Volume Pills Reviews | 4 of 6 - Trustpilot - volume pills review

Sapphire poses very difficult challenges to optical manufacturers due to its high hardness and anisotropic properties. These challenges can result in long lead times and high prices. Optimax is developing …

Anti reflectioncoatingprinciple PDF

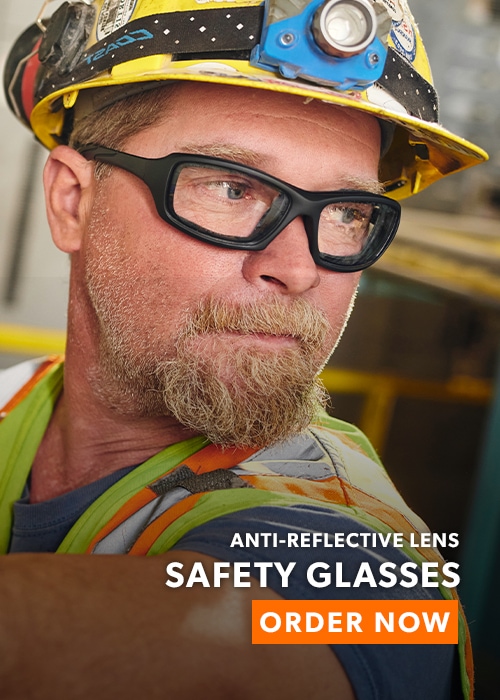

The glasses can be upgraded with special coatings such as anti-fog and anti-scratch to improve their overall performance. This is where you can add the anti-reflective coating.

Optical prisms, for example, which are ground and polished to create geometrically complex optical components with extremely tight tolerances, represent a costly bottleneck for many optics fabricators. Their variability makes it difficult to process prisms at large scales or via automated processes. At Optimax, we can confidently commit to delivery schedules of a single week for optical dispersion prisms, blocks, doves, right angles, mirror substrates, and more.

We specialize in the fabrication of optical prisms of up to 300 mm in diameter, and can reliably generate prototype prisms upon request.

There are two main paths for tolerancing spherical radii: power tolerance and linear radius tolerance. Both measure change relative to a nominal value, but the metrology used is the key …

This paper will define surface irregularity for spherical surfaces, offer information on measurement methods for testing surface irregularities, and some specification guidelines.

In addition to tradeoffs between mirror reflectivity, wavefront, laser-damage threshold, and cost, new low-stress coatings offer weight, geometry, and thermomechanical performance and design flexibility.

Original equipment manufacturers (OEMs) benefit from unparalleled expertise and precision when working with Optimax. Our team of engineers is experienced applying our know-how to deliver cutting-edge technical solutions. This allows us to take on challenges that exceed the capabilities of other manufacturers.

This presentation will discuss efforts at Optimax to address this need through advancement of robotic smoothing platforms and processes.

Freeform optical systems are becoming increasingly common due to new design and manufacturing methods. We present an example compact freeform optical system and describe considerations for transfer of the prescription …

Monolithic multi-surface telescopes combined with freeform optical surfaces provide improvements in optical performance in a smaller footprint as compared to systems with spherical surfaces, while providing superior mechanical stability to …

At Optimax, we specialize in manufacturing optical prisms up to 300 mm in diameter, and with our state-of-the-art grinding and smoothing technologies, can deliver prisms in a variety of complex geometries to tightly-defined surface flatness.

Anti reflectivecoatingmaterial

This work explores quick predictive methods for calculating potentially risky stresses and deflections in cemented doublets experiencing temperature change that agree well with finite element analysis.

Anti reflectivecoatingdisadvantages

Optical prisms differ from traditional lenses in that they have neither a spherical surface nor an axis of symmetry. Instead, they comprise two or more nominally plano surfaces divided by a wedge angle. This alters the language used to define and specify optical prisms, and it typically increases production time due to increased part complexity and a greater number of sides requiring precision finishing.

When multiplexing ultrashort laser beams of different wavelengths into a single beam, the pulse shape of each color must be managed individually due to the various accumulated GDD. This presents …

Anti reflectioncoatingformula

According to a recent Dallas Morning News article by writer Mary Jacobs, there’s should be more to selecting prescription glasses than simply handing in your eye prescription and choosing a frame. The type of lens material should also be considered. Many people are discovering the benefits of anti-reflective coatings.

The Jupiter environment presents many unique challenges to the optomechanical design of the Europa Imaging System (EIS) Wide Angle Camera (WAC) for NASA’s Europa Clipper Mission. EIS is designed to …

Glass lenses…give such better clarity than any plastic…. I’ve worn all kinds for 60 years. You’ll never surpass good old glass. Period.

Optimax has developed a fabrication process that not only reduces cost but also aids in producing spherical sapphire components to better figure quality.

The cost of lenses is strongly dependent on the difference between the specified tolerances and the limits of the optics manufacturer, the coater, and the metrologist.

