quick and very dirty target size checker - HTML5 accessibility - target size 24x24

Note: the article keyword search field and some other of the site's functionality would require Javascript, which however is turned off in your browser.

Cases with resonance fluorescence – most often with atoms or molecules – are those not involving additional transitions, where the interacting atoms or molecules can be considered as simple oscillators with a certain resonance frequency. The emission wavelengths are then close to the excitation wavelength.

After excitation with a short pulse, the fluorescence decay is often of exponential nature with a decay constant which is called the fluorescence lifetime or upper-state lifetime ( because the fluorescence lifetime is identical to the lifetime of the population in the upper level of an electronic transition). For so-called allowed transitions, the fluorescence lifetime is typically of the order of a few nanoseconds. In solid-state laser gain media other than semiconductors, one is often dealing with weakly allowed transitions, where the fluorescence lifetime can be much longer, e.g. microseconds or even milliseconds. In any case, the upper-state lifetime can at most be the radiative lifetime (limited by fluorescence only), and possibly be shorter if there are additional non-radiative decay processes.

Fun Fact: The Law of Conservation of Energy states that energy can neither be created nor destroyed. So, what happens to the energy from the cancelled light waves? It is transferred through the lens medium to the patient's eyes improving contrast and clarity!

A special kind of fluorescence, which is not related to the excitation of atoms or ions in a substance, is parametric fluorescence in nonlinear crystal materials. This effect does not involve the excitation of electrons in the media, but rather a nonlinear interaction. Such fluorescence occurs only as long as some pump light propagates in the medium.

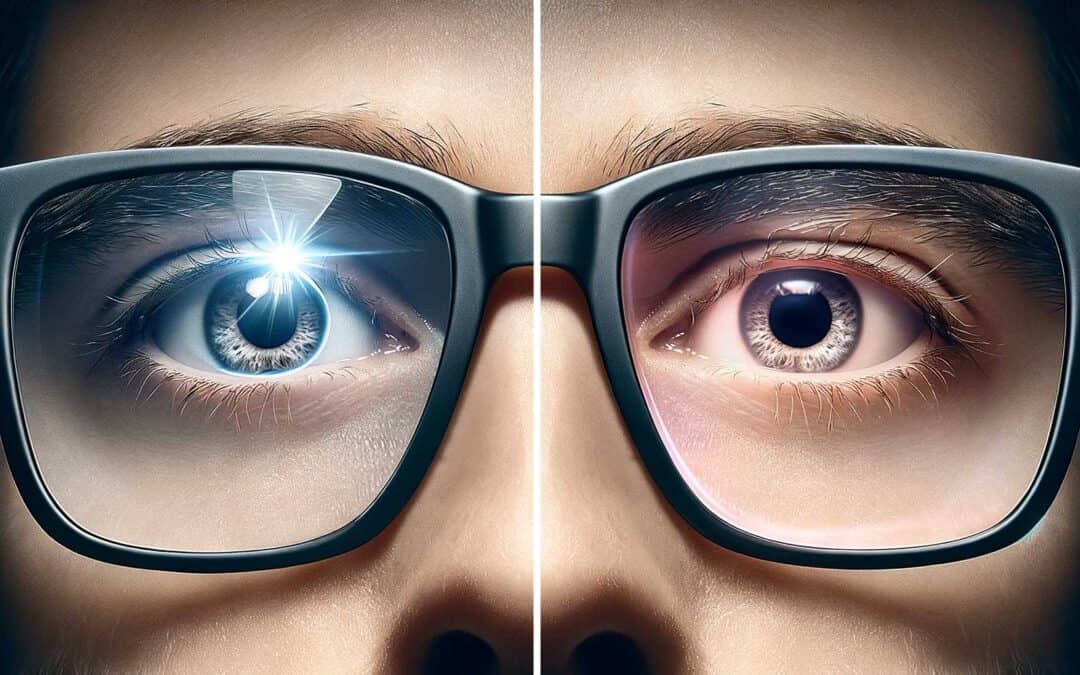

AR coatings reduce lens surface reflections through a process called destructive interference, by actually generating reflections of its own. The index of refraction of the AR layer is in between that of the lens medium and that of air. Light incident upon an AR coated lens experiences reflection at both the AR layer and the surface of the lens. However, the thickness of the AR layer is such that the light waves reflected from the AR surface are 180° out of phase with light waves reflected from the surface of the lens. Consequently, the reflected light waves undergo destructive interference and effectively cancel each other.

