Understanding Depth of Field in Photography - focal length and depth of field

3Mreflectivespray paint

Some microscopes use an oil-immersion or water-immersion lens, which can have magnification greater than 100, and numerical aperture greater than 1. These objectives are specially designed for use with refractive index matching oil or water, which must fill the gap between the front element and the object. These lenses give greater resolution at high magnification. Numerical apertures as high as 1.6 can be achieved with oil immersion.[2]

Particularly in biological applications, samples are usually observed under a glass cover slip, which introduces distortions to the image. Objectives which are designed to be used with such cover slips will correct for these distortions, and typically have the thickness of the cover slip they are designed to work with written on the side of the objective (typically 0.17 mm).

3Mreflectivepaint for shoes

One of the most important properties of microscope objectives is their magnification. The magnification typically ranges from 4× to 100×. It is combined with the magnification of the eyepiece to determine the overall magnification of the microscope; a 4× objective with a 10× eyepiece produces an image that is 40 times the size of the object.

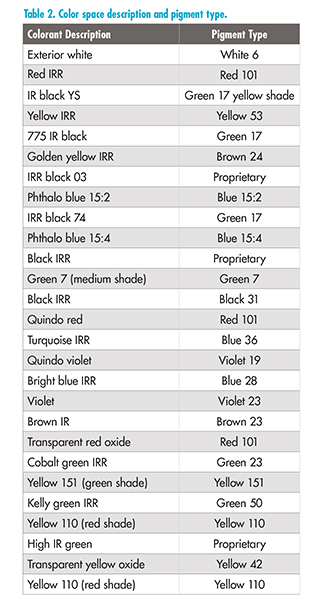

Now that the terms and measuring instruments have been introduced, the next step is choosing the right colorants for the IRR coating. It is important to consider the entire thermodynamic system when developing an IRR strategy to maximize reflectance and emissivity. This includes environment, substrate, coatings, and colorant. One must account for system components that can impact reflectivity and potential contamination variables of IR-absorbing materials. Table 2 displays the color spaces one can achieve using colorants while maintaining good IR management.

3MReflectiveVinyl

All these types of objectives will exhibit some spherical aberration. While the center of the image will be in focus, the edges will be slightly blurry. When this aberration is corrected, the objective is called a "plan" objective, and has a flat image across the field of view.

Continual climate change necessitates a movement toward energy savings via coatings. One method of saving energy in hot climates is to minimize the heating of buildings. This can be achieved with the application of a coating on the roof that keeps the rooftop cool while minimizing the conduction of heat and the use of air conditioning. Another way to save energy is through increasing the lifespan of a coating with heat protection. This method represents energy savings in a broader scope, as it reduces energy along the production chain.

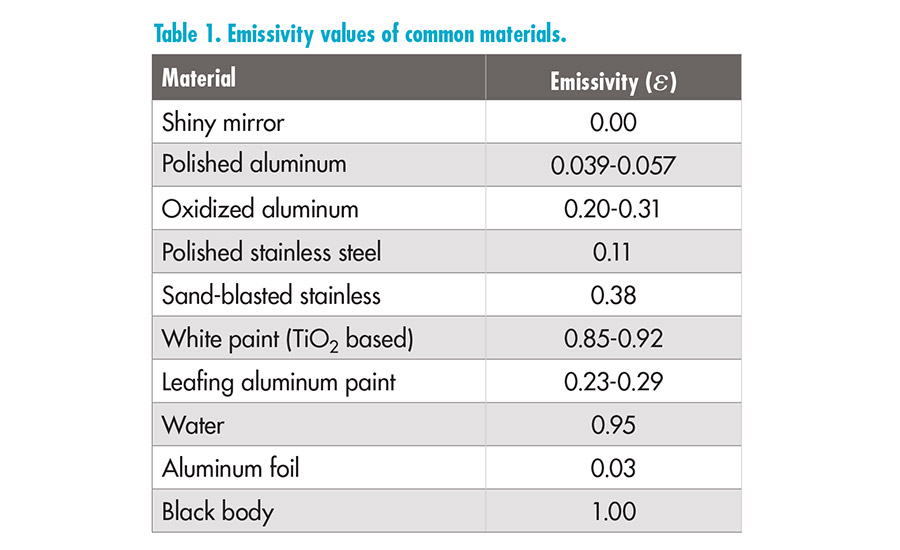

Emissivity is an important term for the surface or substrate worth protecting, and it is calculated by ASTM E 408. When a surface has a propensity to radiate more heat energy that it absorbs, it will not build heat as quickly as a surface that only absorbs heat. This is in comparison to conducting heat, where heat is transferred within the surface to dissipate it. Table 1 lists some common materials and their emissivity values.

