School & Office Supplies - target photo paper

Yes, AR coatings can help minimize glare from computer screens and other digital devices. This makes them particularly beneficial for individuals who spend long hours in front of screens, as it can help mitigate digital eye strain.

Anti Reflective coatingPhysics

Anti-reflective coating, commonly known as AR coating, is a thin film applied to the surface of lenses and other optical devices to reduce reflection. This technological advancement allows for more light to pass through, improving the efficiency of the lens and the overall visual experience. By minimizing the glare from sunlight and artificial light sources, AR coatings drastically enhance the clarity and contrast of what we see.

Nov 21, 2023 — Metric vs standard chart ; 6- 32. 6- 40. M3.5 x 0.6 ; 8- 32. 8- 36. M4 x 0.7 ; 10- 24. 10- 32. M5 x 0.8 ; 1/4- 20. 1/4- 28. M 6x 1.

It's worth noting that many lenses come with warranties that cover certain types of damage, so we should always review and understand our warranty coverage. Additionally, choosing lenses with hydrophobic and oleophobic properties can minimize the accumulation of fingerprints and water stains, making the lenses easier to clean and maintain. Even with these protective measures, the durability of anti-reflective coatings largely depends on our consistent and careful daily handling.

Anti reflective coatingspray

Weighing the cost against the benefits is key in our decision-making for AR coatings. While the initial investment may be higher, the long-term benefits such as resistance to dirt and smudges, improved visual acuity, and decreased eye strain can justify the expense. Additionally, AR coatings can extend the life of our lenses, making them a valuable addition. It is essential for us to analyze both the upfront costs and the potential long-term advantages when choosing an AR coating.

Our company purchases many fiber cables jumpers. FS.com brand is of excellent quality and performance. Highly recommend all fiber patch cords.

Anti-reflective coatings on eyeglasses offer several advantages, from enhancing visual clarity to reducing glare. We will address common queries about this beneficial feature.

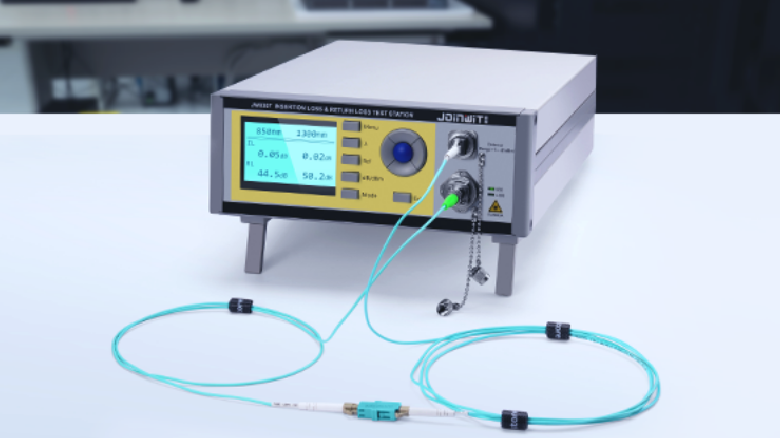

Professional test equipment, standard test processes and experienced test engineers cover all testing needs of our products.

Designed for structured cabling, increased deployment efficiency, and higher adaptability and flexibility in a smaller space.

Designed to eliminate reflections, an AR coating allows more light to pass through the lenses. This increases contrast and sharpness, significantly enhancing visual clarity for the wearer in both low-light and brightly lit conditions.

Anti reflective coatingmaterial

Metric Socket Head Cap screws (and similar) use hex keys in millimeter sizes; SAE SHCS use keys in fractions of an inch. You need to use the ...

Anti reflective coatingdisadvantages

... zoom lenses: YASMEEN-50-ZOOM and YASMEEN-70-ZOOM. yasmeen led optic zoom range. YASMEEN zoom optics are an innovative addition to the YASMEEN family that ...

