Legally Speaking: Generative AI Deciding Who Gets The ... - ring ai

Said settings are located at the bottom of the Website. Furthermore, all browsers may be modified to disable the cookies configuration.

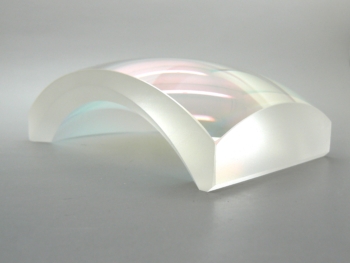

Convexlens

These settings are located at the bottom of the Website http://www.iotlenses.com. Furthermore, as in the case of computer browsers, it is possible to disable or eliminate cookies by changing the options or settings in mobile device browsers.

This is why most browsers offer the possibility to administer cookies: in order to allow for a more accurate control of privacy. Said settings may be located in the “options” or “preferences” section of the browser’s menu.

Combining control of mean power distribution and optimization for binocular performance is achieved with Steady Plus Methodology. This results in the eyes perceiving symmetrical powers for each gaze direction.

Eyeglass lenses are classified as transmissive optical devices because they allow light to pass through. They come in various shapes with unique designs custom-layered onto each to allow precise light manipulation and magnification and to meet a wearer’s needs.

If you wish to change the privacy options, follow the instructions of the developer of your mobile device browser. Find below a few examples of links you may use to modify privacy options on your mobile device.

Accessory for Buslink Profibus-DP Generation C. Straight M12 Female Connector 5 Pins with Screw Terminals.

Astigmatic forms are lenses with at least one astigmatic surface—a surface that does not have a uniform curvature—and therefore lack rotational symmetry.

These lenses have a spherical front surface and an atoric back surface (varying curvatures across the lens) and are also designed to correct ocular astigmatism.

Your privacy is important for us. Therefore, we inform you that we use our own and third-party cookies to perform analysis of the use and measurement of our website in order to personalize content, as well as provide functionalities to social networks or analyze our traffic. To continue accept or modify the configuration of our cookies.

When we speak of optics, optical lens is the first optical component that comes to mind, and indeed optical lenses are now everywhere in our everyday life. We will see the different types, their manufacturing process and their different applications.

Carmen is a Clinical Research Optometrist at IOT Lenses. Her robust background in optometry has seen her serve in various roles, including at Quirónsalud and at +Vision. She holds a Master's degree in Clinical Optometry and Vision from Universidad Complutense de Madrid and an additional expert certification in Clinical Optometry from Udima Universidad a Distancia de Madrid.

Eyelens

The material is cut in preform of specific dimension, heated and then pressed in hot tooling. After unmolding, finishing is done, like grinding of the edges or final polishing can be requested according to the quality requirements and the quality of the tooling.

Though lens shape and lens type are closely related, they have distinct characteristics and impact the lens’s function differently.

Lens

With a meniscus lens, both sides of the lens have a curve, but the curves bend opposite each other. One side will bend outwards, and the other will bend inwards (as opposed to biconvex, where both sides bow out, and biconcave lenses, where both sides bend inward). When looking at the lens, a positive meniscus lens is thicker in the center and thinner at the edges. A negative lens is the opposite and thinner in the center of the lens while thicker at the surrounding edge. The difference comes from addressing varying spherical aberrations.

Download Table | Estimates of the diffraction-limited spot size, d s∞ , for various effective numerical apertures, NA ef f . from publication: The theory ...

The process also referred as cold machining consist of removing material with mechanical friction of grinding or polishing pads including hard grains. The process usually long (some hours) can be semi automated or partially automated. The polishing pads are changed several times along the process with smaller and smaller grain in order to reach the required quality. The higher the polishing quality request, the higher the time a lens need to be polished.

These cookies are essential to provide you with services available through our website and to enable you to use certain features of our website.

We may request cookies to be set on your device. We use cookies to let us know when you visit our websites, how you interact with us, to enrich your user experience, and to customize your relationship with our website.

As optical lenses specifications are complex, we recommend to design them according to the ISO10110 norm, in order to get quicker and more accurate quotes.

Ring Light · 18 Inches 48cm - Ring Light Stand (NEW AND UPGRADED) · 18 Inch Ring Light LED - Ring Light Stand (EXTRA LARGE 48CM) · 22 Inch Ring Light With Bag, ...

Cameralens

The focal point is a specific spot along the optical axis where light rays converge after passing through the lens. This spot is crucial because it is where objects come into focus. The distance from the center of the lens to the focal point is known as the “focal length.” Lenses with a short focal length bend and focus light more sharply, giving them greater optical power. This makes them ideal for applications like reading glasses that require magnifying close objects but less suitable for applications that require significant magnification, like intense corrective lenses. Conversely, lenses with longer focal lengths bend light more gently and have lower optical power, making them better suited for observing distant objects, like when piloting planes or viewing faraway horizons in landscape photography.

