Application of magnetic core surface defect inspection

Introduction

As a key component in electronic devices, the quality of the magnetic core directly affects the performance and reliability of the entire electronic system. During the production, transportation, and storage of the magnetic core, defects such as cracks, chipping, scratches, and stains are prone to appear on the surface. These defects will not only reduce the magnetic performance of the magnetic core, but may also cause electronic equipment failure.

Inspection objectives and significance

1.Accurately identify common defects on the core surface, such as cracks, chipping, scratches, stains, etc.。

2.Realize rapid inspection of core surface defects and improve inspection effi ciency.

Application

1.Object

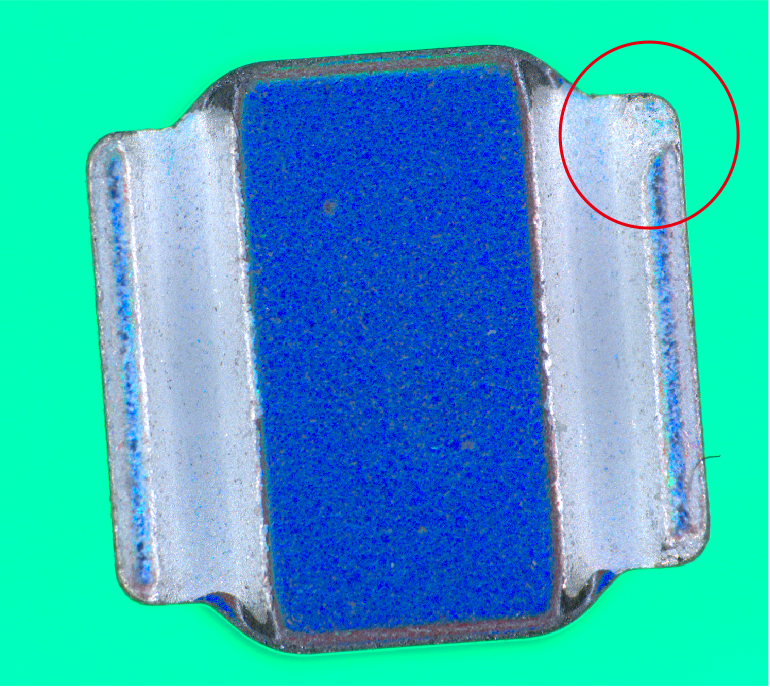

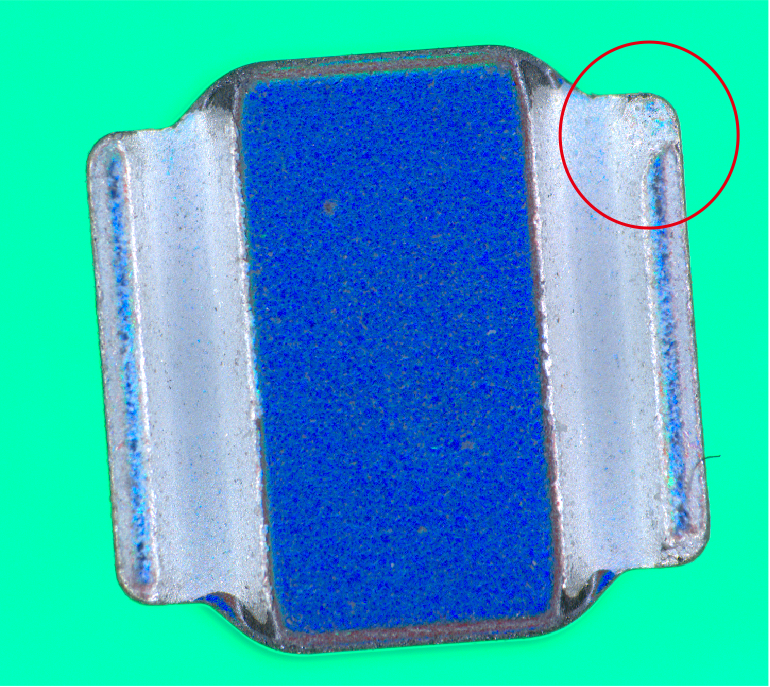

Sample 1 |

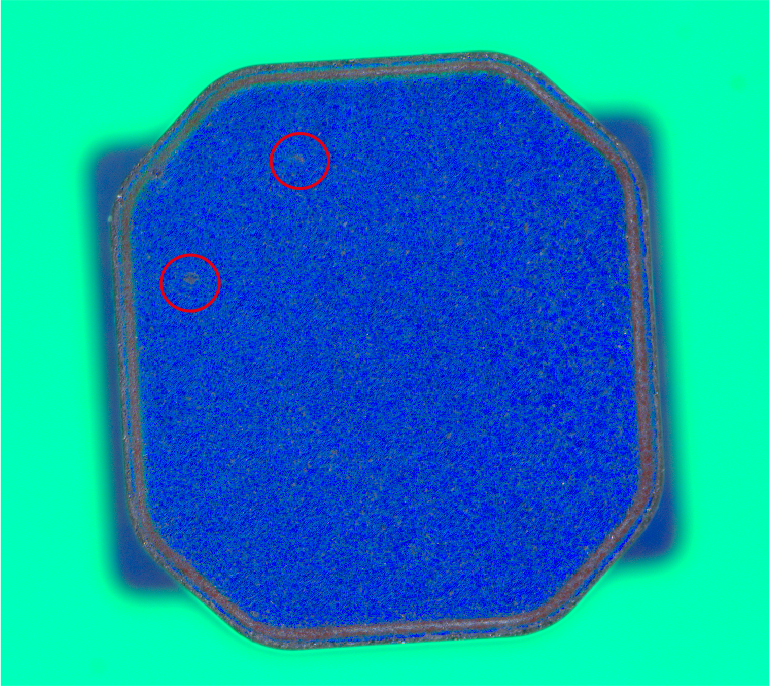

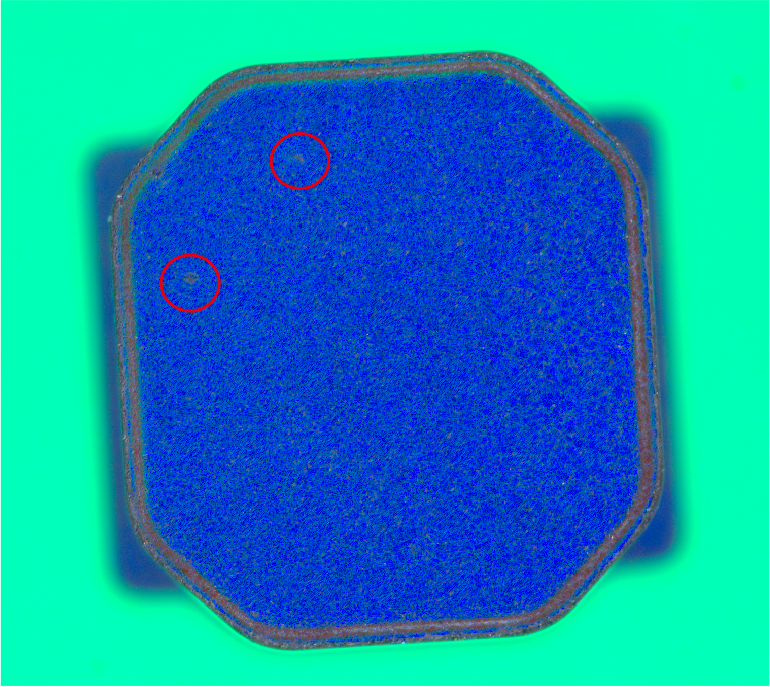

Sample 2 |

2.Selected light: Use a combination of three-color multi-angle ring light + backlight

