New version of SWIR fiber optical light facilitates semiconductor applications

The standard visible light wavelength range of LED light sources is approximately 400nm - 750nm, but the optical fingerprint information of some materials lies in the short-wave infrared range (SWIR, short-wave infrared) of 900nm - 2500nm. In the field of precision testing, traditional halogen light, due to limitations such as high temperature and short lifespan, can no longer meet the stringent requirements of modern industry for NTD.Different SWIR fiber optical light have varying penetration capabilities for product features. Longer wavelength infrared light have stronger penetration and can present more internal features.

Features:

1.Used for exterior and interior inspection

2.9 wavelengths from 810nm to 1650nm are standard

3.Best for replacing halogen light sources

4.Due to the LEDs, it helps to long-term use and reduce the thermal damage to the irradiation

Applications:

1.Semiconductor wafer and chip crack impurity detection

2.Food screening and sorting

3.Condition identification of fillers

4.Low light night vision to observe objects in the night

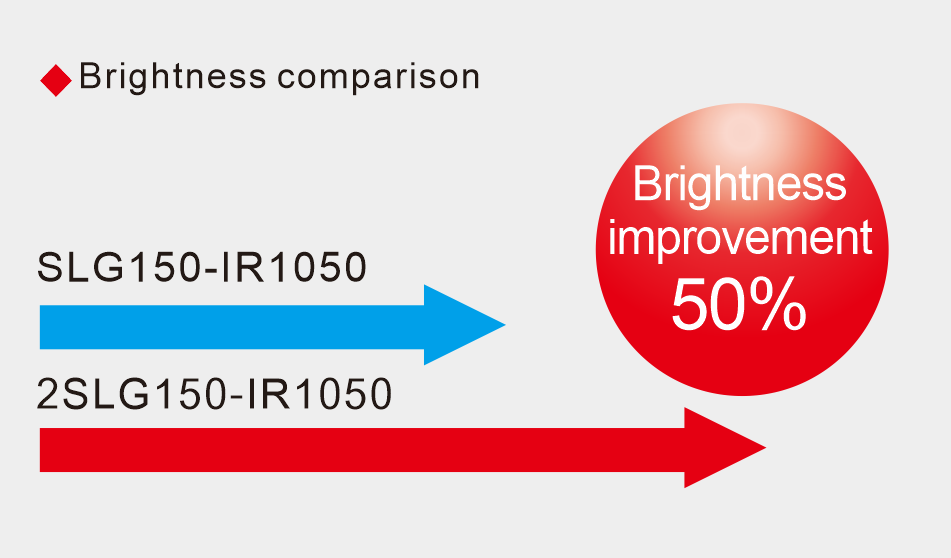

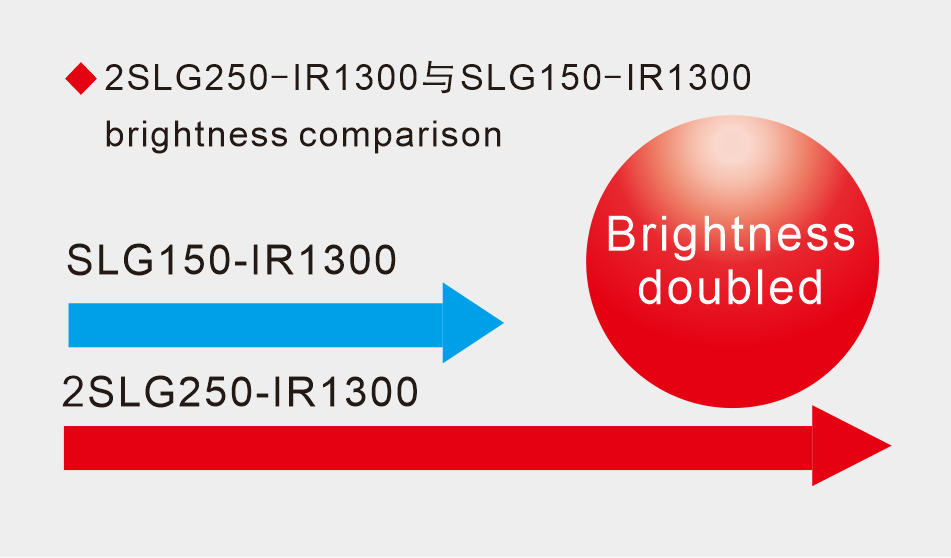

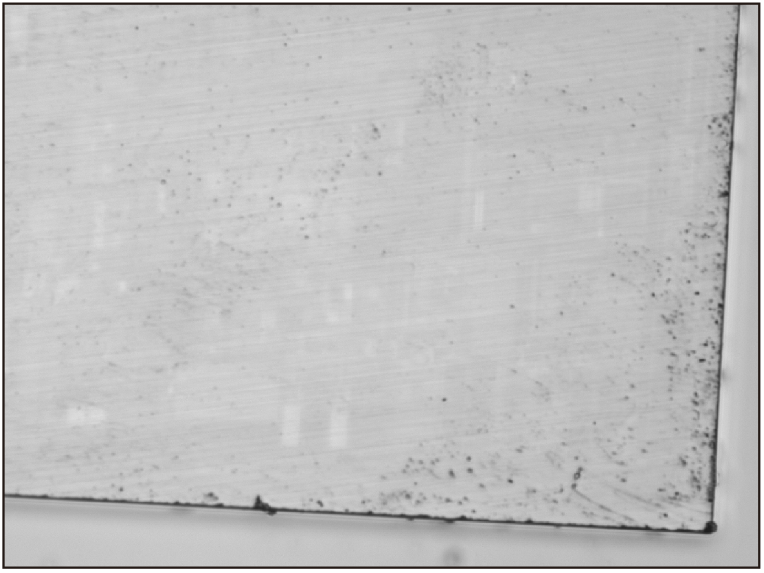

Effect comparison diagram

|

|

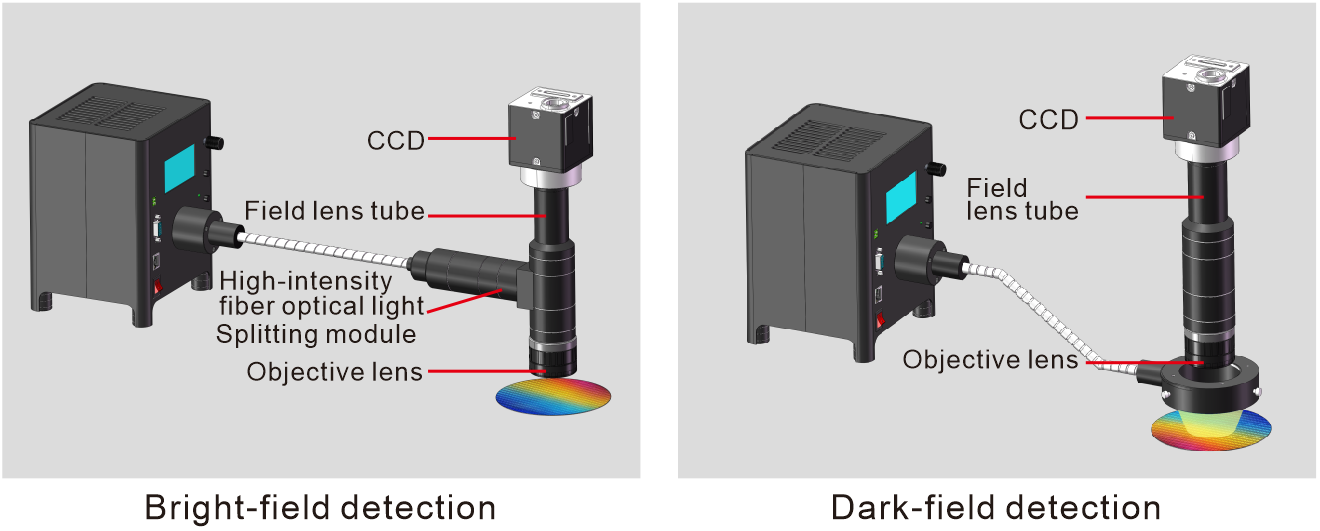

Micro-module wafer application diagram

Imaging example: Inspection of invisible circuits on chips

Based on the original SWIR fiber optical light, our company has launched a new type of SWIR fiber optical light with a brightness doubling and better performance. Centered on LED technology, it has achieved a comprehensive upgrade of the detection light.

