Polarization of Light - linearly polarised light

A Q-switch is an optical component used to “gate” energy in order to generate a short, high peak-energy pulse. The Q-switching element used in Ultra Q is fabricated from highly stable, homogenous materials, which exhibit similar expansion characteristics. Unlike organic polymer materials that can cause inconsistent treatment performance due to material warping and fatigue, the materials used in the Ultra Q Q-Switch are thermally matched to deliver more consistent performance over a number of different operating conditions – ensuring robust, reliable performance and a lifespan of more than 400,000 shots.

Polarization

Photonpolarization

In addition, Ultra Q’s custom-built YAG power supply incorporates a micro-controller and energy compensation algorithm to deliver greater shot-to-shot consistency. Many other YAG lasers use a commercial, off-the-shelf YAG power supply.

Stress Evaluation: Stress, or unwanted refractive index variations, causes a rotation in the angle of polarization. Viewing an unstressed clear object between crossed polarizers should yield a completely dark field. However, when stress is present, the localized changes in refractive index actually rotate the angle of polarization to give varying degrees of transmission - even different amounts of transmission for different colors.

Electricpolarization

Knowledge Center/ Application Notes/ Illumination Application Notes/ Successful Light Polarization Techniques

Video and machine vision systems rely on electronic imagers that typically exhibit anywhere from eight-bit to twelve-bit signal-to-noise ratio. Although sufficient for many applications, cameras in this category may be problematic in cases where the field of view includes extremely bright regions or hot spots. Some objects have certain features that are extremely reflective, or objects may be illuminated from an angle that produces intense reflection. Light polarization filters offer solutions to these and other common imaging problems.

polarization极化

Ultra Q™ allows you to perform capsulotomy and iridotomy procedures at ultra-low energy levels and with an improved safety profile.

Unlike the standard glass components found in other YAG lasers, Ultra Q’s combination of high-grade crown glass materials and multi-layered, anti-reflection coatings on all optical components maximizes light transmission whilst minimizing dispersion to deliver better optical performance. In addition, next-generation filter technology provides the best colour balance possible.

Ultra Q’s continuously variable offset (from 100 to 500 microns) allows you to accurately set the distance between the focal plane and the position of the plasma ball – ensuring more effective and safer photodisruption. Depending on the treatment, the aiming beam focus can be placed exactly in front of, behind, or on the disruption laser focus.

With a fast firing rate of up to 3 shots per second (3 Hertz), Ultra Q saves you time and allows you to perform quick and highly accurate treatments. Ultra Q’s patented, proprietary cavity facilitates more effective heat transfer and cooling, thereby permitting fast, efficient operation. In addition, the system’s pulse capacitors are rapidly recharged between each and every shot without the risk of overheating – ensuring you uninterrupted operation.

Ultra Q™ allows you to cut tissue more effectively using fewer shots and less cumulative energy – dramatically reducing the risk of IOL pitting. Featuring an Ultra Gaussian beam profile, Ultra Q™ focuses more energy into the center of the beam profile to deliver greater energy density, achieving optical breakdown (in air) of approximately 1.8mJ, in optimal conditions. This compares to other YAG lasers, which typically achieve optical breakdown (in air) of 3 to 4mJ in optimal conditions.

polarization中文

By considering light as an electromagnetic wave, we realize that in three-dimensional space a wave can oscillate up and down, side to side, or anywhere in between. Incandescent, fluorescent, LED, and many laser light sources are randomly polarized. In other words, the oscillating angle or plane of light from each point on the light source is varying with time. Taken as a time average, therefore, randomly polarized light sources continuously output all angles of polarization.

Polarizationoflight

Contrast Enhancement: Ring light guides are popular for their even, diffuse illumination. However, glare or reflection of the ring itself may occur. Polarizing the ring output and the lens separately can reduce these effects, and bring out surface details.

Politicalpolarization

Glare From a Plane Surface: Glare from highly reflective surfaces or optical windows is removed by putting a polarizer over the lens. Due to partial polarization of light, the light source may or may not require a polarizing filter in this scenario.

With a two-point focusing system the two aiming beams converge in the focal plane. This simple, yet highly precise aiming system, is the most accurate at indicating when the laser and slit lamp view are in proper focus, as it allows you to see a separation of the two aiming beams (which indicates out-of-focus) with even the smallest of slit lamp (or patient) movements. In comparison, four-point and many other focusing systems require a significant shift in the slit lamp’s position before you can distinguish any separation of the aiming beams

With a tolerance range of ± 8 µm, Ultra Q’s two-point focusing system makes it easy for you to accurately position where the optical breakdown will take place, irrespective of whether you are working in the anterior segment or in the posterior segment.

