CLOSED-DOOR Synonyms: 52 Similar and Opposite Words - door closed

Peat soil

“The pre-shift hoist inspection should also include any guidelines or areas for assessment recommended by the hoist’s manufacturer,” Frazier added. “Those are in the equipment owner’s manual.”

Also, the operator should document the findings of every pre-shift hoist inspection, either on paper or electronically. The facility should retain those records to confirm they are being performed and to identify any areas of concern or patterns of wear.

MHI is the nation’s largest material handling, logistics and supply chain association. MHI offers education, networking and solution sourcing for members, their customers and the industry as a whole through programming and events. Learn more about MHI.

peat moss中文

To create your own maps online and in real time, plan exploration activities by viewing land status or download GIS data to add to your own maps, visit GeoVic.

泥炭

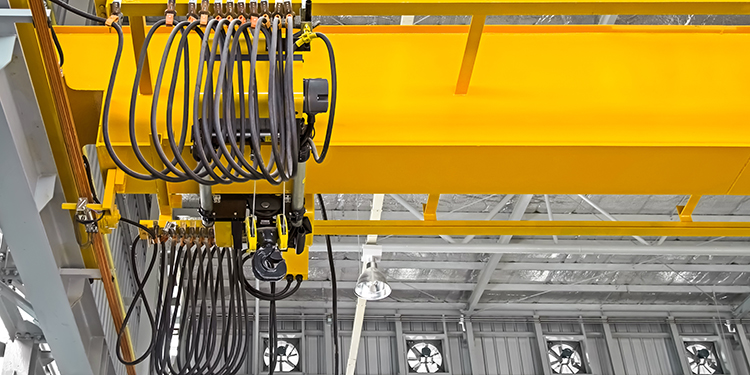

Pre-shift hoist inspections are important because hoists lift and lower heavy loads overhead. A hoist failure could potentially lead to the load falling from its suspended height, endangering the lives of personnel. A drop could also damage the lifted product, surrounding equipment, and facility structures.

We are committed to genuinely partner, and meaningfully engage, with Victoria’s Traditional Owners and Aboriginal communities to support the protection of Country, the maintenance of spiritual and cultural practices and their broader aspirations in the 21st century and beyond.

Sphagnum

Peatland

Peat is an accumulation of partially decomposed plant debris in a water-saturated, anaerobic environment, that is, a peat bog. The unique properties of peat make it useful in agriculture where it is used to assist aeration and water retention in soils, as a potting mix ingredient, as a fertiliser carrier, in mushroom beds and earthworm culture, and in seed inoculating and flower packing.

The existence of many peat deposits in the state, sedge peat in particular, and strong markets in the horticultural and agricultural industries, suggest prospects are good for new peat-producing operations in Victoria.

Additionally, routinely verifying that a hoist is in safe, proper operating condition maximizes productivity. This confirmation reduces the risk of unplanned downtime and can extend the service life of the hoist.

“For operations needing more help with establishing a pre-shift hoist inspection process, HMI offers a comprehensive guide. HMI 100.24 Hoist Inspection and Maintenance Manual is a free download,” said Frazier. “The manual also includes helpful checklists that detail these key inspection areas.”

The high porosity, good absorption and ion-exchange capacity of peat make it a natural filtering and cleaning material. Its uses include industrial and domestic waste treatment, cleaning up oil spills, and filtering sewage.

Bog

peat中文

There are several key areas to assess when performing a pre-shift hoist inspection, noted Matthew Frazier, Senior Manager of Engineering in New Product Development at HMI member Columbus McKinnon. Frazier presented this portion of the webinar.

The Overhead Alliance is the marketing arm to the Crane Manufacturers Association of America (CMAA), the Hoist Manufacturers Institute (HMI) and the Monorails Manufacturers Association (MMA) which provides information on the benefits of using overhead lifting technologies and safety.

Multiple safety regulations and standards call for performing pre-shift hoist inspections. Sources include the Occupational Safety and Health Administration (OSHA), the American Society of Mechanical Engineers (ASME), and HMI. Applicable codes and standards are:

There are many peat deposits in Victoria, for example, in Western Port, South Gippsland, Western District Plains and the Eastern Highlands. Peat in Victoria is used mainly as a soil conditioner. The most recently developed deposit is at Swan Marsh near Colac in the Western District Plains.

peat soil中文

For those looking for a deep dive into pre-shift hoist inspections, HMI produced a webinar focused solely on this topic. In addition to hoist inspection publications, HMI offers a variety of other technical resources — including a comprehensive library of product guides; a hoist certification program; OSHA Alliance safety tip sheets, fact sheets and quick cards; multiple technical papers and more — via its website at www.MHI.org/hmi.

We acknowledge and respect Victorian Traditional Owners as the original custodians of Victoria’s land and waters, their unique ability to care for Country and deep spiritual connection to it. We honour Elders past and present whose knowledge and wisdom has ensured the continuation of culture and traditional practices.

Before using a wire rope, chain, or lever hoist for the first time during a shift or day, it’s important that the operator perform a pre-shift hoist inspection. These inspections, recommended by the Hoist Manufacturers Institute (HMI), ensure the safety of personnel and the proper functioning of the hoist. The HMI Technical Committee recently presented a webinar, “Dos and Don’ts of Safe Hoist Operation,” highlighting several best practices — including inspections. Ultimately, pre-shift hoist inspections keep an overhead lifting operation safe.

Ms.Cici

Ms.Cici

8618319014500

8618319014500