Standard Zoom Lenses - zoom lenses

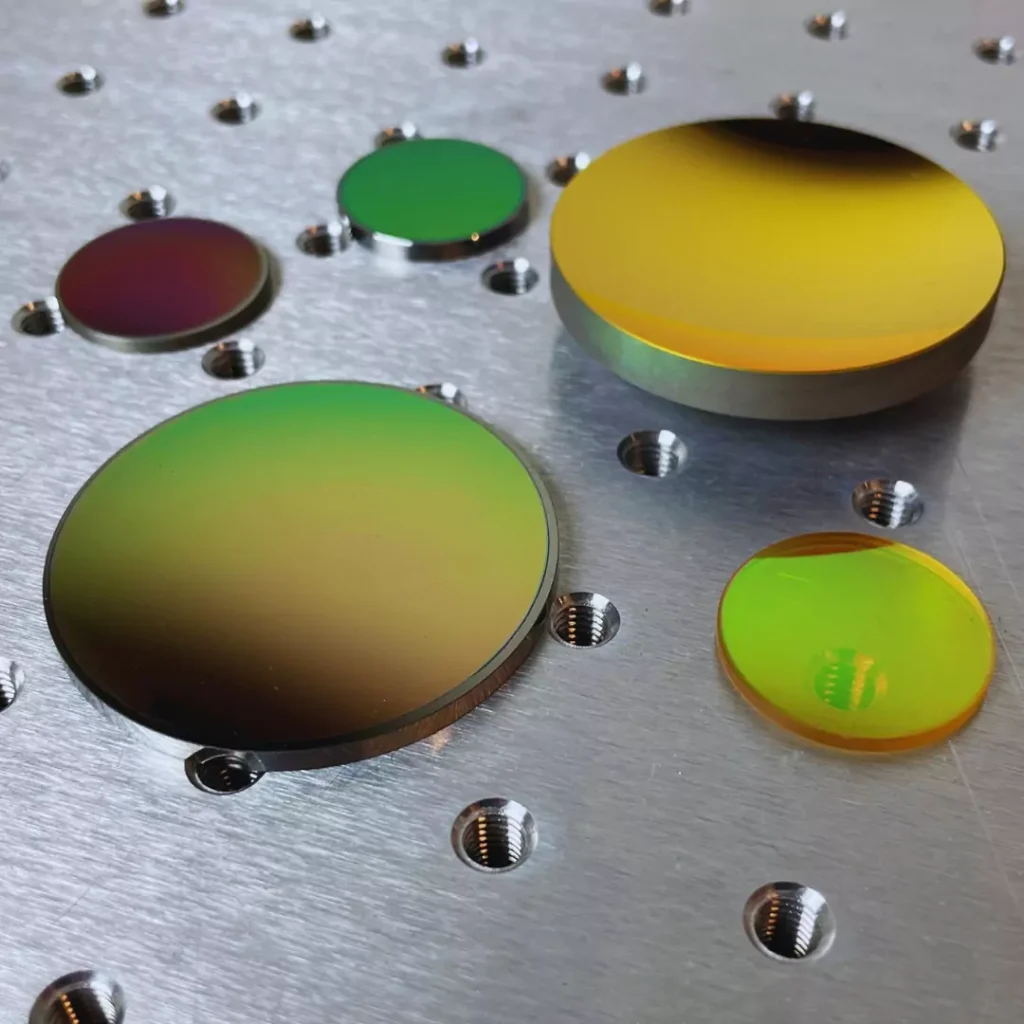

High-quality infrared coatings are indispensable in infrared spectroscopy instruments, ensuring accurate and precise measurement of sample spectra. These coatings optimize signal-to-noise ratios, minimize unwanted reflections, and enhance spectral resolution.

IR coatingglass

NLIR’s mid-infrared spectroscopy solution offers rapid measurement of IR coatings and thin films. With millisecond precision, measure full spectra in transmission or reflection for production monitoring and batch quality assurance.

Optimal anti-reflection coatings are essential for maximizing the performance of infrared cameras used in thermal imaging applications. By minimizing loss through multiple lenses, these coatings ensure efficient transmission of light, resulting in sharper and clearer thermal images.

Idlccoating

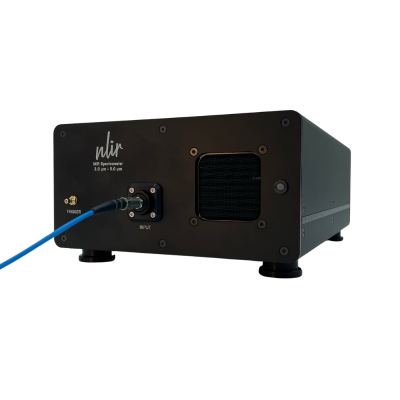

NLIR’s spectrometers are so fast because they use an array detector that can read out data with 400 Hz and even up to 130 kHz.

Hdarcoating

Infrared coatings play a critical role in defense and security applications, such as target detection, surveillance, and threat assessment. These coatings enable the development of advanced optical systems, including infrared cameras and sensors, by enhancing sensitivity, reducing glare, and improving signal clarity.