3.Effect

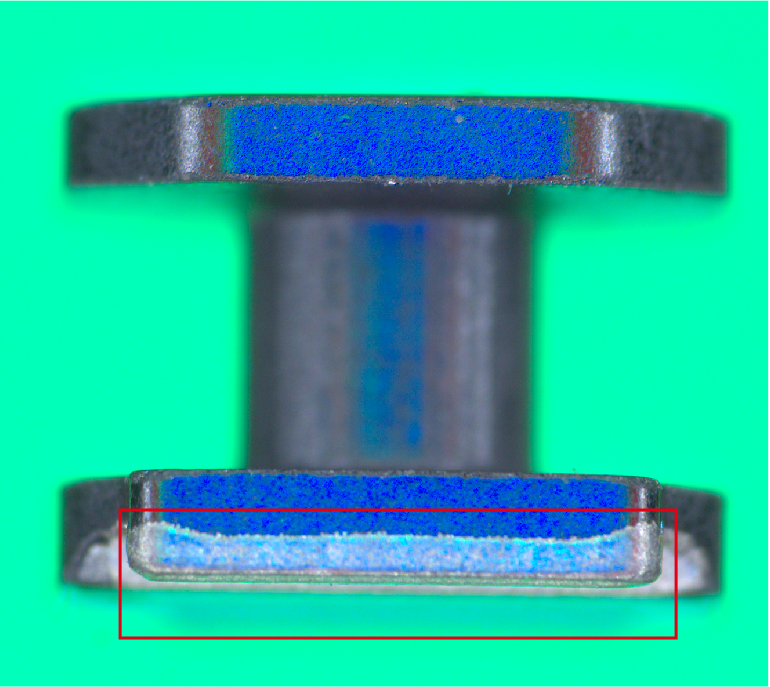

Solder side |

from side |

Left side |

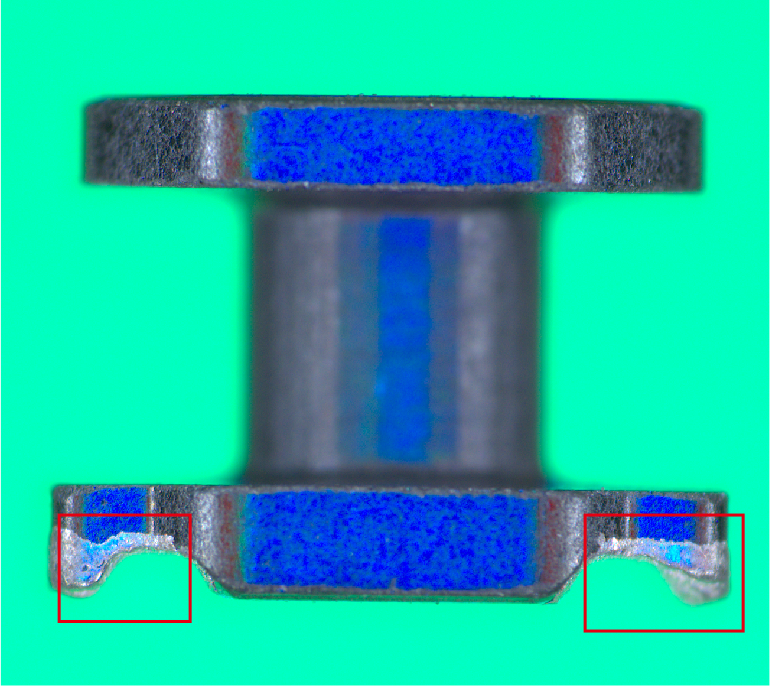

Right side |

Multi-color lighting distinguishes defects from the normal background with distinct colors, making them stand out. For example, a chipped soldering iron on the right side of the solder joint creates a noticeable decrease in the blue coverage area, while the chipped soldering iron on the front side creates a distinct color contrast. The other sides have similar effects. This highly visible image contrast facilitates subsequent machine vision algorithm analysis and processing.

Ms.Cici

Ms.Cici

8618319014500

8618319014500