Spot Lighting Combo Sets - led spot light

Materials with controlled architectures at the nanometer scale can have dramatically improved optical, mechanical, and transport properties compared to their bulk counterparts. However, it has been difficult to maintain nanoscale control of material architecture for samples larger than cm². We seek to use a combination of self-assembly and scalable manufacturing technologies to enable manufacturing of m² of material while controlling nanoscale geometry and chemistry.

Cracking in the drying opal templates used to fabricate inverse opals, however, is a major hindrance to the use of self-assembled nanolattices for practical and fundamental studies. In work published in ref. [25], we conduct desiccation experiments on polystyrene particle opals self-assembled on indium-tin-oxide coated substrates to study their fracture mechanisms, which we describe using an energy-conservation fracture model. The model incorporates film yielding, particle order, and interfacial friction to explain several experimental observations, including thickness-dependent crack spacings, cracking stresses, and order-dependent crack behavior. Guided by this model, we are the first to fabricate 120 μm thick free-standing metallic inverse opals. This work improves our understanding of fracture mechanics in drying particle films, provides guidelines to reduce crack formation in opal templates, and enables the fabrication of free-standing large-area single-crystal inverse opals.

If light strikes an interface so that there is a 90-degree angle between the reflected and refracted rays, the reflected light will be linearly polarized. The special angle of incidence that produces a 90-degree angle between the reflected and refracted rays is called the Brewster angle.

Polarization of light refers to the alignment of the light waves so that they vibrate in a single direction. Light waves normally osciilate in all directions as they move. But when the light is polarized, these vibrations are restricted to one direction only thereby making the light very much organized.

Polarization by Refraction: Light is passed through certain crystals (like calcite or quartz) and splits into two beams with perpendicular polarization directions (birefringence).

[18] James H. Pikul, Sezer Özerinç, Burigede Liu, Runyu Zhang, Paul V. Braun, Vikram S. Deshpande, William P. King, “High strength metallic wood from nanostructured nickel inverse opal materials“, Scientific Reports, vol. 9, January 2019. Top 100 downloaded materials science papers for Scientific Reports in 2019.

Elliptical polarization: It is the type of polarization where the tip of the electric field vector defines an ellipse in any fixed plane traversing, as well as is normal to the direction of propagation.

$$ \mathbf{E}=E_0 \cos (k z-\omega t) \hat{i} $$ Where: $E_0$ : Amplitude $k$ Wave number $\omega$ : Angular frequency $t$ : Time $\hat{i}$ : Unit vector along the $\boldsymbol{x}$-axis

Polarization of light is the act of arranging radiation waves so that they oscillate in a single direction only. In general terms, light waves are free to vibrate in any direction while polarized light waves only vibrate in one specific plane or direction. Polarization is used in different applications including designing of sunglasses that reduce glare, enhancing photography, and investigating of properties of different materials. Read the below article for a better understanding of the polarization of Light.

[25] Zhimin Jiang, Zakaria Hsain, and James H. Pikul. “Thick free-standing metallic inverse opals enabled by new insights into the fracture of drying particle films” Langmuir, 2020.

Circular polarization: It is the type of polarization in which at every point, the electromagnetic field has a constant magnitude, but its direction rotates with a constant value in a plane perpendicular to the direction of the wave.

Linear polarization: Linearly polarized light wave means that the electric field vibrates in a certain linear direction perpendicular to the wave axis, and the magnetic field vibrates in a direction which is perpendicular to both, the advancement axis and direction of the electric field.

