Wire product inspection case

Wire manufacturing occupies a fundamental and core position in the manufacturing industry, and is widely used in many fields such as automobiles, machinery, and electronics. It is an indispensable basic material for industrial production. The rapid development of our country's power, railway, rail and transportation, energy, and communications industries has also provided huge demand for the wire industry, and the wire manufacturing industry still has enormous development potential in the future.

Huge market demand presents both opportunities and challenges for the wire industry. During wire manufacturing, brand, model, specifications, and certification information are printed on the surface of the wire. This printing serves for product identification and specification labeling, while also providing safety reminders to users.

During wire production, defects such as surface stripping, scratches, cracks, raised spots, and dents may occur. By using high-precision image processing technology to replace manual visual inspection during manufacturing, inspection efficiency can be increased by more than three times, effectively reducing the defect rate, saving labor costs, and improving product quality.

With the advancement of technology, machine vision inspection systems have been widely used in wire manufacturing. They employ high-performance industrial cameras, high-resolution industrial lenses, and professional machine vision light sources, combined with advanced image processing functions, to achieve automatic inspection.

Below are imaging examples from the wire inspection case:

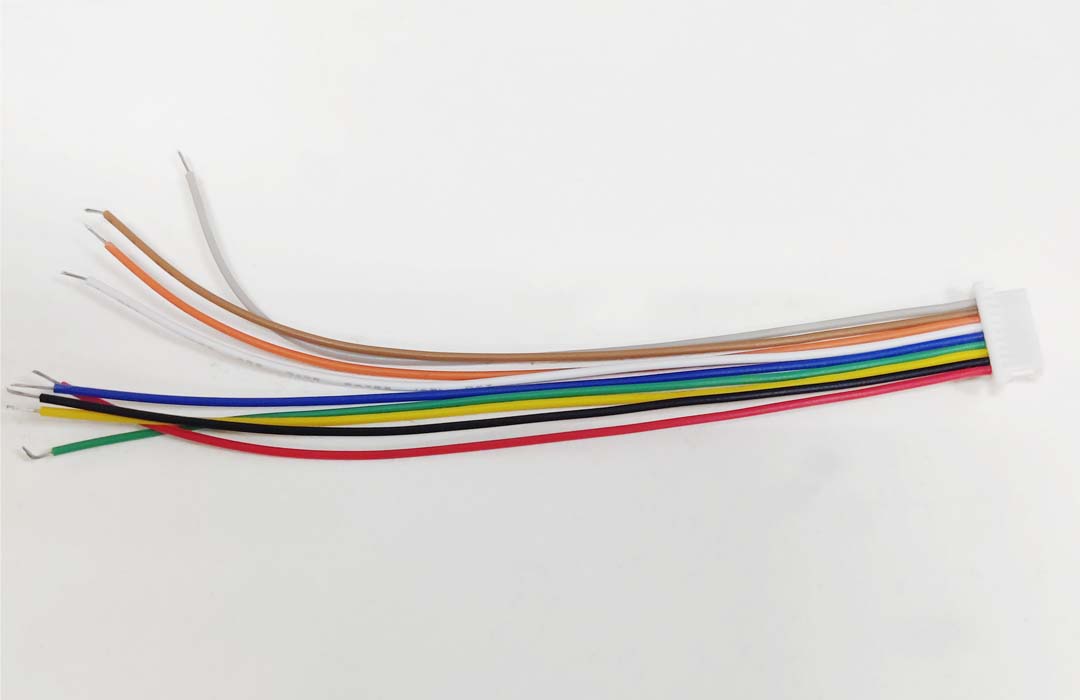

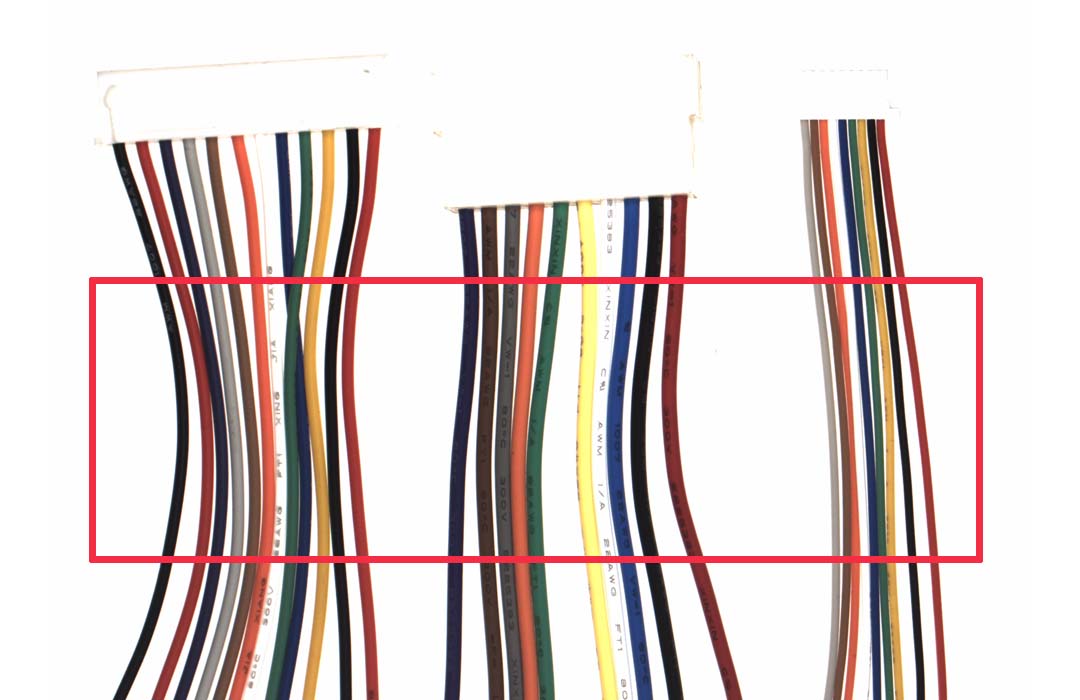

Application: Wire color and wire sequence inspection

Lighting position

Model: LTS-2HPR150-W+4PFT100100-W

The combination of ring light and backlight provides illumination, resulting in clear and distinct outlines of the wires.

