UVP UVX Radiometer - uv radiometer

The use of aspheric lenses can result in improved image quality, with sharper and clearer images and increased resolution. Aspheric lenses can also reduce the size and weight of optical systems, as they can correct for multiple aberrations with a single lens. This is because aspheric lenses can reduce spherical aberrations, distortion, and field curvature, which are often present in traditional spherical lenses.

Aspheric lensglasses

Resolution: 720 × 1152 Pixel size: 22.5 µm Full-frame imaging device with two image area sections that can be clocked separately

Resolution: 240 × 240 Pixel size: 24 µm Designed for very high frame rate and low signal applications

Resolution: 2048 × 515 Pixel size: 13.5 µm Well suited to the most demanding applications, such as spectroscopy.

Alignment and Tolerance Requirements: Aspheric lenses have strict alignment and tolerance requirements during the manufacturing process, which can result in increased production costs and reduced yields.

Aspheric lensbenefits

Aspheric lenses can be affected by various surface shape imperfections, including spherical aberration, astigmatism, coma, distortion, surface roughness, and waviness. The degree and type of surface shape imperfections will depend on the lens design, the manufacturing process, and the lens material properties. Precise control of the surface shape is critical for achieving the desired performance in aspheric lenses.

AsphericLenses price

Resolution: 1404 × 1350 Pixel size: 20 × 30 µm CCD sensor with a graded anti-reflective coating unique to Teledyne e2v

Resolution: 600 × 600 Pixel size: 40 µm Close butted back-illuminated CCD

In conclusion, the production methods for aspheric lenses vary depending on the lens design, the lens material, and the desired production volume. Methods such as spherical molding, lathe cutting, diamond turning, molding and replication, and freeform optics are used to produce aspheric lenses with varying levels of precision and surface quality. The choice of production method will depend on the desired production volume, the lens design, and the desired surface accuracy and quality.

The production methods for aspheric lenses vary depending on the lens design, the lens material, and the desired production volume.

Firebird Optics provides a range of various aspheric lenses with varying materials, focal lengths, diameters as well as optical coatings. If you don’t find what you need feel free to drop us an e-mail at info@firebirdoptics.com.

Another advantage of aspheric lenses is their ability to reduce chromatic aberrations. Chromatic aberrations occur when different colors of light are focused at different points, causing a rainbow-like effect around the edges of an image. Aspheric lenses can reduce this effect by controlling the refraction of light at different wavelengths, resulting in a more accurate and consistent focus for all colors of light.

Fragility: Aspheric lenses are often made from thinner and lighter materials compared to spherical lenses, which can make them more fragile and susceptible to damage.

Resolution: 1024 × 1024 Pixel size: 13 µm Extreme performance in high frame rate ultra-low light applications

Increased Accuracy and Consistency of Focus: Aspheric lenses can increase the accuracy and consistency of the focus for all colors of light, resulting in a more accurate and consistent image.

where z is the height of the surface above the optical axis, r is the radial distance from the optical axis, R is the radius of curvature of the surface, C is the conic constant, k is the conic coefficient, and A, B, and C are the polynomial coefficients. The polynomial coefficients can be adjusted to correct for specific aberrations.

Resolution: 24100 × 128 Pixel size: 7 µm Multispectral, multi-die TDI image sensor array

Resolution: 2048 × 2064 Pixel size: 15 µm Back Illuminated Scientific CCD Sensor

Freeform Optics: Freeform optics is a production method that is used to produce complex aspheric lenses with low to medium volume production runs. This method involves using advanced computer-controlled machinery to machine the lens material to the desired aspheric shape. The surface quality of the lens produced using this method is typically higher than that produced using other production methods, and it allows for precise control of the lens surface.

Spherical Molding: Spherical molding is a production method that is used to produce simple aspheric lenses with low volume production runs. This method involves pressing a heated lens material into a spherical mold, which then deforms the lens material into the desired aspheric shape. The surface quality of the lens produced using this method is limited, and additional surface finishing is typically required to achieve the desired surface accuracy.

The production of aspheric lenses involves several steps, including the design and prototyping of the lens surface, molding or grinding of the lens surface, and coating of the lens surface to increase its transmission. The design of the aspheric surface is determined by mathematical equations that account for the desired correction of aberrations and the desired image quality. The lens surface can be molded or ground to the desired shape using a variety of techniques, including grinding, diamond turning, and injection molding.

