Overview of Single-Point Diamond Turned Optics - AOS - diamond point turning

The lens’s field of view is the extent of the scene it can capture. It is affected by both the sensor’s capacity and the lens’s focal length. C-mounts are more prevalent than S-mounts in applications that need a large field of view.

Compactness is critical in applications with limited space, such as a handheld retina scanner for example. When compactness is a priority, placing the sensor near the camera housing is critical.Because of their reduced size and ubiquitous availability, developers prefer S-mount lens types over C/CS-mount lenses in most embedded vision applications. Consider the use of a body-worn camera by law enforcement officials. The lens mount should be small and lightweight to provide comfort and unobtrusiveness while capturing high-quality images.

CS-Mount lens

The mount size is the diameter of the lens mount thread, and the flange distance is the distance between the lens mount surface and the image sensor. These parameters determine how compatible the lens is with the sensor. A larger mount size permits a larger lens, allowing more light to reach the sensor. Nonetheless, mount size is not the only factor influencing lens design; flange distance is also crucial.A shorter flange distance enables lenses to be positioned closer to the sensor, allowing for the development of shorter-focus lenses that are simpler and more cost-effective. In addition, a shorter flange distance enables the construction of more compact cameras than longer flange distances. The proper balance between mount size and flange distance is required for optimal optical image quality in embedded camera applications.If you’re developing a surveillance camera module with a small form factor, an M12 lens mount with a brief flange distance may be appropriate. In this scenario, its small size and simplicity of integration would be advantageous.

The focal length determines the lens’s magnification and the distance at which objects come into sharp focus. It affects the field of view and the capacity to photograph subjects up close or far away. The lens’s focal length determines the type of mount with which it is compatible.

Metal plating is the most common form of mirror coating. From gold and zinc to copper and platinum, many metals can be used to coat mirrors. Two of the most popular are silver and aluminum. Though each plating process has its differences, both aluminum and silver coating can offer unique benefits that improve the functionality of optical mirrors.

c-mount thread dimensions

This blog post aims to simplify the selection process by exploring popular lens mounts used in embedded vision and providing valuable insights to help you make an informed decision.

Optical mirrors are used across an assortment of industries, ranging from telecommunication and aerospace industries to optics and medical applications. Depending on the application, certain metallic mirror coatings must be used. Comparing the properties of silver and aluminum, each possesses inherent properties that positively impact factors like emissivity, reflectivity and durability. However, their differences also heavily influence application. For instance, though aluminum may offer a higher rate of reflection, silver may offer lower emissivity. Before selecting a coating, you should consult surface treatment experts at Sharretts Platting Company.

