The Vision Council Estimates U.S. Optical Industry Size at ... - us optical

In microscopy, it is vital to have some form of contrast or stain that gives areas of the sample color and makes it possible to image. Advanced fluorescence microscopy techniques take advantage of this.

Field of viewcalculator

The Prime series of 95% quantum efficient, back-illuminated sCMOS cameras are designed to support the most demanding, low-light research applications

A microscope C-mount or F-mount adaptor is needed to connect a scientific camera to the microscope camera port. The mount threading is standardized which means that a C-mount adaptor will connect to all scientific cameras that connect via C-mount. However, the adaptors are microscope specific which means that although any C-mount camera will connect to a C-mount adaptor, the adaptor will only fit microscopes of the matching brand.

What is the field of viewmicroscope

It’s usually possible to find the maximum FOV of the microscope by referring to the field number (FN) displayed on the eyepieces and on some objective lenses. The field number is simply the maximum FOV of measured as a diameter the objective or eyepiece in millimetres, so an objective lens with a field number of 18 would have a maximum FOV of 18 mm. However, the field number always assumes no magnification so to calculate the actual FOV, the field number should be divided by the objective magnification:

That's a good question - excess heat will degrade your LED and greatly lower light output. In general, we recommend a conservative 3-square inches of heat sink surface area per watt; a single high power LED driven around 350mA is generally around 1-watt.

High content imaging is primarily concerned with the automated analysis of large cell populations where the goal is to process as many cells as possible in the fastest time with the highest resolution.

The metals with the best thermal conductivity, from high to low, except for thermal resistance, are silver, copper, gold, and aluminum. Copper and aluminum are the most commonly materials used in heat sinks, but copper is more expensive, heavier and has a higher melting point, making aluminum is the most material used in LED heat sinks.

Field of viewcamera

By recognizing that FOV requirements can be highly variable, we are able to better serve the needs of our customers and offer a broad range of camera FOV options.

Physics and biophysics imaging encompasses a wide range of techniques used to interrogate physical phenomena using high tech imaging systems.

The Prime series of 95% quantum efficient, back-illuminated sCMOS cameras are designed to support the most demanding, low-light research applications

The Evolve family of cameras are high-resolution, back-illuminated EMCCD providing high sensitivity for the lowest light applications.

CMOS made scientific. The Moment is a true global shutter CMOS camera with an ultra-compact form factor, powered through USB 3.2 Gen 2.

The brand new Kinetix family of back-illuminated sCMOS cameras delivers a framerate and field of view unmatched by any other sCMOS camera.

Typically, the design of your LED application restricts the size of a heat sink, causing the heat sink to be inadequate for complete cooling. Other ways to help cool your LED can be active convection or forced air. Forced air can significantly improve cooling, in some applications active cooling can account for 40-percent of the cooling. Due to the natural forced air cooling of cycling, many LED bike light are applied with inadequate heat sink sizes. Under water applications is another case where a heat sink can be under-sized, as typically the water temperature is low enough to act as one large heat sink.

If the goal is simply to attach the camera to the microscope, a 1x adaptor contains no additional lenses and provides no additional magnification or demagnification. This is often the preferred method as it introduces no additional lenses into the system. Every extra lens reduces the number of photons reaching the camera by 3-4% so many researchers will try to avoid this.

The development of larger FOV microscopes and scientific cameras that can take advantage of the F-mount is relatively recent – at the time of writing only one commercially available 25 mm microscope exists. Most modern microscopes have a 19 mm or 22 mm FOV and are therefore still able to use the C-mount. The largest format spinning disk confocal systems are also limited to a 22 mm FOV.

Lori is a professional supplier of LED cooling solutions and LED heat sink manufacturers. LED lighting heat sinks are various, the common types are extruded aluminum led heatsink , LED sunflower heat sink, die-casting led heatsink, stamping led heatsink,cold forged heat sinkï¼skived led heatsink and so on. LORI has rich experience in high power LED heat dissipation. Currently, Lori has provided LED cooling solutions for LED street lights, greenhouse vegetable LED lights, LED projection lights, car lights, tunnel lights, solar street lamps and so on. Lori led heat sink, led heat sink extrusion types as following

Hello, please leave your name and email here before chat online so that we won't miss your message and contact you smoothly.