Limited Availability: Aspheric lenses may not be available in certain sizes or configurations, which can limit their use in certain applications.

Resolution: 1024 × 1024 Pixel size: 10 µm Extreme performance in high frame rate ultra-low light applications

The spherical shape of traditional lenses is determined by the radius of curvature of the lens surface. In order for light to be focused correctly, the surface must be a perfect sphere. However, this shape can cause aberrations that limit the resolution and contrast of the image. Aspheric lenses are designed to overcome these limitations by modifying the shape of the lens surface to correct for aberrations.

Resolution: 2048 × 2048 Pixel size: 13.5 µm Well suited to the most demanding applications requiring a high dynamic range.

Aspheric lenses offer many advantages, such as the correction of spherical aberrations and improved image quality, but also have some disadvantages, including a complex design and manufacturing process, fragility, and limited availability. The choice between using aspheric lenses and spherical lenses will depend on the specific needs of the application and the trade-off between the benefits and limitations of each type of lens.

Resolution: 6144 × 6160 Pixel size: 15 µm Four separately connected image area sections to allow full-frame, frame transfer, split full-frame or split frame-transfer modes

Scientific Instruments: Aspheric lenses are commonly used in scientific instruments, such as telescopes and spectrometers, to provide improved image quality and reduced distortion. They are used in the manufacture of astronomical telescopes, microscopes, and other scientific instruments. Aspheric lenses provide improved resolution and accuracy compared to traditional spherical lenses and are an essential component in many scientific instruments.

Resolution: 0 × 0 Pixel size: 50 µm Back illuminated, deep depleted, low noise CCD image sensors for use in X-ray detection

Source: JML Optical- https://www.jmloptical.com/blog/spherical-vs-aspheric-lenses-how-theyre-used-in-imaging-applications/

What is aspheric lensvs asphericallens

All Teledyne Imaging devices can be supplied partially or fully customized to fit the application and achieve the best possible system performance. Sensor design, manufacture, assembly and test are carried out in-house. Sensors can be back-illuminated for highest sensitivity, designed with very low noise, and available in multiple formats and package types. Teledyne Imaging has capabilities and vast experience in designing and delivering not only CCDs but integrated camera systems, mosaics, and focal planes.

Resolution: 1404 × 1350 Pixel size: 20 × 30 µm CCD image senor optimized for ultraviolet and visible wavelengths

Resolution: 12288 × 64 Pixel size: 7 µm dual zone, unidirectional TDI CCD with continuous vertical clocking and 16 or 8 selectable outputs per zone

Resolution: 1024 × 255 Pixel size: 26 µm Designed for use in the scientific spectroscopy instrument market

Resolution: 1022 × 2050 Pixel size: 26 µm High readout rates and high signal capacity

Resolution: 512 × 580 Pixel size: 16 µm Back illuminated CCD which maximizes the quantum efficiency in the low energy X-ray region.

Resolution: 4096 × 96 Pixel size: 7 µm Backside illuminated five bands TDI CCD image sensor

Reduced Chromatic Aberrations: Aspheric lenses can reduce chromatic aberrations, which occur when different colors of light are focused at different points, causing a rainbow-like effect around the edges of an image.

