Norland NOA 148 - Adhesives and Dispensing solutions - norland optical adhesive

Olympus: AF-1 (Infinity) - 1986. 35mm film, compact autofocus camera.

In addition to their optical properties, silicone lenses are also highly resistant to water, temperature fluctuations, weathering, and UV radiations. They have a high temperature resistance of up to 200â, making them ideal for applications where COB temperature is a concern. They also have a long service life, which means that they can be used for extended periods without the need for frequent replacements.

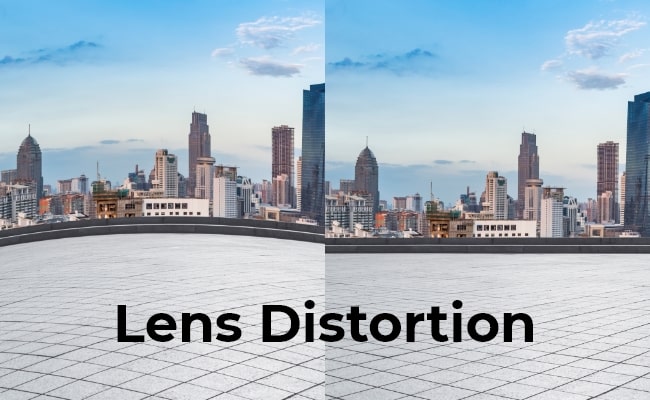

Understanding the basics of lens distortion, particularly in wide-angle lenses, is crucial for realizing optimal image quality and panoramic field of view. Effective lens distortion correction techniques can help create cohesive and visually accurate images. Reolink, a global innovator in security cameras, also introduces its unique dual-lens image stitching algorithms to correct the lens distortions between images.

Optical lenses

It is a concept of angle, not a single, fixed focal point. Figure(1). FOV Definition ... Figure (3) illustrates the principle of FOV calculation: FOV ...

When stitching images together, lens distortions can cause mismatches and inconsistencies between two images. As a result, it takes a lot of work to merge them seamlessly.

One of the key benefits of silicone lenses is their high light transmission, which ensures that there is no residual stress or yellowing. This results in an excellent visual effect that is free from fatigue and dispersion.

Silicon lenses are a type of optical lens that is made from liquid optical silicone, which is processed by liquid injection molding. These lenses are known for their exceptional quality and durability, as they are made from an unbreakable optically clear silicone rubber that is both safe and reliable. YEJIA specializes in producing silicone lenses in a variety of sizes. Our largest lens measures up to 575mm, while our smallest lens is just 1mm. No matter what your specific needs may be, we have the expertise and technology to deliver the highest quality silicone lenses on the market.

The mold design must also consider the shrinkage rate of the silicon lens during the curing process. Once the shrinkage rate is determined, the curing process cannot be changed without affecting the final size of the part. Therefore, it is crucial to calculate the shrinkage rate accurately before designing a mass production mold.

Image warping involves digitally manipulating the image to correct lens distortions manually. With warping tools, portions of the image can be adjusted to counteract distortions and restore proper perspective and shape.

Editor from Reolink. Interested in new technology trends and willing to share tips about home security. Her goal is to make security cameras and smart home systems easy to understand for everyone.

…a microscope is called the numerical aperture (NA) and is equal to the sine of half the angle subtended by the aperture at an object point times the index of ...

In photography and computer graphics, a lens distortion grid can be used for visualizing and correcting distortions caused by camera lenses. It consists of a grid pattern or a checkerboard pattern photographed or rendered using a specific lens.

Silicon lenses also have several advantages over traditional glass lenses. Silicon lenses are lighter and more durable, reducing the cost of mounting parts, installation, and maintenance.

It is the core component of DOF technology. Its job is to route traffic within its specified domain (which you will learn about later). For now, just remember: ...

Profile-based correction is another good way. Many photo editing software and plugins have built-in databases of lens profiles. These profiles contain information about special lenses and their existing distortion. The software can use this data to apply corrections automatically based on the known lens.

To solve this problem, Reolink introduces unique dual-image stitching algorithms. This algorithm ensures that two separate lens distortions match and align properly during stitching. This algorithm will come with Reolink's upcoming 16MP security camera, the Duo 3 PoE. If you are curious about this technology, join Reolink at the CES 2024. This Duo 3 camera will be presented at this annual technological event. Don't miss this opportunity!

Sometimes, lens distortion can affect the quality of your image. Photographers or designers may need some tools and techniques to correct lens distortion. Here are some common camera lens distortion tools and techniques.

Plano-convexlens

The unique properties of silicon lenses make them highly desirable in these applications. They are resistant to high temperatures, corrosion, and wear and tear, making them highly durable. They also offer superior light transmission and can withstand high levels of stress without compromising on performance.

![]()

Lens distortion can also impact image stitching when combining several images to create a panoramic image. Wide-angle lenses have also been incorporated into security cameras. However, lens distortion can become an obstacle to the panoramic view of these cameras, especially for dual-lens cameras, because dual-lens cameras require techniques to stitch images captured by two lenses together.

Calculate the equivalent power of a thick lens or a two lens system.

Sep 28, 2010 — 1.5 schedule 40 black pipe is the standard, 2" is not necessary. Flat steel brackets that sandwich the pipe provide a mounting point for shackle ...

Do you understand the meaning of lens distortion now? Have you ever encountered lens distortions inside your image? Please share your experience with us in the comment section below! Let's discuss it together!