What is themaximum angleofvision for healthy human eye

See what others are doing. Stories and images from scientists using our high-performance sCMOS, EMCCD and CCD cameras to advance their research.

Cooled, low-noise CMOS cameras designed for integration. With unprecedented thermal control, Retiga E cameras are capable of exposures over an hour!

The FOV of a microscope is ultimately limited by a number of factors, such as the objective lens, the tube-diameter of the microscope’s internal optical-system, the eyepieces, the scientific camera sensor size and the camera mounting adaptor

Stamping led heat sink: Stamping led heatsink is a forming and processing method that relies on press and mold to exert external force on plate, strip, pipe and profile to produce elastic deformation, plastic deformation or separation, so as to obtain the required shape and size of the stamping led heatsink .Stamping and forging belong to the same plastic processing (or pressure processing), collectively known as forging. Stamping materials are mainly hot and cold rolled steel and steel strip. Compared with die casting led heat sink and forging heat sink, stamping led heatsinks are thin, even, light and strong. The quality of stamping led heatsinks are very small, the material utilization rate are high and the production efficiency are high.

Biochip, genomics and microarray detection represent a large mix of applications with varying needs of a scientific camera.

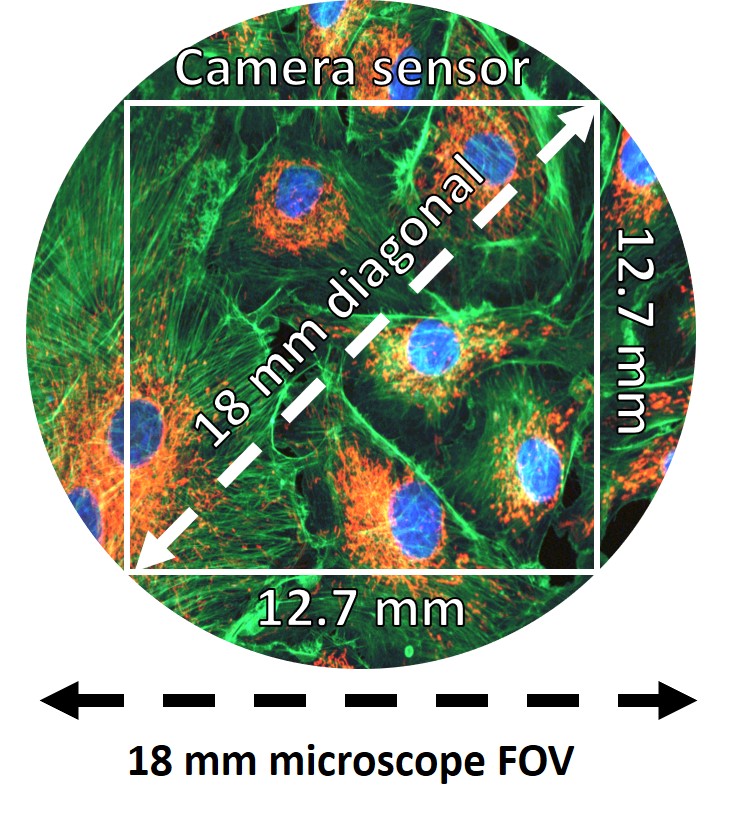

Microscope field of view (FOV) is the maximum area visible when looking through the microscope eyepiece (eyepiece FOV) or scientific camera (camera FOV), usually quoted as a diameter measurement (Figure 1). Maximizing FOV is desirable for many applications because the increased throughput results in more data collected which gives a better statistical measurement for detecting subtle effects and also decreases time needed at the microscope.

At Teledyne Photometrics, we aim to create cameras that can optimally match the FOV of all modern microscopes (Table 1). For this reason, the Prime 95B Series comprises a 19 mm camera, a 22 mm camera and a 25 mm camera. Additionally, the Prime BSI and Iris 9 both fit a 19 mm microscope FOV and the Iris 15 fits a 25 mm microscope FOV. The Kinetix is our largest format sensor which is able to be used to get the maximum FOV out of any system up to 29 mm.