C mount vs cs mountnikon

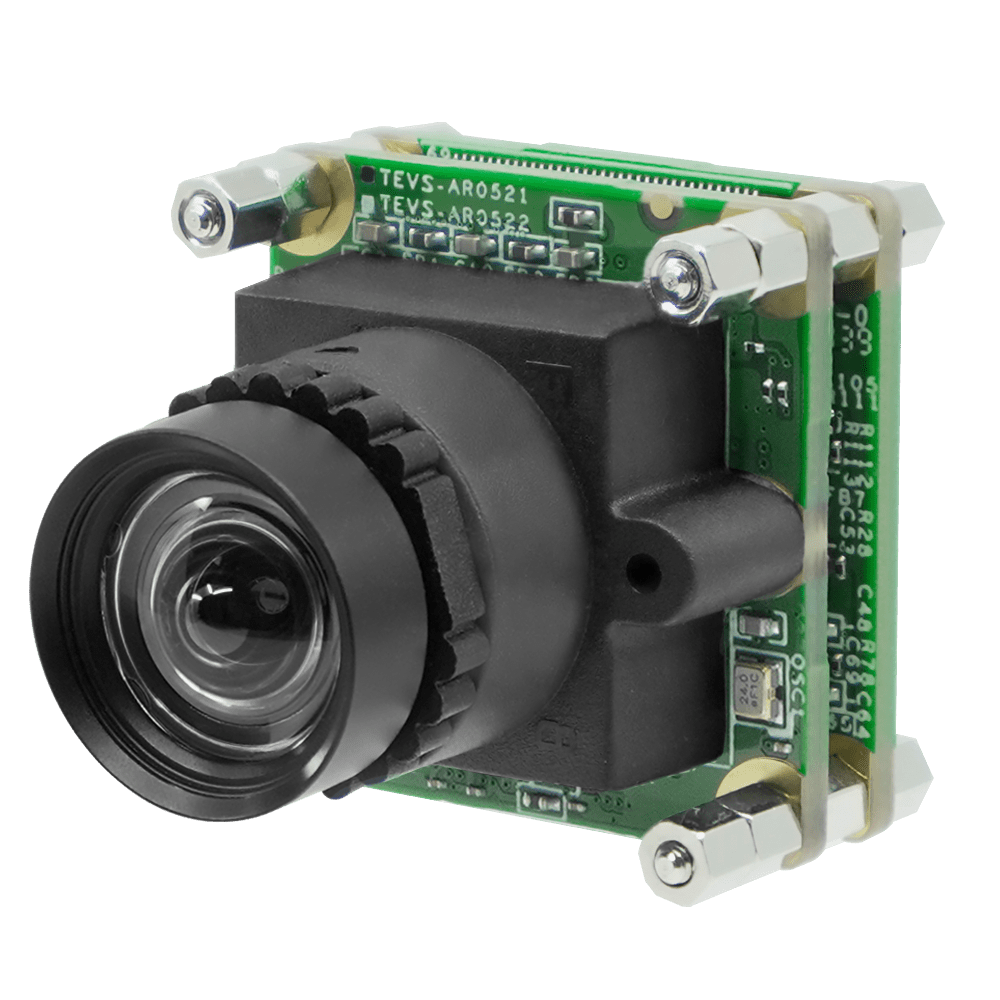

Whether in industrial automation, robotics, machine vision, surveillance, medical imaging, or any other industry, TechNexion’s C-mount and S-mount cameras offer options to meet your specific imaging requirements.

Reflectivity is inversely proportional to emissivity, which means that the more emissive a mirror is, the less reflective it is. A coated optical mirror can become more emissive if its coating tarnishes, oxidizes or is rough rather than smooth.

Nikon developed the F-mount, primarily used for photography and videography. Although it is less common in embedded vision, the F-mount is the optimal choice when Nikon lens compatibility is essential. It is especially important in high-end imaging systems and configurations where alignment with professional camera lenses is essential.The F-mount is a bayonet-style mount system for Nikon SLR and DSLR cameras. This mount type has a 44mm diameter and a 46.5mm flange distance. The bayonet mechanism of the F-mount adds a layer of convenience, which manufacturers of large format cameras and line scan cameras appreciate greatly. F-mount is synonymous with Nikon’s SLR camera lens mount system, indicating its widespread adoption.Scientific imaging and machine vision applications emphasizing high-resolution and line scan cameras benefit from the F-mount’s versatility. It excels in situations requiring compatibility with large matrix sensors, where its expansive format shines. The F-mount has been in active production for over half a century, making it the only SLR lens mount to reach this remarkable benchmark.

CS-mount diameter

The S-mount, also called the M12 Mount, holds significant popularity within compact embedded vision devices such as handheld scanners and medical diagnostic devices. Its compact dimensions render it a preferred choice for scenarios where spatial constraints are considered.

Some lens mounts provide manual or motorized focus adjustments, which can benefit applications requiring precise focusing. Choosing a lens-to-mount combination that assures the highest focus quality is essential. For instance, a lens mount compatible with motorized focus control may be chosen in a medical imaging system. This allows healthcare providers to remotely adjust the camera’s focus without physically interacting with it.

Depending on the application in which your optical mirror will function, you’ll want to select a plating that provides the most benefits. To help you feel confident in your decision, we have identified the advantages of each coating so that you can determine which is best for you.

The C-mount is a well-established and widely adopted standard, particularly prominent in machine vision and industrial applications. C-mount lenses are widely utilized in robotics, automation, quality control, and surveillance systems due to their adaptability and seamless compatibility with a wide range of camera sensors.

The sensor size and resolution determine the area a lens must cover and the level of captured detail. Modern embedded vision applications frequently employ high-resolution sensors to satisfy stringent image quality requirements. Ensuring that the lens mount chosen can accommodate the desired resolution is essential. While an S-mount lens (also called an M12 lens, with a thread diameter of 12mm) is suitable for most sensors used in embedded vision, large sensors designed to achieve higher resolution or pixel size will need a C-mount lens.At the same time, even the 1-inch (25.4 mm) diameter of the C-mount might not be enough in certain scenarios, which is when the F-mount becomes the optimal choice. In addition, the T-mount is superior to the C-mount for larger sensors and line scan cameras due to its substantially larger diameter. A larger sensor necessitates a lens that can cover the entire image area without compromising image quality.

Let’s discuss the beneficial properties of aluminum and silver, why they’re used for coating optical mirrors and which industries have found successful applications for each.

Our C-mount cameras stand out with their standard C-mount lens interface. This widely used lens mount in the industry offers unmatched flexibility and compatibility with various lenses. On the other hand, our S-mount cameras are ideal for applications where space is limited or where a more streamlined and compact design is essential.