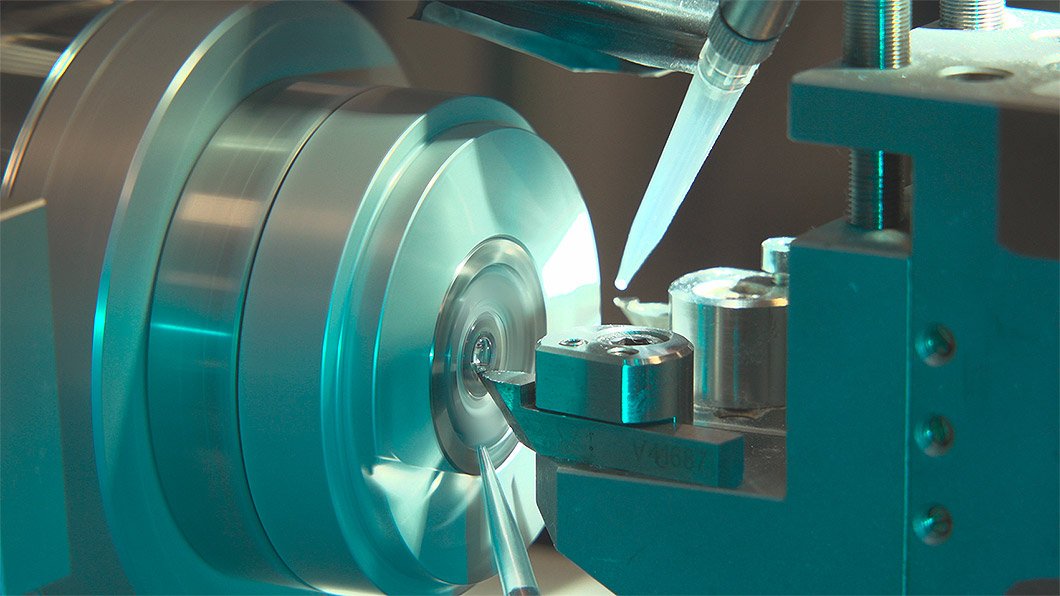

Diamond Turning: Diamond turning is a production method that is used to produce high-precision aspheric lenses with low to medium volume production runs. This method involves using a diamond-tipped cutting tool to machine the lens material to the desired aspheric shape. Diamond turning allows for precise control of the lens surface, and the surface quality of the lens produced using this method is typically higher than that produced using other production methods.

Resolution: 512 × 512 Pixel size: 16 µm Well suited for scientific imaging where the illumination is limited.

Resolution: 8192 × 80 Pixel size: 7 µm TDI CCD image sensor with 7 μm x 7 μm pixels, selectable outputs and 100x antiblooming.

Resolution: 80 × 80 Pixel size: 24 µm Optimised for use at high frame rates

Resolution: 6144 × 6160 Pixel size: 10 µm Back-illuminated spectral response and very low read-out noise give exceptional sensitivity.

The mathematical description of aspheric lenses is based on a mathematical model called a surface profile equation, which defines the shape of the lens surface.

Resolution: 1024 × 1024 Pixel size: 8.5 µm Frame transfer CCD array image sensor with 8.5 μm pixel, MPP mode and 100x antiblooming

Resolution: 1024 × 1024 Pixel size: 13 µm Back illumination technology and extremely low noise amplifiers

Asphericmeaning

Resolution: 1056 × 1027 Pixel size: 13 µm Full-frame architecture well suited to the most demanding scientific applications.

Improved Image Quality: The use of aspheric lenses can result in improved image quality, with sharper and clearer images and increased resolution.

This catalogue presents Teledyne Imaging’s detectors with a high space technology readiness level (TRL) that are available for consideration in instrument designs for future space missions. An overview of each detector is given, along with key parameters and a description of the relevant space heritage.

Teledyne Imaging's Charge Coupled Detectors (CCDs) have extensive heritage and a wide variety of formats and customized features, making Teledyne Imaging the leading supplier of sensors for Space Science, Ground-based Astronomy, and Earth Observation applications over 40 years with an impressive record of successful deliveries to a wide range of customers.

Distortion: Distortion is a type of optical aberration that causes straight lines in the object plane to appear curved in the image plane. This can be caused by surface shape imperfections in aspheric lenses.

Resolution: 2048 × 2064 Pixel size: 15 µm Large image area for demanding scientific imaging applications

Asphericlenses advantages disadvantages

Aspheric lenses are an important tool in the field of optics and can be used to correct various types of aberrations, including spherical aberrations. By modifying the shape of the lens surface, aspheric lenses can improve image quality, reduce the size and weight of optical systems, and increase the accuracy and consistency of the focus. With the increasing demand for high-quality imaging in fields such as medicine, photography, and astronomy, the use of aspheric lenses will continue to play an important role in the advancement of optical technology.

An additional mathematical representation for the aspheric lens formula. Source: https://escooptics.com/blogs/news/concepts-in-light-and-optics-lenses-part-4-aspheres

Laser Systems: Aspheric lenses are commonly used in laser systems to collimate laser beams and focus the laser light to a small spot. They are used in the manufacture of laser pointers, laser cutting machines, and other laser-based applications. Aspheric lenses provide improved beam quality and beam stability compared to traditional spherical lenses, making them an essential component in many laser systems.

