Marine Spill Kit - 1900 Litre - marine spill kit

This begins with Axon's fundamental TASER 10 Training curriculum, which combines online eLearning segments, in-person classroom curriculum (including tabletop drills), as well as physical skill-building, stress-inoculation, and critical-decision-making drills.

It may be helpful to observe behaviour patterns to identify any behaviours of concern. Pedestrian behaviour can be considered including important questions like

Wet floor risk assessment

Perhaps the most important difference—both from an operational and training standpoint—is the fact that the probes themselves are deployed one at a time. Anyone familiar with earlier TASER devices—and that is to say, anything predating this newest, just released version—is accustomed to the fact that a single trigger pull deploys both probes.

Some factors may be particular to individual workplaces. Consider any other factors that could affect slip risk such as hot oil, level changes, etc

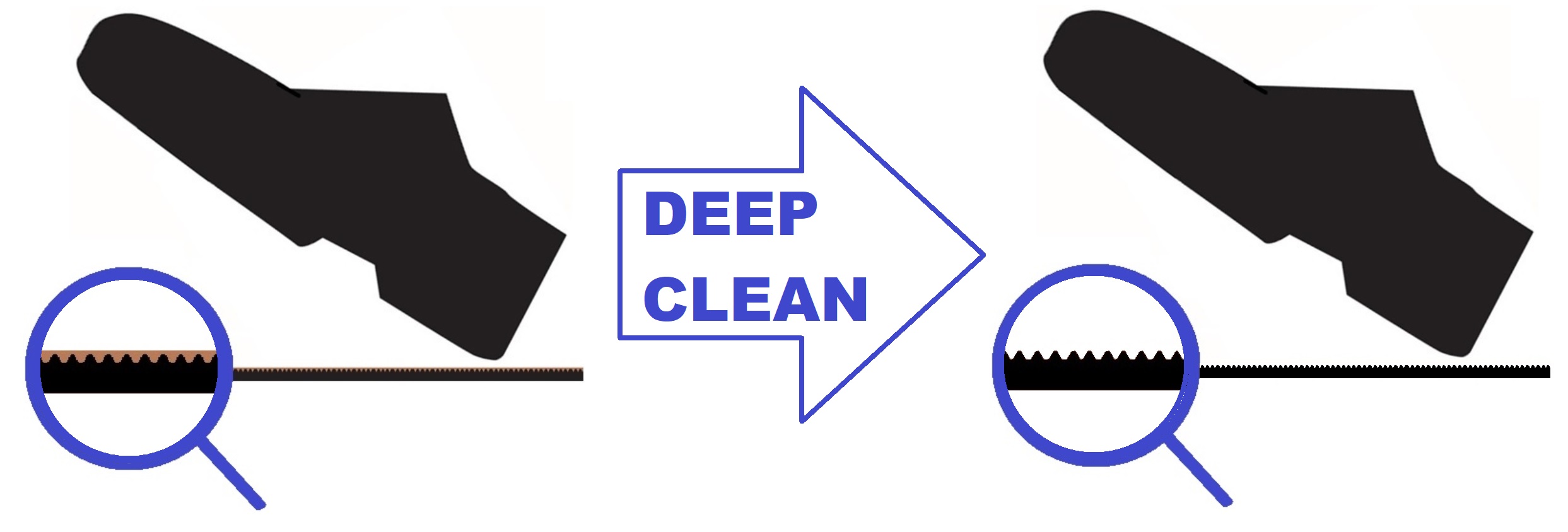

The UK Timber Decking and Cladding Association (TDCA) advise "The key factor in preventing slippery decking is to ensure that the deck surface is kept clean and surface deposits such as mildew, algae and fine mosses are kept at bay." Deep cleaning is likely to be required before most surface treatments/ resurfacing. For effective deep cleaning, use the correct chemical, physical and thermal energy.

The TASER 10 requires two trigger pulls—one per probe—which will almost certainly have some training implications and necessitate serious retraining for most officers.

Wet floorhazardand control

For slippery surface resurfacing consider our advice on “Slip Resistance” under Selecting Slip Resistant Pedestrian Surfaces, for example, specify the expected slip-resistance and anticipated life, allowing for wear and tear. Choose and apply new surfaces carefully. In most cases, a new cleaning regime may be required

Late last month, Axon announced the launch of its next-generation conducted energy weapon (CED), the TASER 10. There are some substantial differences between this new device and every other previous version, including a significantly increased range of 45 feet—compared to previous models that have a 25-foot maximum range—potentially providing increased space and time to de-escalate and resolve confrontations with non-compliant subjects.

Transport – walkways and yardsPublic Admin –walkways, entrances/exits and car parksHealthcare – walkways, bathrooms and entrances/exitsIndustry – walkways and entrances/exitsConstruction – walkways and entrances/exitsRetail - entrances/exits, cold rooms and shop aisles

Pat Madden—TASER Senior Vice President—told POLICE, "There is always going to be a learning curve when transitioning from one technology to another. However, we are finding that with our evaluation partners, officers are finding the TASER 10 intuitive and easy to use."

slips, trips and falls hazards in the workplace

Slips on a level typically occur on contaminated harder surfaces and not on soft surfaces such as carpets. Slippery Surface locations include wet slippery surfaces, walkways, entrances/ exits and bathrooms. Potential slippery surface slip-risks should be risk assessed including history, data and measurements

Our website uses cookies to enhance your browsing experience and to collect information about how you use this site to improve our service to you. By not accepting cookies some elements of the site, such as video, will not work. Please visit our Cookie Policy page for more information on how we use cookies.

