Guide to Road Design - road width australia

RubberParkingstopsAmazon

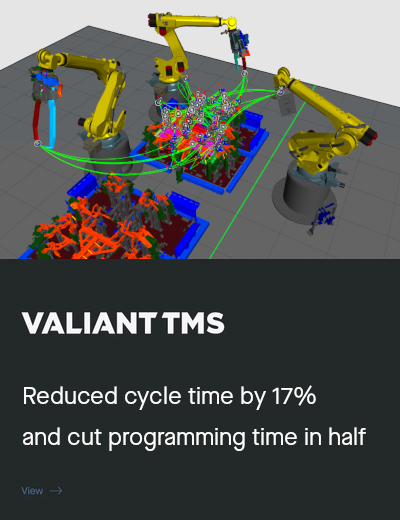

Our software generates collision-free motion paths during runtime. Enable high throughputs and pick-rates for multiple robots while quickly reacting to changes in the market and supply chain.

Realtime Robotics’ innovative technology generates and runs robots through optimized motion plans and interlocks to achieve the shortest possible cycle time in multi-robot cells. Our automated collision-free motion planning software and expertise enables you to:

SmallWheel stops

Wheel stops are one of our biggest selling ranges at Pittman®. We keep large stocks of GNR rubber Park It rubber wheel stops at our main warehouse so that they are ready for collection or overnight delivery nationwide. Our steel wheel stops come directly from the manufacturer, and are again available for speedy delivery to any site nationwide, normally in 2 to 3 days but express options are also possible.

The easier programming is, the more time you’ll save. The more projects you’ll complete. And the more complex applications you can tackle. Learn how we can reduce downtime, increase efficiency and improve overall workcell performance.

Pittman® offers the largest range of wheel stops in both rubber and steel. Our Park It rubber wheel stops from GNR are the preferred choice of car park operators, retail parks, airports, commercial and industrial sites. Our steel wheel stops are the first call for warehouse and distribution sectors already installed in many distribution centres and car parks around the country.

Wheel stopshome depot

RubberParkingStopsnear me

Steel is a highly suitable material for truck wheel stops, ideal for heavy duty requirements. Truck wheel stops are common in warehouses, freight depots and most other industrial settings. Additionally, they can be used as wheel guides for truck parking bays, with a higher profile to suit HGVs and articulated lorries.

Made with a tough PPC plastic material for a hard-wearing design. Plastic wheel stops will not chip, rot or crack while in use. They are highly durable and suitable for use with cars and vans only. The plastic design reduces flexibility so they are only suitable for level surfaces. The non-reflective design also means that they are suitable for well-lit environments.

Wheel chocks are used to prevent vehicles from accidentally rolling. They can be used with cars and vans but are more common with HGVs, trailers, aircraft, and other large vehicles. Wheel chocks are available in rubber and plastic and are loose lay for easy insertion and removal from behind vehicle wheels. Some options can be equipped with chains to bolt them down into the area of use, such as loading bays or airport aprons.

Wheelstop dimensions

Realtime’s Optimization-as-a-Service uses a combination of proprietary optimization software and industrial automation expertise to help you reach your cell’s target cycle time in days or weeks, not months.

Rubber wheel stops are much more durable than concrete designs. The rubber design is also much more cost-effective to install or replace if needed.

For HGVs and larger vehicles you will require truck wheel stops. Truck wheel stops are a rubber kerb designed to stop trucks from colliding in loading bays. A single wheel stop will be required for each vehicle wheel.

Need help choosing wheel stops? Read our wheel stops guide for help on choosing the material or type for your next project.

Most wheel stops are suitable for installing into concrete or tarmac. However, it is advised never to install wheel stops into block paving.

Casterwheel stops

Precast concretewheel stops

Concretewheel stops

There are several measures you can take to make sure wheel stops are not a trip hazard. First, ensure the area is well lit - the wheel stops need to be highly visible at all times, especially at night. Second, only install them in areas with prominent parking spaces in use. Finally, ensure you are purchasing wheel stops with reflective markings for increased visibility.

Be sure to note the surface type and integrity before installing wheel stops. Wheel stops are generally fine to install on concrete or tarmac but are not recommended into block paving. Complete a thorough risk assessment of the area and note any other obstacles or hazards that could effect the use of the wheel stops.

Our proprietary software and industrial automation expertise is the difference maker that can take your projects and performance to new heights.

Rubber wheel stops should have their reflective markings moulded on. The XPT wheel stops come with high quality moulded markings for increased visibility and resistance to wear. Avoid cheaper alternatives that have markings glued on. Adhesive markings are more likely to come off over time.

Are you installing wheel stops in a car park? Or are you trying to bring vehicles to a halt within loading bays? The area will play a big role in what kind of wheel stops you need for your project. Tougher environments will require tougher wheel stops.

It's important to note what vehicles the wheel stops are required for. Most standard rubber wheel stops will suffice for cars or vans, but HGVs will require a more robust option due to the size and weight of the vehicle wheels.

Ireland's largest stock of wheel stops for cars, vans and HGVs. Single piece rubber designs allow for fast installation on concrete or tarmac surfaces. Choose rubber wheel stops - avoid concrete wheel stops and save on replacement and maintenance costs.

Made from a recycled rubber material, rubber wheel stops are hard-wearing during regular use and are suitable for cars, vans and HGVs. Single-piece designs mean fast installation,while the flexible nature means rubber parking blocks can contour to uneven ground. Reflective markings help with boosting visibility.

Ms.Cici

Ms.Cici

8618319014500

8618319014500