UV Exposure Light Box - uv exposure light box

Automotive lighting engineers incorporate our diffusers into taillights and running lights to homogenize the output of LEDs as well as control the beam angle. If you've seen a recent model Dodge Durango while driving at night, you've seen our diffusers in action. Luminit light bending diffusion films are also used in automotive interior lighting, cluster panels, LCD displays, welcome mat lighting and more.

For indoor applications, a Light Shaping Diffuser® can last as long as the light structure. For outdoor applications, measures may need to be taken to prevent yellowing of the film due to exposure to the sun. For outdoor lighting applications, Luminit offers an optional UV-stable substrate to help prevent yellowing.

We recommend our glass diffuser for high temperature and high power laser applications. This diffusion material is stable up to 500 degrees Celsius and offers high transmission and high quality homogenized light for laser and other high damage threshold applications.

Birefingence is the optical property of a material having a refractive index that depends on the polarization and propagation direction of light. In LCD screens, birefringence can create unwanted optical artifacts such as Newton's rings and moire. The high transmission efficiency of Luminit diffusers as well as the ability to homogenize a light source can preserve polarization and eliminate birefingence.

Direction Turning Films can be combined with Light Shaping Diffusers to shape and homogenize the beam in addition to changing the direction. The beam can be shaped in a circular or elliptical pattern dependent on the diffuser angle chosen. These light bending films enable off-axis placement of the incoming beam when direct line of sight is impractical. Applications include LED lighting, avionics displays, traffic signs/displays and LCD backlights. They are also used to change the light beam direction to light a wall, walkway or other lighting target.

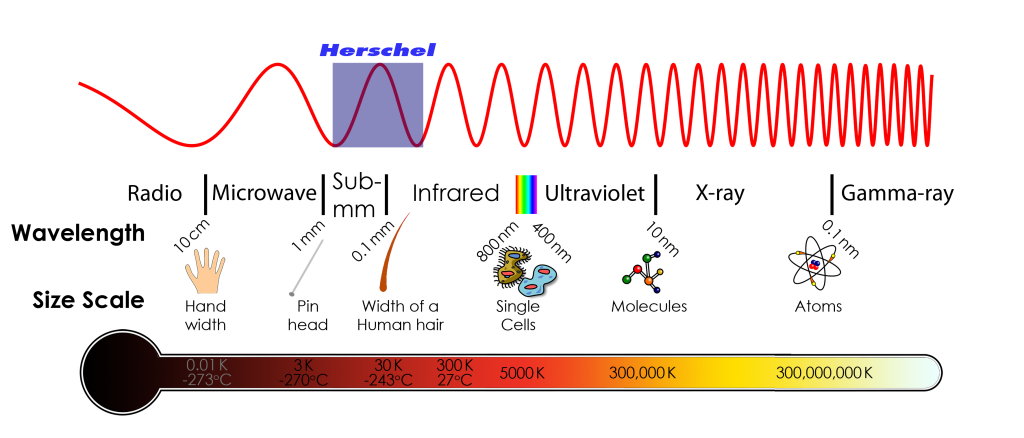

In fact all objects glow (emit electromagnetic radiation), and they do this in the part of the electromagnetic spectrum that depends on their temperature. The diagram below shows how bright objects of different temperatures appear at difference wavelengths.

UGR stands for Unified Glare Rating and is an international standard that measures glare in lighting fixtures and designs. UGR standards are used by lighting designers and manufacturers to mitigate glare from artificial lighting.

infrared中文

This will depend on the secondary optics you are using; however, the following chart can help determine the resultant beam angle.

InfraredWaves

Thin-film Light Shaping Diffusers® are available in rolls, sheets or parts cut to your specifications. Standard rolls are 20” wide and 500’ long. Strip rolls are also available in your specified width. 24"x 24" rigid sheets are available on polycarbonate in various thicknesses. Contact sales for a quote.

Infraredspectroscopy

No, since our technology is based on a surface relief pattern, these parameters are not dependent on the thickness of the substrate. However, there are inherently additional transmission losses if very thick substrates are utilized (Beer’s Law).

Luminit’s DTF (Direction Turning Film) is a non-symmetrical linear micro-prismatic that imparts a 20-degree shift in the angle of a semi-collimated light source. The DTF works well with LED light sources that utilize secondary optics. Some applications include recessed can lights to allow for more wall washing, pathway/stair lighting to reduce glare and increase ground illumination, and pool lighting to increase illumination of the bottom.

We recommend you find a mechanical means of securing the diffuser into your system, for example using the natural tension of a film on curved surface. We offer pressure-sensitive adhesive (PSA) as an option but this process is difficult and you may experience the incorporation of air bubbles during the lamination process.

