Application of Collimated light in machine vision inspection

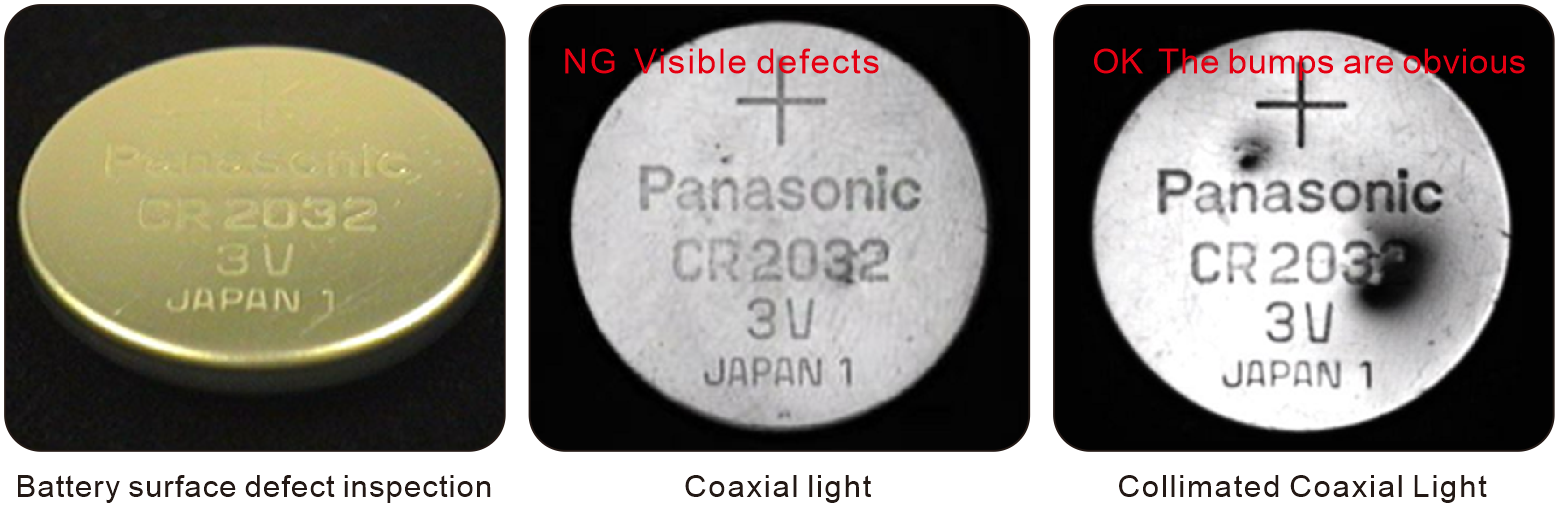

In the field of machine vision inspection, the diversity and complexity of surface morphology poses a huge challenge to inspection accuracy. Collimated light, with its highly collimated and nearly zero divergence characteristics, has become a powerful tool to break through the inspection bottleneck. When facing a flat surface, it spreads light evenly, making tiny flaws invisible in high-contrast imaging; When dealing with convex surfaces, collimated light accurately captures surface undulations and restores subtle height differences through changes in light and shadow; And in contour inspection, its stable projection angle and light intensity can completely outline the boundary lines of the object being measured, accurately locate contour deviations, and provide the machine vision system with detailed, accurate and reliable image information, significantly improving inspection efficiency and accuracy.