Further, the new device can deploy up to 10 probes (compared with four probes previously), which the company says affords officers the opportunity for multiple repeated attempts to make a good connection to create neuromuscular incapacitation (NMI). Axon says that by leveraging "smart technology" the new ECD delivers only the charge necessary to achieve NMI—regardless of how many probes make a connection, the device will only deliver current to the best four connections.

HSE UK provides useful advice on improving slip resistance. The advice on acid-etching (and hydrofluoric acid) is important. HSE UK has a wide range of case studies including cleaning, matting, design, maintenance and training. HSL advise about an abattoir that reduced slips costs from £207,800 to £136,000 over three years by “clear” floor specifications, “matched” footwear, monitoring and removal of chequerplate.

Slippery floorhazardor risk

Provide advice and training on safeguards and controls. Signs and safety colours may be useful to back up training and instructions, and to identify high-risk areas.

Regulations 9, 23, 99 and 105 of the General Application Regulations outline that pedestrian surfaces should be not slippery. In limited cases, there may be a justifiable reason for intentionally slippery surfaces, for example, on a van loaded by sliding the load, anti-climb paint. In these cases, contamination and pedestrian risk factors must be very carefully risk assessed and warning signs and slip-resistant footwear are likely to be required.

To complete a workplace slip-risk assessment, combine the individual slip-risk assessments using a Mapping Tool or using a spreadsheet or some equally effective solution.

For slippery surface treatments consider our advice on “Slip Resistance” under Selecting Slip Resistant Pedestrian Surfaces, for example, specify the expected slip-resistance and anticipated life, allowing for wear and tear. In most cases, a new cleaning regime may be required

Slippery floorhazardprevention

Preventing or restricting pedestrian access in a clear planned matter can be very effective in reducing slip risks, for example

The two-page Slip Prevention and Risk Assessment Tool Sample, or a similar document, can help prioritise areas for attention and record and track progress

Also consider the ability to control footwear in the workplace. Has slip-resistant footwear been identified as required PPE?

Six sectors account for 55% of the workforce but 81% of slips, trips and falls (STF) - these are the “Big Six” sectors. Some areas typically associated with Slips, Trips and Falls (STF) in the “Big Six” sectors can be identified by looking at causes for each sector, for example,

The Safety, Health and Welfare at Work Act requires risk assessment. The Slip Risk Assessment and Prevention Process can be completed with three key steps.

For Slippery Surface Controls, to check the improvement, assess slip-resistance before and after treatment, and monitor periodically thereafter to ensure continued slip-resistance. New cleaning regimes are likely to be required with new, treated, or resurfaced pedestrian surfaces.

The history of incidents and near-slips may indicate that a surface is slippery. Check for a history of slips or near-slips, or other evidence that pedestrians slip on the surface. Check with workers if the surface is slippery, not just when dry but also when contaminated. Employees should be actively asked for their views – "does the surface feel slippery underfoot when dry or wet/ contaminated?"

Where a surface originally had good slip-resistance, it may be possible to restore that initial good grip with a thorough deep clean. Slip-resistance may have been reduced because of a build-up of dirt, detergent, polish, material from shoe soles. For cleaning and deep cleaning it's important to use the correct chemical, physical and thermal energy. Consider the manufacturers advice on floor cleaning for that particular floor. Deep cleaning is likely to be needed before further surface treatments.

The Napo animated video "Shining example" (1 minute, 8 seconds) shows the problem with choosing a floor surface based solely on how it looks

slip, trip and fall hazards control measures

The slip-resistance of a pedestrian surface is likely to change because of traffic, wear and tear, contamination and cleaning. The Safety, Health and Welfare at Work Act requires designers, manufacturers, importers or suppliers of articles to provide or arrange for adequate information to ensure safe use.

Further, agencies that purchase new ECDs in conjunction with Axon's VR training platform can engage in simulated scenarios designed to increase physical proficiency such as body movement and weapons transitions, improve decision-making skills, as well as rehearse and refine verbal de-escalation techniques.

Resurface the pedestrian surface with a material that provides a low slip-risk. Methods of resurfacing a slippery surface include*:

Interestingly, NMI is achieved despite a massive reduction in the voltage output of the device, down to approximately 1,000 volts, compared with roughly 50,000 volts commonly produced by previous generations of TASER devices.

Unsurprisingly, the new ECD integrates seamlessly with the company's cloud-based data storage service—Axon Evidence—in such a way to enable agencies to record (and later retrieve) information on user activity and event logs. Further, the device also features "smart holster" technology which—when paired with certified holsters—allows the TASER 10 to detect when it has been removed from a holster. This de-holstering event then emits a wireless signal to alert nearby body-worn and in-car cameras to begin recording (if they aren't already doing so).

Sliphazards in the workplace

Pedestrian footwear can mitigate against or contribute to slip-risk. Assess the slip resistance of employee footwear (especially slip resistance of the heels) using our advice on slip-resistant footwear.

This web page provides simple step-by-step advice on how to manage, assess and prevent work slips. The advice targets fixed level places of work. See our separate advice on Safer Stairs and Steps and work vehicles

Slip hazardexamples

Madden explained further, "For example, the X26P requires the user to effectively deploy two darts simultaneously, while the TASER 10 allows the user to deploy one probe at a time. The TASER 7 utilizes tilt select to switch between close range and stand-off cartridges, and with the TASER 10, officers can pick their own spread to achieve NMI."

With a single trigger pull resulting in only one deployed probe—necessitating a second trigger pull to hope to achieve neuromuscular incapacitation (NMI)—there will certainly be some serious training implications.

Finally, the company's Master Instructor Schools (MIS)—hosted at a variety of agencies across the United States and around the world—have begun incorporating TASER 10 training into their curriculum.

Ms.Cici

Ms.Cici

8618319014500

8618319014500