Fresnellens

Presentation Mode Open Print Download Current View. Go to First Page Go to Last Page. Rotate Clockwise Rotate Counterclockwise. Text Selection Tool

Commitment to innovation and customization in optical lens technology goes a long way. Tailoring lens designs specifically to the nuanced requirements of a wearer can result in lenses that exceed expectations in performance and quality. Achieving optimal visual clarity involves technologies that achieve the following results:

IOT integrates sophisticated methodologies into each lens to cater to a broad spectrum of visual needs, ensuring function and comfort in every lens design.

Away from the center of the lens, oblique aberrations can reduce optical quality. Minimizing this impact can significantly enhance wearer satisfaction and comfort. Technologies, like IOT’s Digital Ray Path 2, minimize peripheral blur common to lenses such as progressive lenses by incorporating a wearer’s accommodative capacity, creating a high-definition visual experience for wearers.

An optical lens is crafted from transparent materials such as glass or plastic and is designed to manipulate light through refraction. These lenses bend light to bring images into focus, produce magnification, enhance projection, and correct optical aberrations. While cameras and telescopes also use optical lenses, they primarily serve as the foundation for vision-correcting glasses.

LED Backlight Tvs at Office Depot & OfficeMax. Shop today online, in store or buy online and pick up in stores.

Defined in ISO:18476:2017, a free form lens is a lens in which at least one free form surface is produced using free-form technology. This does not include conventional casting/molded front surface progressive-power surfaces.

The form of a lens refers to the physical curvature of the lens surfaces. The form and material of a lens significantly influence how it refracts light. Lenses can be convex, concave, or a combination of both, each form bending light differently. Convex lenses cause light rays to converge, focusing the light, while concave lenses cause light to diverge, spreading it out. The choice of material affects how much light slows down and must be considered when designing lenses to achieve the desired optical properties.

You can change your preferences and decline certain types of cookies to be stored on your computer while browsing our website. You can also remove any cookies already stored on your computer, but keep in mind that deleting cookies may prevent you from using parts of our website.

To learn more about the science and technology driving the forefront of the optical industry, get in touch and see which IOT lens designs are right for your customers.

As light moves through a lens, it refracts or bends. Refraction allows the lens to either converge (focus) or diverge (diffuse) the light rays passing through it. The degree to which the light bends is determined by the lens's refractive index, which dictates how much the speed of light is reduced as it enters the lens material. This slowdown in speed is critical for manipulating light’s path, making it essential for designing optical lenses. Vision is corrected by focusing light precisely on the retina. Additionally, labs can manipulate how and where light converges or diverges by altering the shape and material of a lens.

Within these categories, lens shapes combine in ways that affect light refraction, prompting various changes in vision. The optical industry mainly uses a meniscus lens, while other subcategories are found in equipment ranging from projectors to telescopes.

These are the simplest form and most commonly used, with two spherical surfaces. Spherical lenses have rotational symmetry around the imaginary line that joins the center of each surface.

Optical lens manufacturers can create custom lenses that fix nuanced and specific visual issues by blending various technologies, shapes, functions, and forms. The most common types of lens designs for vision issues are:

The magnification due to the lens is defined as the height of the image divided by the height of the object.

Use: We use HubSpot to analyze user interactions with our Sites and to optimize our marketing efforts. HubSpot cookies allow us to:

This is a generic term which technically encompasses all lenses that are not spherical, like progressives and free form lenses. Aspherical lenses are manufactured from spherical semi-finished blanks with one aspherical surface, usually in the form of a conicoid.

Cookies are small files that web pages, online stores, intranets, online platforms or similar, store in the browser of the user who visits them and are necessary to provide innumerable advantages to web browsing in the provision of interactive services.

We also use different external services like Google Webfonts, Google Maps, and external Video providers. Since these providers may collect personal data like your IP address we allow you to block them here. Please be aware that this might heavily reduce the functionality and appearance of our site. Changes will take effect once you reload the page.

For example, these cookies may track things such as how long you spend on the website or the pages you visit which helps us to understand how we can improve our website site for you.

Website Owner: INDIZEN OPTICAL TECHNOLOGIES SL - CIF B84465921- IOT Postal Address: C/Suero de Quiñones 34-36. 28002, Madrid (Madrid), España Contact: Phone: 91 833 3786 - Email: proteccion_datos@iot.es Activity: Innovation in lenses

In its simplest form, an optical lens focuses or disperses beams of light through refraction. The oldest optical lens discovered, the Nimrud lens, dates back to eighth-century Assyria. The Assyrians crafted this ancient lens from rock crystal with similarities to modern lenses. The discovery of the Nimrud lens as an early precursor to contemporary eyewear reveals the advanced technology of the Assyrians and the longstanding human endeavor to manipulate light and enhance vision through optical lenses. Fortunately for today's wearers, advancements in optical science have significantly broadened the scope and efficacy of lenses.

Description: These allow us to recognize and count the number of users of our Sites and understand how such users navigate through our Sites.

