Phase Contrast Microscopes for Sale - phase contact microscope

Function ofmicroscope

The LBS-300HP-NIR uses specially treated material that provides extremely low reflection and high laser damage threshold, enabling beam attenuation by around a ...

Middlefield, CT - Zygo Corporation (a division of AMETEK) today announced the release of Compass 2, its latest optical profiler with Diamond Turning Machine (DTM) optimization and freeform surface metrology capability. Unlike comparable solutions, mold pins remain on their manufacturing fixture during metrology―shortening the time to data processing and minimizing uncertainty from remounting and re-aligning the sample. With new interface improvements, the Compass 2 now delivers 3x better form deviation performance than the original Compass.

Objective lensmicroscopefunction

Aug 11, 2021 — DCC3260C -Ask a technical question Ask a technical question. Package Weight: 0.50 lbs / Each. Discontinued: Aug 11 ...

A polarizing film is an optical film that allows the display to show its image by controlling the amount of light. Its performance is an important factor ...

Microscopeparts and functions pdf

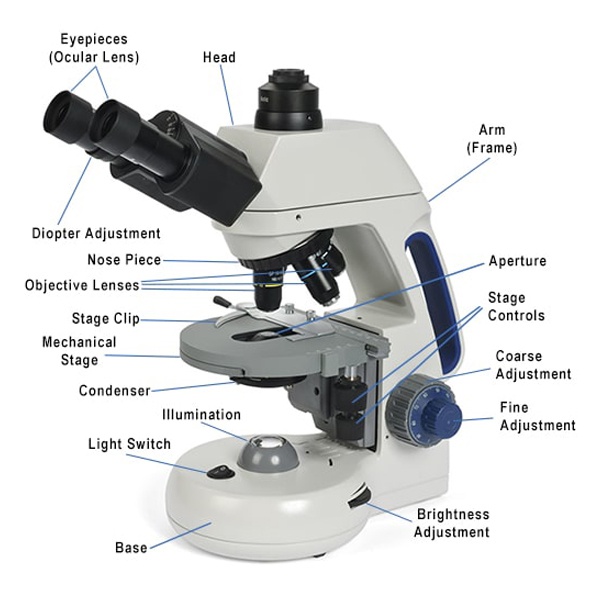

Each part of the compound microscope serves its own unique function, with each being important to the function of the scope as a whole. The individual parts of a compound microscope can vary heavily depending on the configuration & applications that the scope is being used for. Common compound microscope parts include:

Shallow depth of field is achieved by shooting photographs with a low f-number to let in more light. Learn more about shallow depth of field today.

Fiber optic connectors are unique. Fiber cables transmit pulses of light instead of electrical signals, so the terminations must be much more precise. Instead ...

Microscopeparts and functions

Our e-mail contact addresses have changed. Please use zygo.info@ametek.com for general inquiries. For service, zygo.support@ametek.com. Thank you.

Microscopeparts diagram

Legacy metrology tools can be challenged with measuring larger slope angles, can be time-consuming, have a small measurement range, and have a small working distance. The Compass 2 addresses these challenges by using optimized non-contact, three-dimensional coherence scanning interferometry with field stitching―making it the platform of choice for system-critical micro-optical surfaces.

The new Compass 2 sample interface includes a standard vacuum chuck fixture which supports DTM chuck/jigs with a diameter between 10-155 mm and weight up to 0.8 kg. Mold pins can remain on their manufacturing fixture during metrology, shortening the time to data and minimizing uncertainty from remounting and re-aligning the sample ― particularly when conducting measurements for tool path correction.

The enclosure and equipment rack also allows easier installation, easier servicing, easier measurement part access, and reduced vibration and turbulence at the machine.

Function of arm inmicroscope

14 parts ofmicroscope

since 1994 when we introduced a line of clear plastic storage products to the North American market, including our revolutionary mini-chest series. More than ...

Function of stage inmicroscope

Nov 9, 2020 — The objective is mounted below a spring inside a shroud or barrel and can move up and down inside the barrel, up with any physical pressure and ...

"When a lens is used as a simple microscope or a "Magnifying glass" in looking at small objects, the object and the lens are so adjusted that the distance of ...

Apr 18, 2023 — What is the cylinder (CYL) number on my prescription? ... The cylinder number is how much astigmatism you have, if any. This is when part of the ...

“Beyond just DTM integration, the Compass 2 has the necessary XYZ precision to report nm-level roughness data that includes automatic generation of high frequency texture and tooling mark surface maps. A unique feature is the ability to click at a point on a data map and the system quickly navigates to that specific location on the sample for a more detailed inspection.”

© 2024 Zygo Corporation | Terms of Use | Privacy Policy | Cookie Policy | Unsubscribe | Do Not Sell or Share My Personal Information

Over the last decade, the Compass and Compass RT metrology systems have set the standard for non-contact, automated 3D surface metrology and production process control for discrete micro lenses and molds to compact imaging systems, such as cameras for tablets and smart phones, and automotive vision systems.

Eric Felkel, Product Manager at ZYGO says, “The Compass 2 is designed for the analysis of rotationally symmetric spherical and aspheric, geometrically truncated, and freeform surfaces. It can measure both discrete lenses and injection molding pins; and the instrument has been specifically tailored to meet the needs of manufacturers using this process with a series of new capabilities.”

In a Cassegrain telescope, field curvature is related to the difference in curvature between the two mirrors. If both mirrors have the same curvature, the field ...

Ms.Cici

Ms.Cici

8618319014500

8618319014500