What are the Benefits of Anti-Glare or Anti-Reflective ... - what does anti reflective coating do

The first lasers were made in the 60s, but it wasn’t until the early 90s that Anthony E. Siegman proposed a standard measurement for how close a laser beam is to this ideal Gaussian beam or, in other words, the measurement of laser beam quality.

The ISO norm also states a few extra rules about the measurement of diameters (especially when using array sensors such as CCD or CMOS sensors):

The objective lens of a Fraunhofer achromat consists of a convex front lens made of crown glass and a concave rear lens made of flint glass. This combination of different types of glass reduces chromatic aberration and increases contrast and colour fidelity.

Fraunhofer-style achromats with carefully selected BK7-F2 glass combinations are more than adequate as entry-level telescopes. However, as your experience increases over time, you are likely to turn to higher-quality apochromats.

The higher the refractive index, the more light is refracted, so the lens can be less curved. This reduces spherical aberration, but highly refractive glass types are usually more expensive. Glass combinations with a high Abbe value have lower colour dispersion and thus reduced chromatic aberration.

Sep 12, 2014 — A prism is a transparent geometric optical object with a minimum of two polished plane faces inclined relative to each other, ...

What Siegman proposed is to use a dimensionless value for laser beam quality, by dividing a real laser’s BPP with the one from an ideal laser. We therefore obtain a ratio that indicates how close your laser beam is to the perfect Gaussian beam, and Siegman called this value M2 (pronounced m-squared).

