VSGO | Air-Move Air Blower - blower air blower

Magnetron sputtering allows researchers and manufacturers to achieve greater control over coating thickness and composition. The result is coatings with enhanced optical properties, improved durability, and reduced defects.

In medical imaging, advanced coatings are employed to minimise reflections and maximise light transmission in optical components, resulting in improved image clarity and accuracy. In surveillance and remote sensing applications, anti-reflective coatings on lenses and mirrors enable more precise and reliable data collection, even in challenging environmental conditions.

This level of control is opening up new possibilities for customised coatings that can be tailored for specific applications, leading to improved optical performance and enhanced functionalities.

One compelling real-world application of optical coatings can be seen in the field of lidar technology. Lidar, short for Light Detection and Ranging, utilises laser light for range finding and object detection. Optical coatings play a crucial role in ensuring optimal light transmission and accurate measurements in lidar systems.

Our expertise in custom optics and dedication to delivering precision solutions ensure your optical systems perform at their best. Embrace the exciting world of optical coatings and embrace a future of endless possibilities.

Applications of smart coatings can extend to various industries, such as architecture, automotive, and electronics. For example, adaptive coatings that respond to changes in temperature or sunlight can enhance energy efficiency in buildings and improve the performance of solar panels.

7. For metallurgical applications, dark field (DF) in incident light is quite common. The necessary objectives have to have a larger diameter to incorporate the DF illumination ring: a mirror system built around the centrally positioned bright field objective. Analog to the situation in transmitted light, a central stop in the Epi illuminator (some people call this device Epi condenser!) stops the direct light entering the objective. So the periphery of such an objective works as an illuminator, the central part as an imager.

We review the cutting-edge advancements in optical coatings, delving into the different types, their applications, and how they optimise the performance of various optical systems and applications.

Researchers and scientists are actively exploring novel nanomaterials and nanostructured coatings that can deliver enhanced light absorption, reduced reflection, and improved spectral selectivity.

8. For Inverted Microscopes in bio/medical applications, especially higher magnifications need a Long-Working-Distance construction. The LWD feature works of course at the expense of resolution power.

Projectors equipped with a Fresnel lens, recognizable by the particular surface with concentric steps which allow a wide and uniform diffusion of the ...

As technology advances, new applications and devices emerge, presenting unique challenges and opportunities for optical coatings. One of the rapidly emerging technologies where optical coatings are playing a pivotal role is augmented reality (AR) and virtual reality (VR).

The cover slip has to be placed on top of the sample. A slight pressing of a dissecting needle will help to avoid too much embedding medium (water, etc.) between sample and cover slip. The embedding medium in this case works as an additional layer and thus simulates a thicker cover slip. A wrong covering of the sample reduces the N.A. power, means detail information and contrast. So please take care to mount your section properly.

Besides performing the first step of magnification in a compound microscope, means following an imaging purpose, in incident light applications for uncovered specimen this kind of objectives is also used for illumination purposes. Traced from the light source, the light passes these objectives on its way to the sample, thus requesting another kind of anti-reflex coating within the objective. A typical setup for that kind of samples looks like this:

Hybrid Coatings: Combining the strengths of both dielectric and metallic coatings, hybrid coatings offer unique solutions for specific optical requirements. From beam splitters to specialised optical filters, hybrid coatings fulfill diverse optical needs.

Advancements in thin-film deposition techniques have also been a game-changer in the world of optical coatings. Magnetron sputtering, in particular, has gained significant traction due to its precise and uniform deposition capabilities. In this technique, a high-power magnetron generates a plasma to eject atoms from the target material, which then deposit uniformly onto the substrate.

Dielectric Coatings: These coatings are specifically designed to control the interaction of light with optical components. By enhancing transmission, minimising reflections, and improving overall system efficiency, dielectric coatings play a key role in optimising optical systems. For instance, high-performance optical lenses benefit significantly from dielectric coatings, reducing surface reflections and leading to improved image quality.

The advancements in optical coatings are revolutionising cameras and imaging systems used in various industries, such as medical, surveillance, and remote sensing. Optical coatings are integral to these systems, enhancing image quality, sensitivity, and light collection.

The lamp head is adjustable for viewing angle, has an integral flip-up lens dust cover and comes with a 2 1/2" capacity table-mounting clamp. The LEDs are rated ...

Opticalcoating jobs

By harnessing the potential of nanotechnology, optical coatings can be designed to meet the evolving needs of various industries, from telecommunications and data centers to healthcare and environmental monitoring.