In posterior capsulotomy, for example, the ideal placement of the plasma ball is slightly “posterior offset” from the target tissue to be incised, as the plasma ball creates shock waves that move back in the direction of the laser source (that is, towards the operator). This helps to ensure precise treatment whilst eliminating the risks of side effects such as IOL pitting.

Circularly polarizedlight

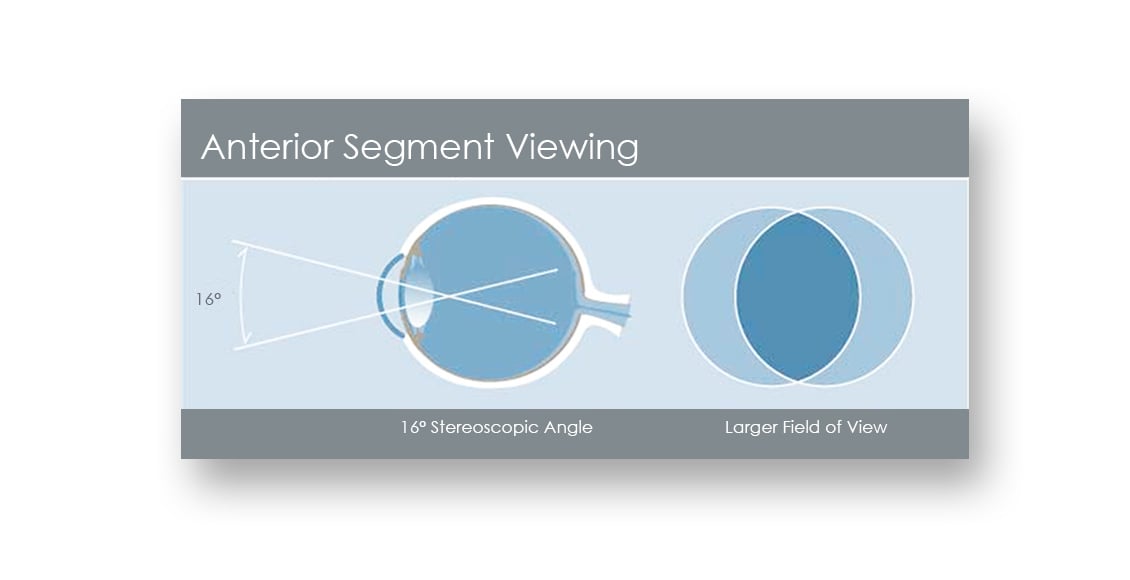

The quality and design of Ultra Q’s slit lamp optics are custom-designed for anterior YAG laser procedures. Featuring Galilean converging optics with a 16° stereoscopic angle, Ultra Q™ provides a more natural stereoscopic view combined with a small depth of field for precision focusing on structures in the anterior segment.

Polarizers absorb incident light oscillating in all but one plane - its polarization axis - yielding linear polarization. Another example of polarization is the partial polarization of light reflecting from a plane surface, an effect less dramatic than a polarizer element. Linear polarization of a randomly polarized light source reduces the intensity of the source theoretically by 50%, and in practice closer to 60-65%. Light that passes through two polarizers with orthogonal polarizing axes will be completely attenuated. However, the almost total elimination of hot spots and glare is exactly what makes a polarizer effective in evening out illumination levels within a field.

Ellex has integrated the laser and slit lamp for greater efficiency and reliability, as well as for improved ease of use. Ultra Q’s compact, efficient design provides you with additional working space – making it easier to align the patient and to position the contact lens. It also offers the added benefit of convenient, simultaneous access to the patient and laser controls.

Eliminating Hot Spots: Hot spots are highly reflective areas within a more diffuse reflecting field. Polarizing the light that strikes these reflective areas, and using a crossed polarizer over the lens, effectively eliminates the hot spots, while evenly illuminating the rest of the field.

Shown are examples of some common polarization of light techniques used in imaging applications. By utilizing a linear polarizer over the light source, the lens, or both, it is possible to eliminate glare from a reflective surface, bring out surface defects or show stress in a transparent object. More detailed information on which type of polarizer is right for your application can be found in our Polarizer Selection Guide.

Considered to be the industry’s leading microsurgical YAG laser, Ultra Q™ features a patented, proprietary cavity and a custom power supply, which allow you to perform capsulotomy and iridotomy procedures at lower, more efficient power levels and with greater shot-to-shot consistency. It is also the world’s fastest YAG laser, with a firing rate of 3 shots per second.

Ms.Cici

Ms.Cici

8618319014500

8618319014500