Aspheric lenses are precision optical components that have a wide range of applications across various fields. Some of the main application examples of aspheric lenses are described below.

Astigmatism: Astigmatism is a type of optical aberration that occurs when light from a point source is focused to two separate points, rather than a single point. This can be caused by surface shape imperfections in aspheric lenses.

where x, y, and z are the coordinates of a point on the lens surface and A, B, C, D, E, and F are the coefficients that determine the shape of the surface. By adjusting the values of the coefficients, the lens surface can be designed to correct for specific aberrations.

Resolution: 9216 × 9232 Pixel size: 10 µm Large image area for demanding astronomical and scientific imaging applications

Surface Roughness: Surface roughness is a deviation from a smooth surface that can cause light scattering and reduced image quality.

The surface profile equation can be expressed as a polynomial or a more complex mathematical function. The coefficients of the polynomial or the parameters of the mathematical function are chosen to produce a lens surface that corrects for the desired aberrations.

Aspheric lenses can be made using a variety of materials, including glass, plastic, and other optical materials. Glass aspheric lenses are the most commonly used in high precision optical systems due to their durability and high index of refraction. Plastic aspheric lenses are more flexible, lighter, and less expensive than glass lenses, making them ideal for mass-produced consumer products such as digital cameras, smartphones, and projectors.

Resolution: 2048 × 4104 Pixel size: 15 µm Back Illuminated, Non Inverted Mode Operation, High-Rho Enhanced Red Sensitivity

Spherical aberrations occur because of the difference in the refractive index between the center and the edge of a spherical lens. Light passing through the center of the lens is focused to a single point, but light passing through the edge is not focused correctly, leading to a blurred image. This effect is more pronounced for lenses with a large aperture, such as camera lenses or telescopes.

Resolution: 1252 × 1152 Pixel size: 22.5 µm Full-frame imaging device with two image area sections that can be clocked separately

Resolution: 4096 × 4096 Pixel size: 12 µm Large image area with back-illuminated spectral response and very low read-out noise. Designed for demanding astronomical applications.

Photography and Imaging: Aspheric lenses are commonly used in cameras and other imaging devices to improve image quality and reduce optical aberrations. They are used in the manufacture of camera lenses, microscopes, and other imaging systems. Aspheric lenses provide improved resolution and sharpness compared to traditional spherical lenses and are commonly used in high-end camera lenses.

Resolution: 384 × 288 Pixel size: 22 µm Inverted mode X-Ray to NIR sensor primarily intended to suit the requirements of astronomy and scientific measuring instruments.

Display Technology: Aspheric lenses are commonly used in display technology, such as projectors and head-mounted displays, to provide improved image quality and reduced distortion. They are used in the manufacture of projectors, virtual reality and augmented reality displays, and other display-based applications. Aspheric lenses provide improved resolution and image quality compared to traditional spherical lenses and are an essential component in many display-based applications.

Resolution: 12288 × 128 Pixel size: 7 µm Five band multispectral TDI CCD image sensor with selectable stages.

Asphericallensphotography

Resolution: 36200 × 128 Pixel size: 7 µm Backside thinned, multispectral, multi-die TDI image sensor array

Coma: Coma is a type of optical aberration that causes light from a point source to be focused to a comet-like shape, rather than a point. This can be caused by surface shape imperfections in aspheric lenses.

Aspheric lenses solve this problem by modifying the shape of the lens surface. Instead of a spherical surface, aspheric lenses have a surface that deviates from a perfect sphere. This allows for a more precise control of the refractive index, resulting in a more accurate focus of light. The aspheric surface is designed using mathematical equations that account for the desired correction of aberrations and the desired image quality.

Resolution: 2048 × 1024 Pixel size: 13.5 µm CCD Sensor with full frame architecture, back illumination technology, and an extremely low noise amplifier. Well suited to the most demanding applications such as astronomy.

Resolution: 1024 × 512 Pixel size: 50 µm Back illuminated, deep depleted, low noise CCD image sensors for use in X-ray detection

Complex Design and Manufacturing Process: Aspheric lenses require a more complex design and manufacturing process compared to spherical lenses, which can lead to higher costs.