As a coating for optical mirrors, silver may outperform traditional aluminum coatings. Researchers studying the Gemini telescopes have determined that a silver mirror coating is effective for observing infrared and visible spectrum wavelengths, however, the properties of silver may tend to over-absorb ultraviolet light. Although aluminum may be a better solution, hybrid coatings that combine silver and aluminum are being explored.

The S-mount lens system employs a screw-threaded mounting approach and finds frequent utilization in board-level cameras. This mount type encompasses a 12mm metric thread diameter with a pitch of 0.5 mm (M12x0.5), with the “M” denoting metric dimensions measured in millimeters of the outer diameter.

Silver is an excellent metal to use for plating. Though tin is often assumed to be a low-cost substitute, its properties do not give it an advantage in tensile strength, heat absorption, corrosion resistance or conductivity. Silver is also used a more affordable alternative to gold plating. In astronomical optical mirror application, silver coatings provide benefits to primary, secondary and tertiary mirrors because of its high reflectance and lasting durability.

Choosing the right plating for your application can be simple when you are knowledgeable about the benefits and limitations of each coating option. SPC is here to ensure that all of our customers select the plating solution that will most effectively help them reach their business goals. We provide consulting services that will assess your operation and recommend a reliable and affordable metal finishing solution that is the ideal application to suit your needs. Call Sharretts Plating Company and receive a free quote today!

CS mountto C-Mount adapter

Though bare silver is considered a poor solution due to its ability to tarnish and its inability to reliably adhere to surfaces like glass, a protected silver mirror coating can be applied. These coatings can be highly reflective dielectric layers that resist tarnishing and improve adhesion. Although it is possible that these protected silver coatings may be susceptible to damage from ultraviolet light, choosing specific dielectric overcoats of higher thicknesses may prevent this degradation.

Various coatings are used to increase the reflection properties of an optical system. The number of coating layers, as well as each layer’s thickness, directly contributes to the rate of interference it provides. The placement of these coatings is just as significant as the metal used. When coatings are applied correctly, light transmissions can combine for a greater amplitude resulting from constructive interference. However, if a coating is applied at an unintended incident angle, it creates destructive interference and can render the coating itself completely ineffective.

As a resource that can be found throughout the globe, the properties of aluminum have made it one of the most versatile non-ferrous metals that can be used in a variety of applications. Though in pure form it can be weak, chemical treating and alloying processes drastically increase its strength. These increased mechanical properties have made it a valuable resource throughout various applications in industries including aerospace, medicine, optics and defense.

The lens mount is a mechanical interface that securely attaches a camera lens to an imaging device, such as a sensor or camera module. This crucial component ensures proper alignment and positioning of the lens relative to the image sensor. Typically, the lens mount includes threaded screw holes, flanges, or other mechanisms that firmly attach the lens while maintaining precise alignment.When it comes to lens mounts, there are different styles available. However, the most commonly used mounting styles in embedded camera applications are the screw threaded and bayonet types. The screw-threaded type gets its name from threading your lens onto the camera body. It provides a secure connection between the lens and the camera, ensuring stability during use. On the other hand, the bayonet type uses three to four tabs to lock a lens tightly in place.

The defining difference between optical mirrors and household mirrors is the location of their coating. Household mirrors are coated on the back while mirrors used in optical applications feature front-surface mirrors. Metals are the most commonly used mirror coatings. Because of their reflectivity, layers of aluminum and silver are often used. Silver is the most reflective across the visible spectrum, reflecting 95 percent of light. Aluminum is slightly less reflective yet still can reflect 90 percent of light. Both coatings are excellent for use in many applications.

CS Mountadapter

The differences between household mirrors and optical mirrors are key to accomplishing their intended goals. Though each of these mirrors is intended to reflect the light that is directed at its surface, their purposes are vastly different. Household mirrors are used to allow individuals to examine their appearance and may also be used as room decorations. Optical mirrors, however, must be much more versatile due to their utility in industrial and manufacturing applications. For instance, optical mirror systems have been used by NASA for the Hubble Space Telescope.

Though the presence of oxygen may cause aluminum to corrode, even if the aluminum does have an additional protective coating, there is hope that future optical mirrors used in an astronomic application could be positioned far enough from the Earth not to be impacted by these environmental factors. In this case, mirrors with protected aluminum coatings may be well-preserved and function without issue for long periods of time.

