Using a window as a light diffuser - diffuser window

The key component of the fiber laser cutting machine is the fiber laser itself, which produces a highly focused beam of light capable of cutting through even some of the toughest materials with ease.

FiberOptic Cutter Tool

However, not all laser cutters are created equal. Some have more powerful lasers, which allows them to work with thicker materials or create deeper cuts. Others may have more advanced features like auto-feeders or dual-laser capabilities, which can increase the speed and efficiency at which you can process your projects.

If you are looking for a production partner that can help to reduce your costs while maintaining high-quality standards, look no further than Gensun. Our state-of-the-art laser cutting services are second to none, enabling us to deliver the highest quality results quickly and efficiently.

Scoffin suggests that in cancer treatment, for instance, where every tumour is different: “You can imagine a world where you can design exactly the right molecule to go and attack that specific tumour, and you have a synthesiser where you can draw that molecule, click a button and it makes it. That opens up a huge world of possibility in terms of that kind of personalised precision medicine.”

This process relies on the careful regulation of electromagnetic wavelengths, which allows laser beams to transmit information with incredible precision and efficiency.

A full skeletal editing toolbox could do more than that. It could in theory lead to futuristic inventions such as automated synthesis laboratories, and even personalised medicine.

CNC milling is a CNC process that involves the use of rotating cutters to remove portions of a block of material (or workpiece) till the desired custom shape (or feature) is made. It allows manufacturers to create intricate parts accurately while meeting tight...

How to jointfiberoptic cable without machine

Once they have succeeded in piecing together a molecule they want to work with, medicinal chemists must then optimise it to improve efficacy and reduce side-effects – turning the “hit” compound into a “lead” compound.

When it comes to altering an existing molecule more fundamentally – such as within the rings of carbon atoms at the centre of many organic compounds – Levin likens those atoms and bonds to the connectors and rods in a child’s Tinkertoy set: “It’s very obvious when you’re looking at the toy that the best way to change it would be to pull out the part you don’t want and put the new one in,” he says. “It has always bothered me that that’s not something we have the capacity to do chemically.”

Scientists usually make new drugs by identifying a biological target that plays some role in a disease, and then screening hundreds of thousands of molecules to find a “hit” compound that might interact with it. “Making molecules for a drug discovery project requires many chemical steps and significant time,” Dr David Blakemore, head of synthesis, inflammation, immunology and anti-infectives chemistry at Pfizer, acknowledges.

Skeletal editing could help to speed up drug discovery dramatically, and chemists such as Julia Reisenbauer, a PhD student working in Prof Bill Morandi’s team at the Swiss Federal Institute of Technology, and Prof Sarah Wengryniuk at Temple University in Philadelphia, have now developed reactions that can insert single nitrogen and oxygen atoms into the central rings of some molecules, sidestepping the need to start from scratch.

This can be laborious. For example, chemists will often test versions of a molecule with a nitrogen atom occupying every possible position in its structure, and while editing atoms on a molecule’s periphery can be relatively straightforward, changing those at its core can be as tricky as the last round in a game of Jenga.

“Currently, we are examining the available skeletal editing methodology to see how applicable it is across a broad range of molecules to help us understand scope and limitations,” says Blakemore at Pfizer. “We already have a project where we have used a skeletal editing reaction to make a simple scaffold that was elaborated to a lead compound.”

Inspired in part by the revolutionary genome-editing technology Crispr-Cas9, Levin and Sarpong are among a handful of chemists developing new methods to insert, delete and swap individual atoms within molecules. They call it “skeletal editing” and they hope it will change their field – and our world.

A new method called ‘skeletal editing’ offers a hugely simplified way to alter matter, paving the way for world-changing innovations in personalised medicine and sustainable plastics

He’s joined by a growing number of labs globally whose efforts are fast increasing the pace of discovery. “If the toolbox that I’m imagining actually comes to fruition,” he says, “it will really replace a lot of the ways that we do chemistry.”

The metal machining and casting processes are often portrayed as a “pick one or the other” comparison for fabricators. But as we hinted in our recent article about casting vs. machining, there are many cases where the most efficient means of production will leverage...

To make a new synthetic material, chemists will often take monomers – small molecules that can be bonded together – and repeat them many times to form polymers. This traditional approach limits their designs to using only available monomers, which can be difficult to access, or unsustainable.

Blakemore says it is “still early days”, adding that their project demonstrates the “potential power” of skeletal editing. Indeed, it was only in 2018 that Sarpong’s group became one of the first to start working with these reactions, with most advances happening in the last two years, but progress has been fast. Levin estimates that a complete skeletal editing toolbox for drug discovery would involve maybe a thousand different reactions, and is now about 5% full. “But you have to remember, it’s been two years,” he says, “5% is not bad, you know; 5% is pretty good, actually.”