Spherical Aberration: Spherical aberration is a type of optical aberration that occurs when light from a point source is not focused to a single point. In aspheric lenses, this can be caused by deviations from the desired surface shape or by variations in the lens material properties.

Resolution: 2048 × 4612 Pixel size: 13.5 µm Well suited to the most demanding astronomical and scientific imaging applications.

Visible and infrared image sensors that set the standard for the world's leading ground-based astronomy applications and observatories

Aspheric lenses are optical lenses that deviate from the ideal spherical shape. They are used to correct various types of aberrations, such as spherical aberrations, distortion, and field curvature, which are often present in traditional spherical lenses. The use of aspheric lenses can lead to improved image quality, reduced lens size, and increased system efficiency.

Resolution: 264 × 2048 Pixel size: 15 µm Full frame spectroscopic format sensor

Lathe Cutting: Lathe cutting is a production method that is used to produce high-precision aspheric lenses with low volume production runs. This method involves turning a spherical lens blank on a lathe and then cutting the lens material to the desired aspheric shape. The surface quality of the lens produced using this method is limited, and additional surface finishing is typically required to achieve the desired surface accuracy.

Resolution: 12288 × 128 Pixel size: 7 µm 12k pixel backside illuminated, bidirectional, multispectral TDI CCD

Aspheric lenses are precision optical components, and as such, they can be affected by various surface shape imperfections that can degrade their performance. Some of the main surface shape imperfections of aspheric lenses include:

Medical Devices: Aspheric lenses are commonly used in medical devices, such as endoscopes, to provide improved image quality and reduced distortion. They are also used in ophthalmic lenses, such as contact lenses and intraocular lenses, to correct visual aberrations and improve visual acuity.

Resolution: 4096 × 4112 Pixel size: 15 µm Exceptional sensitivity with minimum readout times

Reduced Size and Weight of Optical Systems: Aspheric lenses can reduce the size and weight of optical systems as they can correct for multiple aberrations with a single lens.

Aspheric lenses are widely used in a variety of applications across various fields, including photography and imaging, laser systems, medical devices, scientific instruments, and display technology. Aspheric lenses provide improved resolution, accuracy, and image quality compared to traditional spherical lenses, making them an essential component in many precision optical systems.

What is aspheric lensused for

Resolution: 4096 × 3112 Pixel size: 12 µm Designed for the World Space Observatory Ultraviolet Spectrographs (WUVS) instrument, Teledyne e2v is supplying the CCD and the assembled cryo-cooled UV detector subsystems.

Resolution: 2048 × 2048 Pixel size: 15 µm Well suited to the most demanding applications, such as astronomy

Resolution: 4096 × 4004 Pixel size: 10 µm Back illumination and an extremely low noise amplifier

Resolution: 384 × 1024 Pixel size: 27 µm Close butted CCD, with a dead region of less than 300 microns wide on three sides

Resolution: 2208 × 320 Pixel size: 30 µm Split frame transfer backside thinned area array CCD image sensor with 30 μm x 30 μm pixels, selectable outputs and exposure control

Resolution: 2051 × 4096 Pixel size: 15 µm Full frame imaging CCD designed to operate in Inverted Mode for low dark signal.

Resolution: 128 × 128 Pixel size: 24 µm Low noise output amplifier circuit

The mathematical description of aspheric lenses is based on a surface profile equation that defines the shape of the lens surface. This equation can be represented as a conic section or an aspheric polynomial, and the coefficients or parameters of the equation are adjusted to produce a lens surface that corrects for the desired aberrations. The use of mathematical models and simulations allows for precise control of the lens surface, leading to improved image quality and reduced aberrations.

Correction of Spherical Aberrations: Aspheric lenses are designed to reduce spherical aberrations, which cause blurred or distorted images, by modifying the shape of the lens surface. This results in sharper and clearer images with increased resolution.

Molding and Replication: Molding and replication is a production method that is used to produce aspheric lenses with high volume production runs. This method involves creating a mold of the desired aspheric shape and then using this mold to replicate the lens using a suitable lens material. The surface quality of the lens produced using this method depends on the quality of the mold, and additional surface finishing may be required to achieve the desired surface accuracy.

Ms.Cici

Ms.Cici

8618319014500

8618319014500