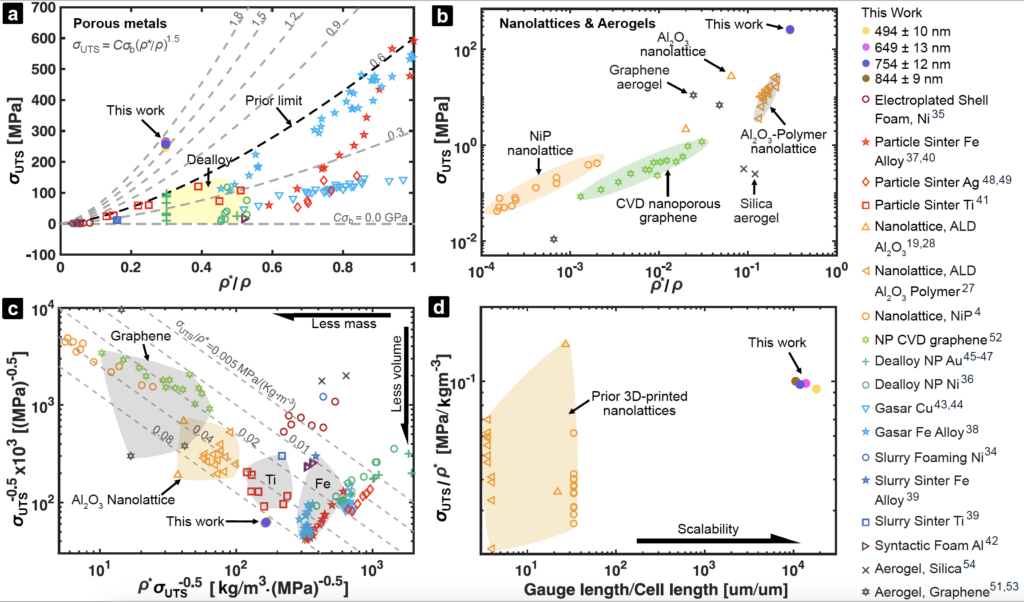

We have developed a nickel-based cellular material which has the strength of titanium and the density of water (Fig. 1). The material’s strength arises from size-dependent strengthening of load-bearing nickel struts whose diameter is as small as 17 nm and whose 8 GPa yield strength exceeds that of bulk nickel by up to 4X (Fig. 2). The mechanical properties of this material can be controlled by varying the nanometer-scale geometry, with strength varying over the range 90–880 MPa, modulus varying over the range 14–116 GPa, and density varying over the range 880–14500 kg/m3 (Fig. 3). We refer to this material as a “metallic wood,” because it has the high mechanical strength and chemical stability of metal, as well as a density close to that of natural materials such as wood. In addition, its cellular nature allows for future multifunctional material integration.

It means that the light emitted by the sun travels in all the given directions, i.e. on different polarized lights. And when it is transmitted over a distance, it has a slight separation, and is separated only when its measuring angle is equal to the angle of separation. Because sunlight is everywhere, it is said that light is not polarized. When uninterrupted light falls on an exposed surface with an incident angle equal to the angle of division of the earth or also called Brewster's angle, it is called polarized-polarized. When uncollected light is transmitted through a separating sheet, it is separated.