Cutting fiberoptic cable

In that sense, skeletal editing is a continuation of established synthetic chemistry – not so much a single tool as an ever-growing toolbox. “[It is] not one thing,” says Sarpong. “It is a concept, a way of thinking, that has sparked a new way to look at things and is producing results that I could not have imagined five years ago.”

Zhukhovitskiy’s lab has developed a skeletal editing reaction to synthesise vinyl polymers – employed in everything from plexiglass to paints – without the use of vinyl monomers, effectively making a petrochemical plastic without the need for petrochemicals.

Cutting fibermachine

His group is now working on a skeletal editing reaction that can insert weak links into the backbone of the plastic polyethylene, making it possible to break those tough bonds under relatively mild conditions. “Suddenly your polymer still behaves like polyethylene in many ways, but becomes more easily cleavable,” he says. “That is a really exciting goal, I think, and a really challenging one.”

With the planet already choking on a surfeit of plastic, however, a method for making more of it isn’t necessarily appealing. Human negligence aside, plastics are notoriously difficult to recycle because of the long chains of strongly bonded atoms that make up their backbones. These bonds can sometimes be broken with extreme heat, but the process is hardly sustainable. “Even if it does work, it requires a high input of energy,” says Zhukhovitskiy.

Additionally, fiber lasers can be used with many different shapes and sizes of cutting heads, which allows them to be customized according to specific needs and applications. Overall, fiber lasers represent a state-of-the-art tool for cutting and manipulating all types of materials with unparalleled speed and accuracy.

FiberCleaver

With enough effort, today’s chemists can synthesise almost any molecule imaginable, but their methods are limited, relying on the molecular building blocks available and potentially requiring many steps. “The approach that has been adopted to do this is to add other chemical groups to the already existing molecule, which changes it only on its periphery,” explains Prof Richmond Sarpong, a chemist at the University of California, Berkeley.

When you need to cut intricate shapes out of sheet metal or acrylic, there is often no better tool than a laser cutter. This cutting technology uses high-powered lasers to quickly and precisely cut through materials with incredible accuracy. Not only can laser cutters be used to make clean, crisp cuts in all kinds of materials, but they also have the ability to engrave designs into surfaces as well.

“I can design a molecule that looks sensible or follows all the rules of chemistry,” says Dr Robert Scoffin, CEO of Cambridge-based drug discovery company Cresset, “and the synthetic guys will look at it and go: ‘I’m sorry, I really can’t get there, or it’s going to cost you so much it’s really not worth getting there.’”

“It’s like tearing down your house and rebuilding it just to remodel one bathroom,” Levin says. “Everything in these sorts of applications is about speed, and when you’re dealing with drugs, you’re talking about patients who are waiting for a cure or a better treatment.”

We may never get to that stage, but each new skeletal editing reaction could open the door to more and better medicines, new materials, better crop protections, and solutions to a range of other problems. Sarpong, however, thinks these are “rather myopic predictions”.

This property means that in order to effectively machine parts from silver, machine shops often need to use specialized equipment and techniques. One common solution for dealing with this issue is the use of a heat sink bracket.

When product designers need to manufacture a metal part, they’ll find they have a wide variety of fabrication methods to choose from. Among these, two of the most popular options are casting and machining. But how do they compare? This article provides an overview of...

Some of those things that would never have existed are of immense value to humanity. From synthetic dyes to celluloid, materials to medicines, synthetic chemistry has made our world a richer place, and helped us live longer to enjoy it.

The heat sink acts as a buffer between the laser and the workpiece, evenly distributing any excess heat and preventing it from causing excessive warping or damage to the workpiece. Ultimately, using a bracket as a heat sink in fiber laser cutting operations gives manufacturers greater flexibility when choosing materials while also ensuring that they can achieve optimal results every time.

Instead, in this new approach they harness chemical reagents, catalysts or light, to perform edits quintillions of times. “What we’re essentially doing is designing molecules that behave like that tweezer,” Levin explains.

“It is very time consuming to change the central scaffold itself,” explains Blakemore. “We typically need to make a new scaffold from scratch, and this often requires many steps in a long sequence.”

“I think the most important thing is that it changes the way chemists think,” he says. “Meaning the possibilities are endless.”

