Tungsten / Quartz Bulbs & Lamps - quartz light

24 inchRing Lightwith Stand

Steel is the most widely used metal in the world today and offers a great balance of material properties at a good cost. But when steel, at a density of 7.8g/cm³, is too heavy for the application, product designers must turn to one of the lighter materials available. While many plastics are available to lighten the load, lightweight metals are a popular and sturdy choice.

At nearly a third the weight of steel (2.70g/cm³), aluminum is the most widely used non-ferrous metal in the world. Aluminum offers great corrosion resistance, and some alloys can offer strength that approaches that of carbon steel. Despite being more costly than steel, aluminum is cheaper than both magnesium and titanium.

Ring LightStand with Phone Holder

Ring Lightwith Stand and Remote

Titanium is the heaviest of the three lightweight metals on our list at 4.51g/cm³. It’s also the most expensive and the most challenging to machine. As a result, titanium is often reserved for more demanding applications that require a more robust material.

The three metals discussed in this article are all great ways to save weight on your product. You might consider them if you’re looking to make something that’s more convenient for consumers to hold and use, or looking to improve performance and reduce friction by lowering overall assembly weight. Choosing which one to use ultimately comes down to factors like cost, strength, and durability requirements.

Ring LightStand only

AmazonRing Lightfor Phone

Companies around the world use CNC machining to craft high-quality components from diverse materials like ceramics, wood, and composites. Metal and plastic take the forefront in mass production, with metals enjoying wider machinability. Machinists can adeptly tackle...

As an alloy, titanium is the strongest metal on this list by far. It also has excellent corrosion resistance, performs well at high temperatures, and works well for implants thanks to its high biocompatibility. But it does come with a few drawbacks.

Aluminum offers very high formability and machinability, good weldability, and high ductility. It has both high thermal and electrical conductivity. Despite this, it is susceptible to wear, has a lower strength-to-weight ratio than titanium, and does not perform well at high temperatures. Aluminum and magnesium have similar melting points at 660°C (1220°F) and 650°C (1202°F), respectively

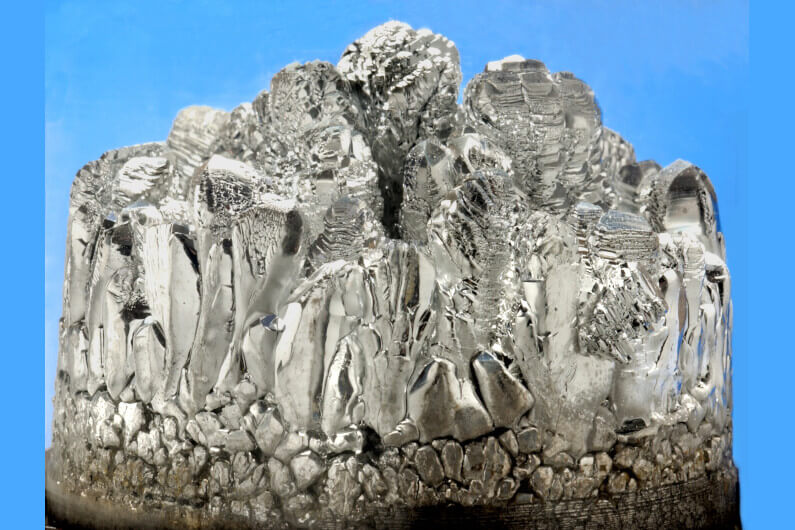

More expensive than aluminum, but cheaper than titanium alloys, magnesium is used as the base for the lightest structural alloys around. Magnesium on its own is vulnerable to corrosion and chemical degradation, and it also offers a lower strength than the other metals in this article. However, modern magnesium alloys and coating techniques are helping to improve the strength and durability of magnesium products.

AmazonRing Lightfor Laptop

Gensun Precision Machining offers rapid prototyping and precision machining services for innovative companies around the world. Whether you need a custom prototype, low-volume production, or high-volume production, our service is second to none. With a strong emphasis on quality control, we get the job done right, every time!

Our machine shops provide professional CNC machining services for titanium and aluminum alloy products, along with a wide range of other metal and non-metal materials. If you’re looking to manufacture lightweight products and need to partner with a cost-effective, quality-focused vendor, contact Gensun today.

The most popular lightweight metals and alloy alternatives to steel are aluminum, titanium, and magnesium. To help designers evaluate these lightweight metals, we’ve created a short guide that compares the benefits and drawbacks of each, along with some common applications.

The evolution of CNC machining has been marked by significant technological advancements. From the early days of punch tape and rudimentary programming, CNC machining has evolved to incorporate sophisticated software and high-speed, multi-axis machines. In recent...

CNC milling is a CNC process that involves the use of rotating cutters to remove portions of a block of material (or workpiece) till the desired custom shape (or feature) is made. It allows manufacturers to create intricate parts accurately while meeting tight...

Magnesium offers high machinability but is generally only machined by specialist shops willing to accept the danger of highly combustible magnesium dust. It also offers a unique damping ability that makes it useful for mitigating vibrations on sensitive equipment. Most magnesium applications are geared toward taking advantage of its extremely light weight (1.74g/cm³), including:

Ms.Cici

Ms.Cici

8618319014500

8618319014500