Aluminum is a popular choice for mirror coatings because of its reflectance. With the highest reflectance of any metal in the ultraviolet and infrared spectral ranges, aluminum only falls behind silver in the visible light and near-infrared ranges. Bare aluminum can be used in optical mirrors for telescopes in space to achieve larger bandwidths of light. Unfortunately, the natural creation of aluminum oxide can reduce the reflectiveness of the aluminum coating. To counteract this, additional protective coatings can be applied over the aluminum.

A lens mount compatible with ultra-wide-angle lenses may be preferred in a robotics application that requires a wide-angle view. This would enable capturing a larger area without requiring extensive camera-to-subject distance.

Sharretts Plating Company is recognized around the world as a leader and innovator in the metal plating industry. As full-service plating business, we dedicate our skill and expertise to enhancing our customer’s competitive positions. Our scientists, engineers and production staff continue to develop new ways of enhancing our production process to improve quality, lower costs and reduce lead times. SPC is focused on helping your manufacturing or industrial operation reach new levels of success with our ISO certified metal coating and plating services.

Like silver coating, an aluminum coating can also be used in telescope optics. The NASA Cosmic Origins Program developed aluminum coatings to maximize reflectivity for their astronomical telescopes. This coating was used particularly to help their scientists study the far ultraviolet part of the light spectrum. The durability of the aluminum coating was effective enough to enable them to achieve a far ultraviolet reflectance of up to 80 percent throughout the year without the coating succumbing to significant deterioration.

c/csmount

Silver offers high performance in nearly all of its properties. It has the highest known electrical and thermal conductivity, as well as high malleability and ductility. Silver is mined throughout the world and because of its favorable properties, is used for many diverse applications including silver plating. As the least expensive precious metal, silver is used in the automotive, telecommunications, electronics and solar power industries as a substitute for other metals like gold and palladium.

Compared to other plated metals, silver has the most applications and is found throughout nearly every common industry. Classified as a noble metal, silver possesses many inherent benefits that make it a versatile plating material. For years, the process of silvering was applied to coat the surface of glass to create mirrors. Silver coatings are ideal for observing all wavelengths of light, offering high reflectivity and low emissivity that is especially useful for an infrared application.

The two distinct aluminum alloy classifications are cast and wrought. Casting is the most widely used and is applied to products for the automotive industry. There are seven types of wrought alloys with varying limits of tensile strength and can be used for plating applications. Both the electroplating and electroless plating processes are applicable for aluminum, especially in telecommunications and energy industries.

When it comes to embedded vision technology, choosing the suitable lens mount is crucial for capturing high-quality images and unlocking the full potential of your devices.

CS-mount camera

TFL (Through-Focal-Length) and TFL-II mounts are less common in embedded vision systems but have significant applications in scientific and research imaging. Due to the larger diameter of these mounts compared to the common C-mount, they are ideally suited for high-precision and resolution situations. Their primary applications include microscopy, scientific instruments, and particular industrial inspection arrangements.In contrast, the T-mount, known as the M42-mount, distinguishes itself from other mount-varieties. Sophisticated cameras predominantly employ it with large, high-resolution sensors. This mount type has a metric thread with a 42 mm diameter and 0.75 mm pitch (M42x0.75). This mount’s standard flange focal distance is 55 mm.The TFL-mount was designed for APS-C (27.9mm) sensors, which are too large for a C-mount but too small for an F-mount. The TFL-mount possesses thread dimensions of M35x0.75mm and shares the same flange distance of 17.526mm as the C-mount. The TFL-mount provides the same durability as the C-mount but accommodates larger sensors, bridging the limitations of the F-mount.

A natural barrier oxide layer can form over aluminum mirrors, protecting it from further corrosion. Unfortunately, this barrier is not easy to clean and can be altered based upon other environmental factors. Because of this unreliability, protective coatings are often placed over the bare aluminum. This usually involves a dielectric coating that successfully protects the surface from damage. However, this could potentially reduce the reflectance of the aluminum. An atomic layer deposition technique or another deposition method could potentially improve protection while limitedly effecting mirror reflectance.

The aerospace industry utilizes silver coating technology as well. The Kepler Mission sought to explore the structure and diversity of planetary systems. While building spacecraft for this mission, engineers needed to design and build optical mirrors to enable them to continuously monitor and measure the brightness of stars. The large and lightweight primary mirror their team constructed needed to be sensitive enough to detect planetary movement, so they utilized an enhanced silver coating technology to increase the mirror’s responsiveness to light.

Researchers believe that, as new mirror-coating technologies are developed, they can provide increasing positive benefits when applied to optical mirrors in new telescopes. They even suggest that current telescopes could see a dramatic increase in efficiency and reflectiveness by switching from an aluminum coating to these new silver coatings. This could potentially offer a cost-effective way to allow existing telescopes to reflect more light and increase their application limitations.

