Polarized vs. Non-Polarized Sunglasses - polrized

This is the finest (“least rough” in technical terms) and highest quality surface roughness that are offered. It is suitable for parts that are under high tension or stress. It is also required for rapidly rotating components such as bearings and shafts. This surface roughness takes the most effort to manufacture and should only be specified when smoothness is of primary importance.

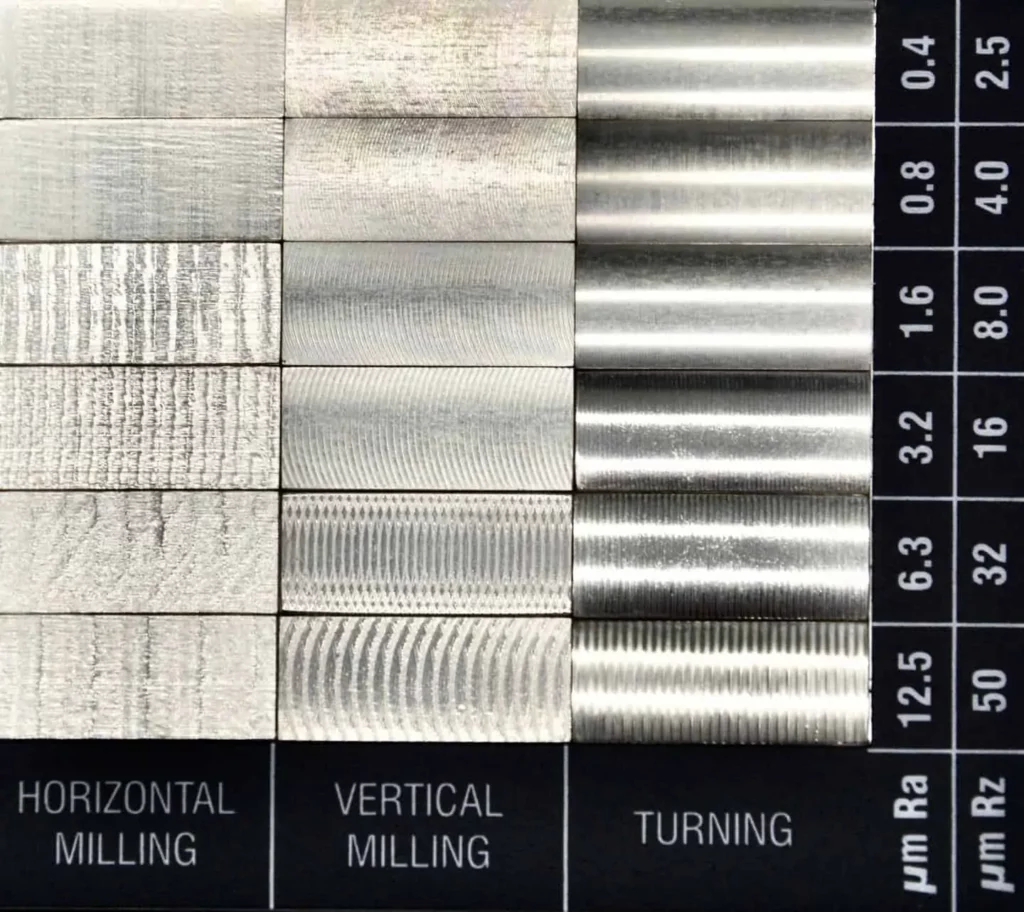

A part’s surface roughness after machining is usually not random. Instead, steps are taken to ensure that a specific roughness is achieved. This means that surface roughness values are planned in advance. However, not just any value is usually specified. In manufacturing, there are specific Ra values that are considered industry standards, as specified in ISO 4287. These are the values that may be specified during CNC machining. They range from 25 μm to 0.025 μm and apply to all kinds of manufacturing and post-processing operations.

Digital tools or software can ease your life as a photonics professional by either helping you with your system design or during the manufacturing process or when purchasing components. Check out our compilation:

LUCID cameradocumentation

Lucid Vision Labs, Inc. - 12.08.2022 – The 47-MP Atlas10 camera features Sony's IMX492 rolling shutter CMOS sensor, which offers 8240 x 5628 pixel resolution, a 4/3-inch sensor size, and operates...

Light going through a double convex (biconvex) lens will converge at a focal point. If a biconvex lens is near an object inside its focal point, a virtual ...

LUCID cameramanual

Lucid Vision Labs, Inc. - Helios Flex is a robust, pre-calibrated Time-of-Flight MIPI module which can easily be integrated into embedded platforms for industrial and robotics applications. The module...