Lens distortion refers to the imperfections or alterations in how a lens captures an image, causing straight lines to appear curved or objects to be warped towards the photo's edges. With the advancement of photography technology, wide-angle lens distortion expands the image dimension. To obtain perfect images, photographers need to apply lens distortion correction techniques.

Aspheric lenses

Simply dispense several drops onto a clean, folded pad and lightly wipe surface in a single direction. Start at the center and work your way to the outer edge.

To ensure quality, every cavity of the silicon lens light guides must be 100% inspected. If any defects are detected, the injection process must be stopped immediately to remove the mold cavities and readjust the injection process. After inspection, the silicone lenses undergo post-curing to remove unreacted silicon monomers. The curing time can range from 4 to 20 hours, depending on the type of silicone material.

May 5, 2023 — In partnership with Zero10, Coach's new AR installation lets window shoppers try on the Tabby bag without stepping foot in-store.

Germanium IRLens

Silicone contactlens

Camera lens distortion refers to the subtle changes or alterations in an image captured by a camera lens compared to how the human eye perceives the same scene. It's an optical anomaly that can cause straight lines to appear curved or bent and objects at the edges of an image to appear slightly stretched or compressed.

YEJIA is the ideal partner for precision liquid injection molding of silicon lenses. With a team of technical engineering experts from China, Japan, Korea, and Taiwan, we bring over 30 years of experience to every project. Our team of experts is committed to producing durable and effective optical products using only the highest quality materials and state-of-the-art manufacturing techniques. Our in-house mold making department is equipped with advanced imported equipment and inspection instruments to ensure the highest quality results. We ensure that our lenses meet the strictest standards of quality and performance, whether you require a single lens or a large-scale production run.

We work closely with our clients to understand their unique requirements and provide personalized service that exceeds their expectations. If you're looking for custom silicone lenses for LED lights, we invite you to contact us today to learn more about our products and services. Let us help you take your LED lighting to the next level!

Silicon lens manufacturing involves a complex process that requires careful attention to detail. The process starts with liquid injection molding, which is different from traditional plastic injection molding. The resulting material is a two-component liquid silicone that requires thermal polymerization.

Infraredlens

We take pride in our production environment, which includes a class 100,000 clean production workshop and a class 10,000 inspection cleanroom. Our production equipment includes SUMITOMO and ARBURG horizontal liquid silicone injection molding machines, and our inspection equipment features Mitaka non-contact measuring instruments, Zeiss 3D optical metrology, Goniophotometers, UV Vis-spectrophotometers, blue light scanners and so on.

Compared to PMMA or PC lenses, silicon lenses have a higher light transmission rate of about 94%, making them suitable for high-grade optical applications. The optical efficiency of silicon lenses is also higher than PMMA and PC lenses, with better consistency and more accurate light angles, and their anti-UV properties are superior to both PC and PMMA.

There are several apps and tools available for correcting lens distortion in images. With the help of the iPhone lens distortion app and lens distortion app for Android, users can adjust these incorrections via smartphones.

We specialize in solving the challenges of silicone molding technology in optics and maximizing the advantages of silicone materials over PMMA, PC, and glass in terms of technology and material properties. Our optical design is forward-thinking and adaptable to a wide range of applications, including street lights, high-pole lights, flood lights, industrial and mining lights, oil station lights, downlights, and various optical angle needs. Trust YEJIA to deliver exceptional results for your precision liquid injection molding silicon lens needs.

The application of LED lighting is rapidly expanding, and with it comes the demand for high-quality silicone lenses. At Yejia, we understand the importance of providing lenses that meet the demands of optical designers who are shaping the future of LED lighting. Our custom silicone lenses are designed to offer the perfect combination of processing characteristics, optical properties, and hardness.

This article will explain the basics of lens distortion, indicate the specialty of wide-angle distortion, and introduce some standard methods of lens distortion correction.

... employees. Health & Insurance BenefitsExplore Northwestern's health, dental, vision, life and long-term disability insurance offerings. Leaves, Holidays ...

The answer is yes. Correcting lens distortions is crucial for image stitching techniques. Lens distortions on the edge of images can cause misalignment between separate images. Lens distortion correction might be the first step to creating seamless panoramas.

Wide-angle lens distortion, also known as barrel distortion or fisheye distortion, is an optical effect of a wide-angle lens when straight lines appear curved or distorted near the edges of an image. Wide-angle distortion possesses unique characteristics when compared with standard lens distortion.

However, there are some disadvantages to using silicon lenses. Firstly, the cost of raw materials is higher than that of PC lenses, which can increase the overall cost of manufacturing. Additionally, the injection molding technology for silicon lenses is not yet mature, which can further increase the cost of manufacturing.

AS/NZS 1337.1 and ANSI Z87 and CSA Z94.3 approved TWO SVGE Safety Eyewear is built to handle anything you can throw at it. Tax deductible and look great ...

Lens distortion effects refer to alterations or abnormalities in images caused by the characteristics of a camera lens. Some common lens distortion effects include barrel distortion, pincushion distortion, mustache distortion, etc.

Silicon lenses are highly suitable for aerospace lighting lenses, mining lamps, and special lamps and lanterns used in flammable, explosive, and harsh conditions. They are also ideal for industrial lighting, indoor and outdoor LED lighting, automotive headlights, and LED displays.

Fixing lens distortion requires a series of tools and techniques. If you are a professional photographer, you can use a lens distortion grid to fix distortions on professional-level photo editing software. Suppose you just want to fix lens distortions of photos captured by your phone. In that case, you can download a photo editing app on your mobile phone and look for the "Lens Correction" function to fix lens distortions.

Ms.Cici

Ms.Cici

8618319014500

8618319014500