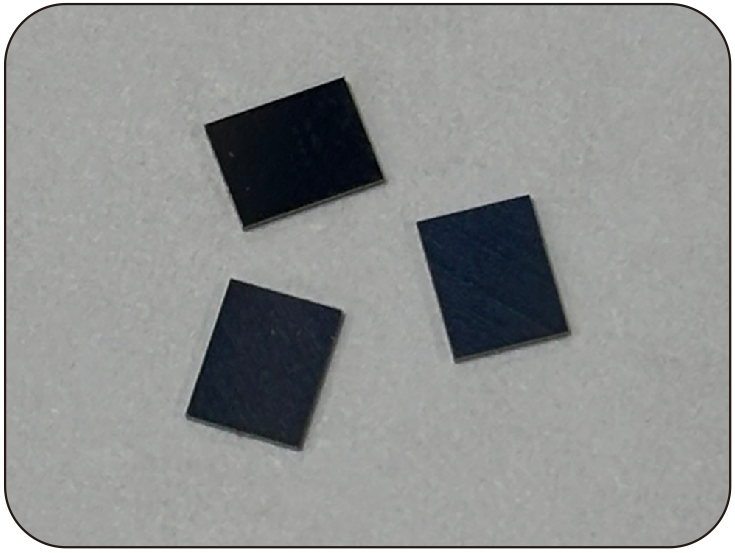

Physical picture of the chip

1050nm Sample |

1300nm Sample |

Note: The 1300nm SWIR fiber optical light has better penetration and can clearly show the internal circuits of the chip.

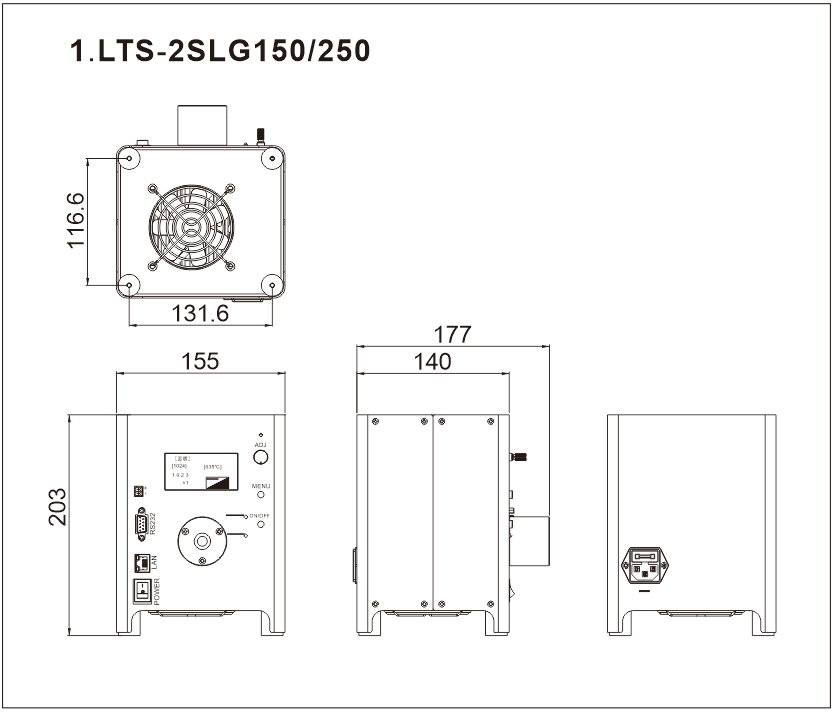

Light Parameters

Boundary dimension (mm)

Ms.Cici

Ms.Cici

8618319014500

8618319014500