Tract Troic UHD 12.5x50 - binoculars specification - tract binoculars

There is no advantage, and no difference really. It is not confusing if you just use the naming conventions, pitch, yaw, roll. Good luck!

roll,pitch yawrobotics

I noticed the same thing, it appears to be really silly and annoying but I’m sure there is a historical reason for it. Either way it’s just a small annoyance that you’ll get used to soon enough.

yaw,pitchroll xyz

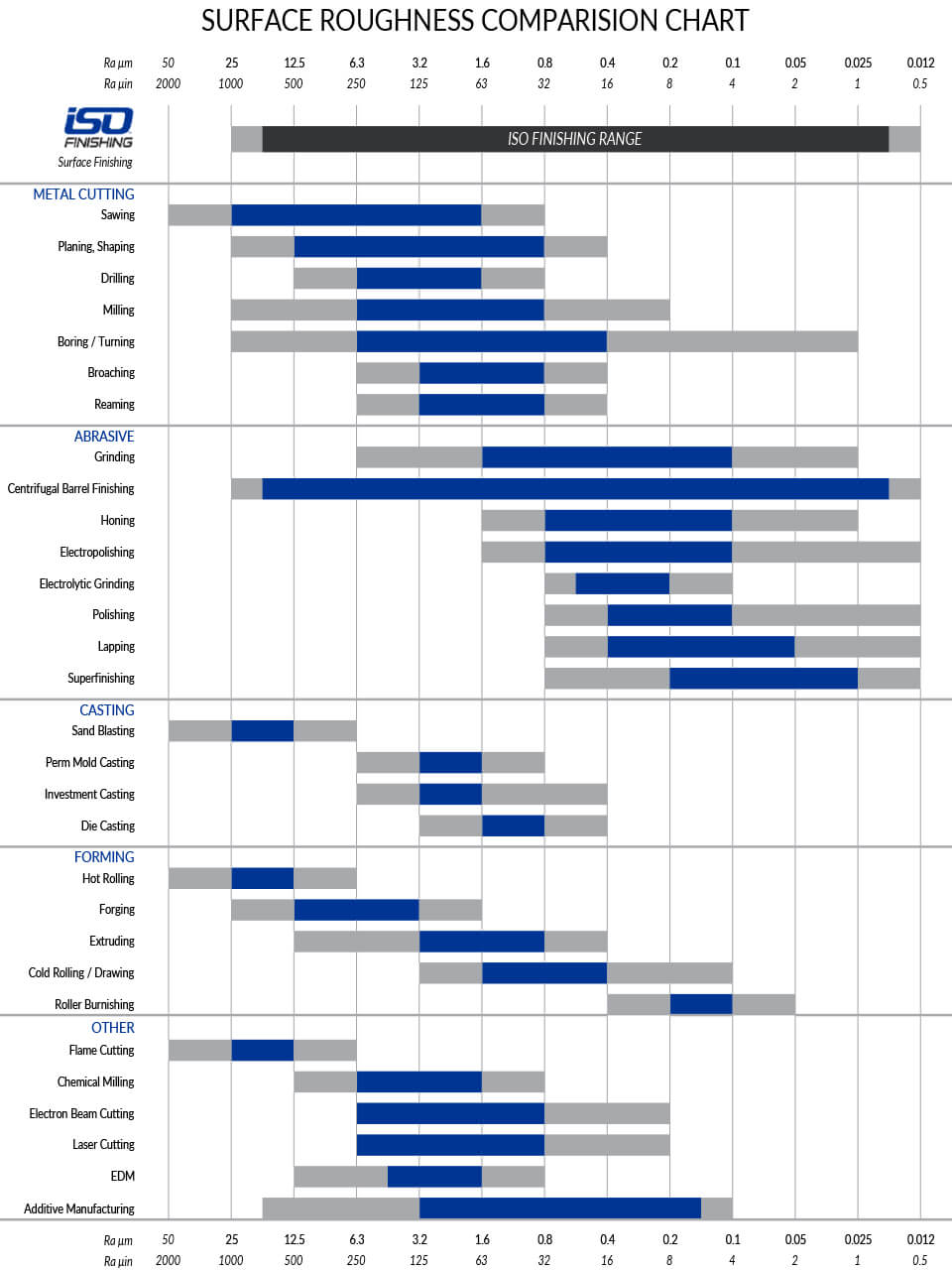

There is a wide range in the variations of surface roughness and edge condition depending upon the production process used. Listed below are common manufacturing techniques with their corresponding standard Ra values and the typical Ra value ISO Finishing can achieve following surface finishing.