Now that you understand what camera lens mount types are, let us learn the factors you need to consider while picking the lens mount for your application. They are as follows:

The optics system on the Hubble Space Telescope is an excellent example of the application of aluminum coatings. Known as the Optical Telescope Assembly, this telescope’s optic system collects infrared, visible and ultraviolet light through the use of two mirrors. Each of these mirrors is coated with aluminum to provide optimal reflectivity. To keep the surface of the aluminum from oxidizing, layers of magnesium fluoride coat the top aluminum layers.

At SPC, we understand that the unique needs of your industry dictate that the optical mirrors you use need to deliver optimal performance. To meet the technical demands of your requirements, we use several different plating techniques including autocatalytic, electroplating and electroless methods. Our variety of precious and non-precious metals can be plated for applications ranging from power generation and optics to the medical, oil, gas and aerospace industries. For nearly 100 years, we’ve provided our clients with innovative metal finishing solutions to suit their specific needs. As one of the leading plating companies in the industry, SPC is ready to provide you with reliable and affordable silver coating and aluminum plating for your optical mirrors.

The C-mount connection comprises an imperial thread with a one-inch diameter and 32 threads per inch. This resembles a metric thread, with dimensions comparable to M25.5 x 0.75 mm.The rear focal distances of the C-mount and CS-mount connectors are an important differentiating characteristic. C-mount connectors have a fixed rear focal distance of 17.526 mm, exactly 5 mm more than CS-mount connectors. While a CS-mount lens cannot be used directly with a C-mount camera, a C-mount lens can be used with a CS-mount camera via a CS-mount adapter, typically a 5 mm spacer ring.

Introducing TechNexion, the leading provider of cameras with C-mount and S-mount configurations. With our wide range of camera options, we cater to all your imaging needs.

With our wide range of camera models and features, you can select the appropriate lens type that suits your needs perfectly. Check out our embedded vision solutions here.

Silver coated mirrors can be used in telescopes. For example, the Gemini Observatory has switched from using an aluminum coating on their telescopes to a silver coating. This resulted in a direct improvement in lowering the emissivity of their primary and secondary mirrors and increasing the telescope’s sensitivity. As one of the only telescopes to use silver mirrors, the Gemini Observatory is achieving significant infrared optimization. Though environmental factors do lead to the silver tarnishing, they employ an annual multi-layer coating process to protect the surface from tarnishing.

The choice of coating may enhance or diminish the emissivity or reflectivity of the mirror. When choosing a coating for your optical mirror, you want to ensure the proper plating for the intended application. Determining the most applicable selection involves understanding how the properties of the various metal finishings will impact the mirror’s performance. Two crucial aspects of a mirror’s performance are its reflectivity, how much light it reflects, and emissivity, the energy radiated from its surface.

Specializing in metal finishing solutions, SPC is ready to lend our knowledge and expertise to help you determine the best plating for your optical mirrors. We’re able to efficiently coat metals, plastics, ceramics and glass. With hundreds of years of combined plating experience, we’re equipped to meet the needs of nearly any industry. SPC is the proud plating business leader and innovator that you can count on to satisfy even the most demanding technical requirements.

For instance, a lens with a focal length of 50 mm requires a larger holder height, rendering it irreconcilable with an M12 holder. M12-mount/CS-mount lenses typically have reduced focal lengths. A lens mount compatible with variable focal length lenses (zoom or varifocal lenses) could be selected for an embedded vision system that monitors production lines. This would allow the magnification to be adjusted to focus on specific aspects of the production process.

Enhanced protective silver coatings are being explored to provide maximum reflectivity while improving the lifespan of the silver base. One prospective process that would create stronger corrosion barriers is through plasma-enhanced atomic layer deposition, using aluminum-oxide as the top layer that acts as a barrier to help protect against corrosion and maintain reflectivity. Results of testing show that these added layers successfully protect against corrosion and moisture. These plasma-enhanced barriers can be applied to optical mirrors that require high reflectivity and absorbency.

The CS-mount is similar to the C-Mount, except it has a shorter flange focal distance, making it appropriate for smaller sensors. CS-mount lenses are commonly used in security cameras and machine vision installations because they allow for compact designs without sacrificing optical quality. This lens mount has a flange focal distance of 12.5 mm and is the ideal standard for low-cost embedded vision applications.The CS-mount’s specifications are nearly identical to the C-mount’s, except for a 5mm reduction in flange focal length. This makes CS-mount a viable solution for limited space, and the reduced focal distance allows for more streamlined designs without sacrificing optical quality.

Ms.Cici

Ms.Cici

8618319014500

8618319014500