Die cast aluminum led heat sink: Die casting led heat sink is a kind of pressure casting parts, it is to use the die casting machine, which installed pressure casting mold, the heating for liquid copper, zinc, aluminum or aluminum alloy into the mouth poured into the die casting machine, die casting machine die casting, casting the shape and size of aluminum or aluminum alloy parts, such parts are usually called aluminum die casting. Die-cast aluminum heat sink for led are generally large in size, with irregular design and controllable production cost. The led heatsinks cannot be made very thin, so it is difficult to maximize the heat dissipation area.The commonly used die casting materials for the LED heat sink are ADC10 and ADC12.

The style of the fin of the LED heatsink significantly affects its ability to release heat into the environment. However, the shape of the led heat sink fin usually depends on the shape of the heating part. For example, in contrast to a flat-finned heatsink, an appropriate design would use a radial finned style when cooling the cylindrical shape.

Supplying custom cameras to instrument designers for most of our 40 year history, we will work with you every step of the way.

One of the key parameters of the LED heat sink is the material that makes up the heat sink. In order to effectively remove heat from the heating components, the heat sink for led

The brand new Kinetix family of back-illuminated sCMOS cameras delivers a framerate and field of view unmatched by any other sCMOS camera.

The maximum field of view of the microscope is affected by the objective lens, the tube-diameter of the microscope’s internal optical-system, the eyepieces, the scientific camera sensor size, and the camera mounting adaptor. For optimal imaging performance, it’s best to match the microscope FOV to the scientific camera FOV to capture as much information as possible and avoid vignetting. Teledyne Photometrics cameras are designed to match these specifications to offer the maximum field of view possible.

The QImaging CCD family of scientific cameras are designed with solutions for electrophysiology, long stare, color imaging, documentation and live cell imaging.

What is the field of viewformula

Cold forged heat sink: Cold forged heat sink is made by steel, aluminum alloy sheet stamping, pull to rise, make a cup of tube type of led heatsinks, cold forged heat sink inside and outside perimeter smooth, LED cold forged heat sink commonly used aluminum alloy material is AL5052, AL6061, AL6063, the quality of cold forged heat sink is small, high material utilization, high production efficiency, is a low cost solution. This process is mainly used in the manufacture of LED light heat sink.

Supplying custom cameras to instrument designers for most of our 40 year history, we will work with you every step of the way.

Adapters can have lenses in them to magnify or demagnify the image before it reaches the camera. This can be used to better match the camera FOV to the microscope FOV. For example, if the camera has an 11 mm diagonal FOV but the microscope is capable of an 18 mm FOV, a 0.67x adaptor would demagnify the image and allow it to be displayed on the 11 mm camera. However, this increase in FOV comes at the cost of reduced resolution.

Heat sink used with LED is designed to absorb and disperse excess heat away from the LED diode and into the heat sink. Passive or active air circulates around the heat sink to help cool it. Too much heat can damage LED phosphors, this results in lower light output, color changes and or a significant decrease in life expectancy. Unfortunately, the most common problem we see in LED lighting applications is that the heat sinks are too small or not at all. To avoid these thermal problems we provide a wide variety of LED heat sinks below, which include: anodized extruded linear heat sinks, LED housings, LED light engine housings, small finned heat sinks. To learn more about LED heat sink take a look at this article here.

The Iris family of sCMOS cameras deliver up to a 15 megapixel sensor with a 25 millimetre field of view for high-resolution imaging over a large imaging area.

Camera specification sheets will display the camera FOV as a diagonal measurement (usually in millimeters). Ideally, the diagonal camera FOV should match the diameter of the microscope FOV to capture as much of the available image as possible. However, this does mean that the horizontal and vertical FOV of the camera will be less than the microscope diameter.

Human eyefield of viewin mm

The Evolve family of cameras are high-resolution, back-illuminated EMCCD providing high sensitivity for the lowest light applications.

Adaptors can also affect the microscope and camera FOV depending on the type of adaptor used. A C-mount adaptor is the most popular microscope camera adaptor and is restricted to a maximum 22 mm FOV. The F-mount adaptor is a larger format adaptor capable of reaching >30 mm FOV.