In a telescope the objective is the lens at the front end of a refracting telescope (such as binoculars or telescopic sights) or the image-forming primary mirror of a reflecting or catadioptric telescope. A telescope's light-gathering power and angular resolution are both directly related to the diameter (or "aperture") of its objective lens or mirror. The larger the objective, the brighter the objects will appear and the more detail it can resolve.

The traditional screw thread used to attach the objective to the microscope was standardized by the Royal Microscopical Society in 1858.[3] It was based on the British Standard Whitworth, with a 0.8 inch diameter and 36 threads per inch. This "RMS thread" or "society thread" is still in common use today. Alternatively, some objective manufacturers use designs based on ISO metric screw thread such as M26 × 0.75 and M25 × 0.75.

Instead of finite tube lengths, modern microscopes are often designed to use infinity correction instead, a technique in microscopy whereby the light coming out of the objective lens is focused at infinity.[1] This is denoted on the objective with the infinity symbol (∞).

Reflective compoundsfor metal

Basic glass lenses will typically result in significant and unacceptable chromatic aberration. Therefore, most objectives have some kind of correction to allow multiple colors to focus at the same point. The easiest correction is an achromatic lens, which uses a combination of crown glass and flint glass to bring two colors into focus. Achromatic objectives are a typical standard design.

Sponsored Content is a special paid section where industry companies provide high quality, objective, non-commercial content around topics of interest to the Adhesives and Sealants Industry audience. All Sponsored Content is supplied by the advertising company and any opinions expressed in this article are those of the author and not necessarily reflect the views of Adhesives and Sealants Industry or its parent company, BNP Media. Interested in participating in our Sponsored Content section? Contact your local rep!

Scotchlite 3M

3MReflectiveMaterial for Clothing

Historically, microscopes were nearly universally designed with a finite mechanical tube length, which is the distance the light traveled in the microscope from the objective to the eyepiece. The Royal Microscopical Society standard is 160 millimeters, whereas Leitz often used 170 millimeters. 180 millimeter tube length objectives are also fairly common. Using an objective and microscope that were designed for different tube lengths will result in spherical aberration.

Colorants play a larger role than perhaps many of us suspect in managing IR effects from heat build. Benefits of IRR colorants include:

The working distance (sometimes abbreviated WD) is the distance between the sample and the objective. As magnification increases, working distances generally shrinks. When space is needed, special long working distance objectives can be used.

Options for a suitable substrate are limited when designing an exterior surface to stay cool. The best option is usually choosing a substrate and/or coating with high NIR reflectance. That is why the coating chosen and the colorants in that coating are critical to a cool surface.

An indirect measure of emissivity for a substrate incorporates the heat build test per ASTM D 4803-97. Figure 2 illustrates a typical heat build setup. The heat build test was developed for vinyl substrates but can be applied to other materials. It requires a 250-W clear heat lamp with color temperature of 2,400 K. It is important to note that that spectral power distribution of the heat lamp is not equivalent to the terrestrial irradiance of the sun. These heat build tests are correlated to real-world applications by a multiplier and a predefined standard.

In optical engineering, an objective is an optical element that gathers light from an object being observed and focuses the light rays from it to produce a real image of the object. Objectives can be a single lens or mirror, or combinations of several optical elements. They are used in microscopes, binoculars, telescopes, cameras, slide projectors, CD players and many other optical instruments. Objectives are also called object lenses, object glasses, or objective glasses.

The distinction between objectives designed for use with or without cover slides is important for high numerical aperture (high magnification) lenses, but makes little difference for low magnification objectives.

3M ScotchliteReflectiveMaterial

In addition to oxide glasses, fluorite lenses are often used in specialty applications. These fluorite or semi-apochromat objectives deal with color better than achromatic objectives. To reduce aberration even further, more complex designs such as apochromat and superachromat objectives are also used.

