Spherical Aberration — Starizona - spherical abberations

We ensure our customers security of supply. As long as the customer requires a lens Resolve Optics will continue to manufacture and supply those lenses.

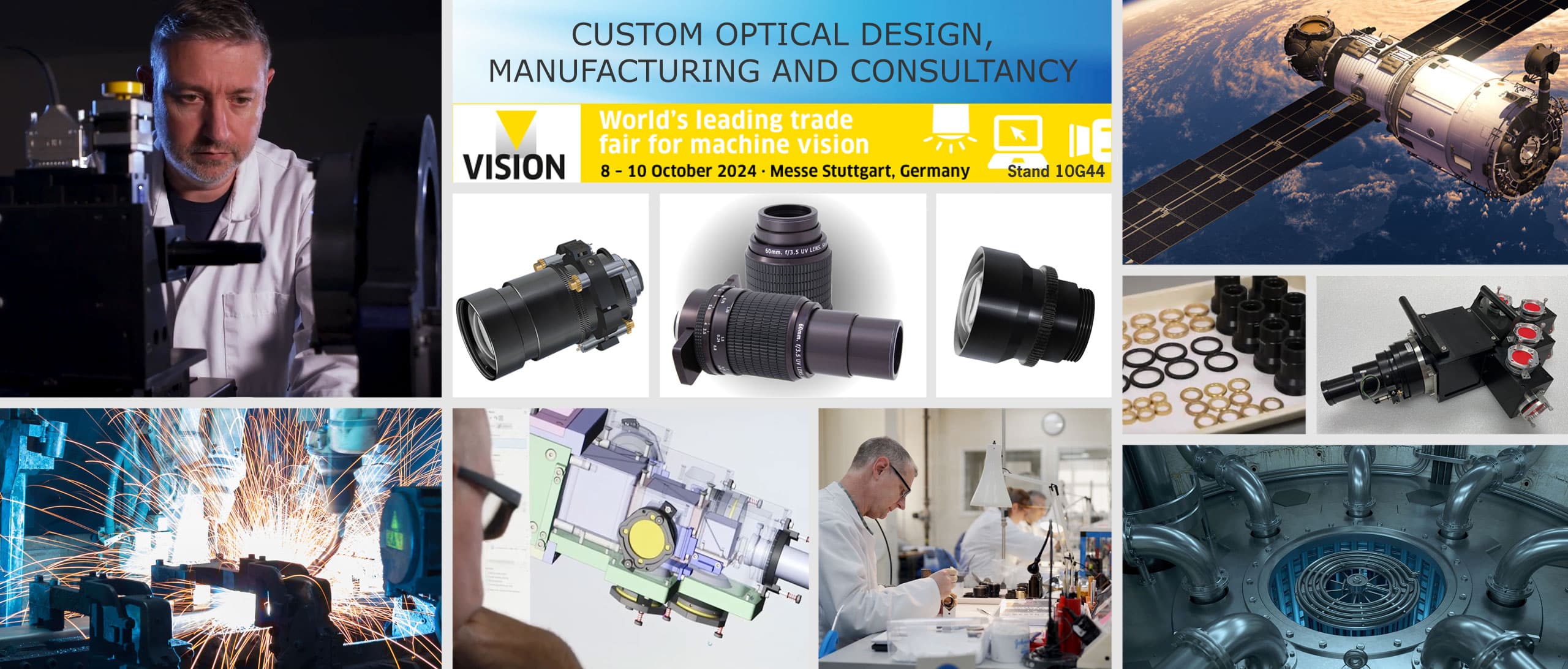

Resolve Optics has developed the rare capability to produce small quantities of high performance, mounted lenses with the professional look, feel and quality equivalent to the best professional photographic and broadcast TV lenses.

The most common beamsplitter design is perhaps the cube beam splitter, constructed of two prisms attached together to form a cube structure, this beam splitter splits the input light into two beams with 90 degrees angle between them and no beam shift. This type of beam splitter typically provides a 50/50 Reflection/Transmission (R/T) ratio (but not limited to it) and can come in either polarizing or non-polarizing designs.

For high temperature applications, optical systems need to be designed to ensure performance is maintained at the application operating temperature. More information…

A diffractive beam splitter is a periodic, grating-like, diffractive optical element (DOE). It splits a single input laser beam into any number of output beams in any desired predefined arrangement and separations. The output beams are sometimes referred to as the diffraction orders.

Other applications use a 1-dimensional array of spots typically with stage movement or a scanner to enable multiple processing. Some of the more common applications in this sector includes:

Holoor

Another application using a 2-D multispot configuration is structured light laser projection for 3D sensing or flash LiDAR.

The Design, Manufacture and Testing of our products is carried out at our Chesham facility, utilising up-to-date 3D CAD software, laboratory environment production facility with a cleanroom maintained to ISO standards and state of the art MTF testing equipment.