Object |

Effect picture |

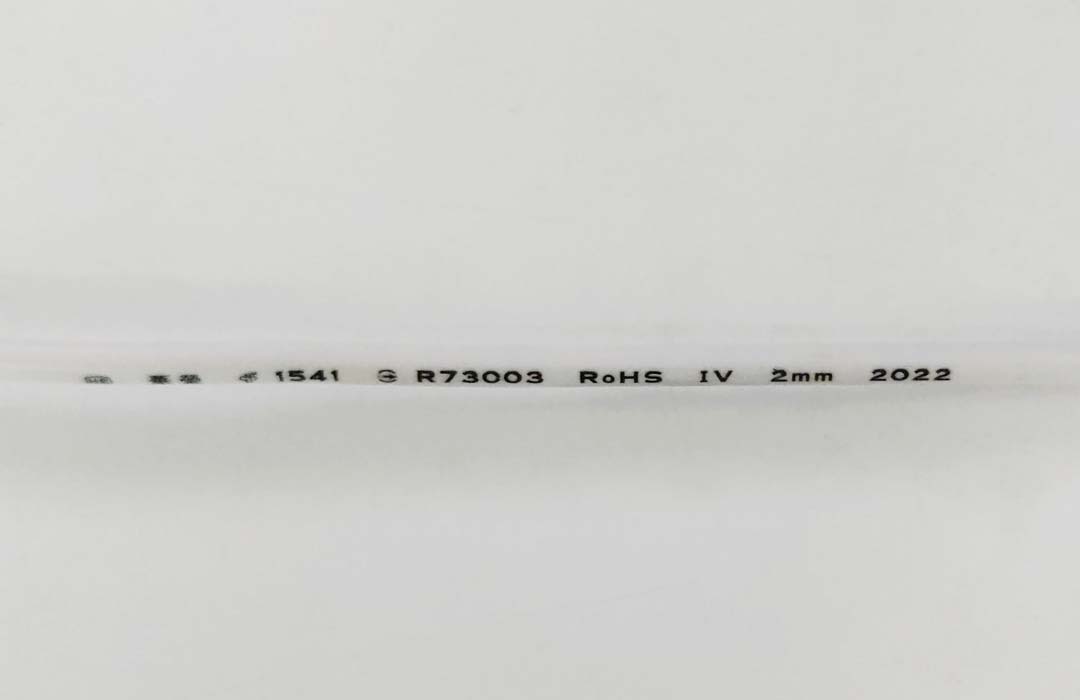

Application: Wire Character Printing Inspection

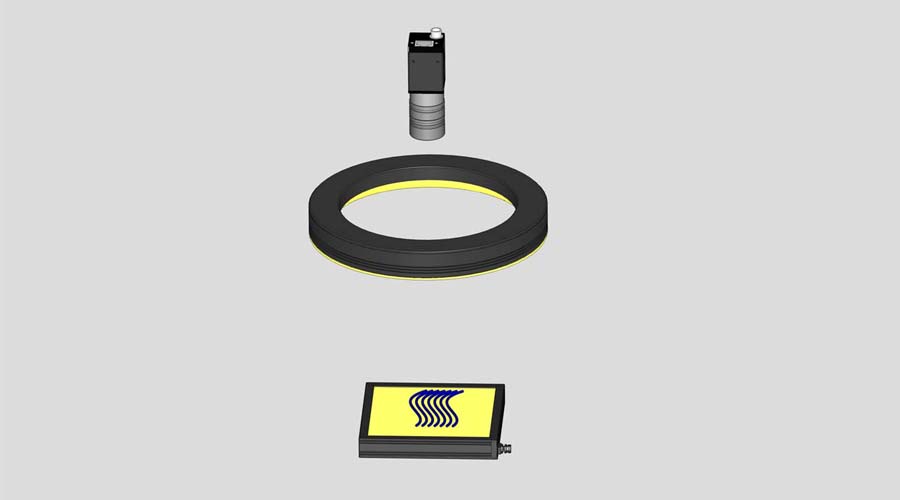

Lighting position

Model: LTS-4BR15030-W

Using bar light ensures the characters and outlines without reflect.

Object |

Effect picture |

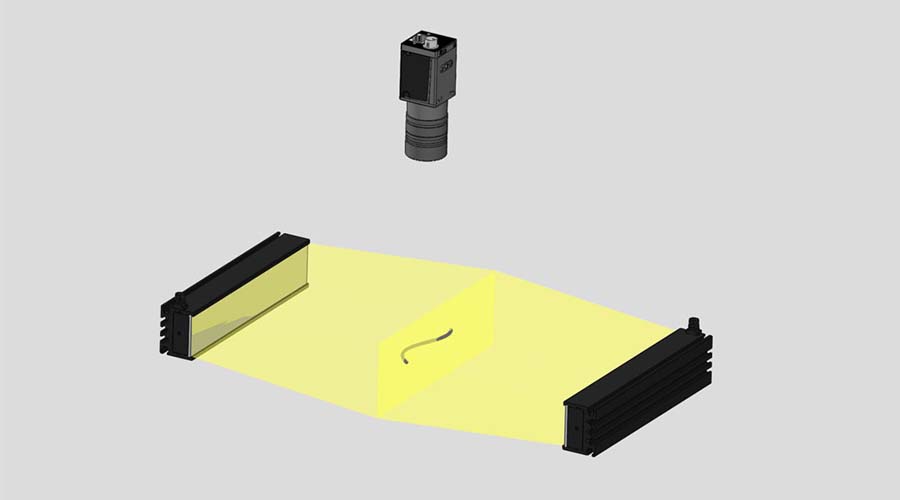

Application: Wire surface defect inspection

Lighting position

Model: LTS-RN4045-W

Using a ring light to illuminate from both sides, the surface of the line is highlighted with black, while defects are highlighted with bright, creating a clear contrast between black and white.

Object |

Effect picture |

Thank you for watching. Please feel free to contact us if you need our services. See you next time!

Ms.Cici

Ms.Cici

8618319014500

8618319014500