As the world continues to focus on sustainability and environmental impact, the optical coatings industry is also making strides towards developing eco-friendly and sustainable solutions. Researchers are exploring environmentally friendly materials and manufacturing processes that minimise waste and reduce the use of harmful substances.

6. Following another international coding, Phase Contrast objectives are marked with a green inscription. Phase contrast is a contrast method for transmitted light, but the respective objectives can also be used in bright field. A slight reduction of image quality is system immanent.

This adaptive capability opens up new possibilities for self-cleaning coatings, dynamic optical filters, and responsive coatings for energy-efficient devices.

With the growing complexity of optical systems, the demand for optimised coatings has never been greater. Researchers are leveraging advanced simulations and modeling techniques to design coatings tailored to specific applications. Computational methods based on principles of quantum mechanics and electrodynamics enable accurate predictions of coating behaviour and performance.

5. Objectives for Polarization Microscopes just have one purpose. Here we do not talk about color fidelity (in any case Plan Apos will be best) or transmission rates (Fluorite objectives with a reasonable quantity of glass built in are mostly recommended). Here we talk about strain-free glass elements mounted without tension within the objective. Once this target is achieved, the purpose of these objectives is fulfilled: maximum extinction when polarizer and analyzer are crossed.

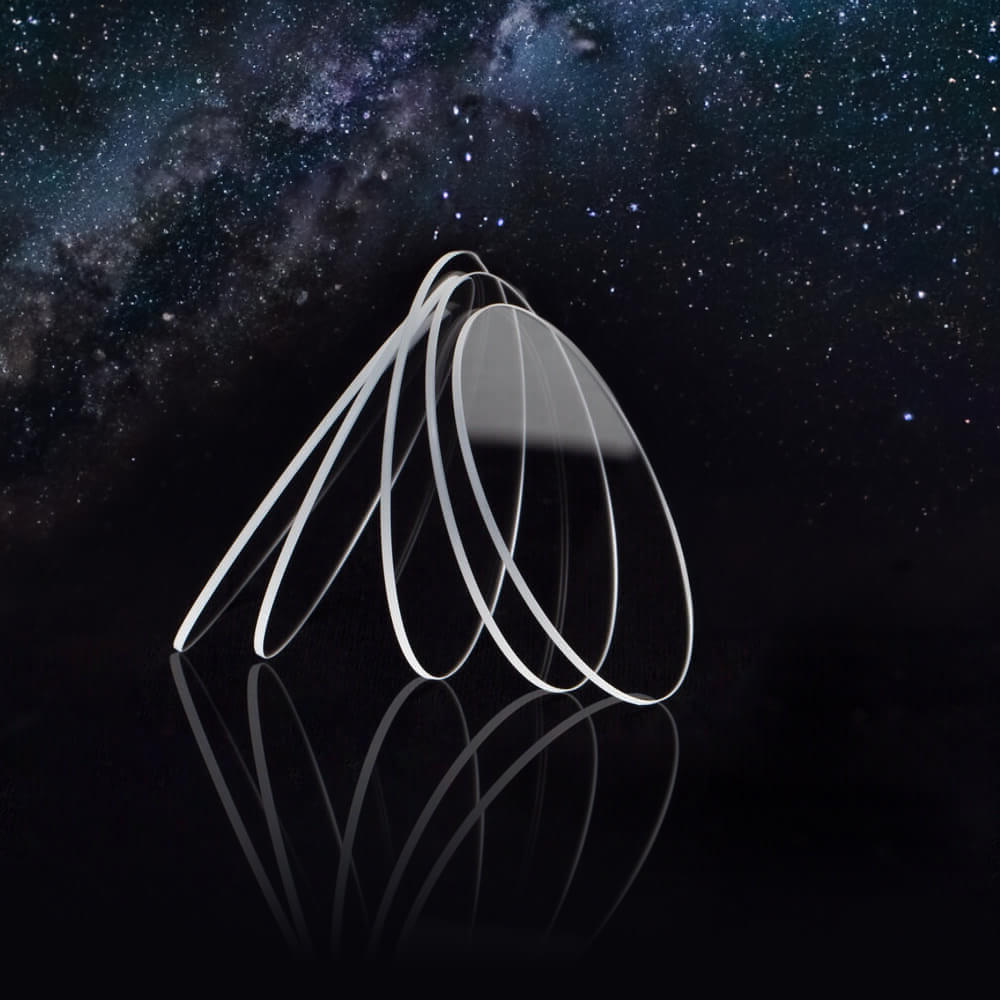

Our lenses are available with or without anti-reflection coatings and can be made from glass, crystalline, or plastic substrates. We utilize cutting-edge ...