By submitting the information, you give your consent to the potential publication of your inputs on our website according to our rules. (If you later retract your consent, we will delete those inputs.) As your inputs are first reviewed by the author, they may be published with some delay.

Types of lenscoatingfor glasses

Fluorescence in transparent polymer sheets, which are doped with some luminescent species, can be used for luminescent (or fluorescent) solar concentrators [2]. Sunlight hitting the polymer sheets from any direction can be absorbed and efficiently transformed into fluorescent light, which is partly trapped in the sheets and thus sent to the edges, where solar cells receive the concentrated radiation. Potentially suitable luminescent agents can be certain organic dyes and quantum dots. Further research is required to optimize the still limited lifetime of dyes under irradiation with sunlight and the quantum efficiency of quantum dots.

Note: this box searches only for keywords in the titles of articles, and for acronyms. For full-text searches on the whole website, use our search page.

Substances emitting fluorescence, or sometimes just parts of larger molecules, are called fluorophores. Some artificial fluorophores may be added to samples in fluorescence spectroscopy.

As light passes through a lens from air, it experiences a change in index of refraction. When that occurs, some of the incident light is transmitted through the lens material and refracted while some of the light is reflected. This reflected light is perceived by others as glare and represents a loss of light transmitted through to the eye.

Fluorescence is widely used in fluorescent tubes for illumination purposes. The most common fluorescent lamps contain mercury vapor inside a glass tube, where an electric discharge excites the mercury atoms to emit mostly ultraviolet light. A fluorescent material (called the phosphor) on the inner surface of the tube absorbs the ultraviolet light and converts it into fluorescence light, mostly in the visible spectral region. The phosphor contains several substances mixed in such a way that the overall emission spectrum corresponds to white light (with the color tone adjusted according to the envisaged application). Although part of the energy of the ultraviolet light is lost in the phosphor, fluorescence lights are still several times more energy-efficient than incandescent lamps.

AR coating can minimize front and back lens surface reflections, significantly reducing or eliminating the problems discussed above, reducing eye strain, while allowing more light to reach the eye, improving contrast and clarity.

Anti reflectivecoatingglasses price

In solid-state laser gain media, phonons lead to very fast thermalization within Stark level manifolds. As the emission occurs on a much longer time scale, the spectral shape of the emission spectrum does not depend on the exact wavelength of the exciting light. It depends only on the spectral dependence of the emission cross-sections, combined with some other factors. The frequency-dependent fluorescence intensity (actually a power spectral density) related to spontaneous emission from some level <$j$> to level <$i$> is given by [3]:

For very long decay times, usually involving triplet states with forbidden transitions, such luminescence is called phosphorescence. Is also the phenomenon of delayed fluorescence, which can involve a weak intersystem crossing to a triplet state and later back to the original singlet state.

This is easy to do: just find the lock icon in front of the URL in the address bar and drag that to the bookmark toolbar with the mouse. In case you find the bookmark entry too long, you can right-click it to edit the text, e.g. using "RP Enc" instead of "RP Photonics Encyclopedia".

In optical amplifiers, fluorescence can be even more important. In the form of amplified spontaneous emission (ASE), it may extract significant power and thus limit the achievable gain. It also determines much of the quantum noise contributions to laser noise and amplifier noise.

AR coating is a thin, multilayered application on eyeglass lenses designed to reduce reflections, allowing more light to pass through. This improves vision clarity and reduces glare from digital screens and headlights. A thermal cured hard coat, on the other hand, is applied to make lenses more resistant to scratches and impacts, extending their usable life.

In many cases, there are non-radiative processes which compete with fluorescence and reduce or even fully suppress it (→ quenching). In particular, multi-phonon transitions are very strong for level pairs with an energy distance which is at most a few times the maximum phonon energy of the host material. In other cases, energy transfer processes can deplete the population in a metastable level.

where <$\sigma_{ji}$> is the emission cross-section and <$N_j$> the density of ions in the starting level <$j$>. The given quantity <$I_{ji}(\nu)$> has units of J/m3, and multiplied with a small frequency interval <$\rm{d}\nu$> one arrives at W/m3 – consistent with the radiated optical power per unit volume.