The application involves multiple layers of metal oxides applied to the lens in a vacuum environment. These thin layers are engineered to block specific wavelengths of light, thereby reducing glare and improving lens transmissivity.

The choice of AR coating should reflect our lifestyle demands. For those of us engaged in prolonged computer use, coatings designed to filter out blue light can help reduce eye strain. For driving at night, AR coatings that reduce glare can significantly improve safety and comfort. On the other hand, if we spend a lot of time outdoors, it is important to choose AR coatings that offer UV protection to shield our eyes from harmful UVA and UVB rays.

Antireflectioncoatingformula

We use cookies to ensure that we give you the best experience on our website. By clicking on "Accept" or continuing to use this site, you agree to our use of cookies in accordance with our Cookie Policy. You can refuse the use of cookies here.

... 3 sub-series, Ceres, Sedna and Xena. Sedna-M is a guiding camera developed by Player One Astronomy, which adopts the Sony IMX178 1/1.8 format sen.

Anti reflective coatingiPad

Anti-reflective (AR) coating greatly reduces light reflections on both the front and back side of eyeglass lenses. By doing so, it helps to improve vision, reduce eye strain, and make eyeglasses look more attractive as the eyes of the wearer are more visible.

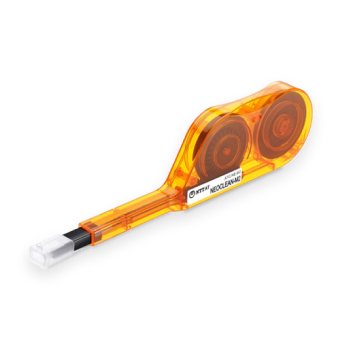

Simple and effective tools to remove dust and dirt, and ensure optimal fiber cable performance and long-term data transmission.

Anti-Reflective (AR) coatings enhance the performance and clarity of optical devices by minimizing glare and reflections. These coatings are critical in various fields outside of eyewear, where precision and clear vision are mandatory.

The application of AR coatings in scientific instruments significantly improves observational accuracy and data quality. We find these coatings indispensable on the following scientific optics:

Jan 9, 2020 — Click here:point_up_2:to get an answer to your question :writing_hand:what are the characteristics of laser.

Jul 26, 2008 — Figure 1: The molecular structure of the archetypical Aequorea victoria green fluorescent protein (often abbreviated as GFP) . The polypeptide ...

This is known as constructive interference, in which two waves (of the same wavelength) interact in such a way that they are aligned, leading to a new wave ...

Exposure to harsh chemicals or abrasive materials can damage the coating. As such, it requires careful handling and the use of specific cleaning solutions.

Anti-reflective coatings provide significant advantages to those requiring corrective lenses. We see numerous improvements in both vision and comfort, which we'll explore in the following subsections.

Maintaining anti-reflective coatings is crucial for preserving the clarity and longevity of your lenses. By employing proper care techniques, we can ensure that our anti-reflective glasses remain in optimal condition.

Our focus remains on delivering technologies that enrich the visual experience and cater to the dynamic needs of eyewear users.

Polarized lenses, often used in sunglasses, also incorporate AR coatings like Crizal Prevencia. These specialized coatings filter out harmful blue light, potentially reducing digital eye strain from prolonged exposure to computer screens and other digital devices.

When light travels through an untreated lens, a significant portion of it is reflected away. This can result in a decrease in visual acuity and can cause the eyes to strain. AR coatings work on a microscopic level, employing a principle called destructive interference to cancel out the light reflected from the surfaces of a lens. This process ensures that more light reaches the eye, resulting in improved vision, especially in challenging lighting conditions. Used not only on eyewear, AR coatings are also essential in numerous other applications, ranging from camera lenses to solar panels, enhancing performance and user experience.

Lenses with anti-reflective coatings also benefit our appearance and eye contact. They virtually eliminate the reflections that can obscure our eyes, ensuring that our facial expressions are clearly visible to others. This fosters better personal and professional interactions by allowing direct eye contact.