The Sun has a surface temperature of nearly 6000 Kelvin (where the Kelvin temperature scale is the same as the familiar Centigrade scale except that the zero degrees C is about 273 degrees Kelvin). Its radiation peaks in the visible part of the spectrum at wavelengths of about half a micron, as shown by the yellow-green line in the graph above.

Our Light Shaping Diffusers® are bending, shaping and enhancing light beams in automotive lighting, exterior/interior lighting, in stages and concert halls, projection systems, monitors and displays, bar code scanners, and more. Our LED diffusers are sculpting light in some of the world's most famous landmarks.

Yes, Luminit Light Shaping Diffusers® are commonly used as an LED strip light diffuser to eliminate the hotspots without a significant reduction in the amount of the light, provided that the diffuser is placed a sufficient distance from the LEDs. A rule of thumb is that the diffuser must be at least as far away from the LEDs as the LEDs are spaced apart.

Yes, Luminit Light Shaping Diffusers® are available in various circular and elliptical angles in pre-cut sheet format for lower volume applications.

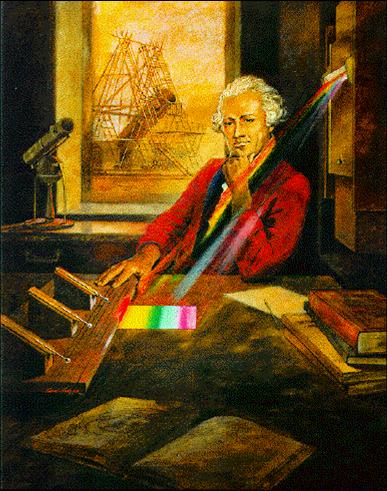

It is interesting that the basic technique used by Herschel to discover infrared radiation is still used in modern instruments today, including instruments on board the Herschel satellite – the only real difference is a factor a billion or so in sensitivity.

Our blue protective film is used to protect the diffuser during transit to reduce the chances of scratches. We advise customers to remove the film within three months of arrival. The reason for this is that there is a chance that the adhesive on the film can cure or harden and stick to the diffuser.

Since our microstructures are random and non-periodic, the Light Shaping Diffuser® is not wavelength-dependent, so it works well from 400nm to 700nm.

Yes, Luminit optical diffusion films are so precise that beam shaping is possible. Our patented holographic master recording process allows a variety of circular and elliptical light patterns. Standard circular angles range from 0.5˚ to 100˚ FWHM. A wide variety of standard elliptical angles, ranging from 10˚x0.2˚ to 95˚x35˚, are available.

The light will follow the specular ray. When the AOI is non-zero, the distribution center will follow the transmitted direction. The Zemax models we provide offer a good prediction of the ray distribution. You can see the light path and distribution patterns.

Infrared radiation was discovered by William Herschel in 1800. He was studying the heating effect of different colours of light by using a prism to produce a spectrum of colours and thermometers to measure their heating effect. He noticed that the heating effect got stronger as he went from the blue end of the spectrum to the red. In a moment of inspiration, he moved the thermometer beyond the visible red end and found that the heating effect was even greater.

Yes, you can layer multiple sheets of DTF to increase the angle of redirection; however, there will be significant transmission loss.

We have models available for Zemax OpticStudio on our DLL downloads and offer our models libraries such as Photopia, LightTools, and Lucidshape. Visit our Modeling/Simulation page for more information.

Because we replicate our holographic LED diffusers directly onto rigid panels instead of through a lamination process, our LED diffuser panels will not become brittle, peel or yellow over time.

FWHM is an abbreviation for Full-Width Half-Maximum which is the angle of diffusion that would be seen after a collimated laser passes through the diffuser.

infraredlight中文

There are currently two different types of DTF products, one is a 20⁰ bend-off axis material for visible or white light and the other is a 10⁰ bend-off axis for 810nm (IR) LEDs.

Yes, our lighting diffuser film is approved by AMECA as meeting the three-year weathering test of SAE J576 for plastics used in optical lenses and reflectors on motor vehicles.

Midinfrared

Luminit offers a sample page with 9 samples about 1” square as well as larger A4 sized sheets of select single angles on 0.010” thick polycarbonate. Please select Request a Sample on the Luminit home page. While we do offer this complimentary kit to qualified customers, a UPS, FedEx or DHL account number is required.

We humans, slightly warmer than room temperature, glow in the mid infrared and we’re brightest at about 10 microns wavelength (black line in the graph). These days we are all familiar with infrared imaging, which allows us to see in the dark using electronic detectors that record infrared light emitted by warm objects such as people. The pictures below show SPIRE team member Prof. Peter Ade in visible light (wavelength about 0.5 micron) and infrared light (about 10 microns).

Our display Brightness Film (DBF) is a light management film that increases the brightness of LCD displays. DBF is a prismatic structure with either a 1, 2, 3.5, 10 or 20-degree diffuser on the other side of the film. DBF is also available without the diffuser.