NLIR’s spectrometers use detector arrays with 2048 pixels, so the resolution can be as low as 2.5 cm⁻¹ in a wide optical bandwidth.

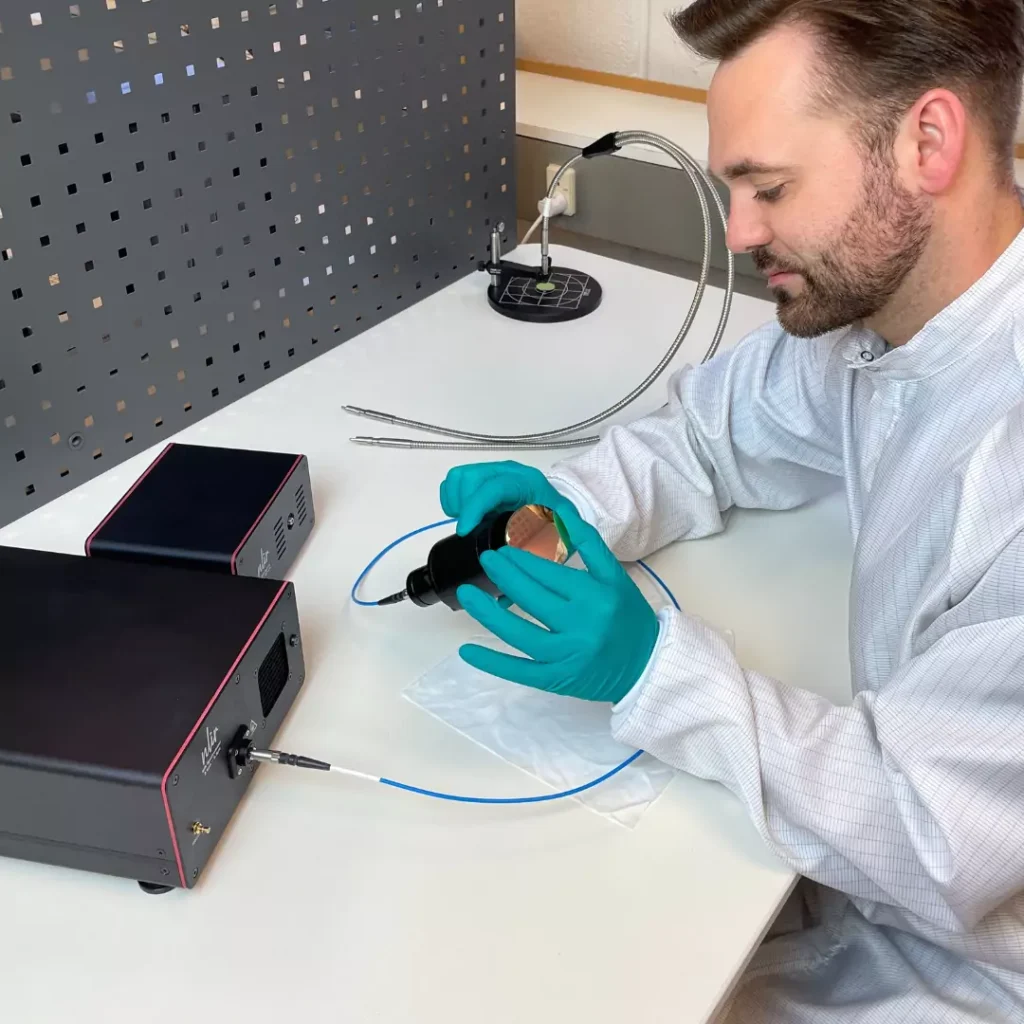

Fiber-coupled bundle that enables easy transmission measurements of infrared optical materials with applied coating or thin film. Available as reflection setup as well.

UmicoreCoatingServices

Anti reflectivecoatingspray

Offering a 2.0 – 5.0 μm bandwidth and 400 Hz readout, our spectrometer is ideal for IR Coating quality control in large batches.

Our broadband thermal light source fiber-coupled with the 2.0-5.0 µm Spectrometer, makes an easy bundle solution to your measurement setup.

Using NLIR’s spectrometers for measurement of infrared optical coatings is straightforward. Just set up your devices, plug it to our software, and get measurement data as you go.

Across various scientific disciplines, from astronomy to material science, optimal infrared coatings play a crucial role. These coatings provide precise wavelength selectivity and minimal signal loss, enabling researchers to achieve optimal performance in diverse experiments and measurements.

Ir coatingvs infrared

The NLIR spectrometer measures spectra in only milliseconds. The integration time can vary from 100s of ms down to 11 µs depending on the need. The external trigger can be used to capture data at the right time in order to optimize monitoring speed.

Our breakthrough technology can help you monitor your IR Coating quality in a wide range of industries, including but not limited to infrared coatings used in thermal imaging, infrared spectroscopy, defense and security, industrial and scientific research and many more!

The NLIR Spectrometers are based on a novel measurement technology that upconverts the MIR light to near-visible light. The near-visible light can then be detected by silicon-based CMOS detector arrays.

Ms.Cici

Ms.Cici

8618319014500

8618319014500