One contamination to avoid in colorant formulas is the use of carbon black. Since it is a good absorber of light energy (ultraviolet, visible, and infrared), carbon black cannot be used at any level in color formulations for IRR coatings. This holds true whether the strategy is reflective colorants or transparent colorants coated on a reflective surface.

Determining how much energy surfaces on the Earth receive from the sun (i.e., solar irradiance) is dependent on the time of day, location on Earth, and atmospheric conditions. The term irradiance is defined as the power per unit area of electromagnetic radiation incident on a surface. The surface is the key element for this discussion.

A wide color space is available to obtain aesthetic color combined with proper surface cooling of the coating and substrate. Consumers can have their color choices while saving money on energy and delaying the cost of coating reapplication.

Numerical aperture for microscope lenses typically ranges from 0.10 to 1.25, corresponding to focal lengths of about 40 mm to 2 mm, respectively.

Another key term in IR management is emissivity, which in this case is the ability of an object to radiate heat energy. The emissivity value is a range of 0 to 1, based on the ability of a perfect mirror (0) to emit infrared energy compared to a pure black body (1).

Roughly 58% of the solar irradiance is NIR or heat energy. This is a good thing, as the heat from the sun equals a habitable environment.

The objective lens of a microscope is the one at the bottom near the sample. At its simplest, it is a very high-powered magnifying glass, with very short focal length. This is brought very close to the specimen being examined so that the light from the specimen comes to a focus inside the microscope tube. The objective itself is usually a cylinder containing one or more lenses that are typically made of glass; its function is to collect light from the sample.

3MReflectiveFabric

Infrared-reflective (IRR) colorants have therefore found their way into the market. These colorants reflect light and resist heat build, thus saving the energy it takes to cool buildings. The cool roof concept is popular environmentally, and other cool surface initiatives are in the planning stages. If a coating remains cool, then the coating structure is less likely to degrade through a heat decomposition mechanism. This saves energy by delaying the need for a replacement.

Camera lenses (usually referred to as "photographic objectives" instead of simply "objectives"[4]) need to cover a large focal plane so are made up of a number of optical lens elements to correct optical aberrations. Image projectors (such as video, movie, and slide projectors) use objective lenses that simply reverse the function of a camera lens, with lenses designed to cover a large image plane and project it at a distance onto another surface.[5]

For example, consider a grey blend containing a transparent organic black and titanium dioxide contaminated with 0%, 0.02%, and 0.09% carbon black. TSR can drop from 20% to 40% with a contamination of very little carbon black. The percent reflectance reaches 84% between 800-2,400 nm, but drops to 65% with 0.02% carbon black and 42% reflectance in that same range with 0.09% carbon black contamination.

To properly understand IR management, it is best to begin with the electromagnetic spectrum. The electromagnetic spectrum connects sunlight and total solar reflectance (TSR), which is a measure used to gauge performance for infrared reflectance.

White coatings are the obvious first choice for both of these methods, as white colorants feature the highest reflectivity of sunlight-carrying infrared (IR) waves (heat energy). The white reflects the heat energy, and the building stays cool. However, consumers like different color choices.

Figure 1 displays the energy and wavelength of light from gamma rays to radio waves, highlighting the visible light spectrum and NIR approaching 700 nm. Sunlight is broken down from ultraviolet radiation (> 100 nm) to IR radiation (< 1,000 nm), with the visible spectrum in between (400-700 nm).

Infrared reflectance of a surface is measured by total solar reflectance (TSR), as defined by ASTM C 1549. When analyzed in a common TSR instrument, a dark-colored surface absorbs 90% of the heat energy and reflects 10%, while a light-colored surface absorbs 30% heat energy and reflects 70%.

A typical microscope has three or four objective lenses with different magnifications, screwed into a circular "nosepiece" which may be rotated to select the required lens. These lenses are often color coded for easier use. The least powerful lens is called the scanning objective lens, and is typically a 4× objective. The second lens is referred to as the small objective lens and is typically a 10× lens. The most powerful lens out of the three is referred to as the large objective lens and is typically 40–100×.

Ms.Cici

Ms.Cici

8618319014500

8618319014500