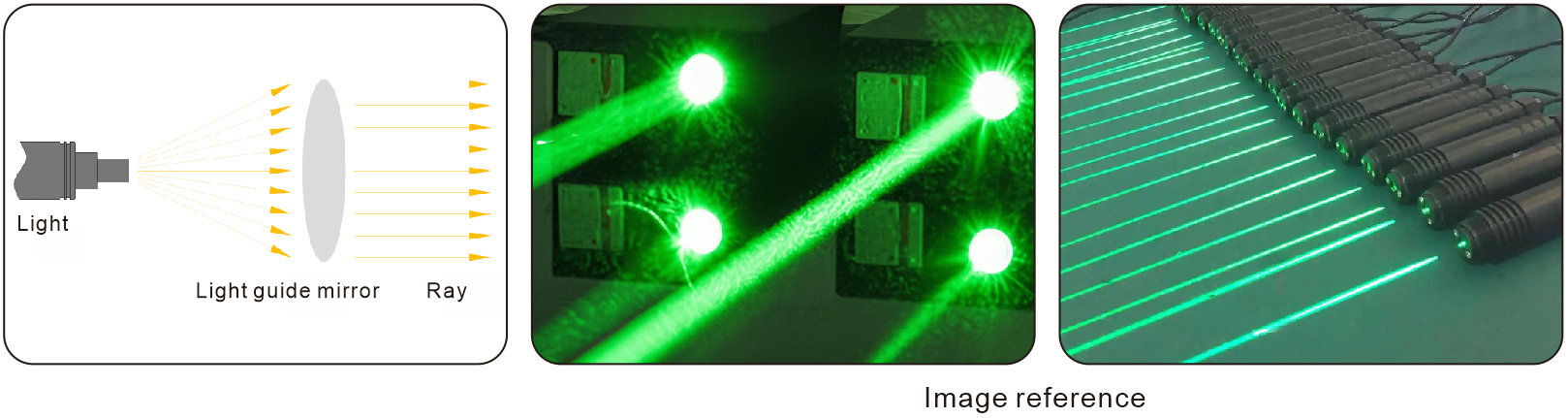

Collimated light: Refers to light whose rays are collimated to each other, whose propagation directions are almost the same, and whose divergence angles are very small.