Lucid Vision Labs, Inc. - 15.09.22 - Lucid's focus during Vision is on the Triton camera family, which has received a number of new additions.

Lucid Vision Labs, Inc. - Lucid Vision is now mass producing the Atlas10 cameras with the Sony IMX487 ultraviolet (UV) sensor.

Price: for a standard aluminium alloy (e.g. 3.1645) this option adds approximately 2,5% to the production price. This could increase with the complexity of the part.

Price: for a standard aluminium alloy (e.g. 3.1645) this option adds approximately 5% to the production price. This could increase with the complexity of the part.

Lucid Vision Labs, Inc. - Lucid Vision Labs first demonstrated the color version of its upcoming 5 Megapixel Phoenix polarization camera during the Computer Vision and Pattern Recognition Conference (CVPR)...

Lucid Vision Labs, Inc. - 31.08.2022 – The machine vision camera manufacturer will showcase expanded camera series and new technologies at Vision.

Polarizer PlatesWire Grid Polarizer PlatesPolarizers are optical elements allow light polarized in only one selected direction to pass through, ...

Digital tools or software can ease your life as a photonics professional by either helping you with your system design or during the manufacturing process or when purchasing components. Check out our compilation:

Lucid cameracost

15.06.2022 - The jury of the inspect award 2022 has nominated ten products each in the categories "Vision" and "Automation + Control". Now it's the turn of the readers of...

Lucid Vision Labs, Inc. - Lucid Vision Labs' new Atlas IP67 models feature a 5 GigE PoE interface and are equipped with popular Sony Pregius Global and rolling shutter CMOS image sensors.

The jury of the inspect award 2022 has nominated ten products each in the categories "Vision" and "Automation + Control". Now it's the turn of the readers of...

21.06.2023 - The jury of the inspect award 2023 has nominated ten products each in the categories "Vision" and "Automation + Control". Now it's the readers' turn to vote.

The following explores the roughness levels that we offer at Xometry Europe and all you need to know in order to select the right Ra value for your application.

The jury of the inspect award 2022 has nominated ten products in the categories "Vision" and "Automation + Control" and the voting runs from now until September 24, 2021...

17.06.2021 - The jury of the inspect award 2022 has nominated ten products in the categories "Vision" and "Automation + Control" and the voting runs from now until September 24, 2021...

13.03.2018 - Lucid Vision Labs, Inc. is pleased to announce its new German subsidiary, Lucid Vision Labs GmbH, based in Ilsfeld, Baden-Württemberg, Germany that has commenced operations...

06.05.2019 - 3D imaging technology plays a powerful role in industrial applications. Depending on the application requirements, such as distance to target, level of accuracy and precision...

LUCID Camerasupport

Lucid Vision Labs, Inc. - Lucid has introduced a new Triton 2K line scan camera with IP67 for industrial applications. The Triton line scan camera is the latest addition to the Triton series and has the...

12.07.2023 - How it works, what is behind it and how to use a Raspberry Pi for it: We have put together the best videos on ToF for you.

At Xometry Europe, we offer four surface roughness levels that are also the values typically specified for CNC Machining applications:

Lucid Vision Labs' new Atlas IP67 models feature a 5 GigE PoE interface and are equipped with popular Sony Pregius Global and rolling shutter CMOS image sensors.

Lucid Vision Labs, Inc. - 22.06.2022 – Lucid adds Jupyterlab development environment to Arenaview for testing, validating and prototyping camera features and system performance

The jury of the inspect award 2024 has nominated ten products in each of the categories “Vision” and “Automation + Control”. Online voting is now open.

LUCID cameraMount

Lucid Vision Labs, Inc. - 28.04.2022 - Lucid Vision Labs has announced the launch of Atlas Swir IP67-rated 1.3 MP and 0.3 MP cameras.

CNC machining is a highly accurate and precise manufacturing process that can create parts with tolerances as tight as 0.025 mm. However, being a subtractive manufacturing method, CNC machining leaves cut marks that create a level of roughness on the finished product’s surface.

Lucid Vision Labs, Inc. - The new Atlas10 camera features Sony’s 4th Gen Pregius S CMOS sensors, capable of 1.2Gb/s bandwidth over 10GBASE-T PoE and delivering a new level of imaging performance for high...

AR coatings protect your glasses against scratches and smudges, resulting in lenses that last longer. They also prevent oil, water, and dirt from sticking to ...

This fine-tip, high-precision tweezer works with components as small as 0.01 mm and is good for holding wires and surface-mount parts in place while ...