These cookies are strictly necessary to provide you with services available through our website and to use some of its features.

We provide you with a list of stored cookies on your computer in our domain so you can check what we stored. Due to security reasons we are not able to show or modify cookies from other domains. You can check these in your browser security settings.

If you do not wish to be tracked by cookies, Google has developed a complement which may be installed on your browser. Find it here: http://goo.gl/up4ND.

Description: HubSpot cookies are used to track visitors and understand their behavior on our Sites. This helps us to better engage with our users and improve their experience.

Refraction drives optical lens technology, but it also collaborates with other factors, like shape and focal length, to manipulate light and images when a wearer looks through the lens.

This Website http://www.iotlenses.com does not install cookies on the Users’ devices prior to acceptance thereof by the Users.

Additionally, IOT has a presence in portals and third-party services for which, if you want to know the privacy conditions and use of cookies, you should consult the policies provided by them:

We hereby inform you that if you reject the installation of cookies or disable these in your browser settings, certain services may not be available to you and therefore you may not be able to gain access to certain services and/or make full use of this Website http://www.iotlenses.com.

Designing of optical lenses can be done with specific software, Zemax being the most famous of them. It usually require optical designer with sound understanding of optical materials, optical shapes and optics manufacturing constraints.

We fully respect if you want to refuse cookies but to avoid asking you again and again kindly allow us to store a cookie for that. You are free to opt out any time or opt in for other cookies to get a better experience. If you refuse cookies we will remove all set cookies in our domain.

As individuals can have unique visual requirements, lens forms sometimes combine elements from different meniscus lens types to provide proper visual corrections.

These are lenses that consist of a spherical and cylindrical surface. Spherocylindrical lenses were the first lens form used to correct ocular astigmatism.

Click on the different category headings to find out more. You can also change some of your preferences. Note that blocking some types of cookies may impact your experience on our websites and the services we are able to offer.

Infraredlens

Combining complex curvatures on both lens surfaces results in variable base curves and flatter lenses. Camber technology provides labs with advanced custom lens curves bespoke to a patient’s visual needs. The technology provides an optimal visual experience for even the most complex presbyopic prescriptions.

These cookies are used to provide you with a more personalized experience on our website and to remember choices you make when you use our website.

DG BEADLE · 1940 · 8 — IT is usually assumed that the depth of focus, t, of a well-corrected microscope objective is given by one or other of the following formulæ: where N is the ...

Diamond turning is usually used for complexe shapes and don’t necessitate further polishing. The equipment is similar to a CNC machining center where lenses are made one by one.

Cookies which are not mandatory to navigate this Website http://www.iotlenses.com may be disabled by entering “Set cookies on the button below to the right”.

Convexlensimaging

2023813 — Modern lenses attempt to set the angle of incidence and angle of refraction to equal values to decrease the amount of aberration, and feature a ...

This cookie notice provides information about the types of cookies INDIZEN OPTICAL TECHNOLOGIES SL uses and why we use them. Your access to, and use of, the Site http://www.iotlenses.com. We inform you about our cookies Policy.

lenses中文

The science behind optical lenses determines how well they function. The design and technology they incorporate impact all aspects, from light refraction to visual focus to oblique aberrations.

Cookies are very small text files that are stored on your computer when you visit a website. We use cookies for a variety of purposes and to enhance your online experience on our website (for example, to remember your account login details).

QEnm ...

Lenses can also be classified according to their form and structure. Frequently used lens forms in ophthalmics consist of:

In order to enhance the optical properties of a lens, optical coatings are often applied on the lens. Optical coatings consist of thin layer(s) of metal or chemical elements that can reduce reflection of light on a certain wavelength range these coatings are called AR (Antireflect) coatings.

These cookies are used to collect information to analyze the traffic to our website and how visitors are using our website.

The best 360 viewer on the market. Sleek, lightweight, 100% responsive, image-enhancing, and so much more! Fast. Unmatched loading time for your 360 tours.

Thanks to our Steady Methodology, the swim effect found in progressive lenses is reduced by controlling for unwanted cylinder power and changes to mean power in the periphery. The additional technology added to the lens design significantly reduces blurring around the edge.

Most common optical lenses are made of optical glass (from main manufacturer like : Schott, Corning, Ohara or CDGM) but can also be made of metal (Germanium) or other materials (ceramics, Silicon, Zinc selenide, sapphire, polymers etc.).

Spherotoric lenses consist of a front surface sphere and back surface torus and are the modern solution to correct ocular astigmatism.

An optical lens is a passive optical component that is transparent to wavelength in the optical field (from deep UV to far IR) and that will alter the path of light either in converging or diffracting the light.

Because these cookies are strictly necessary to deliver the website, refusing them will have impact how our site functions. You always can block or delete cookies by changing your browser settings and force blocking all cookies on this website. But this will always prompt you to accept/refuse cookies when revisiting our site.

Ms.Cici

Ms.Cici

8618319014500

8618319014500