Light Shaping Diffusers® are often applied in architectural lighting, can lights, decorative lighting, pool lighting, set/event lighting and wall wash lighting where the effects of the Light Shaping Diffuser® can be quite dramatic. LED Light Shaping Diffusers® are also used in illumination systems such as aircraft inspection lights; backlit systems such as cellphone and PDA displays; LCD screens and more. One of the most common uses for our light diffusers is to eliminate hot spots on LED light strips.

near-infraredlight

Luminit Monolithic Glass Diffusers are made with an etching process, while our Glass on Glass light diffusers have pseudo-random microstructures that are cast and cured onto the surface of the glass. Temperature is one of the factors that differentiate the two. Our Glass on Glass diffusers are stable up to 500° C and are suitable for high-temperature laser applications. Monolithic glass is also rated for high temperature but is more suitable for lighting applications.

Visiblelight

Yes, we are able to increase the transmission by adding AR coating to both sides of our diffuser having the percentages 95~98 depending on the beam angle. Our microstructures are refractive, so the performance will be constant up to ~1200nm.

Clearly, depending on what it is that we want to observe, we need to look in different parts of the spectrum, and no one part will tell us everything. The Earth’s atmosphere transmits well in the visible and radio regions, but it blocks out everything from gamma rays to ultraviolet and most of the infrared. So to study the Universe at those wavelengths we need to launch space-borne observatories.

The whole region with wavelengths ranging from 1 micron to 1 mm is loosely called the “infrared”, but astronomers tend to break this up into sub-regions: the “near infrared” (from 1 to 5 microns); the “mid infrared” (5 to 30 microns), the “far infrared” (from 30 to 300 microns) and the “submillimetre” (from 300 microns to 1 mm). The exact boundaries are somewhat arbitrary, and the exact definitions can vary.

Infraredwavelength

The diffuser has improved transmission characteristics if the microstructure side is facing the light source, but it has better source hiding characteristics if the microstructure side is facing away from the light source.

Clouds of interstellar gas and dust that form stars are typically at temperatures of about 50 K (that’s about –220oC). They glow at far infrared wavelengths and are brightest at about 100 microns (red line in the graph above). And the universe itself is filled with radiation corresponding to a temperature of just less than 3 K – very cold indeed – with peak emission in the millimetre wavelength range (blue line in the graph above).

The electromagnetic spectrum spans a wide range of wavelengths from very short wavelength and highly energetic gamma rays to very long wavelength and low-energy radio waves. The visible part of the spectrum is only a small portion. Infrared light is the same as the light that we can see except that the wavelength is longer and outside the range that our eyes can sense.

Luminit replicates diffusers on polycarbonate and acrylics (PMMA). We can also replicate our diffusers on glass products.

The transmission efficiencies of Luminit optical diffusers are rated between 85-92% (depending on the angle). This very high-efficiency rating is due to the fact that our technology is based on diffractive microstructures. Smaller angle diffusers have the highest transmission.

This depends on the angle of divergence and spacing of the light sources. With 110° Field of View, surface mount LEDs, the relationship is around 1:1. That is, if the LEDs are spaced 1 inch apart then you will need a little more than 1-inch distance from the LEDs to our largest diffuser angles. Here is an illustration demonstrating the ratios with various angle diffusers.

Though our LED diffuser sheets are often installed in outdoor environments, they are not waterproof. Submerging the diffuser film or sheet in water would dissolve the microstructures and render the diffuser unusable.

The EVD unit has an 81% transmission efficiency in the “on” state and 78% in the “off” state measured at 550 nm at 28°C. Anti-reflection coated glass laminates are available on a special order basis to improve transmission.

Light Shaping Diffusers® are micro-structures pseudo-randomly embedded on a substrate (such as film) which perform optical diffusion. When applied to a lighting structure, the Light Shaping Diffuser® can manipulate light by changing the direction of its energy. This allows our Light Shaping Diffusers® to clean up and shape a light beam to suit a particular purpose.

Yes, our Light Shaping Diffusers comply with RoHs standards. An environmental compliance statement can be downloaded here.

Luminit's unique LED optical diffuser material is available in a variety of circular and elliptical angles from 1° to 100° on thin film or rigid substrates. Standard angles include: 80ºx50º, 60ºx10º, 80º, 60º, 40º, 30°, 20°, 10°, and 5°. We also offer non-standard angles, including 1°, 2°, 3.5°, 30°×35° 40°×1°, 60°×1°, 69°×30°, 75°×45°, and 90°×10°.

We suggest you handle the diffuser with clean latex gloves. High angle diffusers are very prone to damage due the height of the microstructures. They can be cleaned carefully using optical wipes and ethanol using the industry-standard “drop and drag” technique.

Ms.Cici

Ms.Cici

8618319014500

8618319014500