Price: for a standard aluminium alloy (e.g. 3.1645) this option adds approximately 11-15% to the production price. This could increase with the complexity of the part.

22.06.2022 – Lucid adds Jupyterlab development environment to Arenaview for testing, validating and prototyping camera features and system performance

LUCID cameradriver

Surface roughness is a measure of the average texture of a part’s surface, in this case, after CNC machining. There are different parameters used to define surface roughness. One of the most ubiquitous of these is Ra (Roughness average), which is derived from the differences between heights and depths on a surface. Ra surface roughness is measured microscopically and is usually in micrometres (x 10~⁶ m). Note that surface roughness in this context is different from surface finish. The surface finish of a machined part can be improved via various finishing methods such as anodizing, bead blasting, and electroplating. Surface roughness here refers to the as-machined surface texture of a part.

How it works, what is behind it and how to use a Raspberry Pi for it: We have put together the best videos on ToF for you.

American Polarizers Inc was founded in 1978. The company's line of business includes the manufacturing of instruments and apparatus that measure an optical ...

12.08.2022 – The 47-MP Atlas10 camera features Sony's IMX492 rolling shutter CMOS sensor, which offers 8240 x 5628 pixel resolution, a 4/3-inch sensor size, and operates...

29.11.2017 - Lucid Vision Labs, Inc., a new designer and manufacturer of innovative industrial vision cameras, will be exhibiting for the very first time at the International Technical...

Usually, there are only slightly visible cut marks with this option. This Ra rating is recommended for tight fits and stressed parts, and is sufficient for slow-moving and light load-bearing surfaces. However, it is not suitable for fast rotating parts and parts subject to intense vibration. This surface roughness is produced using high speeds, fine feeds, and light cuts under controlled conditions.

26.03.2019 - Lucid Vision Labs will be demonstrating its latest GigE Vision industrial cameras at Automate in Chicago, IL, from April 8-11th, 2019. Automate is the broadest automation solutions...

The jury of the inspect award 2023 has nominated ten products each in the categories "Vision" and "Automation + Control". Now it's the readers' turn to vote.

LUCIDVision Labs

05.06.2024 - The jury of the inspect award 2024 has nominated ten products in each of the categories “Vision” and “Automation + Control”. Online voting is now open.

At Xometry, we can manufacture your CNC machined parts with any of these surface roughnesses options. Simply upload your model on our instant quoting platform and select your preferred surface roughness to get a quote in a second.

Different roughness values are required for different applications. Lower surface roughnesses should only be specified when necessary. This is because the lower the Ra value, the more machining effort/operations and quality control will be required. They can significantly drive up machining costs and time. Post-processing operations aren’t usually applied when specific surface roughness values are required. This is because these operations cannot be controlled precisely and may affect the dimensional tolerance of parts.

Introducing the 21mm Deep Impact Socket 1/2 Drive (80mm Long). This socket comes with Retaining Pin. Shop now.

He also represents clients before a wide range of federal, state and self-regulatory agencies including the Securities and Exchange Commission (SEC), the US ...

Surface roughness significantly affects the functionality, performance, and durability of parts in certain applications. It influences the friction coefficient, noise level, wear and tear, heat, and adhesiveness of a part in use. The importance of these factors vary by application, and so while the surface roughness of a part is inconsequential in certain applications, it is critical in many others. These applications include high tension, stress, and vibration scenarios, mating and moving assemblies, fast rotating parts, and medical implants. As earlier stated, different levels of surface roughness are required in different applications.

At CVI Laser Optics, we specialize in the design and manufacture of high performance optical components for use in lasers, laser beam conditioning, ...

LUCID cameraprice

Ocular Lens (or eyepiece). Focuses the image from the objective into your eye. · Eyepiece Tube. Connects the eyepiece with the objective lens. · Objective Lenses.

3.2 μm Ra is the recommended maximum surface roughness for parts subject to stress, loads, and vibrations. It can also be used for mating moving surfaces when the load is light and motion slow. It is machined using high speeds, fine feeds, and light cuts.

This is the standard commercial machine finish. It is suitable for most consumer parts and sufficiently smooth, but it contains visible cut marks. It is the default surface roughness applied unless otherwise is specified.

Various kinds of beam dumps can be used for temporarily or permanently blocking a laser beam, often for reasons of laser safety. High-power versions are fan- ...

Considered high grade, this surface finish requires very close control to produce, costing more. It is required for parts that are exposed to stress concentration. When the motion is occasional and the loads are light, then it can be used for bearings.

Ms.Cici

Ms.Cici

8618319014500

8618319014500