Unfortunately, they are not in order. For example to create a rotator in C++ the constructor is: FRotator ( float InPitch, float InYaw, float InRoll )

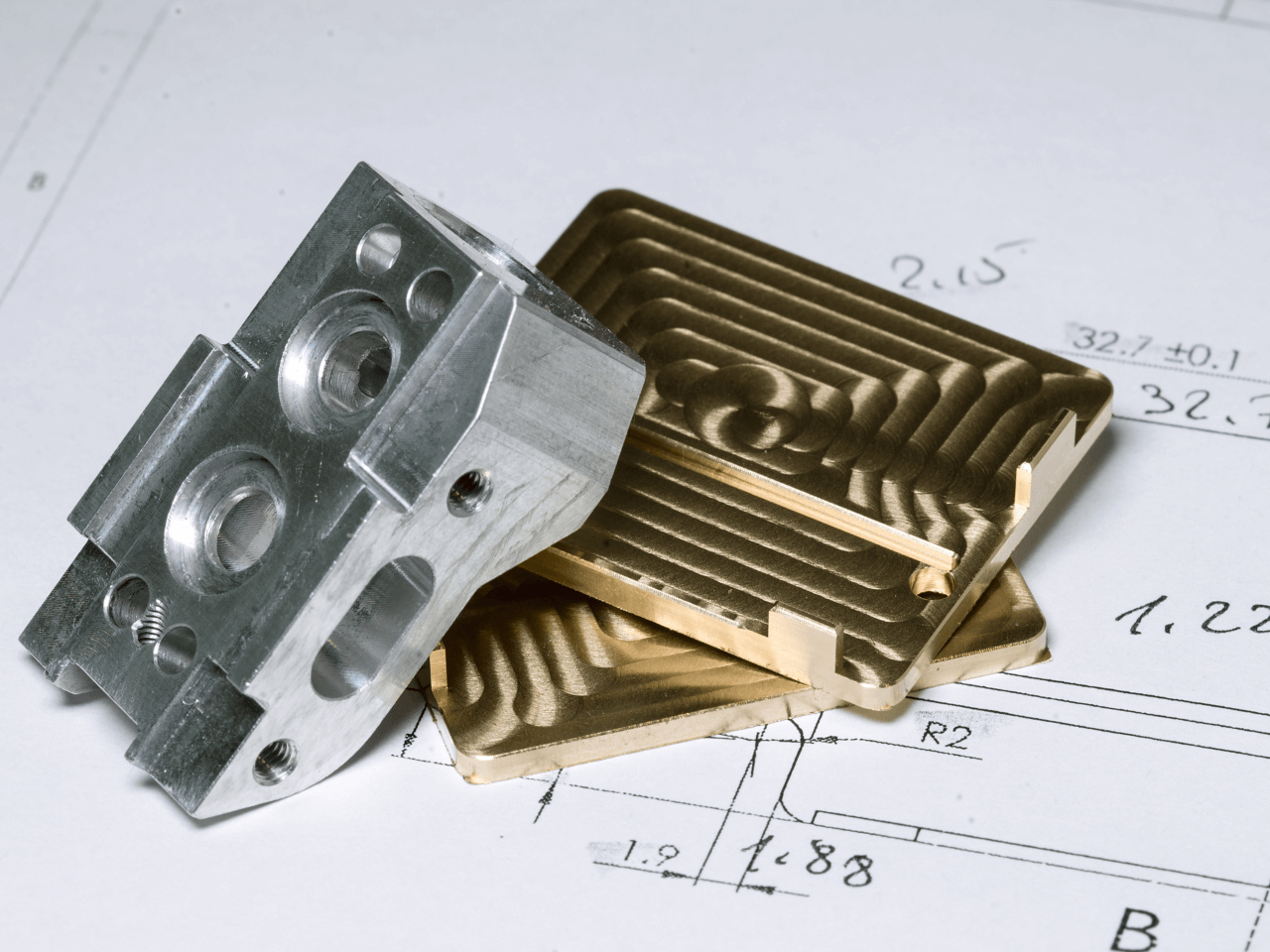

ISO 9001:2015 certified and FFL licensed, ISO Finishing is an expert in creating customized, documented and repeatable isotropic surface finishing processes. We are experienced in working with all material types and our surface finishes meet the strictest requirements.

Pitch yawmeaning

Yaw,pitchroll

It’s really confusing to me that UE mixes x,y,z rotations with pitch, yaw, and roll rotations. If I make a rotator in C++ for example I have to give the angles in order pitch, yaw and roll. However, in the blueprint class editor, rotations are in x, y, and z. So pitch, yaw and rolls would be y, z, and x… Not only different names, but also a different order. Besides the names and the order, is there any other differences between these two systems? If not, what is the advantage of using both systems in one engine? It seems so pointlessly confusing…

The best way to show you first-hand how our finish will be your finish is to process your sample. Let us show you what we can do. LET’S GET IT FINISHED.

Surface texture refers to the deviations in surface topography characterized by different properties such as form, waviness, roughness and flaws. While all of these properties impact a product’s performance, surface roughness is the direct result of the material condition and production process used. Surface roughness is a good indicator of how a mechanical product will interact with its environment and its performance.

I was confused for like 3 hours and thought I was dumb, but then I realized that the Yaw is in the X position in C++ and in the Z position in the blueprint editor lol.

Hello, I just discovered that in rotators, when the pitch (y) goes over 90 or under -90, roll (x) & yaw (z) are subtract by 180 and y goes the over way (the exact formula is y<0 ? (-90 + (-90 -y)) : (90 + (90 -x))) It's causing me...

Ms.Cici

Ms.Cici

8618319014500

8618319014500