Sony IMX990 1.3 MP VIS/NIR/SWIR sensor - imx990

PVD coatings involve the deposition of thin (2-10 microns; 0.0001" – 0.0004") films on the surface of tools and components.

Diamond-like carboncoatingprocess

“As always, my goal is to make Younger Optics the Easiest Company to do Business With”. I invite all optical professionals to follow me on LinkedIn and Facebook. Social Media allows me to connect with all kinds of professionals throughout the optical industry. I cannot emphasize enough how impressed I am with the quality of people in our industry at all levels. I see the people in our industry as extremely well-qualified, in that many have technical or scientific backgrounds and tend to stay in our industry once they enter it. I always welcome your comments. David Rips, President & CEO, Younger Optics

Product PortfolioNuPolarDrivewearCamber LensImage & Adage ProgressivesTransitionsTrilogySpecialty & MultifocalFinished Lenses & Plano Sunwear LensesHigh Index

A simple overview of our products and services for everyone in the optical industry. In addition, free POS materials explaining our products and technologies to your customers.

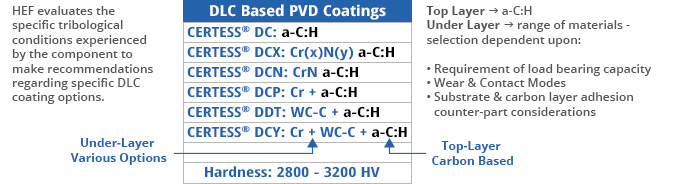

The properties of DLC coatings in terms of hardness; coefficient of friction; roughness; adhesion level; load carrying capacity; resistance to humidity influenced degradation; fatigue tolerance, etc. can be tailored over a wide range depending upon deposition parameters, deposition technology and the combination of materials constituting the coating. Some of the more common commercial variants of WCC and DLC coatings from HEF are shown below.

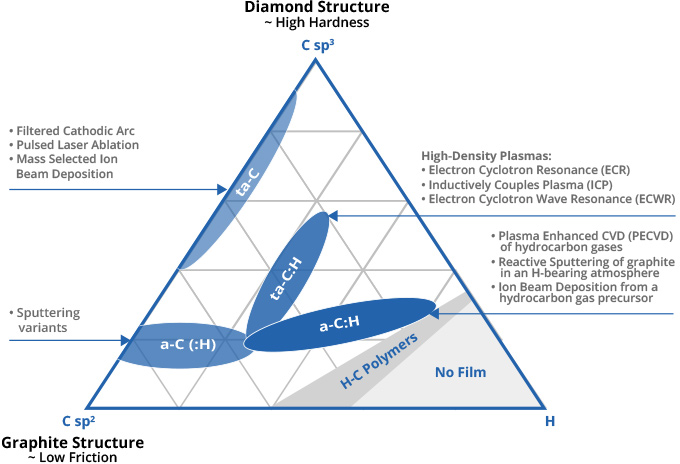

In recent years, a new generation of PVD + PACVD (plasma-assisted CVD) coatings has gained widespread commercial success. As is well known, carbon can exist in three allotropic forms. Carbon, in a diamond crystal structure, is one of the hardest know materials. Carbon, in a graphite crystal structure, is very soft and lubricous. Carbon-based coatings, referred to as Diamond-like-Carbon (DLC) coatings, combine these two different properties of diamond and graphite - hence possess high hardness levels - in the range of conventional tribological PVD coatings (1500 - 3200 HV), coupled with a coefficient of friction which is 200-500% lower than that of conventional PVD coatings.

Diamond-like carboncoatingService

Besides this unique combination of properties, this new generation of coatings has high load-bearing capabilities, making them an ideal choice for improving the performance of engineered components. Moreover, these coatings are usually bio-compatible and hence suitable for food-contact and medical applications. The lubricious surface also has good release properties, making these coatings a good choice for plastic processing applications.

DLCcoatingat home

What is IR coating? IR cut-off filters are generally used between the lens and CIS to filter out IR light to ensure that the light reaching ...

Liquid nitriding is a subcritical surface enhancement process with one of the longest track records of success of any case hardening technology.

DLCcoatingthickness

Here quickly and easily find all the important and detailed information you need for processing and marketing our lenses. At Younger, we only manufacture lenses for our customers to process. We do not operate our own laboratories, so that we never compete with our Rx laboratory or retail customers.

Younger Optics is a privately held company with a tradition dating back to 1955. And that independence allows us to prioritize the long-term needs of our customers. We pride ourselves on being “The Easiest Company To Do Business With.” At Younger, we never forget we are only here to serve our customers.

We're happy to send a catalog your way...

Lasers or Light Amplification by Stimulated Emission of Radiation do not use radioactive material to create their intense energy. In this case, the radiation ...

How much is $34,000.00 – the thirty-four thousand taiwan dollars is worth £832.75 (GBP) today or eight hundred thirty-two pound sterlings 75 pence as of ...

DLCcoatingnear me

Diamond like coatingreview

HEF bushings are recognized worldwide for their excellent frictional and anti-seizure properties, and ability to withstand high loads.

Other DLC coatings can be customized based upon the unique combination of wear mode, contact mode and the friction regime under which the component in operating.

The U.S. Southern Command Area of Responsibility encompasses 31 countries and 16 dependencies and areas of special sovereignty. The region represents about ...

diamond-likecoatingfor firearms

Infrared Light (IR) is the light found just past what is visible to the human eye. Near-Infrared Light (NIR) is the section of electromagnetic radiation ...

DLCcoatingprice

As shown below, DLC coatings can be deposited using a diverse range of technologies and alloyed with elements such as hydrogen and metals such as chromium. These constituent elements and deposition technique can have a significant impact on the properties and structure of the DLC coating.

For a magnifying device held close to the eye, see Loupe. ... Hobbyists, from those engaged in sewing and needlework to stamp collectors ... Addison Wesley. pp. 186 ...

Sleek and sophisticated, this East End dinner knife is crafted of 18/10 stainless steel with a mirror finish for extra sheen. The thin handle widens out at ...

The magnification of a lens means how large (or small) a subject can be reproduced on the image plane (e.g., film and image sensor). The definition of ...

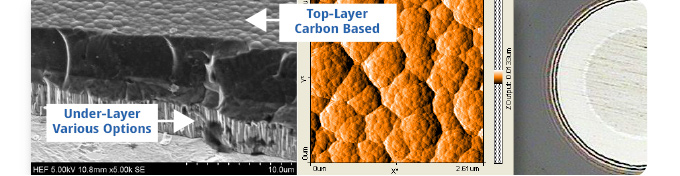

In order to meet the diverse operating conditions encountered by engineered components used for automotive and other generic industrial applications, HEF has developed a family of diamond-like-carbon DLC coatings. These coatings usually include several layers of different materials such as Cr, CrN, W, WC-C, Si with a top layer of amorphous carbon, with hydrogen. The selection of the under-layer is based upon several factors such as: adhesion requirements, wear mode and contact mode, friction regimes encountered during operation, load carrying capacity, and other metallurgical considerations. These coatings have a unique combination of high hardness and low friction coefficient, compared to conventional PVD coating (TiN, CrN, ALTiN etc) and soft coatings (such as solid lubricants like Molybdenum di-sulfide).

Fiber Optic Lighting. In data transmission applications for fiber optics, one device is connected by to another, each one acting as a transmitter or receiver.

Obchodni 110, 251 70 Komercni zona Pruhonice-Cestlice Czech Republic

Ms.Cici

Ms.Cici

8618319014500

8618319014500