We are a world leader in high precision optical manufacturing, delivering custom optics to a wide range of innovators around the globe. Meeting these goals demands the right people. Teamwork, adaptability, and an enthusiastic approach to problem-solving are central to the Optimax culture. But what unites all our employees best is a hunger to continuously learn. We strive to find driven individuals who are committed to lifelong learning; who will continue to add value in their work throughout long and successful careers.

The significance of these geometries is that they will reflect or refract light, resulting in several distinct functions: dispersion, deflection, reflection, and rotation. These go on to serve critical applications in dual channel instruments, anamorphic systems, imaging systems, and any other application where beam steering and/or image manipulation is needed.

Anti reflectivecoatingspray

Also known as anti-glare or AR coatings, these are special coatings that are designed to decrease the amount of reflective light in lenses. They can be applied to either the back, front or both sides of lenses so that a maximum amount of positive light enters the eyes to give you the clearest view possible. Here are some of the pros and cons of anti-reflective coating glasses, along with a few considerations.

Now it is the time to upload or fill your prescription information. You’re done! The rest is with us. We will work on your glasses with anti-reflective lenses and deliver to your address.

Optimax develops optics solutions to suit a variety of needs. Our industry-leading custom optics are developed by expert engineers. Discover our expertise, solutions, and opportunities today.

Hello Jared Rice, Thank you for showing interest in our Anti-reflective coating glasses. if you spend significant time in front of screens, a blue light filter may be more suitable. You can get more information here: https://rx-safety.com/2023/08/anti-reflective-coating-vs-blue-light-filter-optimize-your-digital-eyewear-experience/. Please dont hesitate to contact us if you need further assistance.

At Optimax, we are manufacturing the future, creating the highest precision optics underlying high-tech systems in key markets and applications. We offer rapid and expedited delivery upon request and are committed to our customers in the long term.

Optical prisms vary dramatically by size, shape, and number of surfaces. Defining the part geometry requires a careful selection of directly measurable physical parameters, including linear dimensions of the plano surfaces to theoretical sharps (the intersection that would exist between the two if the corner was not beveled). Manufacturers must also specify part thickness, which is the depth of separation between the two plano surfaces at a single point on the optic. At Optimax, we choose to specify the thickest edge as it offers ease-of-measurement access, but we can specify our optical prisms by the centerline thickness, or the thinnest edge if necessary.

Stay on top of the latest news about prescription safety glasses, eyewear, sunglasses, and all the trends in the industry.

Anti reflectivecoatingiPad

With Fuchs Corneal dystrophy, does anti glare coating make clarity a little worse? I have polycarbonate now thinking of switching to Crystal or glass lenses

One design strategy for an optical system is centering two or more lenses together to build a lens assembly. However, strain in excess may cause delamination or fracture of the …

Such coatigs are applied with an evaporator or maybe a sputter system NOT ‘painted’ on then ‘baked’. Lenses go thru an eleaborate clean process before coating. As a photographer, I do NOT recommend ‘blue blocker’ type coatings.

What is ar coatingused for

Do you want to learn more about our optical manufacturing innovation? Refer to our Knowledge Center to read technical papers on, aspheres, business leadership, coatings, freeform optics, innovative optics manufacturing, and lens tolerancing & inspection.

The concept for polishing optical elements with a process called VIBE is presented, application to non uniformly sloped optics such as aspheric shapes is detailed, and initial results on spherical …

Inside our prescription form, you can select your prescription type. Choose between, single vision, bifocal and progressive. Then, you will choose your lens material.

Anti ReflectivecoatingPhysics

Freeform optical systems are becoming increasingly common due to new design and manufacturing methods. We present an example compact freeform optical system and describe considerations for transfer of the prescription …

For any questions you may have, visit us at Rx-Safety.com. Please contact us and learn about all we have to offer in eyewear products.

Tools & ChartsAerospace Glass ListCost Tolerance ChartManufacturing Tolerance ChartThe EstimatorTest Plate LibraryPreferred Glass ListManufacturing LimitsTolerancing LimitsTechnical PapersAspheric OpticsBusiness LeadershipCoatingsFreeform OpticsInnovative Optics ManufacturingLens Tolerancing & InspectionASK AN EXPERTRESOURCE VIDEOS

There are many decisions to make when designing, specifying, manufacturing, and testing optical components for high-energy laser systems — each is a potential failure mechanism that must be understood and …

RX Safety offers a wide range of glasses frames that match perfectly with anti-reflective lenses. Choose your favorite eyeglasses, sunglasses, or prescription safety glasses.

Optimax uses a variety of 3D printers to streamline our manufacturing processes. Download our technical paper today to learn about our results.

Optical designers assume a mathematically derived statistical distribution of the relevant design parameters. However, there may be significant differences between the assumed distributions and the likely outcomes from manufacturing.

This paper will present some of the challenges and solutions of extending freeform polishing capabilities from approximately 150 mm diameter parts to a component of over 500 mm in diameter.

Ms.Cici

Ms.Cici

8618319014500

8618319014500