Pixelink - pixelink camera

Emissivity vsreflectivity

“The plating job was head and shoulders above what has been done for aircraft instruments here in the past…the performance of the vessels gave us nearly double the sensitivity, due in part to the extremely high reflectivity of your finish…” -Dr. Thomas B. Reyerson, National Oceanic and Atmospheric Admin.

emissivity +reflectivity= 1

For advanced users, Pixelink Capture offers options of more complex image enhancements for exposure control, filtering, frame-by-frame property changes, multi-camera application testing and configuration, all viewable in the preview window prior to capture.

“We’d like to thank you for your efforts on our baffle polishing and gold coating. The parts, and especially the processing steps were a challenge for fabrication. Your flexibility and perseverance were keys to working towards successful parts and maintaining our assembly schedule.” – Farshid Azad, Joaquin Mason, Ronald Bento, L3 Communications

Ir reflectivityvs emissivity

Pixelink Capture streams real-time, high-quality video that can be viewed in a multi-window environment which includes a preview window, a configuration window, and a real-time graphical histogram on a monitor providing the ability to adjust image size, color and exposure interactively through an easy-to-use control interface prior to image or video clip capture. The camera begins streaming at the point the application is launched.

Emissivity andreflectivityformula

I was indeed flattered when Leonard Hanssen of NIST requested us to supply a quantity of twenty-five specular mirrors coated with Laser Gold, and the same quantity of diffuse substrates that he would supply, on which we would do the Laser Gold plating.

“I am very pleased and proud with this new release of Pixelink Capture,” said Lisanne Glavin, Vice President, Engineering. “We have a talented team of engineers, here at Pixelink, and their commitment to quality is reflected in this new release that offers improved functionality to this best in class software application.”

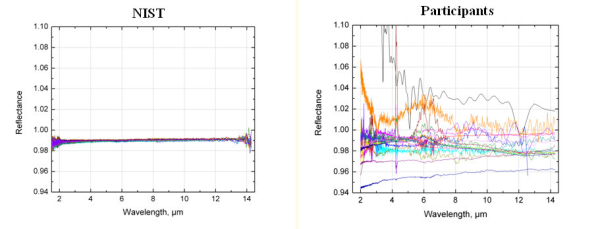

The Epner mirrors were two samples, of a five sample group that was individually calibrated at NIST and then sent to twenty-three participating optical laboratories in a groundbreaking nationwide “Star” Intercomparison of Infrared Reflectivity, with each lab getting its own separate sample set.

“Your Contribution has been invaluable and we could not have accomplished our goal without you.” - Stephen Hixson, Northrup-Grumman

Infrared wavelength

Incredibly, the Epner Technology specular mirrors, when calibrated by NIST prior to their distribution to the participating labs, all tracked at 99 percent with each mirror creating a single flatline on the graph! (see Fig.1)

Ir reflectivitypdf

“…as part of MESSENGER’s current preparations for our ‘Mercury Orbit Insertion’ next month, the MLA Instrument was brought out of hibernation for a series of turn-on test last week and the laser still worked perfectly, which would not be possible if the plating inside the laser cavity had degraded.” - Arlin E. Bartels, NASA

This reflectance chart depicts measurements made by three separate organizations, China Lake Naval Weapons Center, (measurement made under the renowned Jean Bennett), Hughes Aircraft’s Optics Lab, then in Culver City, Ca. and AZ Technology, a NASA source in Huntsville. In all cases, the measurements were made with the Laser Gold plated over a highly polished, low scatter electroless nickel substrate. At 700nm wavelength reflectivity is an astounding 97% and >99% @10 microns. Measured at 6 degrees angle of incidence. Read More

“We are constantly looking to improve the user experience for our customers,” added Paul Saunders, President of Pixelink. “We are excited about this new release. Customers using our cameras to build vision application solutions can now take advantage of this robust piece of software to better their multi-camera inspection application development and processes.”

To obtain the complete report of this unprecedented study, including the list of the 23 participants, the stucture and analysis of the results, including all the graphs, click below (All this makes for a large file [9.95MB], so be patient!).

Ir reflectivitytest

Pixelink Capture is a real-time, interactive, multi-camera software application. It is compatible with all Pixelink’s PL-B and PL-D line of cameras and has been developed using the most advanced software development tools in the market to provide an unmatched multi-camera user experience.

“The performance of the Epner sample was outstanding, providing a Q of approximately 3700 as opposed to the best previous value of 3200 (typical production values are around 2800).” - Catherine Nagel DeFreese, Motorola, Inc.

Ir reflectivityformula

Our rough, diffuse Laser Gold coated samples showed similar consistency when measured by NIST for the pre-comparison data points. (see Fig. 2)

Our mirrors were diamond turned copper blanks supplied by Kugler of Salem, Germany, while the NIST blanks were roughened by arc-spraying aluminum on a machined brass substrate.

Pixelink, a Navitar Company and a global provider of industrial cameras for the machine vision and microscopy markets, has announced the new release of their flagship software application Pixelink Capture.

Users can drag and drop or arrange windows as they like. As a multi-camera application with a built-in autofocus application, Pixelink Capture offers tremendous flexibility and power allowing vision engineers the ability to configure and test multi-camera vision applications.

Laser Gold plating reflectivity is greater than 99% at 10.6 microns and greater than 97% at 0.7 microns when measured on a low-scatter substrate, measured at 6 degrees angle of incidence. The reflectivity in the infrared equals and often exceeds that of a freshly vapor-deposited gold. Because of its outstanding cleanability, stability and reflectivity, in 1984, the National Bureau of Standards, (NIST), chose Laser Gold plating as the Standard IR reference material (#2011). For more than twenty years, Epner Technology had been the sole source supplier of these standards.

While the measurments of the specular sample from a few of the 23 participants ranged from 94% to 102%, according to Leonard Hanssen and Boris Wilthan, Directors of the study, the overall comparison results were “encouraging.”

The new release of Pixelink Capture adds an enhanced set of callback filters, improved video & still frame capture mechanisms, the ability to flip & rotate images and enhanced region of interest (ROI) capability. Pixelink Capture now also supports continuous auto exposure, user interface enhancement and support for the latest Pixelink Cameras, which utilize the Sony Pregius IMX264, IMX267 and IMX304 image sensors.

Ms.Cici

Ms.Cici

8618319014500

8618319014500