2. In some medical work flows it is common to omit the covering of the sample. In this case Non-Cover-Glass objectives without cover slip correction are necessary, especially for objectives with an N.A. ≥ 0.30. The higher the N.A., the more the correct objective (0.17 vs. 0) has an influence on the image quality. Non-covered blood smears are typical samples.

One of the most exciting recent developments in optical coatings is the emergence of nanostructured coatings. Engineered at the nanoscale, these coatings allow precise control over their optical properties, enabling groundbreaking applications. By manipulating the structure and composition of the coating at the nanometer level, researchers can achieve enhanced light absorption, reduced reflections, and improved spectral selectivity.

Types ofoptical coatings

The integration of smart coatings with optical functionalities is another exciting area of research and development. Smart coatings can respond to external stimuli, such as temperature, humidity, or light, and adapt their optical properties accordingly.

Optical coatings are also at the forefront of innovations in display technology, particularly in augmented reality (AR) and virtual reality (VR) devices. These immersive technologies demand high-quality optical coatings to deliver realistic and vibrant visual experiences to users.

Opticalcoating process

Metallic Coatings: Known for their high reflectivity properties, metallic coatings, such as aluminium and silver, find extensive use in mirrors and other optical components. These coatings are vital in telescope mirrors, allowing astronomers to capture distant celestial phenomena with exceptional clarity and precision.

Anti reflective coating

As AR and VR technologies continue to gain popularity in gaming, entertainment, training, and other applications, the demand for high-quality optical coatings is expected to rise.

SMX3000LVNC - APC Smart-UPS X, Line Interactive, 3kVA, Rack/tower convertible 4U, 120V, 6x 5-15R+3x 5-20R+1x L5-30R NEMA, Network card, Extended runtime ...

Nanostructured coatings find extensive use in optical filters, solar cells, and anti-reflective coatings. For instance, in solar cell technology, nanostructured coatings can optimise light trapping, enabling more efficient energy conversion.

Optical coatings play a pivotal role in the world of optics, providing essential functions to optical systems. From increasing reflectivity to enhancing transmission and reducing unwanted reflections, optical coatings are instrumental in driving innovation in optical technologies.

There are various types of optical coatings which can be applied to a range of optical components and glasses from UV to IR and anti-reflection.

Explore Lithium Fluoride (LiF) optical material, offering superior transmission in UV and IR ranges. Ideal for specialized optical applications.

The field of optical coatings is ever-evolving, with remarkable advancements that continue to revolutionise the world of optics. Researchers and scientists are at the forefront of this progress, exploring new materials and techniques to improve coating performance and meet the ever-increasing demands of optical systems.

Types of lens coating for glasses

We use optional cookies to review analytics that help us to improve our website experience. By clicking accept, you are giving consent for us to do this. You can find out more and manage cookies in our privacy policy.

The latest advancements in optical coatings have opened up exciting new applications, pushing the boundaries of what optical systems can achieve. From cutting-edge technologies to real-world industries, optical coatings are playing a pivotal role in revolutionising various applications.

Different samples require different microscopes. This rule refers to the fact that an opaque, bulky sample with a reflective surface needs another treatment than a transparent, unstained smear from the cavitas oris. The microscope stand offers the necessary space for a correct positioning of the sample and all options for the appropriate illumination method.The microscope objective is an even more specific item. Here we talk about the required resolution power (= numerical aperture), but also about cover glass correction, immersion method and working distance.1. The standard upright microscope for transmitted light is constructed for glass slides with a 0.17mm cover slip. This restriction is indicated on the objective sleeve:

Sep 3, 2021 — Meanwhile, lenses with short focal lengths have a larger depth of field, which enables them to get a wider range of elements in focus.

Researchers at the Massachusetts Institute of Technology (MIT) have made significant strides in this area, utilising nanostructured coatings to enhance the efficiency of perovskite solar cells by capturing a broader spectrum of sunlight.

Jan 30, 2023 — To calculate the total magnification provided by any digital microscope we generally multiply all the individual magnifications (objective ...