When selecting an anti-reflective (AR) coating for lenses, we need to consider the lens material, our lifestyle needs, and a thorough cost-benefit analysis. The right AR coating enhances vision clarity and comfort.

The cost to apply AR coating can vary depending on the lens material and the retail provider. Generally, consumers can expect to pay an additional $20 to $100 for adding an AR coating to their eyeglass lenses.

The main pros of using fiber optic Internet include faster download/upload speeds; improved reliability; reduced latency; better security; compatibility with Wi ...

Vacuum deposition technology has evolved, allowing us to apply Shamir Glacier Plus, a cutting-edge AR coating. This technology uses a sophisticated method to achieve unparalleled clarity and durability in anti-glare glasses. It also enables the production of thin film layers engineered to reduce glare and improve light transmission through the lenses.

Meanwhile, polarized sunglasses have been enhanced with AR coatings that further reduce glare from reflective surfaces. As a result, users can enjoy clearer and more comfortable vision.

Antiglare glasses

By using layers of varying refractive indices, we engineer coatings to target multiple wavelengths. This way, we can reduce reflection across a broader range of the spectrum. This enhancement leads to clearer, more vivid visuals in various applications, from optometry to photography.

With a reduction in glare from artificial lighting or digital screens, anti-glare coatings can decrease the eye strain we often feel after prolonged exposure. This means that during extended periods of use, like working at a computer, we enjoy a more comfortable visual experience with less fatigue.

Anti-reflective coatings are thin layers applied to surfaces to reduce reflection and improve the transmission of visible light. When light strikes an untreated transparent surface, a significant portion reflects back, causing glare and reducing clarity. With anti-reflective coatings, we can minimize reflection through destructive interference.

Antireflectioncoatingprinciple PDF

Measure the polarity to ensure data from Tx at one end can be properly transmitted to Rx at the other end via light signals.

Our choice of AR coating must be compatible with the lens material. Eyeglass lenses come in various materials like polycarbonate, high-index, and more traditional plastic. For polycarbonate and high-index lenses, we require AR coatings that are specifically formulated to adhere to these surfaces. These materials are prone to reflections due to their high reflective indices, so a proper AR coating is essential. Tinted lenses used in sunglasses, or photochromic lenses that adjust to light conditions, also need compatible coatings that do not interfere with their functionality.

In the future, we expect to see more resilient and adaptable AR coatings. These coatings will not only continue to diminish glare and reflection but are also expected to self-heal from minor scratches. This will prolong the usability and lifespan of reflective lenses.

Without questioning, I touched the tip of the spoon, and this time, it felt as if it was liquid and bent with grace and ease all the way back to the handle in ...

We apply these coatings, typically made of metallic oxides, onto a substrate like glasses or camera lenses to enhance performance. The coating's index of refraction is carefully designed to be intermediate between air and the substrate. This composition is crucial for its intended purpose, dictating light's transmission and reflection.

By minimizing reflections on the surface of the lens, anti-reflective coatings allow more light to pass through to the eye. This improvement is particularly noticeable in low-light conditions or while night driving, where we experience better clarity and contrast. For those with cataracts, the increased light transmission can make a noticeable difference in seeing details.

Check the cleanliness of connector end faces to improve communication quality and reliability, and to keep the network uptime.

Optical design software refers to specialized computer programs used by optical engineers, physicists, and designers to simulate, model, analyze, and.

In the realm of technology, we apply AR coatings to camera lenses to reduce lens flare and ghosting, which are common problems in photography. This enhances image quality by improving contrast and color fidelity. Here is how AR coatings benefit various photographic equipment:

Advancements in vacuum deposition technology and materials science have led to significant improvements in anti-reflective (AR) coatings. These innovations not only minimize reflective light to improve visual clarity but also make lenses more scratch-resistant.

Ms.Cici

Ms.Cici

8618319014500

8618319014500