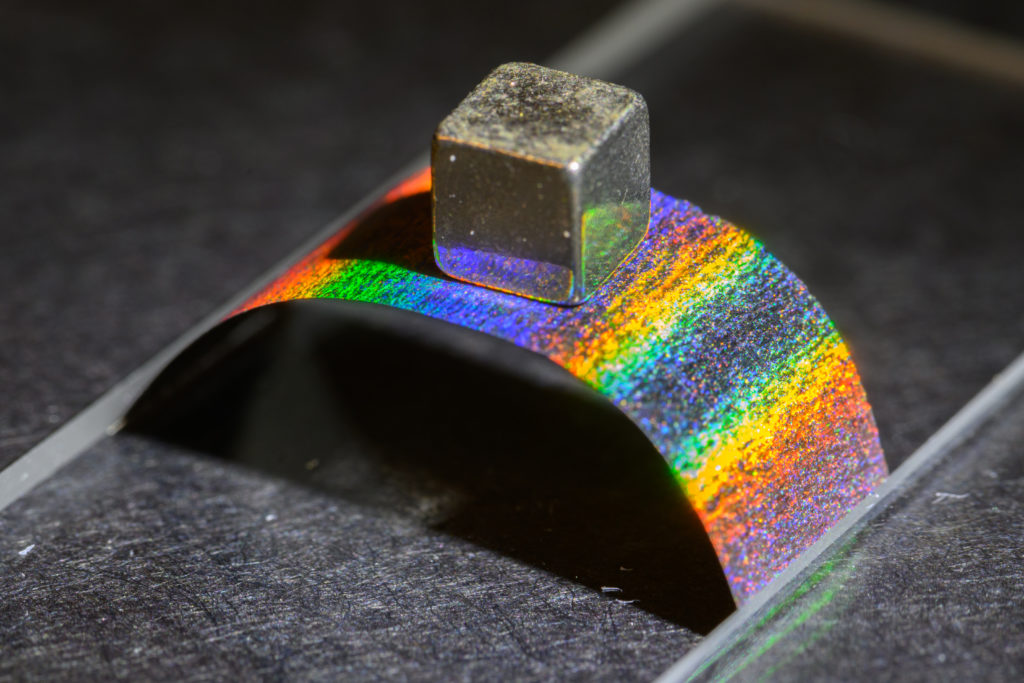

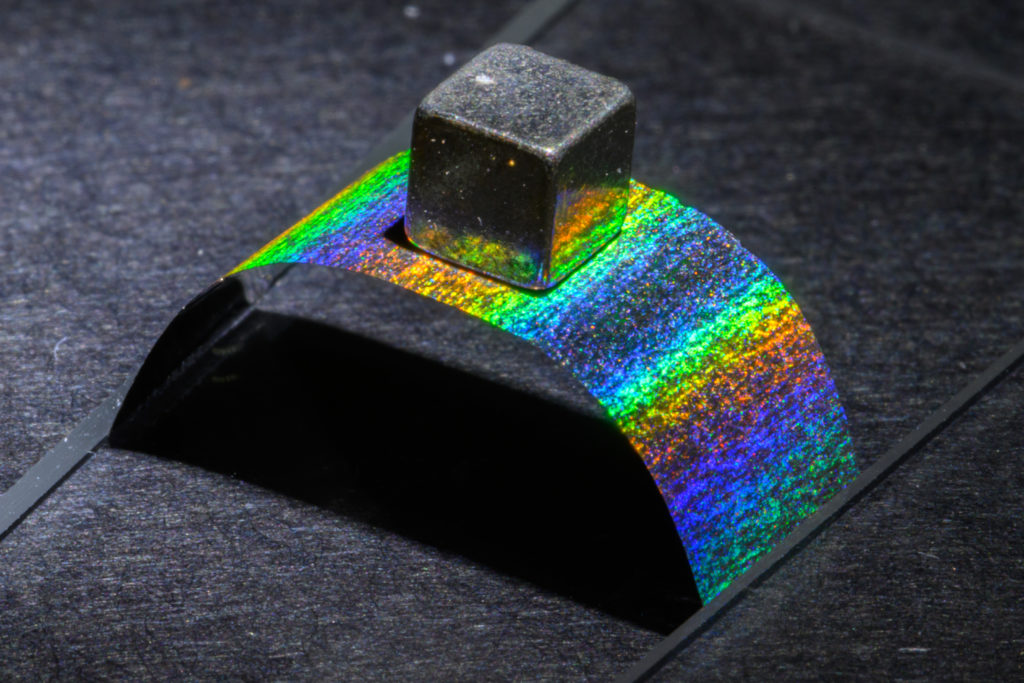

In work published in Nature Materials (Ref. [30]), we demonstrate a crack-free self-assembly approach to fabricate cm-scale multifunctional metallic nanolattices with 100 nm periodic features and 30 nm grain sizes, which corresponds to a 20,000X increase in crack-free area and 1,000X the number of unit cells in the loaded direction than prior nanolattices. These nanolattices have 257 MPa tensile strengths at 1.12% strain and a density of 2.67 g/cm3, which is 2.6 times the strength of the strongest porous metals with the same relative density at any scale. We eliminated cracks during self-assembly by maintaining a wet template and utilizing electrostatic forces to assist metal electrodeposition through the template. The resulting nickel nanolattices have excellent photonic coloration and approach their macroscopic theoretical tensile strength. The high absolute strength and the low density would allow nickel nanolattices to replace sandwich panel cores with 50% smaller volume than porous titanium, 50% lower mass than porous iron, and, importantly, 10X less volume than other nanolattices.

Separation is also possible by re-emitting light. Procrastination occurs when light rays pass from one information to another. On top of these two things, the path of the pole changes where it goes. The pointed beam receives a certain degree of separation.

Polarization by Reflection: When unpolarized light is reflected at a Brewster's angle, the reflected light is Polarized light.

Polarization by Transmission: This method utilizes Polaroid sheets which only allow vibrations in one direction to pass through.

Polarisation angle is the angle at which unpolarized light or other electromagnetic radiation must be incident upon a nonmetallic surface for the reflected radiation to acquire maximum plane polarization.

[8] James H. Pikul, Paul V. Braun, and William P. King, “Micromechanical devices with controllable stiffness fabricated from regular 3D porous materials”, Journal of Micromechanics and Microengineering, vol. 24, 105006, 2014

[30] Zhimin Jiang and James H. Pikul. “Centimetre-scale crack-free self-assembly for ultra-high tensile strength metallic nanolattices” Nature Materials, 1-7, 2021.

Ms.Cici

Ms.Cici

8618319014500

8618319014500