Neutral density filters, also known as ND filters, are essential tools for any photographer or videographer. They're designed to reduce the amount of light ...

Opticalcoating companies

AR and VR devices require advanced coatings to deliver immersive and realistic visual experiences to users. Coatings that minimise reflections and enhance light transmission are essential for AR and VR headsets to provide clear and vibrant images.

In AR and VR headsets, advanced anti-reflective coatings ensure minimal glare and maximum light transmission. This results in crystal-clear images and a more immersive user experience. By reducing reflections and increasing light throughput, these coatings elevate the performance of AR and VR devices, enhancing their usability in diverse applications, from gaming and entertainment to training and simulations.

by F Pampaloni · 2004 · Cited by 114 — Title:Gaussian, Hermite-Gaussian, and Laguerre-Gaussian beams: A primer ... Abstract: The paper aims at presenting a didactic and self-contained ...

Optical coatingsapplications

Green coatings that adhere to strict environmental standards are gaining traction in various industries. These coatings not only provide optical functionalities but also contribute to reducing the ecological footprint of optical systems. The demand for sustainable optical coatings is expected to rise, especially in industries with stringent environmental regulations, such as renewable energy, automotive, and aerospace.

Fiber optic adapters designed to mate together fiber optic patch cables.

Researchers and manufacturers are actively developing specialised coatings tailored to the unique requirements of lidar applications. This ongoing research in coating design is instrumental in advancing lidar technology and its widespread adoption in various industries, including automotive, agriculture, and environmental monitoring.

For “dry” objectives with high numerical apertures (≥ 0.7) it is helpful to use cover slips with a minimized tolerance in thickness. The lab suppliers offer glasses with a tolerance of +/- 0.005mm. Together with a “flat” embedding of the sample, preconditions for a good image result are given.

Optical coatingsfor lenses

Posted by Kelvin Biggs, Managing Director | Optical Services, Optical Technology

Welcome to UQG Optics! It looks like you are visiting from outside the UK. Select your preferred currency below to see appropriate pricing. Contact us for additional support or to discuss specific requirements.

The idea behind such a construction is quite clear. The samples for an inverted microscope are positioned in a petri dish, a flask or any other “high volume” vessel. Adherend cells at the bottom of the vessel have to be treated with an objective of 1.1mm cover slip correction (in this case the bottom of the vessel is equivalent to the cover slip). Floating cells or water samples from a pond need the additional LWD feature. Only this construction allows a focusing “through” the sample, inspecting the complete fluid layer. A short look on motorized inverted microscopes gives us an interesting hint: Before changing the objective by rotating the nosepiece, first drive down the revolving nosepiece. This will avoid scratches on the front lens. Parfocality of the objectives in this case is less relevant.

As technology continues to advance, the future of optical coatings holds exciting potential for even more innovative applications and developments. Here, we explore some of the emerging trends and areas of focus that are shaping the future of optical coatings.

These advanced design tools significantly accelerate the development of new coatings, allowing for rapid prototyping and optimisation. Researchers at the National Institute of Standards and Technology (NIST) have been using these simulations to design high-performance optical coatings for hyperspectral imaging systems used in environmental monitoring.

Welcome to UQG Optics! It looks like you are visiting from the US. Select your preferred currency below to see appropriate pricing. Contact us for additional support or to discuss specific requirements.

4. For maximum resolution power, immersion objectives are the best option. Mostly it is immersion oil with a defined refractive index (1,51) to be in use, but please realize that water or glycerin in some cases are preferred. The necessary immersion medium is indicated on the objective sleeve. Immersion for that kind of objectives is not an option, it is an imperative!

Selecting the right optical coatings drives efficiency and precision across various industries. From dielectric coatings optimising light transmission to metallic coatings revolutionising telescope mirrors, optical coatings are instrumental in shaping the future of optics. As the field evolves, the latest developments and future trends in optical coatings will continue to propel optical technologies forward.

The use of nanotechnology in optical coatings is an area of increasing interest and research. Nanotechnology allows the precise engineering of coatings at the nanoscale, enabling control over optical properties with unparalleled precision.

In autonomous vehicles, lidar sensors heavily rely on optical coatings to maximise the detection of surrounding objects and obstacles. These coatings enhance the efficiency of lidar sensors by reducing reflection losses and minimising signal noise. As a result, lidar systems can provide more accurate and reliable data for safe navigation and object recognition.

Ms.Cici

Ms.Cici

8618319014500

8618319014500