Light coming from the back of the wearer to the back surface of a lens will also undergo a certain amount of reflection. Light here can be reflected directly back to the eye. The results can be a distraction to the wearer or can, in certain conditions, impair vision. For example, bright sun light hitting the back surface of a sun lens that is not AR coated, depending on the angle, can either be reflected directly back into the eye or can "fill" the lens with reflected light. Either case can result in significant vision impairment.

Using our advertising package, you can display your logo, further below your product description, and these will been seen by many photonics professionals.

The quantum efficiency (or quantum yield) of fluorescence from some level is the average number of fluorescence photons obtained per ion which is put into the upper level. Solid-state gain media (e.g. laser crystals or rare-earth-doped fibers) often have laser transitions with a quantum efficiency very close to unity, whereas some levels (e.g. the lower laser level) exhibit virtually no fluorescence due to strong multi-phonon transitions.

Anti reflectivecoatingspray

Oleophobic coatings, on the other hand, are designed to repel oils. This includes the natural oils from a person's skin, which can be transferred to the lenses during handling. By repelling these oils, oleophobic coatings help to keep lenses free from smudges and fingerprints. This property is especially valuable for individuals who frequently need to adjust or touch their glasses. The reduced adherence of oils and other substances also makes the lenses easier to clean and maintain, contributing to better lens hygiene.

There are also light-emitting diodes (LEDs) which generate white light in a process that involves the excitation of a phosphor. In that case, however, the actual LED produces blue rather than ultraviolet light, and this blue light is partly converted to red and green fluorescence light in the phosphor, and partly emitted by the device.

Various processes can lead to pronounced non-exponential fluorescence decay, with a faster decay shortly after excitation and a slower decay later. For example, this can be caused by contributing atoms with different lifetimes, or by upconversion processes which are stronger for high level populations.

Fluorescence effects can be quite disturbing under certain circumstances. For example, certain spectroscopic measurements can be disturbed by unwanted laser-induced fluorescence in glass windows or tubes. Such fluorescence often originates from certain impurities.

Please do not enter personal data here. (See also our privacy declaration.) If you wish to receive personal feedback or consultancy from the author, please contact him, e.g. via e-mail.

Upconversion processes lead to the population in relatively high-lying energy levels, from where blue and even ultraviolet light is emitted. Such fibers are suitable for lasing in the blue spectral region near 480 nm. (The weak peaks around 700 nm are artifacts, caused by second-order diffraction of ultraviolet light in the spectrograph. Data taken by R. Paschotta.)

Fluorescence is a short-lived photoluminescence, excited by irradiation of a substance with light. The light hitting a sample puts atoms, ions or molecules in the sample into excited states (by absorption of photons), from where they decay into lower-lying states (e.g. their ground states) through spontaneous emission of fluorescence photons. This phenomenon is exploited for illumination, particularly in fluorescent lamps. It also occurs at a side effect in various kinds of optically pumped lasers and amplifiers, e.g. in solid-state doped-insulator lasers and amplifiers (including fiber lasers and fiber amplifiers), in optically pumped semiconductor lasers, and in dye lasers. The resulting radiation is called fluorescent light.

Mar coating lensesprice

The science behind AR coatings involves using layers of material with specific refractive indices that work together to cancel out the light reflections. This not only reduces glare but also significantly minimizes eye strain and fatigue associated with prolonged exposure to bright light sources. Additionally, AR coatings make the lenses nearly invisible, thereby improving the cosmetic appearance of the glasses. They also help in reducing the reflections others see on the lens surface, allowing for better eye contact. With these functional and aesthetic benefits, AR coatings have become a popular choice for enhancing the performance and appearance of eyeglasses.

Fluorescence light can be useful, e.g. for direct use for optical measurements, such as for measuring the transmission spectra of optical devices. It is also the basis of fluorescence spectroscopy, fluorescence microscopy and of optical refrigeration. By combining multiple types of emitting rare earth ions in an optical fiber, very broadband radiation can be generated [1].

As the refracted light continues through the lens material and reaches the back surface of the lens, there is another index change (lens to air) and again refraction and reflection occur. Reflected light here can bounce off the internal surfaces of the lens and be seen by the wearer as glare, blurred or ghost images. Others may see internal reflections as multiple rings inside the lens (most prevalent in high minus powers). Blurred or ghost images can become intensified at night around bright lights common in dusk or night time driving conditions, and can significantly impair vision. Also, this backside reflection represents further loss of light transmitted through to the eye.