Different kind of Collimated light

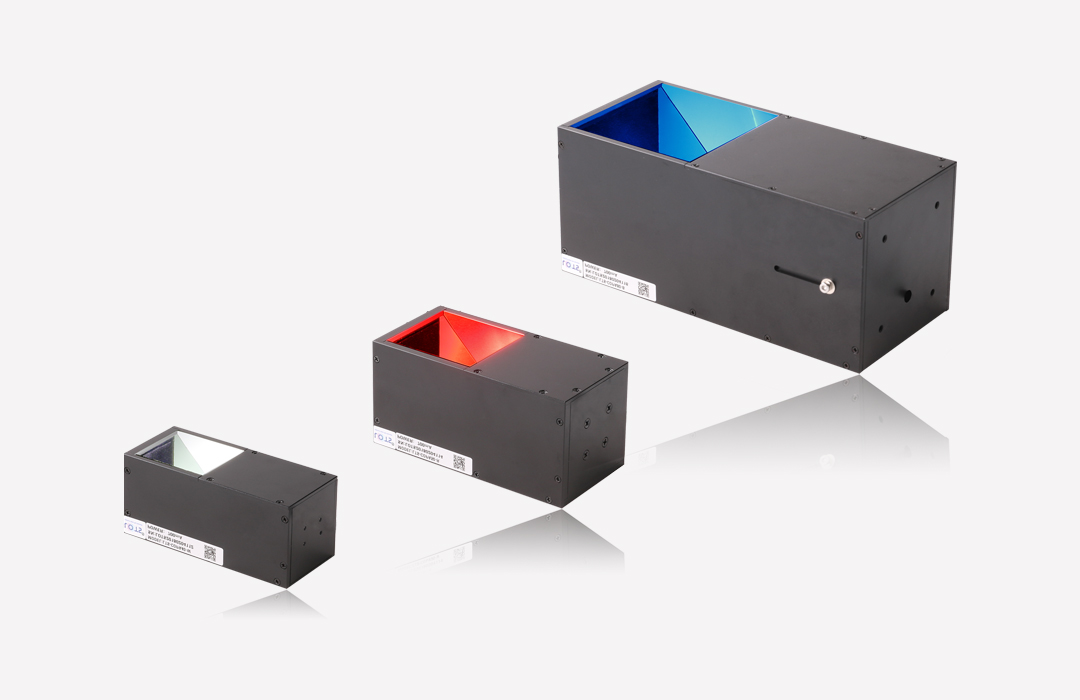

Coaxial light |

Collimated Coaxial Light |

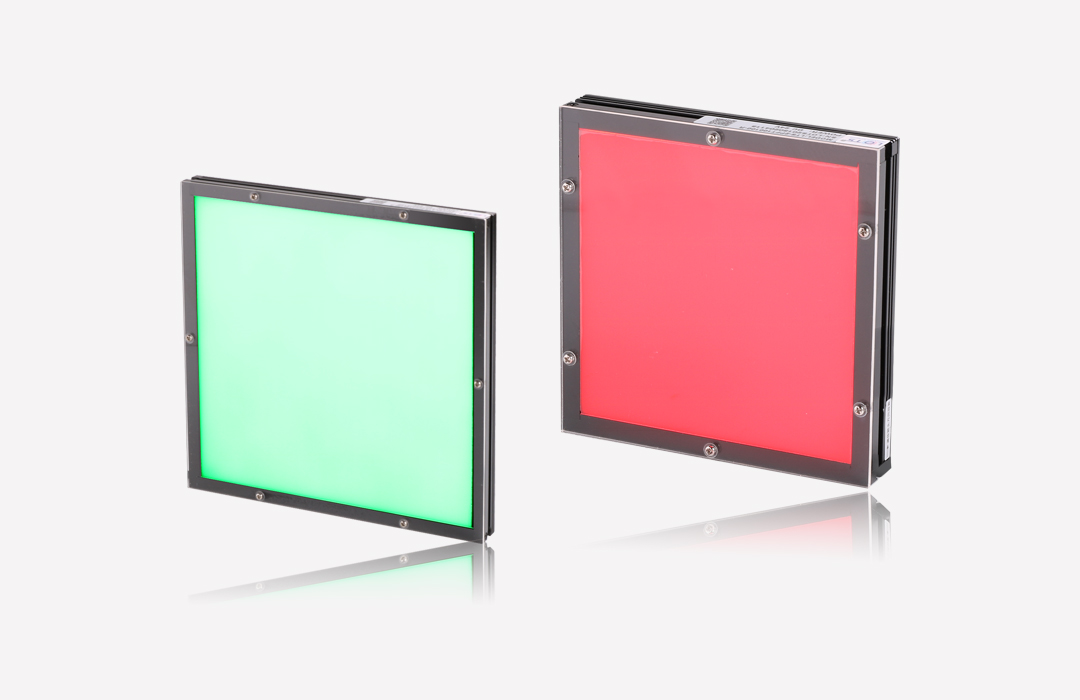

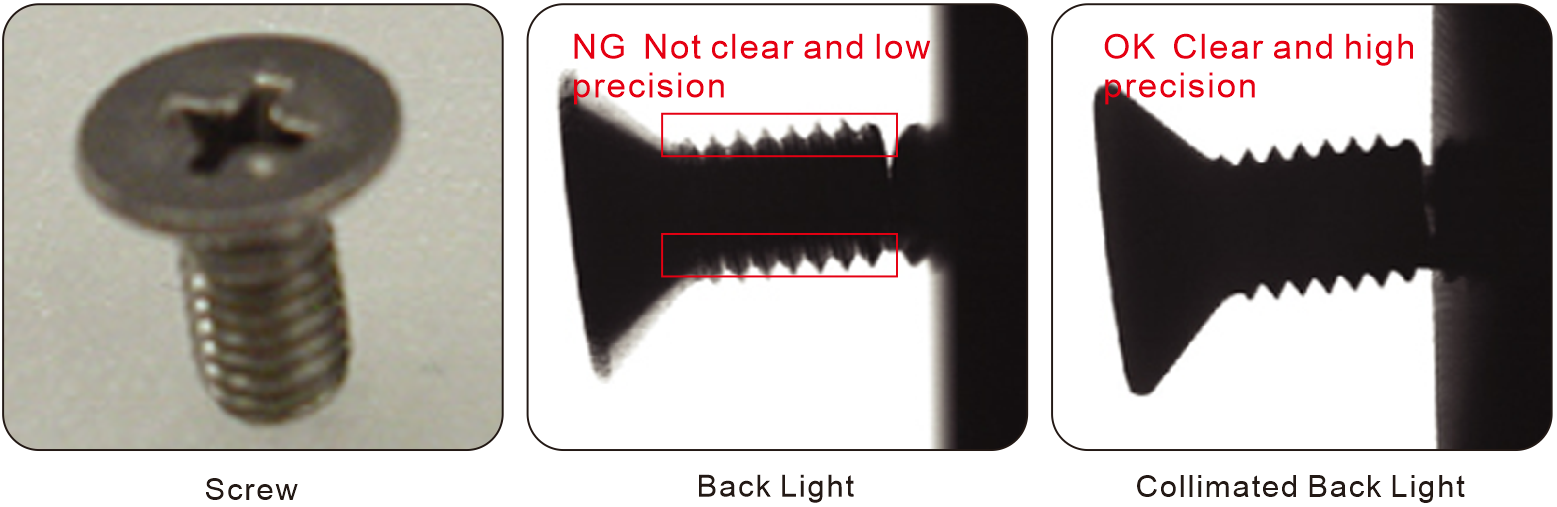

Back Light |

Collimated Back Light |

Bar Light |

Collimated Collector Light |

Application of Collimated light:

Collimated light has high requirements on the surface flatness of the object and high degree of authenticity restoration of the edge of the object.

From capturing subtle flaws on flat surfaces, to restoring the curved shape of surfaces, to accurately outlining contour boundaries, the stable and uniform light projection and unique optical properties of the collimated light can effectively meet the requirements of high-level visual inspection. Its zero-divergence beam characteristics eliminate shadow interference, and its high-contrast imaging effects highlight surface differences, providing a reliable and efficient solution for complex and diverse inspection needs.

Ms.Cici

Ms.Cici

8618319014500

8618319014500