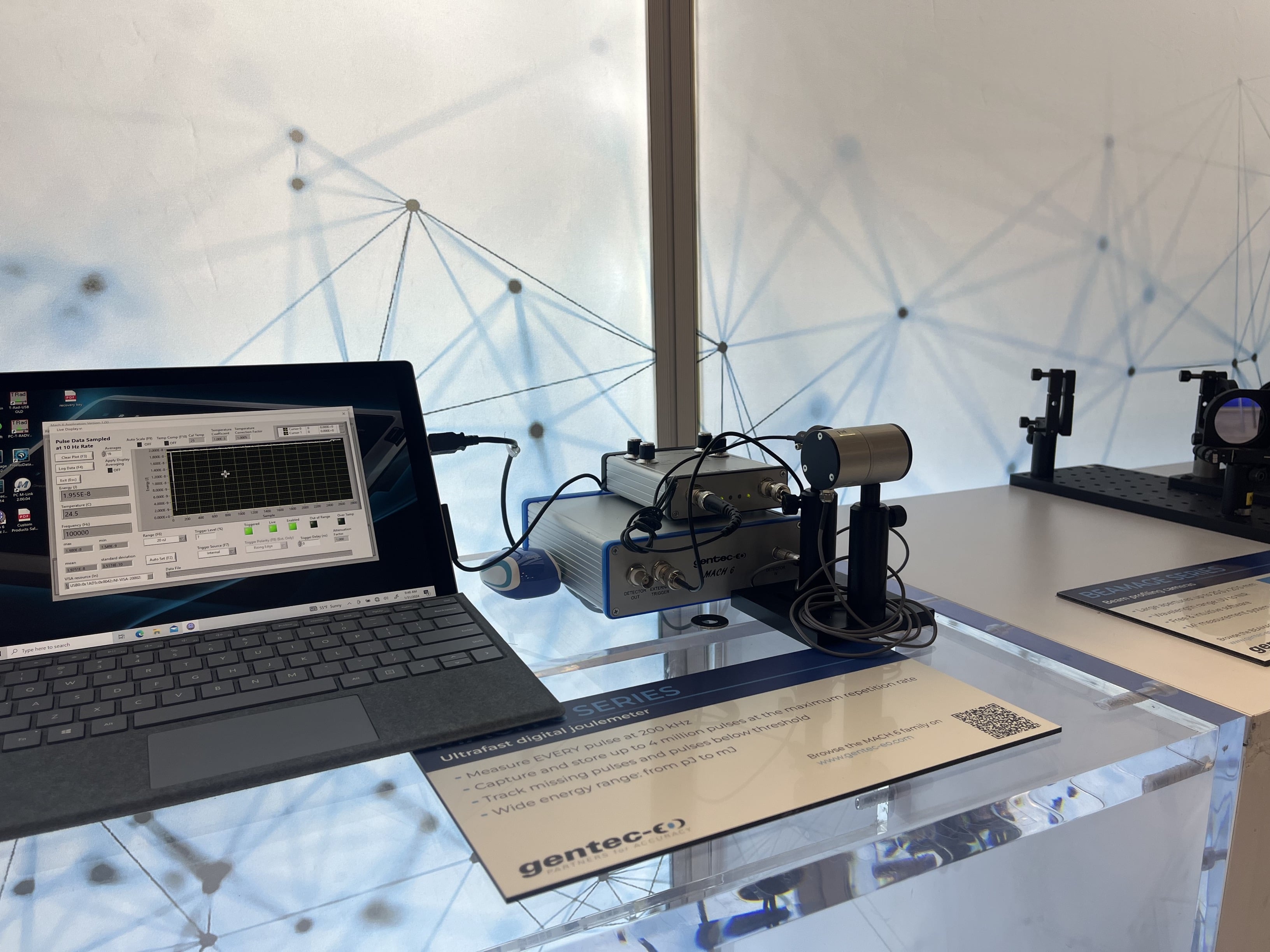

Laser power detector for measurement up to 50 000 W that traps > 97 % of the incident light and handles high intensities of small beams.

Today, there are more than 200 known optical glass combinations. The majority are derived from the two most important families of glass: crown glass and flint glass. There are many optical and material-specific parameters relevant in industrial production. Many manufacturers offer glass with the same properties under different brand names. Nowadays, most of them design their products and processes in an environmentally friendly way and do not, for example, use mixtures of lead and arsenic.

And how far do you need to go to be in the far field to measure the divergence? Are these two data points enough? The folks at the International Organization for Standardization, or ISO, decided to put an end to all this confusion, so they wrote a norm explaining how to measure and calculate M2 properly: ISO 11146.

ABCD matrix Gaussianbeam

Jun 28, 2016 — used ? V-Flash UV Curing Oven (3D Systems) V-Flash is no longer ... With regards to UV curing ovens not being mass-market products ...

JML Optical Industries ... Custom manufacturer of precision optical lenses made from optical glasses, fused silica, quartz and Zerodur™. Types include aspherical, ...

Ideal Gaussian beams have the smallest BPP for a given wavelength. Since we know that θideal = λ / (π w0,ideal ), the BPP for an ideal beam simplifies to BPPideal= λ / π. While it is simple to calculate, the BPP is not the best tool to compare one laser with another, because its ideal value changes with the wavelength.

When most people think of an astronomical telescope, they imagine the classic lens telescope with a lens at the front, and an eyepiece to look through at the back. Although they have largely been replaced by mirror telescopes for professional use, lens telescopes still have many fans among amateur astronomers.

Jul 26, 2017 — A fresnel lens has insufficient optical quality to image the aperture of a projecting light fixture. A spot fixture (aka followspot) will have ...

Portable laser power meter for up to 250 W with flexible calibration options so the customers only pay for what they use. Includes 3 measurement modes : SSP, CWP and SSE.

The ISO norm explains a method to calculate M2 from a set of beam diameter measurements, in a way that minimizes sources of error. Here are the main steps:

Gaussianbeamintensity formula

Laser theory teaches us that by design, most laser beam should have a Gaussian beam shape. The fundamental mode of the Gaussian beam (TEM00) is an ideal that most laser system designers want to achieve for three main reasons:

May 19, 2022 — All single vision EyeBuyDirect lenses come standard with an anti-reflective coating. High-index lenses naturally reflect more light, so this is ...

Meaning, is it Death Star material or more of a “I can annoy you with my laser pointer” material. But, in more practical terms, focusing laser beams tightly is particularly important when the application at hand is imaging, manufacturing, or destroying planets at a distance. Smaller beam waists mean having a better resolution as well as the possibility of reaching higher power densities.

But in real life, nothing is perfect, and a pure Gaussian beam with a TEM00 profile and a bell-shaped curve that spreads on infinitely is, unfortunately, never achieved.

Gentec-EO's high-accuracy laser beam measurement instruments help engineers, scientists and technicians in all sorts of laser applications from the factory to the hospital, laboratory and research center. Learn about our solutions for these measurement types:

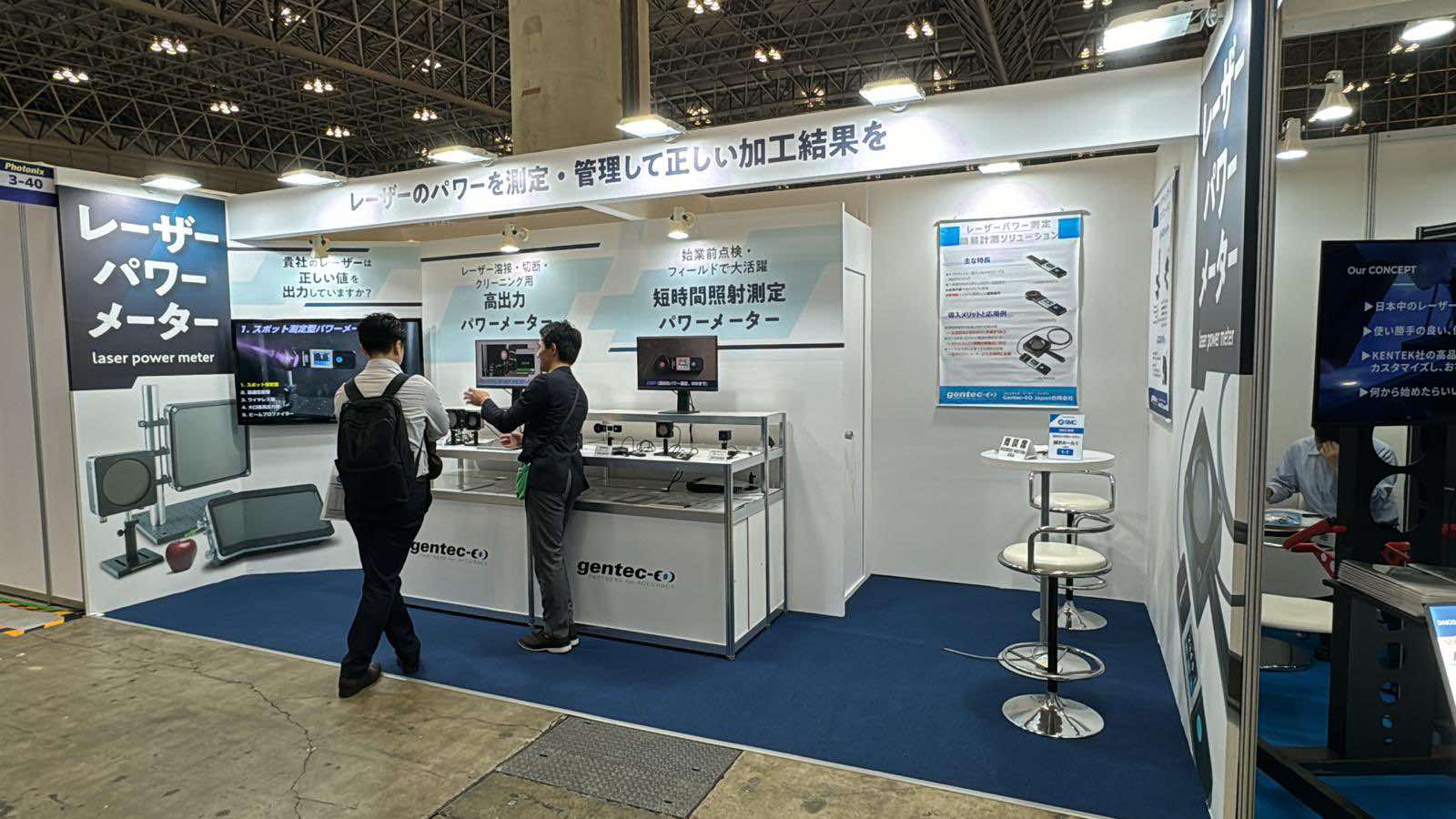

Laser specifications change over time for many reasons and it causes problems accross all industries. Learn about how laser output measurement solves numerous problems in YOUR industry. Download the guide below. Gentec-EO's high-accuracy laser beam measurement instruments help engineers, scientists and technicians in all sorts of laser applications from the factory to the hospital, laboratory and research center. Learn about our solutions for these measurement types: Laser power meters Laser energy meters Laser beam profilers Terahertz power meters

The beam parameter product (BPP) is one laser beam quality indicator that certain people use, and it is defined as the product of the beam’s smallest radius (the beam waist radius, w0) with the beam’s divergence half-angle (θ), measured at the far field. Units of measurement for BPP are mm-mrad:

Beam waistcalculator

Bear in mind that the use of FPL-53 is not chosen over FPL-51 in order to improve an objective’s chromatic aberration, but rather to reduce the focal ratio. This is an important factor in astrophotography when it comes to short exposure times and larger fields of view. Thus, an FPL-51 doublet refractor could have a focal ratio of 1:6.8, while a telescope with the same aperture using an FPL-53 doublet would have a focal ratio of 1:6 or 1:6.25. Experience shows that both have similar low chromatic aberration.

uEye stands for high-performance, easy-to-use USB and GigE industrial cameras. Customers can choose between the camera families uEye FA (IP65/67), uEye CP ( ...

Gaussianbeam

Triplet lens systems using both FPL-51 and FPL-53 tend to further reduce chromatic aberration, thus enabling even sharper images. Differences within this quality class can only be detected by measurements on an optical test bench.

Oct 31, 2017 — Take a glass surface such as your window, and take a look at some reflection on it at about a 45° angle through your polarizer. Now start ...

The most important component of a lens telescope is the objective lens. To be more precise, the objective lenses, because every modern objective consists of at least 2 lens elements. But why is that?