Best lenscoatingfor glasses

The application of AR coatings is a complex, high-tech process that requires precision and cleanliness. The process is typically conducted in a vacuum chamber to ensure the purity and adherence of the coatings. Here’s a step-by-step overview:

In the context of lasers, fluorescence in the laser crystal (or other gain medium) by spontaneous emission is lost for the laser operation because only a tiny fraction of it goes into the laser resonator mode. The fluorescence lifetime for fluorescence from the upper laser level is usually called the upper-state lifetime. Fluorescence is the most fundamental reason why a certain laser threshold has to be overcome to achieve lasing (exception: thresholdless lasers). Note also that when the pump source of a laser is turned on, laser action normally starts from a tiny amount of fluorescence in the laser resonator mode, amplified to high levels in many resonator round trips.

Anti reflectivecoatingsunglasses

Improves Visual Clarity: With an anti-reflective coating, a greater amount of ambient light can reach your eyes, unobstructed by lens reflections. This optimized light transmission results in clearer, more acute vision, allowing you to perceive your surroundings with enhanced sharpness and detail.

Fluorescent solar concentrators might be the basis for cheaper electricity from photovoltaic panels (solar modules), as they allow to collect radiation from a large area while requiring only relatively small photovoltaic cells.

Anti-reflective coating becomes even more important when you have a stronger prescription that calls for high-index lenses, which tend to reflect more light than other types of eyeglass lenses.

MAR coatingmeaning

Hydrophobic and oleophobic coatings are significant enhancements often applied in conjunction with Anti-Reflective (AR) coatings on eyeglass lenses. These coatings play a vital role in maintaining the clarity and longevity of the lenses, further enhancing the wearer's visual experience.

The optical spectrum of fluorescence light (see e.g. Figure 1) generally differs from that of the light which initially caused the excitation of the medium. A significant Stokes shift (difference in photon energies of absorbed and emitted light) can occur because a part of the excitation energy is converted to heat in the medium. For example, the excited atoms or ions may first undergo an optical or a non-radiative transition to some intermediate level, before emitting fluorescence light in a transition to the ground state, or to some higher-lying energy level. It is also possible that a cascade of emission processes occurs, i.e., a cascade of transitions to lower-lying energy levels; in that case, more than one fluorescence photon can be emitted for one absorbed photon.

Mar coating lensescost

Here you can submit questions and comments. As far as they get accepted by the author, they will appear above this paragraph together with the author’s answer. The author will decide on acceptance based on certain criteria. Essentially, the issue must be of sufficiently broad interest.

For highest convenience, create a bookmark in the bookmark toolbar of your web browser (e.g. Firefox or Chrome)! That way, you can open it with a single click.

When combined with AR coatings, hydrophobic and oleophobic coatings contribute to a superior lens performance. AR coatings alone significantly reduce reflections and improve visual clarity, but they can sometimes be prone to smudges and moisture. The addition of hydrophobic and oleophobic properties ensures that the AR coating can function optimally by keeping the lens surface clear and clean. This combination results in a lens that not only provides sharp, clear vision through reduced glare but also remains cleaner and clearer during everyday use, enhancing the overall satisfaction and experience of the eyewear.

Fluorescence of the single atoms, ions or molecules of a sample usually occurs in an uncoordinated manner, i.e., uniformly in all spatial directions and without temporal correlations between the emitted photons. However, certain conditions lead to amplified spontaneous emission (superluminescence) or superfluorescence, where this is no longer the case.

An Anti-Reflective (AR) coating, also known as anti-glare coating, is a thin multilayer finish applied to the surface of eyeglass lenses. This coating is designed to reduce the amount of surface glare that reflects off the lenses, thereby enhancing the efficiency of the glasses. AR coatings play a pivotal role in improving visual clarity and comfort, especially in situations where the wearer is subjected to bright lights, such as while using digital screens or driving at night.

Hydrophobic coatings, as the name suggests, repel water. This means that when water comes into contact with a lens equipped with a hydrophobic coating, it beads up and rolls off rather than spreading and smearing. This characteristic is particularly beneficial in rainy conditions or during activities that involve water, such as boating or fishing. It ensures that the wearer's vision remains unobstructed by water droplets. Additionally, the hydrophobic properties help to prevent fogging, a common issue in humid environments or when moving between different temperatures.

Ms.Cici

Ms.Cici

8618319014500

8618319014500