CMOS made scientific. The Moment is a true global shutter CMOS camera with an ultra-compact form factor, powered through USB 3.2 Gen 2.

If you are looking for an led heatsink for your application, there are several important led heat sink design factors to consider before customizing the led heat sink. When customizing and designing appropriate heatsink for led, we will keep the following important heatsink parameters in mind.

High content imaging is primarily concerned with the automated analysis of large cell populations where the goal is to process as many cells as possible in the fastest time with the highest resolution.

It’s possible to use a camera with a larger diagonal FOV than the microscope to capture the entire microscope FOV (Figure 4). However, this is not optimal as there will be substantial vignetting at the corners of the image. Ideally, when choosing a scientific camera, it should have a diagonal FOV that matches the specifications of the microscope it will be used with.

Biochip, genomics and microarray detection represent a large mix of applications with varying needs of a scientific camera.

All cameras are controllable with the PVCAM driver and supported in Ocular software. The PVCAM driver SDK can also be used integrate into other software packages.

Cooled, low-noise CMOS cameras designed for integration. With unprecedented thermal control, Retiga E cameras are capable of exposures over an hour!

Human FOV in games

All cameras are controllable with the PVCAM driver and supported in Ocular software. The PVCAM driver SDK can also be used integrate into other software packages.

The QImaging CCD family of scientific cameras are designed with solutions for electrophysiology, long stare, color imaging, documentation and live cell imaging.

See what others are doing. Stories and images from scientists using our high-performance sCMOS, EMCCD and CCD cameras to advance their research.

must have a high thermal conductivity. Some of the common materials for led heat sinks are aluminum and copper. Lower-grade heat sinks can also be made of stainless steel or other metal alloys, and these materials are also more cost effective in larger sizes or for the led heat sink price.

Using the field number to calculate microscope FOV works well when imaging using the eyepieces but not when imaging using a scientific camera. Like most digital cameras, scientific cameras use square or rectangular sensors. This means that a scientific camera cannot capture the whole, circular FOV that the microscope is capable of. Instead, the camera FOV must fit inside the microscope FOV (Figure 3).

The Iris family of sCMOS cameras deliver up to a 15 megapixel sensor with a 25 millimetre field of view for high-resolution imaging over a large imaging area.

Field of viewhuman eye

In microscopy, it is vital to have some form of contrast or stain that gives areas of the sample color and makes it possible to image. Advanced fluorescence microscopy techniques take advantage of this.

A 20x objective with a field number of 18 would actually have a FOV of 0.9 mm. Likewise, a 100x objective with a field number of 18 would have a FOV of 0.18 mm. The more an object is magnified, the smaller the field of view will be. Therefore, when looking to increase FOV, one of the first considerations should always be whether it’s possible to decrease magnification (Figure 2).

Good news! You have already signed up to our mailing list. If you would like to amend your preferences, please look out for one of our emails- don’t forget to check your junk folder just in case.

Physics and biophysics imaging encompasses a wide range of techniques used to interrogate physical phenomena using high tech imaging systems.

Extruded aluminum led heat sink: This extruded aluminum LED heat sink is formed by aluminum extrusion, and by CNC machining, embedded in heat pipe, and finally finished by surface treatment. Extruded aluminum Led heatsink is liquid aluminium formed through a fixed mold. Then cut the led heat sink aluminum profile and mchined into the desired shape. The post-processing cost is high, and the fin can be made very thin to increase the heat dissipation area. When the led heat sink works, air convection diffusion heat automatically formed, and the heat dissipation effect is good. Common materials used in aluminum extrusion are AL6063 and AL6061.

In general, you will find metal alloys used in heat sink led because they have high thermal conductivity (equal to low thermal resistance). Thermal conductivity is the ability of a material to transfer heat through itself, which allows it to transfer heat efficiently from a low surface area environment to a high surface area environment. Copper has a thermal conductivity of 388w/mC, while "optimal" aluminium 6061 has a thermal conductivity of 180w/mC. As a result, copper is more than twice as efficient at transmitting heat through itself.

Ms.Cici

Ms.Cici

8618319014500

8618319014500