Some of the classic applications who have managed to make the most of these unique components use them to generate a 2-dimensional matrix of spots to cover an entire large area work surface. These include:

Resolve Optics Ltd has for over 20 years developed OEM quantity special lenses and optical designs for small and large high technology businesses. Our customers have benefited from our novel and economic optical solutions. Several are currently world leaders in their niche high technology markets.

Drawing upon our experienced team of optical designers we are able to quickly gain an understanding of the basic physics of the technology associated with each customer’s product enabling us to propose novel solutions.

A short introduction to light beam splitting with emphasis on a diffractive beam splitter, it’s unique qualities and advantages

Different types of beam splitters are used to control different parameters of the output beams (such as optical power ratio, polarization, number of spots and separation angle between them) to achieve various desired outputs.

A: Depending on the functionality you are trying the achieve and your input beam characteristics, there are 3 main types of beam splitters:Beam splitter cube - splits a light beam to two beams with 90 degrees angle between them, typically with 50/50 R/T ratio. Can be polarizing or non-polarizing.Plate beamsplitter - splits a light beam to two beams with 90 degrees angle between them, R/T ratio is determined by coating.Diffractive beam splitter - splits a laser beam into any number of desired beams in ant configuration.

Resolve Optics designs, develops and manufactures bespoke optical systems. We react quickly to the initial enquiry, whilst ensuring we understand the customer’s application and requirements and at the same time, we ensure that the customer understands our specifications and designs making the whole process as simple and clear as possible.

Resolve Optics is a specialist supplier of athermalized lenses designed to maintain focus over a wide temperature range. Standard, off-the-shelf lenses developed for imaging applications perform well in temperature-controlled environments or where temperatures vary...

Manufactured to the highest quality standards from cerium doped glass, Resolve Optics Ltd offer a range of fixed focus radiation resistant lenses that can withstand radiation exposure of up to 100 kGy (100,000,000 rads) and temperatures up to 55⁰C without...

Another common beamsplitter option for splitting the input light beam into two output beams, is the plate beamsplitter. This device consists of a flat optical window, one side coated with partial reflective coating and the other side typically coated with anti reflective coating to avoid undesired Fresnel reflections. The angle between the transmitted and reflected beams is 90 degree, and the R/T ratio can be controlled by the deployed coating. In this case the transmitted portion of the beam does suffer from a slight beam shift.

Beam splitters are optical devices who, when used in an optical system, split the incident input beam into two or more beams at the output.

Diffractive beam splitters, like all DOE, are planar and thin, window like optics, thus are easy to integrate into any system.

Beamshaper

The DOE beam splitter uses microstructures fabricated on a flat optical window to create a phase delay pattern on the beam propagating through it and thus utilizes the wave nature of light to split the output as desired. These structures are designed to a specific wavelength, and if used with a different one will cause a reduction in efficiency and change the diffraction angles.

The third type of beamsplitter, used in completely different applications, is the diffractive beam splitter, also known as a “multispot” (MS) or “dot generator”. Unlike the former types of beamsplitters, diffractive beam splitters are not limited in their functionality to generating only 2 output beams. They can be designed to generate multiple output beams in a desired configuration from a single input beam. Diffractive beam splitters are non polarizing optics, that operate at the discrete wavelength for whom they were designed (and the narrow bandwidth around it +-1.5%).

A: A diffractive beam splitter is used in any laser application where one wishes to increase throughput and has sufficient power to process several spots at the same time . Some of these include: perforation, surface structuring, fractional skin treatments, scribing, dicing, cutting and welding

A: Depending on the functionality you are trying the achieve and your input beam characteristics, there are 3 main types of beam splitters:

A: A diffractive beam splitter is used in any laser application where one wishes to increase throughput and has sufficient power to process several spots at the same time . Some of these include: perforation, surface structuring, fractional skin treatments, scribing, dicing, cutting and welding

Resolve Optics has delivered the first batch of a new version of its popular Model 357 non browning 10x zoom lens to a leading manufacturer of radiation resistant instruments. Optimised for a ¼-inch format camera sensor – the new lens can withstand exposure to...

Many applications in nuclear plants and reprocessing facilities incorporate remote monitoring cameras to assist in ensuring safe and productive operation. More information…

Resolve Optics Ltd has for over 20 years developed OEM quantity special lenses and optical designs for small and large high technology businesses. Our customers have benefited from our novel and economic optical solutions. Several are currently world leaders in their niche high technology markets.

The greatest advantage of a diffractive beam splitter laser system is its ability to massively increase an optical system’s throughput by a factor equal to the number of diffracted orders.

Resolve Optics has developed the rare capability to produce small quantities of high performance, mounted lenses with the professional look, feel and quality equivalent to the best professional photographic and broadcast TV lenses.

Another application using a 1-D multispot configuration is the unique diffractive beam sampler which offers real time sampling of the laser beam along the optical path.

An automatic return fire system or gunfire locator is a system that detects, conveys and automatically returns a ballistic response to the location of gunfire or other weapon fire using optical sensors.More information…

Ms.Cici

Ms.Cici

8618319014500

8618319014500