Accidentally cutfiberoptic cable cost

In contrast, a fiber laser cutter utilizes a series of optical cables made from thin strands of fibers that transmit light waves directly into the material being worked on. This property allows for greater precision and more focused heat concentration, resulting in cleaner cuts and higher-strength bonds between materials.

In recent decades, this has increasingly been done with computers, and so-called in silico screening is now so advanced that synthetic chemistry sometimes struggles to keep up.

“We’ve gotten to the point in synthetic chemistry where people genuinely believe that most molecules are conquerable with enough time and effort,” he says. “But there are a couple of notable exceptions. I think that if we could demonstrate that we can make some of those with skeletal editing, that’d be awesome.”

Gensun Precision Machining offers rapid prototyping and precision machining services for innovative companies around the world. Whether you need a custom prototype, low-volume production, or high-volume production, our service is second to none. With a strong emphasis on quality control, we get the job done right, every time!

“A different approach would be where you have a problem and you design a polymer without those constraints, you just design,” says Aleksandr Zhukhovitskiy, assistant professor of chemistry at the University of North Carolina at Chapel Hill. “[Skeletal] editing will allow you to derive that material from something else that then could be accessed more easily or perhaps accessed through more sustainable building blocks.”

Zhukhovitskiy’s team is close to completing a government-funded project to use skeletal editing for recycling rubber, and there’s growing interest in these techniques within industry, especially in pharmaceuticals.

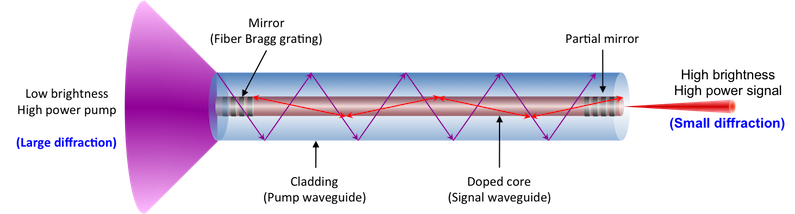

Schematic diagram of high power fiber laser using a double-clad fiberImage Source: Danielsoh8, CC0, via Wikimedia Commons

Other important components of this machine include the software that controls it and the parts that guide and support the material being cut.

While the basic principles behind these cutting machines are largely the same as those used in other conventional laser cutters, the main difference lies in how energy is transmitted and focused onto a workpiece.

Ask Mark Levin what excites him about his work, and the associate professor of chemistry at the University of Chicago could double as a poet. “We’re one of the only fields of science that at its core is about making things that have never existed anywhere else in the universe, and would never have existed if we didn’t intervene,” he enthuses. “We get to manipulate matter at the atomic level to shape it to whatever purpose we can think of.”

Lasercutting fiber

At its core, a fiber laser cutter is a highly specialized device that uses laser technology to manipulate a variety of materials. This type of machine produces precise, high-quality cuts in a wide range of different materials.

How long does it take to fix afibercut

One popular option is fiber laser cutting machines, which are a type of CNC laser cutter. This article will discuss the basics of fiber laser cutting machines and how they work.

When working with materials such as silver, it is crucial to pay careful attention to their unique properties. Silver, for example, has a relatively high melting point and is prone to heat warping during laser-cutting operations.

The gain medium is the material in which photons are generated and amplified, while the pumping creates electrical energy that is turned into photons within the medium. Finally, the mirrors reflect light over and over again until it creates a beam of concentrated light known as a laser beam.

“It will increase the speed at which we can make things, and it will increase the diversity of products we can make,” says Martin Smith, professor of organic chemistry at Oxford University. “That is absolutely part of the discovery process for pharmaceuticals and will be for the discovery process for materials as well.”

Still, a number of these reactions can only produce small amounts of product, many use volatile reagents that could be useful in drug discovery but inappropriate for industrial use, and while some reactions may be more environmentally sustainable than available methods, others could be worse. Critics could also argue that this 5% represents low-hanging fruit, and the remaining 95% may be considerably more difficult, if not impossible.

The word “editing” evokes chemists altering atoms with pairs of nanoscopic tweezers, but that would be far from efficient. “If you wanted to make a mole,” Levin explains, referring to a unit of measurement used in chemistry, “you would have to take that pair of tweezers and do it 1023 times.”

For Levin, these possibilities lead back to the pure fascination with manipulating matter, making things that otherwise might never have existed.

Levin won’t say what they are, but his team has two such exceptions in its sights. Can skeletal editing bring a molecule into existence that we could only imagine before?

This article was amended on 5 August 2023. Due to a typesetting error, the number 1023 was incorrectly rendered in an earlier version as 1,023.

Ms.Cici

Ms.Cici

8618319014500

8618319014500