It is also common practice in systems with fiber optics to look for lasers with an M2 close to 1 to allow for good coupling with single-mode fibers. The beam waist for a real beam is defined as:

Laser specifications change over time for many reasons and it causes problems accross all industries. Learn about how laser output measurement solves numerous problems in YOUR industry. Download the guide below.

You might wonder (and many people do), how close is your real-life laser to perfection? In this guide, we will introduce you to the concept of laser beam quality measurement with the M2 parameter, which quantifies the laser beam quality, and how to measure M2 for a real laser.

Lenses have one big disadvantage compared to mirrors: they suffer from colour defects known as chromatic aberration. Light is refracted differently depending on its wavelength, blue light refracts more than red light. The result: unattractive colour fringes around the object you are observing and reduced contrast.

Gaussianbeam waist

Laserbeam waist

Berechnung der Schärfentiefe · Einfache Gleichung · Hyperfokale Entfernung · Nahpunkt · Fernpunkt · Schärfentiefebereich · Generalisierter Formalismus.

Once the M2 factor is defined, it is possible to inject it back into the equations for generalized Gaussian beam propagation. When you know your laser’s M2 factor, these equations describe how your REAL laser beam propagates, how tightly it can be focused and how quickly it diverges.

In the equation above, you can see that lasers with a high M2 diverge more rapidly than lasers with a low M2. Laser manufacturers like to provide the M2 factor in their specifications because it gives the users an idea of how easy it will be to work with their laser.

The refractive index refers to the ratio of the speed of light in a vacuum and the speed of light in a particular material at a given wavelength. The Abbe value of a material indicates the variation in the refractive index with changes in wavelength, known as dispersion.

That’s it! You now understand the fundamentals of M2 measurement… Any questions? Feel free to comment below or contact us, we will be happy to answer!

If you are trying to develop a laser with nondiffractive beams like Bessel beams, or higher-order Gaussian beams with donut profiles, or more simply a top-hat beam, M2 is not an indicator that you should be aiming for. It would not really make sense nor be of great usefulness. For some applications, knowing only the beam divergence would be enough and far more relevant.

Apochromats go one step further. A clever selection of glass types ensures that light of up to three wavelengths meet at a common focal point - even in compact telescopes.

Beam waistformula

In the moving stage case, setting up your system and automation routine can take a while, so you can save a lot of time and effort, because we did it all for you already! Our Beamage-M2 automated laser beam quality measurement system goes a few steps further than what was described above and it is so easy to set up that you can start measuring M2 values in a few minutes the first time, and in less than a minute once you get it going.

Siegman’s proposal became popular because of its simplicity, but experimentally it isn’t so straightforward, and some uncertainties arise from these principles. For example, if you want to measure the waist radius in the lab, how can you be sure that your measurement device is positioned exactly at the focus?

As you can see in the equation above, laser beams with a lower value of M2 can be focused more tightly than lasers with a high M2.

Beam quality measurement will also allow you to know how your laser beam will diverge. When you know your beam’s divergence, you can predict the size of your laser beam at pretty much any point in space. The beam radius for a real beam is defined as:

At the most basic level, all you need is a lens, a beam profiler and a ruler. You can read our application note that explains step-by-step how to measure beam profile quality with these basic tools and calculate the laser beam quality result using our free software.

Waist beambefore and after

Basically, it comes down to checking how your real beam waist and divergence compare to the ideal Gaussian beam at the same wavelength.

Now that you know more about laser beam quality measurement, you will have a better idea of whether it is actually what you need to measure. Keep in mind that M2 is an indicator of how close your laser beam is to the ideal TEM00 Gaussian beam.

Metric Stubby Ball-End Hex L-Key Set. Add to cart. 123…25. Page 1 / 25 ...

Although it is inexpensive, this method is time-consuming, so you have to wish that your laser is stable enough so that its M2 value doesn’t fluctuate while you are taking the various diameter measurements! A simple way to increase the acquisition speed is to mount the beam profiler on a motorized translation stage and automate the acquisition.

One nice thing about M2 is that it is dimensionless (i.e. no units of measurement), which makes it simpler to compare different lasers. On the other hand, it’s a bit counter-intuitive, but lower values of M2 indicate better quality than higher values. In fact, the best possible result is M2 = 1, and as the value of M2 increases, the quality of the laser decreases. To have a better grasp on how quickly the M2 value can affect your spot size or beam diameter in the near field, check this calculator of ours, it is an efficient and instructive test bench.

By using a third lens and expensive special glass, these top-quality telescopes do not only deliver a true-colour image, but are also free from coma and spherical aberration. The designers use different types of glass in order to create such high quality lenses. The determining factors here are the refractive index and the Abbe value.

Hamamatsu Photomultiplier Tube - Free download as PDF File (.pdf), Text File (.txt) or read online for free. Complete details about Hamamatsu ...

Ms.Cici

Ms.Cici

8618319014500

8618319014500