method is considered when implementing rotationally symmetric optical elements. This is an efficient cutting process. High cutting speed and high surface finish of Ra<5nm can be achieved with this technology. The tools used in this technique account for the dimensional accuracy of the part in production. Expert engineers calculate tool radius and radius compensation values ââfor the entire toolpath during machining. For accuracy in the sub-micron range, the waviness of the tool needs to be controlled at a tool radius of 0.1 micron level

An Optical Beamsplitter is an optic or optical device that is used to split a beam of light in two. Newport offers a wide variety of Beamsplitters in various shapes. Circular beamsplitters, plate beamsplitters and cube beamsplitters can be purchased for polarizing or non polarizing beamsplitting applications. Newport offers both broadband and laser line cube beamsplitters. These beamsplitters are made from high grade glass materials with laser grade surface flatness and surface quality and have a tighter tolerance on the splitting ratio. High damage threshold coating and quality substrate material allow them to withhold high laser pulse energy.

... ports. Create accurately synced ambient backlighting for your TV with RGB and RGBW LED lights. Experience the best in smart lighting ecosystem today.

Our state-of-the-art multi-axis CNC machining milling equipment allows us to deliver mechanical optics to meet your exacting requirements and to make your designs within tolerances of ±0.0005" or better.

Our state-of-the-art multi-axis CNC machining milling equipment allows us to deliver mechanical optics to meet your exacting requirements and to make your designs within tolerances of ±0.0005" or better.

Ms.Cici

Ms.Cici

8618319014500

8618319014500